- Making Control system

This page is my work process for week 10 machine building. We plan to make Vacuum Forming.

1. The Parts I used

Below is the required parts which I picked up.

- Board

- Raspberry Pi Pico x1

- SPAEKFUN Logic Level Converter: x2

- Photocoupler TLP293 x2

- Pin Header1x2 P2.54 x10

- Pin Header1x4 P2.54 x2

- Output

- Solid State Relay: SSR-40DA x2

- Motor driver_Quimat 4A TB6600 x2

- Bipolar Stepper Motor 17HD48002H-22B x2

- Input

- Power Supply

- CURE Switching Power (12V 10A 120W) x1

- Terminal Block (T20C03)

- Power code (KB-D3247A) x1

- DC-DC converter kit (AE-OKL-T/6-W12N-C) x1

- AC inletx1

- Wall outlet x1

- F cable (VVF 2.0x2) x 1m

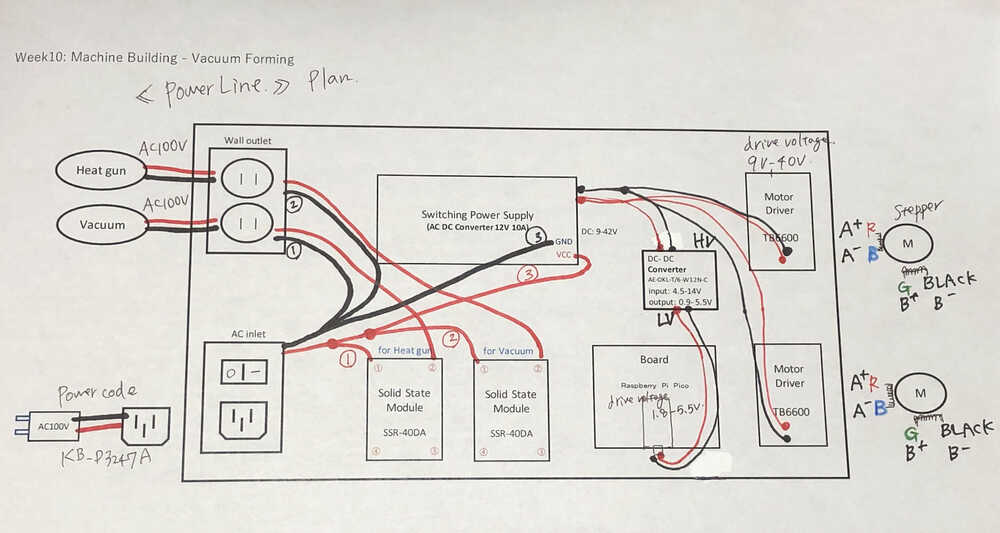

2. Power Line (Plan)

Below is Plan for Power Line, Vacuum Forming.

