- Laser cut (individual assignment)

individual assignment

- design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways, and for extra credit include elements that aren't flat

1. The machine I used

- FABOOL Laser CO2

- format: png, jpeg, jpg, bmp, gif, tiff, tif, svg, dxf

2. Installed Software (Add-in)

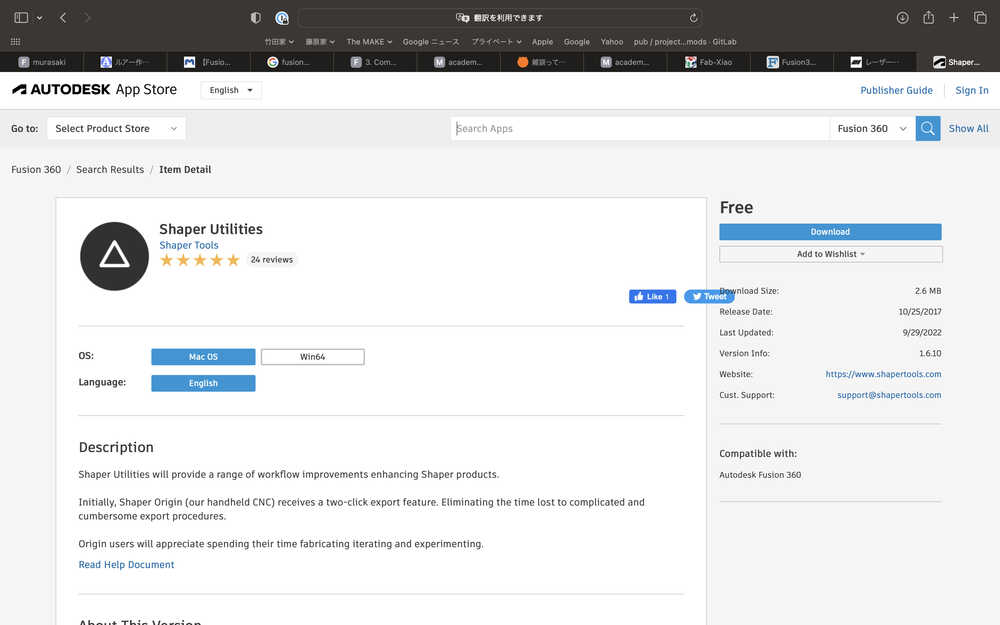

2-1) Shaper Utilities

- I heard that Fusion360 add-in "Shaper Utilities" is useful tool to convert Fusion360 models to SVG files from West-harima founder.

Go to AUTODESK App Store and search "Shaper Utilities".

