Week08. Electronics Production

1. Assignment and Result

About the process, I made new page and made links are below, because the long page makes me confuse.

| GROUP ASSIGNMENT | THE RESULT |

|---|---|

| - characterize the design rules for your in-house PCB production process | Process -> Kitakagaya: Week8 Electronics Production 1. Board Design (2D data) 2. Create tool Path (MODS) 3. Milling (MDX-40A, using VPanel) |

| - extra credit: make it with another process | |

| - extra credit: send a PCB out to a board house |

| INDIVIDUAL ASSIGNMENT | THE RESULT |

|---|---|

| - make and test the development board that you designed to interact and communicate with an embedded microcontroller |

PROCESS -> ATtiny414 Board with LED and Switch 1. Design board with Kicad. 2. Create tool Path (V Carve Pro) 3. Milling (MDX-40A, using VPanel) 4. Soldering 5. Programming (Arduino IDE, and ChatGPT) |

| - extra credit: make it with another process | - |

2. HERO SHOT

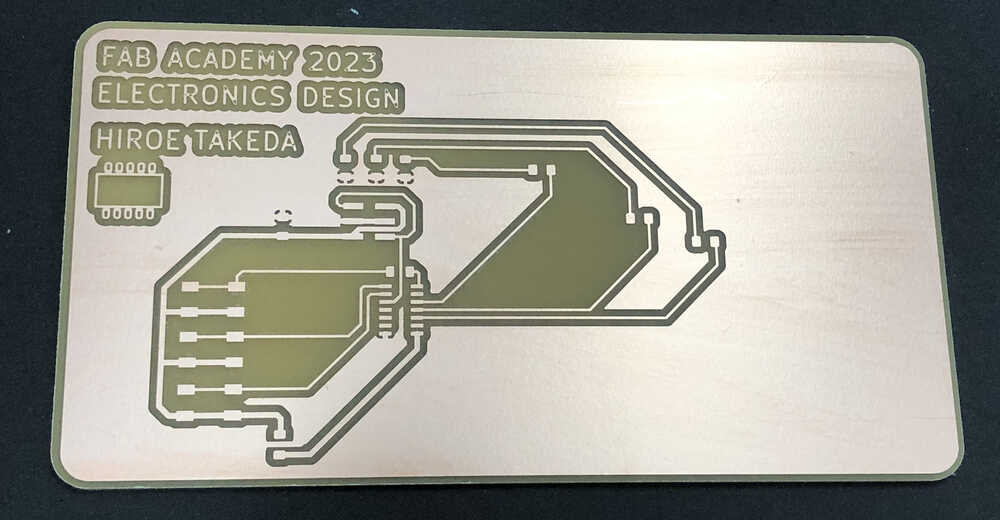

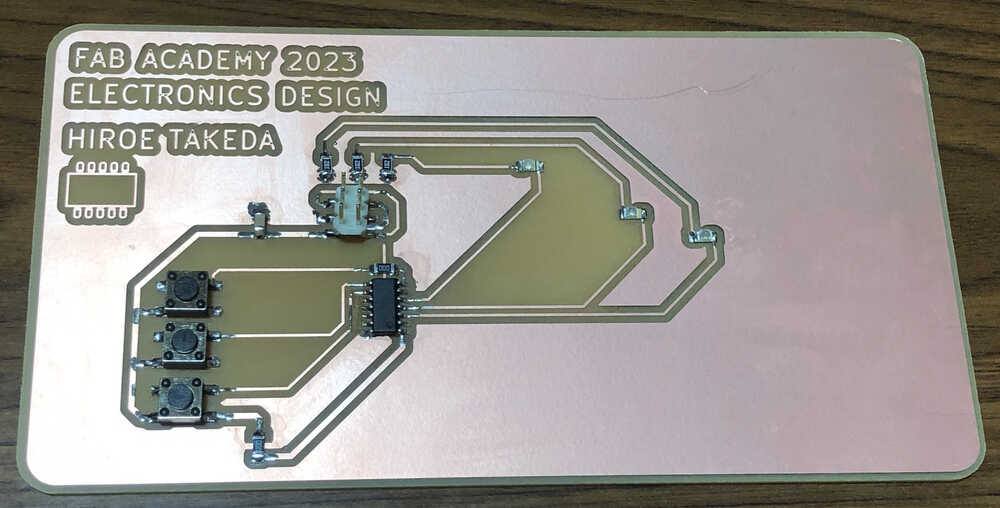

My original Board

My original development board with ATtiny414, with LED and Pushbutton switch.

3. The Video

I put the map on the board. The map is for Kinki region in Japan, and the LED is location of FabLab West-harima, FabLab Kobe, and FabLab Kitakagaya. The each LED blink with each pushbutton switch, as below Video shows.

4. Main Flow of Electronics Production

- select chip & parts and check datasheet

- Board Design

- Create tool Path

- Milling

- Soldering

- Programming

5. My Thought

- The first time I cut a board in pre-study, it took a long time and try a lot. During pre-study, need to mill so many hours, as the mill is not reached to board. One time, the mill flute is broken, as I made the mistake the wrong origin.

- I think I was able to cut the substrate well because I have practiced many times before and took on this week's challenge.

- Creating a board is very time consuming, about design board, and Soldering, and tester and programming.

- Soldering small electronic components is extremely difficult. Soldering small parts (especially ATtiny414 and FT230) leg by leg was quite difficult. I realized my old eyesight for the first time with this solder. I thought it would have been easier if I had taken FabAcademy when I was younger.

- During the soldering process, we checked many times to make sure the orientation of electronic components is correct.

- We learned in advance to use Kicad and to solder, which was good. Otherwise, I would have cried by now.