3. Datasheet

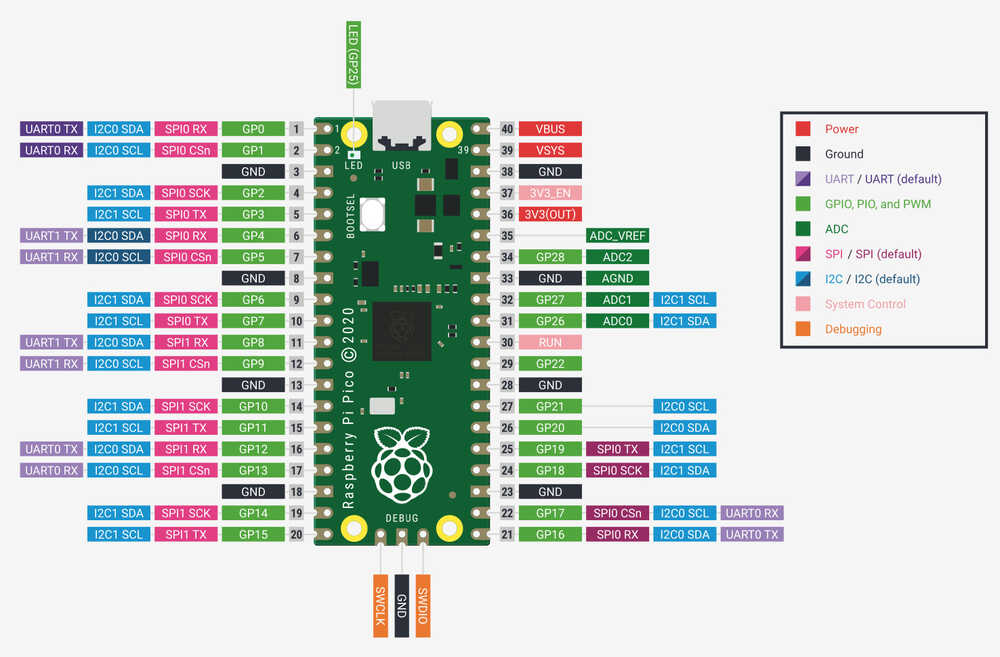

- Raspberry Pi Pico (Pinout)

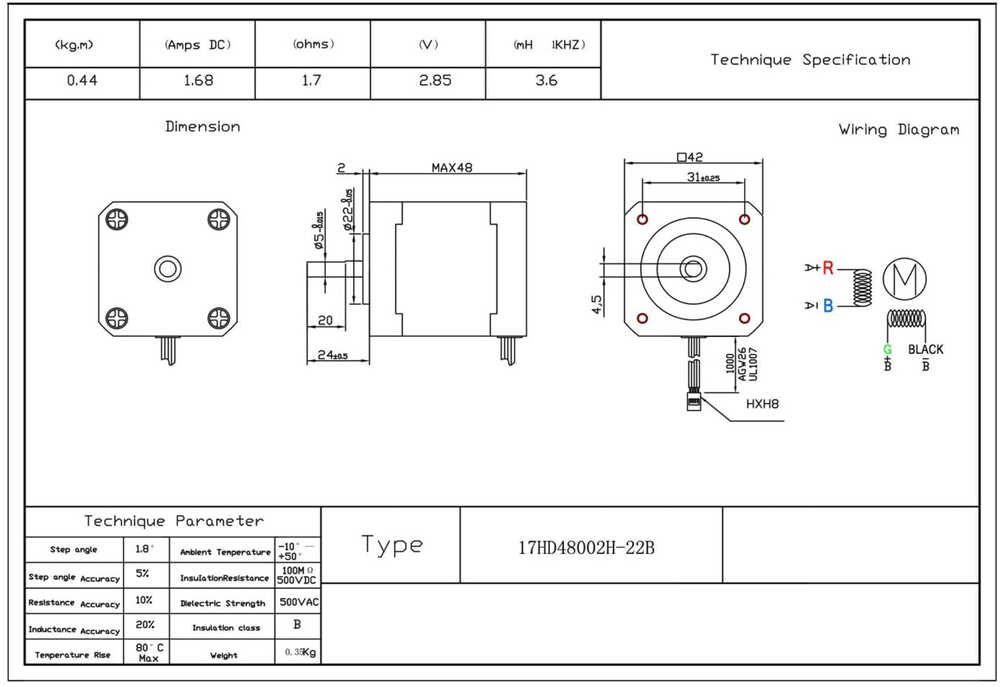

- Stepper 17HD48002H-22B

- 1 Step angle =1.8° (200 pulse(step) for 360°)