Download mac OS

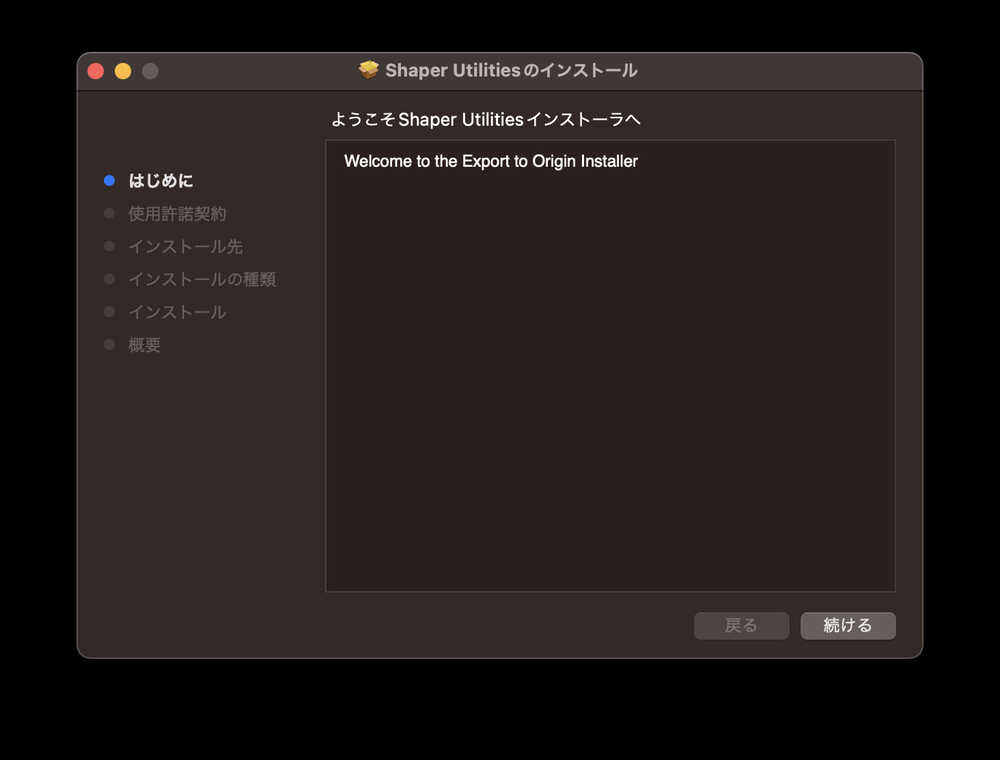

Open Download file, and Install start!

Open Download file, and Install start!

Install complete!

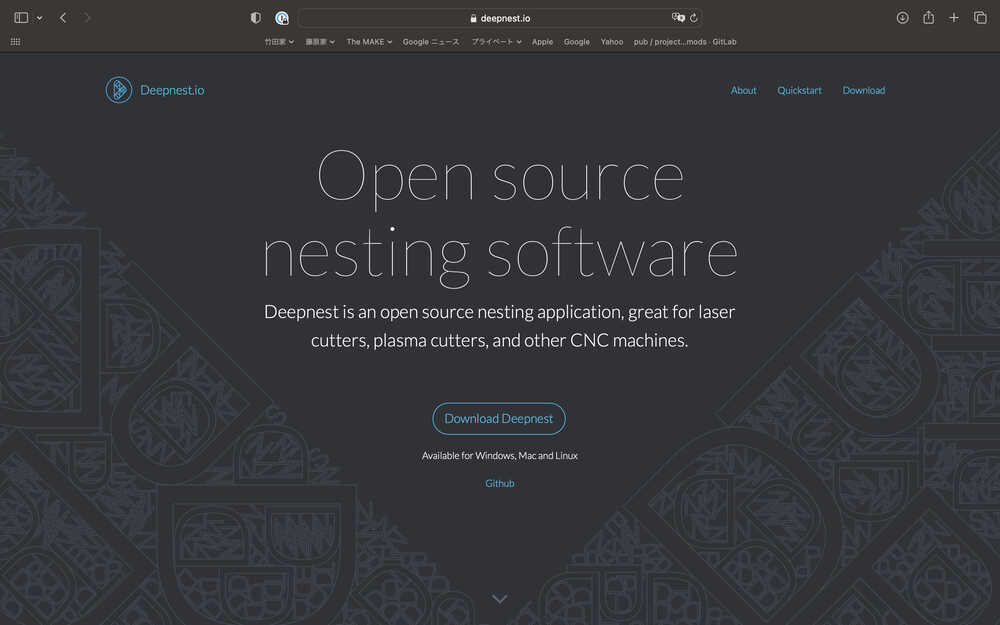

2-2) Deepnest

- I heard Deepnest is good tool, it is an open source nesting application, great for laser cutters, plasma cutters, and other CNC machines, and install from deepnest.

Install complete! (Version: Deepnest-1.0.5-mac)

2-3) SmartDIYs Creator

- Free software (Formats such as svg, jpg, and png.)

- Download SmartDIYs Creator from smartdiys.com .

- Open Download file, and start Install.

- During install, Chosen the devise "FABOOL Laser CO2" to set work size. I chose "FABOOL Laser CO2", so the worksize (wide 600mm height 440 mm) is appeared automatically.

- Install complete (Version 1.5.1, mac)

2-4) Amphetamine (for mac)

- Amphetamine is Sleep Control Apps for mac.

- It get from Mac App Store.

- NOTE: When sleep run, the laser cut stop, so I should prevent Sleep function.

3. Design

3-1). Consider the design

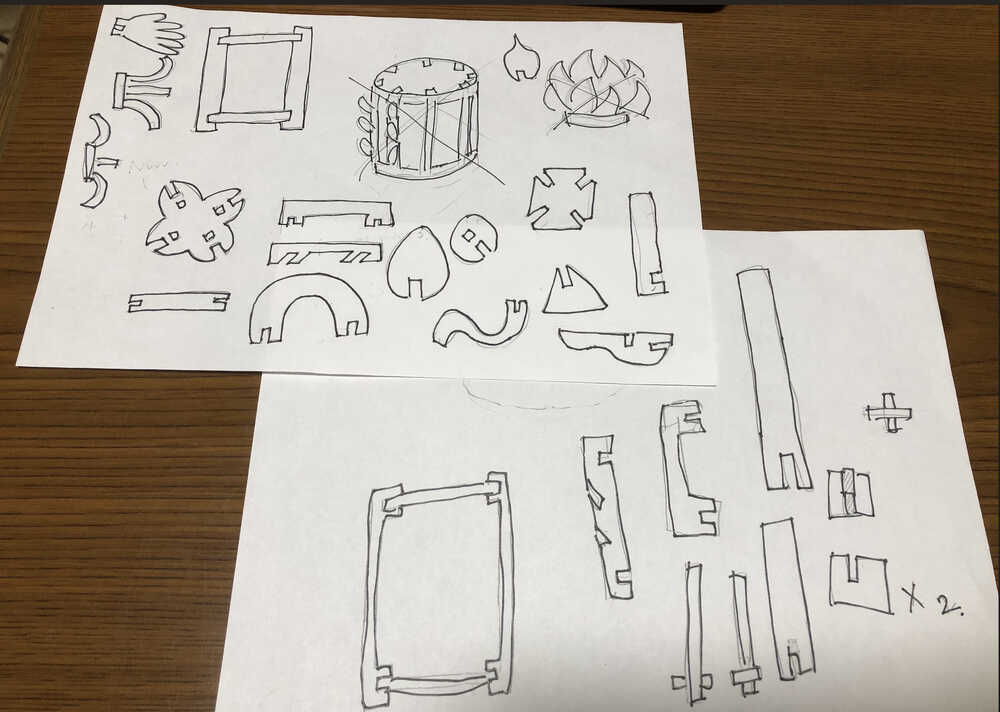

The first couple of days, during the past week, were the worst, as I was unable to design and document because the first design was beyond my skills. So I changed my plan to create a simple shape that I can make the parts and document within 1 week, and started by thinking of structural clues from hand-drawn and scissors-cut parts.