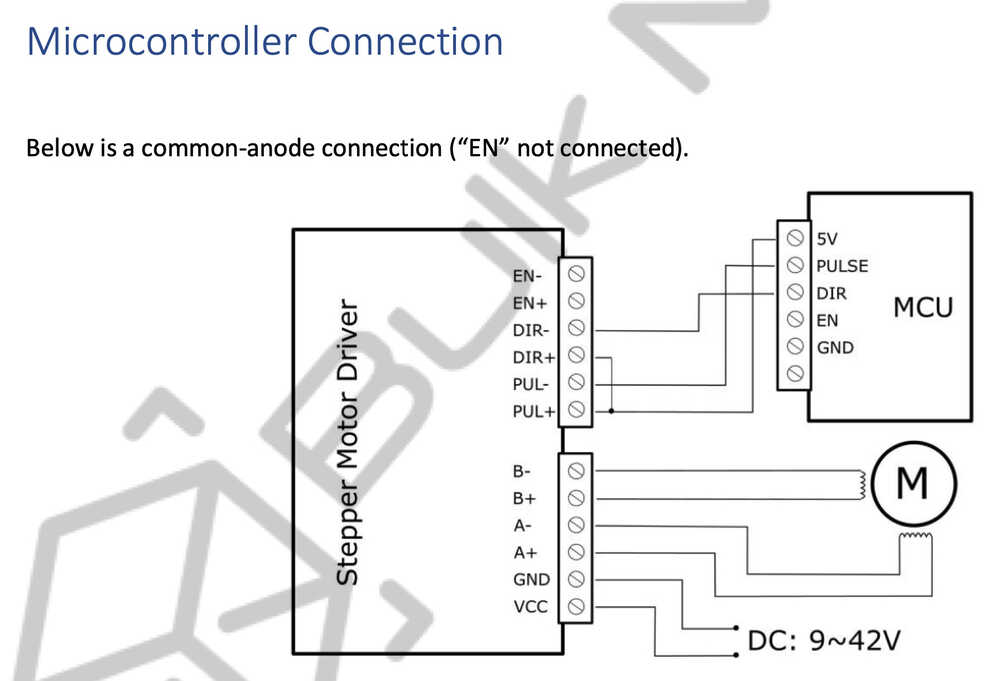

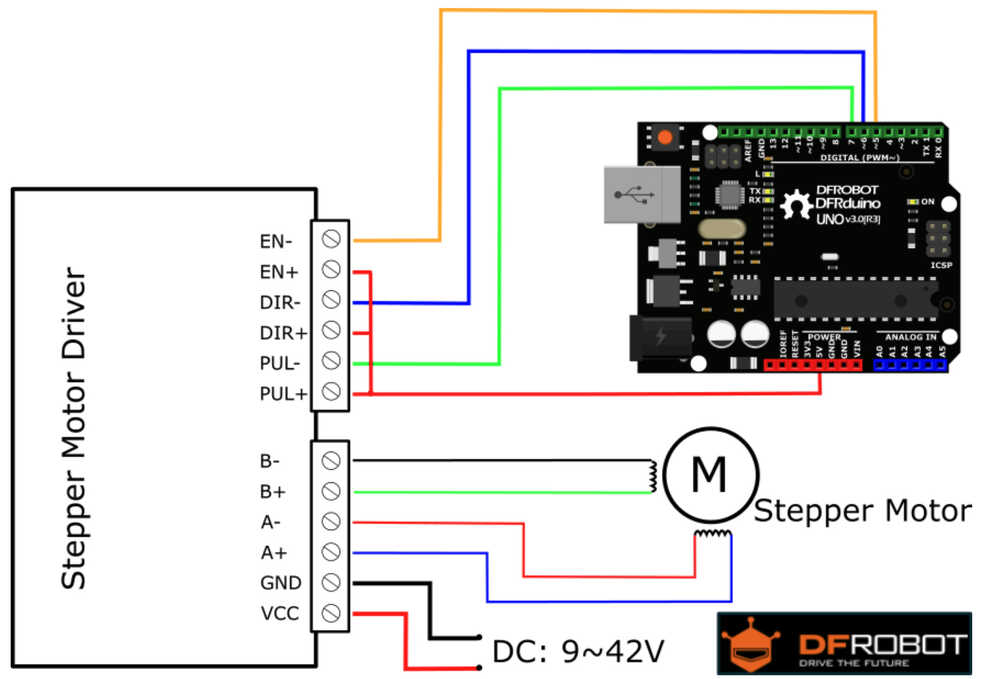

- Motor Driver TB6600

- Input Current: 0-5.0A

- Output Current: 0.5-4.0A

- Power (MAX): 160W

-

Micro Step 1,2/A, 2/B, 4, 8, 16,32

-

Microcontroller Connection is below in datasheet.

- Microcontroller Connection is below in DFROBOT.