Sketch

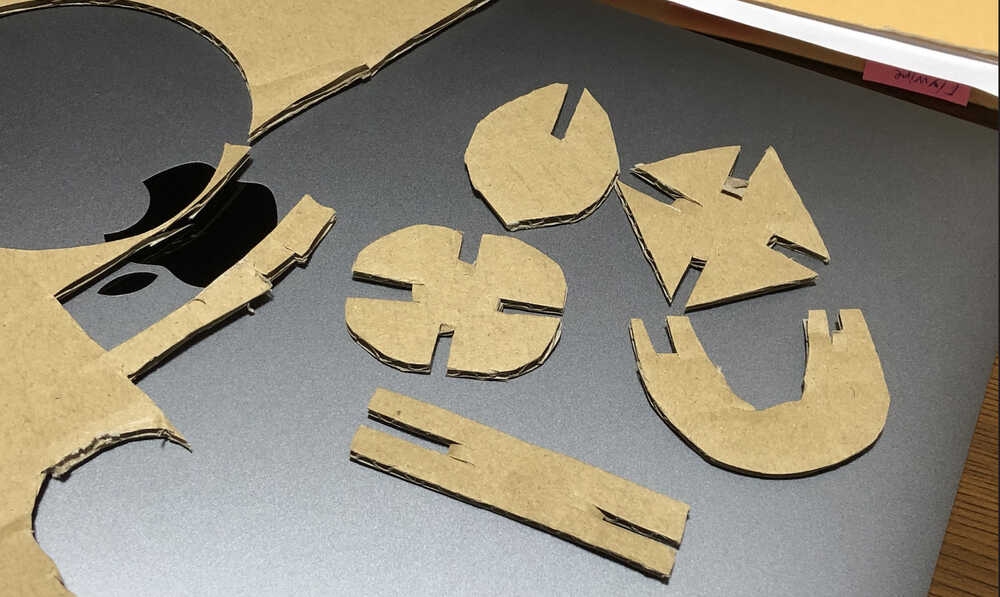

Idea part, cut with scissors

Idea part, cut with scissors

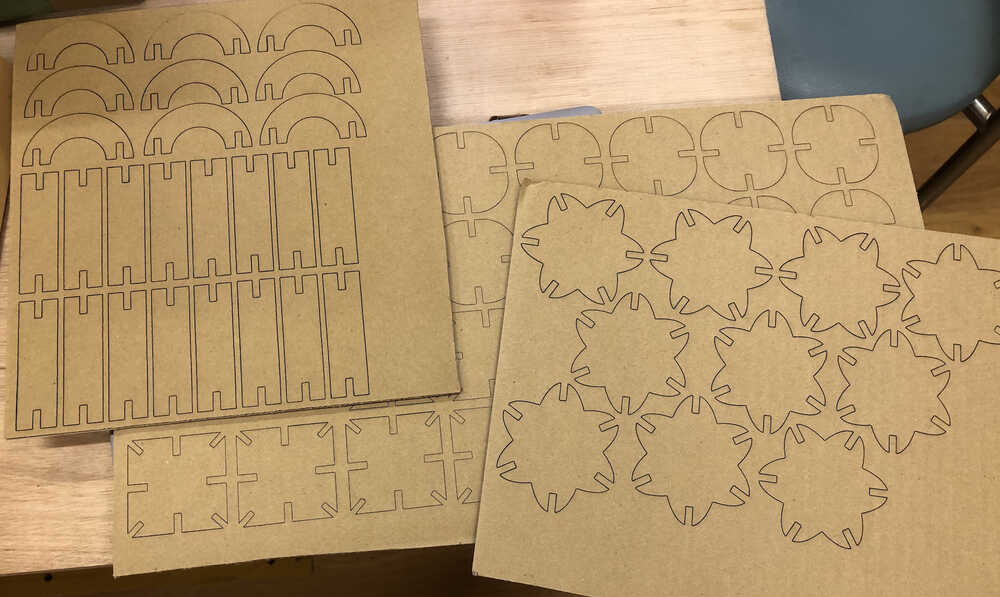

Then I decided to create puzzle pieces about 5 cm square in size and make various parametric kits.

Then I decided to create puzzle pieces about 5 cm square in size and make various parametric kits.

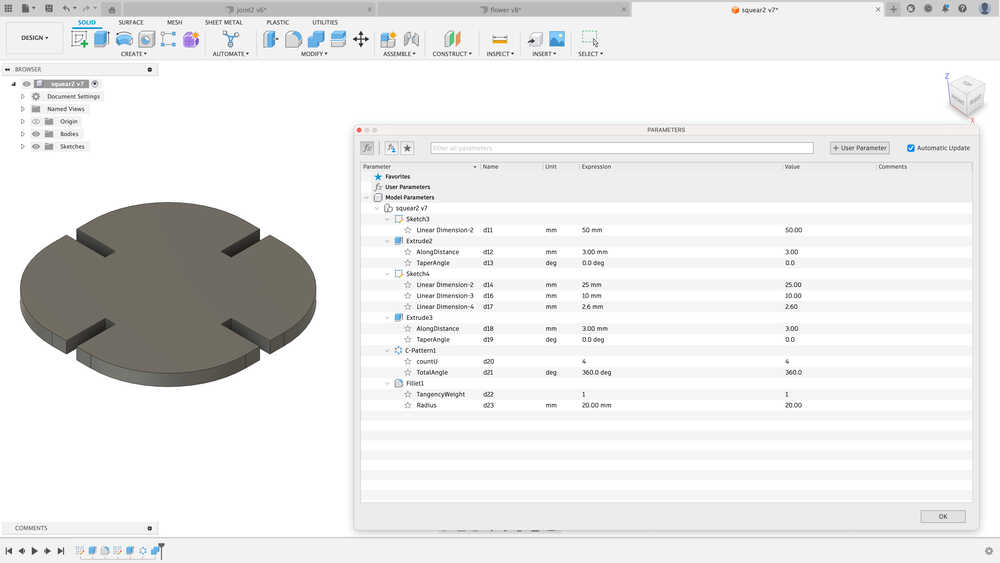

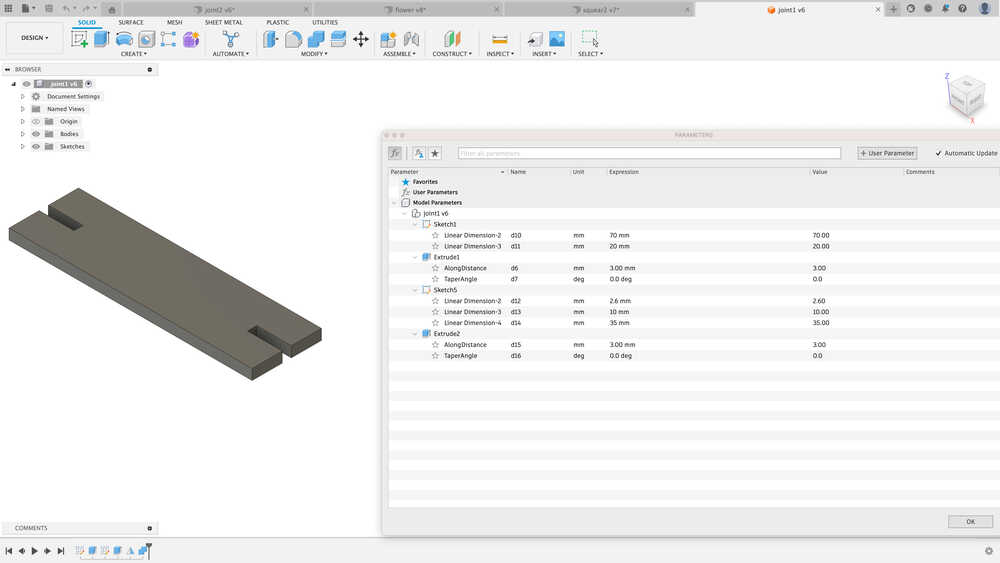

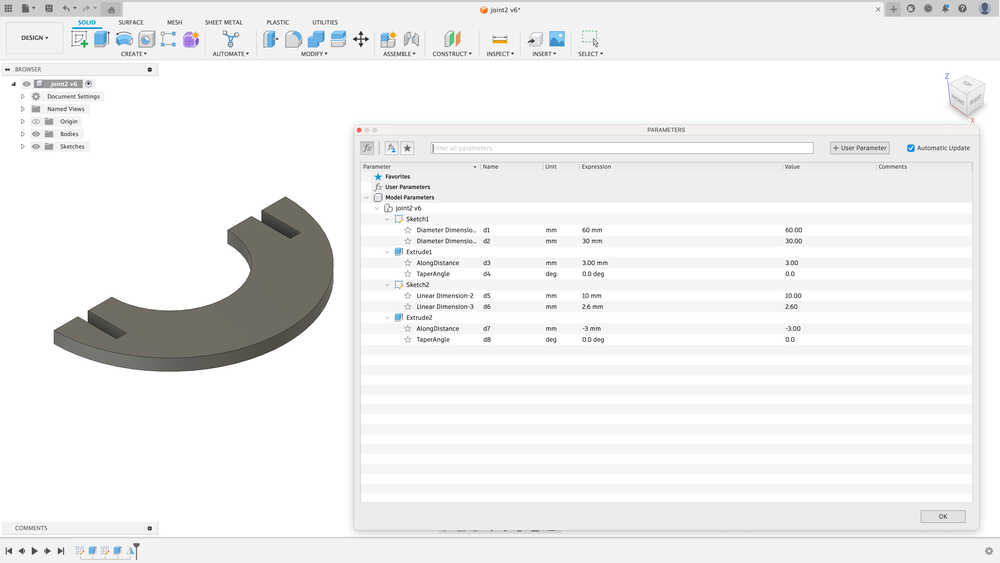

3-2). Design each parts

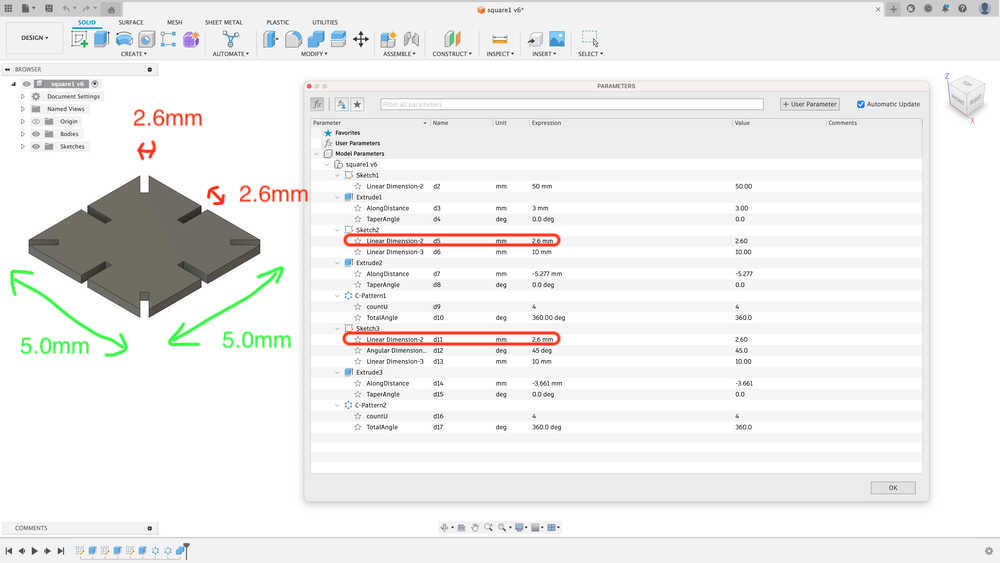

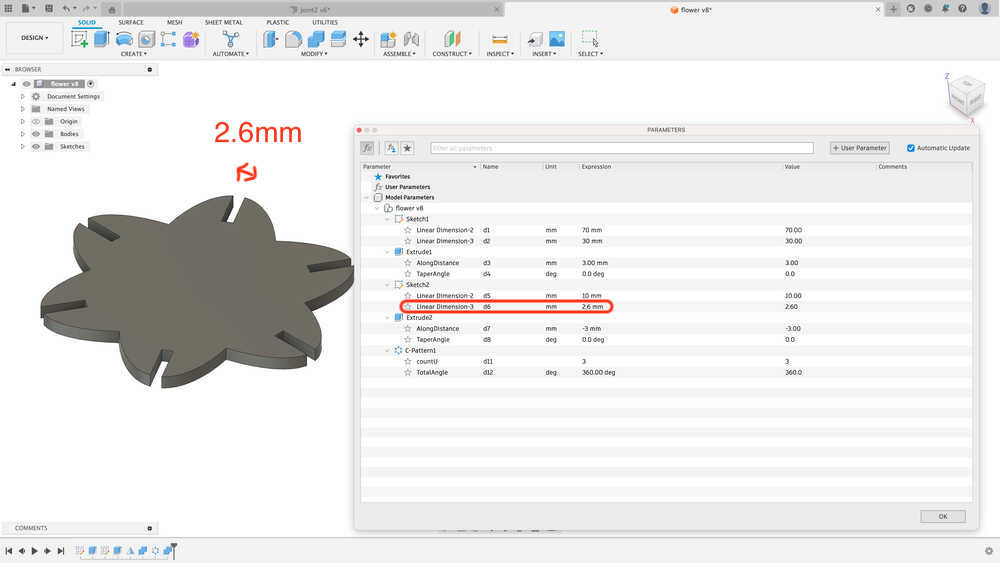

- In Fusion, design each parts. I felt it was necessary to create a model that would be easy to modify later.

-

I used the same material as the group assignment for the kit.

(t3.0mm cardboard / Actual t vary: 2.6mm-2.8mm -> the average t 2.7 mm.)

Kerf: 2.70mm (real measure average of the cardboard) - 2.60mm (Bestfit) = 0.10 mm kerf of cardboard -

It is important to modified the Kerf test result (Bestfit 2.60mm) of Group assignment to the width of the joint of each part.