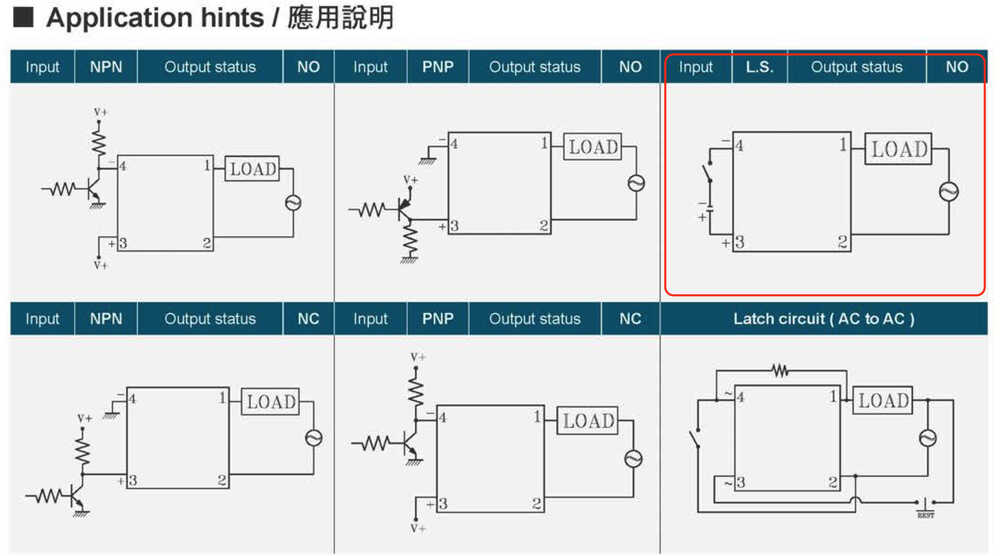

-Solid State Relay: SSR-40DA

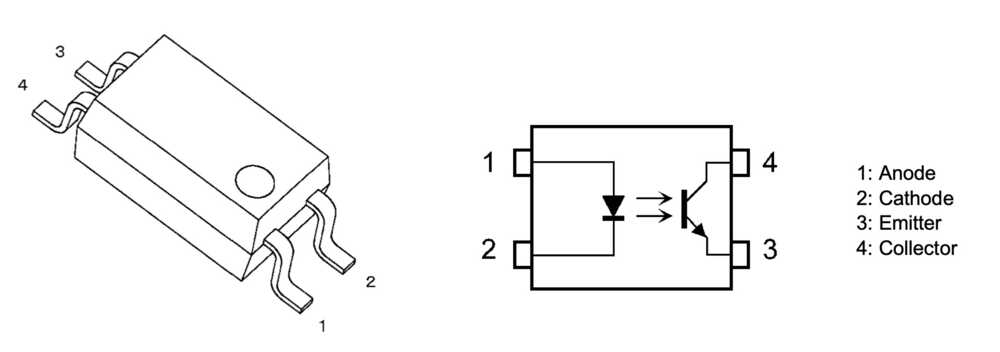