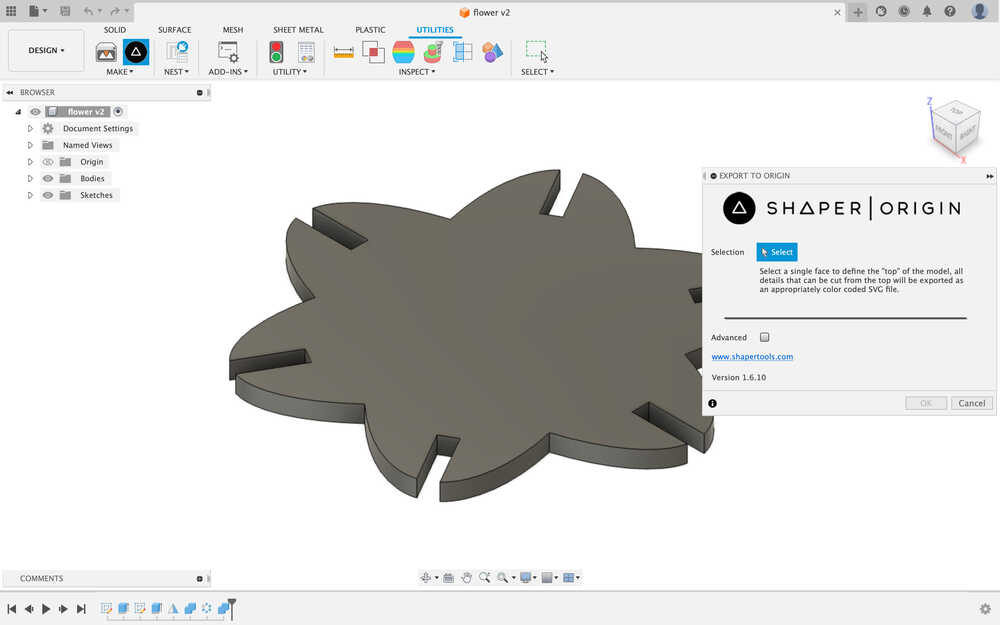

4. Make SVG file of top face

4-1) Making SVG file from fusion model

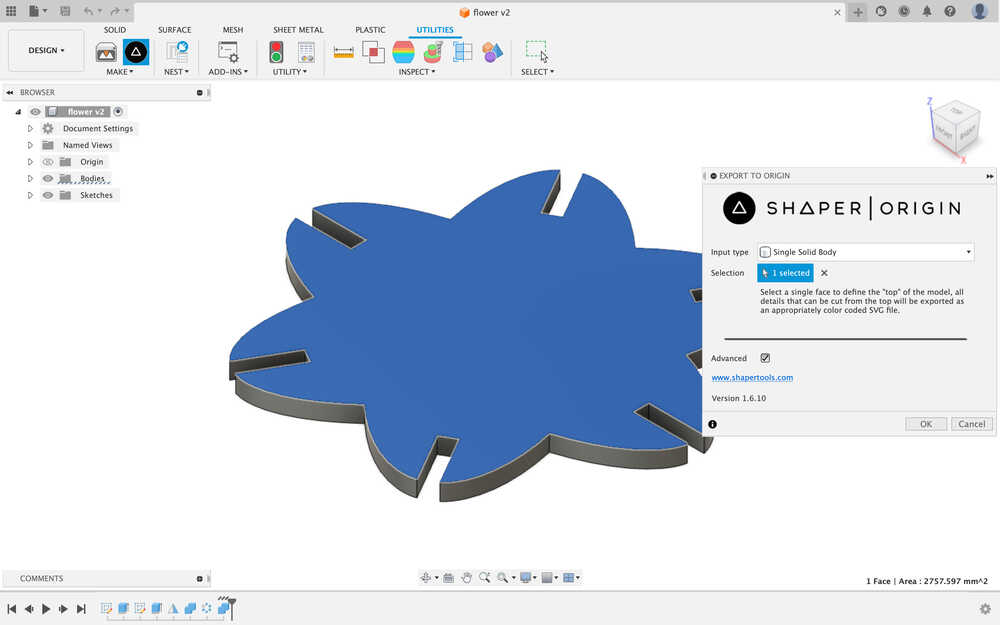

- In Fusion > Utilities > Export to Origin

- Select the top face, and click OK. > download SVG file.

NOTE:

- This function is Shaper Utilities (Add-in for Fusion360) as I mentioned in "1. Installed software (Add-in)".

- The SVG is with fill, so need edit.

4-2) Edit SVG file

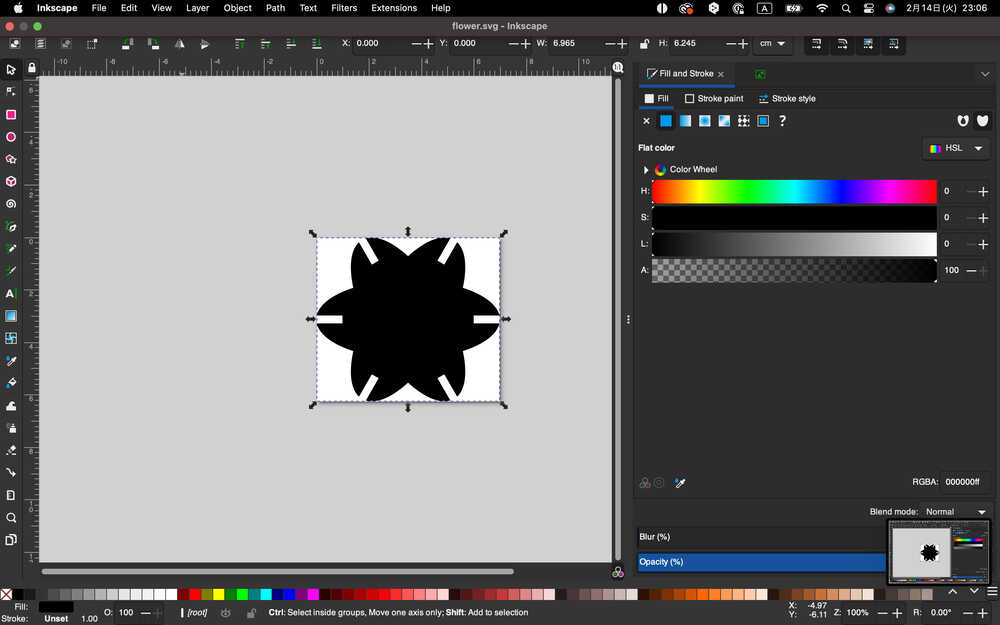

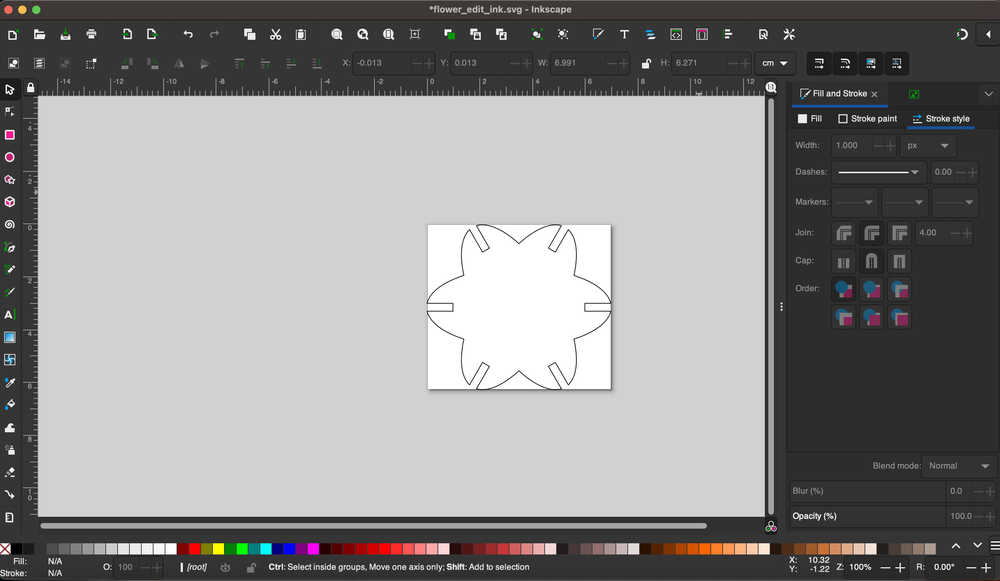

- Open Inkscape and import SVG file.

- Edit (Fill: x / Stroke: black / Stroke style: Width:1.0 px)

I check that the Length of kerf is enough length. It seems OK.

5. Cut

- Cut with the parameta using FABOOL Laser CO2 using the Group Assignment.

- power 15%, speed 750 mm/min and 2 times

6. Assembly

Mix 5 parts and I made 3 parametric construction kit.

7.Useful Links

8. My impression

- The first couple of days, during the past week, were the worst, as I was unable to design and document because the first design was beyond my skills. I missed plan and just lost couple of days.

- Considering the skill in 1 week is important. For me, it is best to make simple design.

- I felt it was necessary to create model that would be easy to modify later.

- It was fun time to assemble. The assemble shape is created during assemble.

- To create the feel of a lampshade, I hung it from a single string. I was nervous that it might fall off, but it was fine.

- The eyeballs were at FabLab west-harima, so I put the elephant construction kit on. It became more like an elephant.

- Later, I learned from instructor that "It is better that you create your own personal dimensions (User parameters in Fusion) for critical aspects of your design (kerf, material thickness, final size ...). Modification of the model parameters might lead to undesired errors. "