- Photocoupler TLP293

4. Board Making

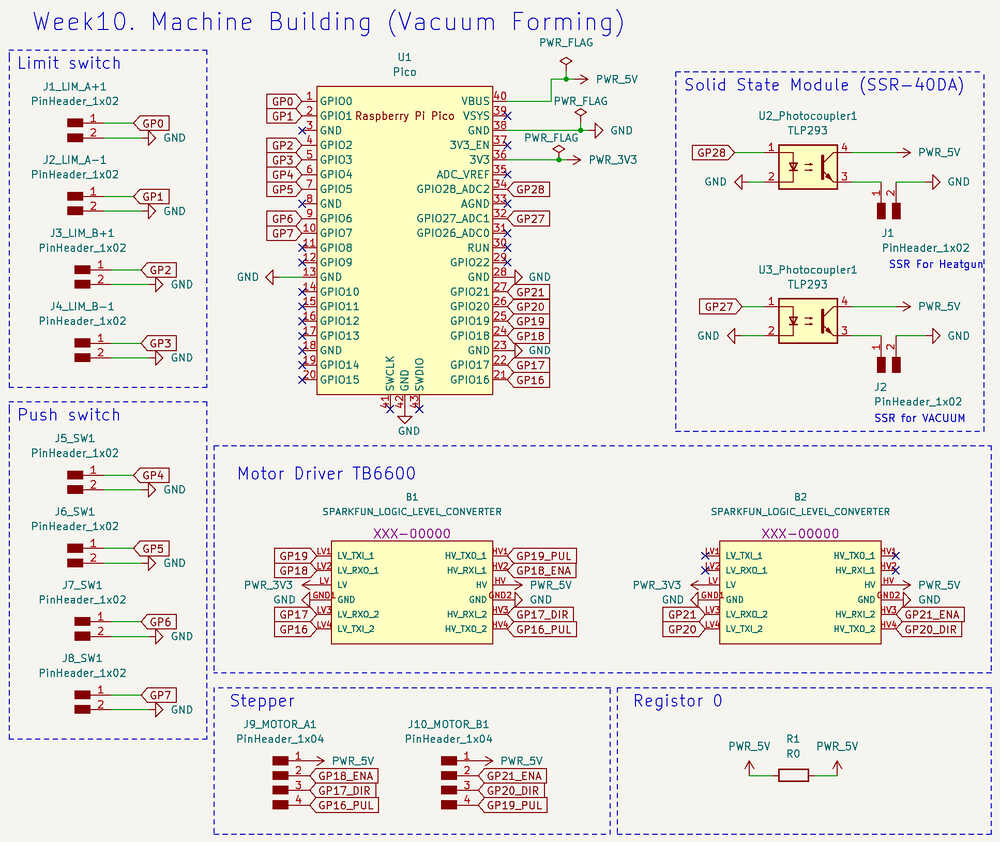

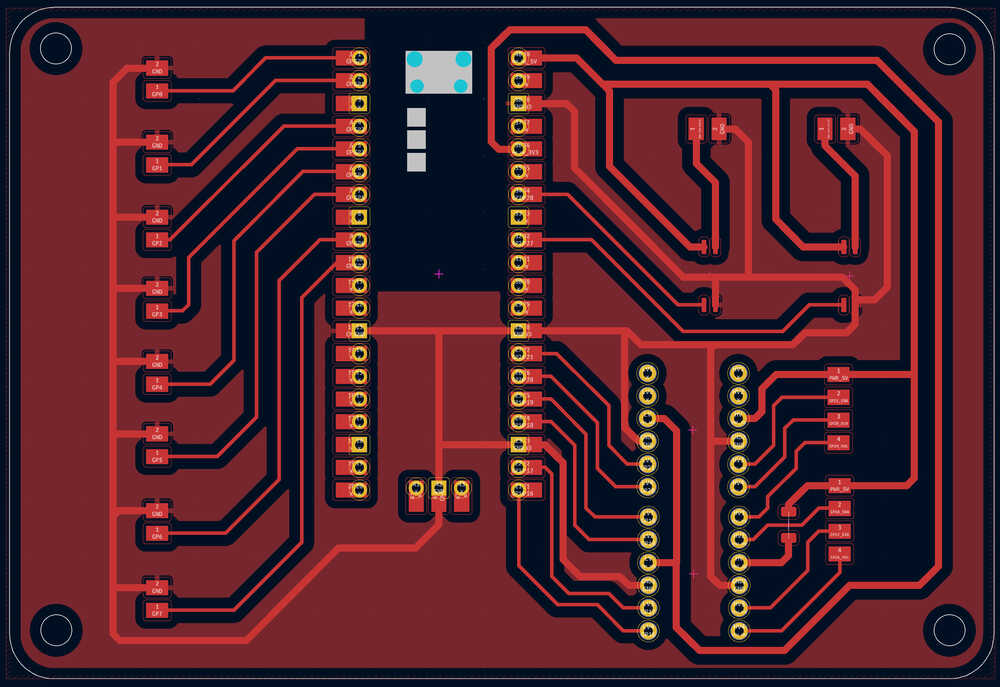

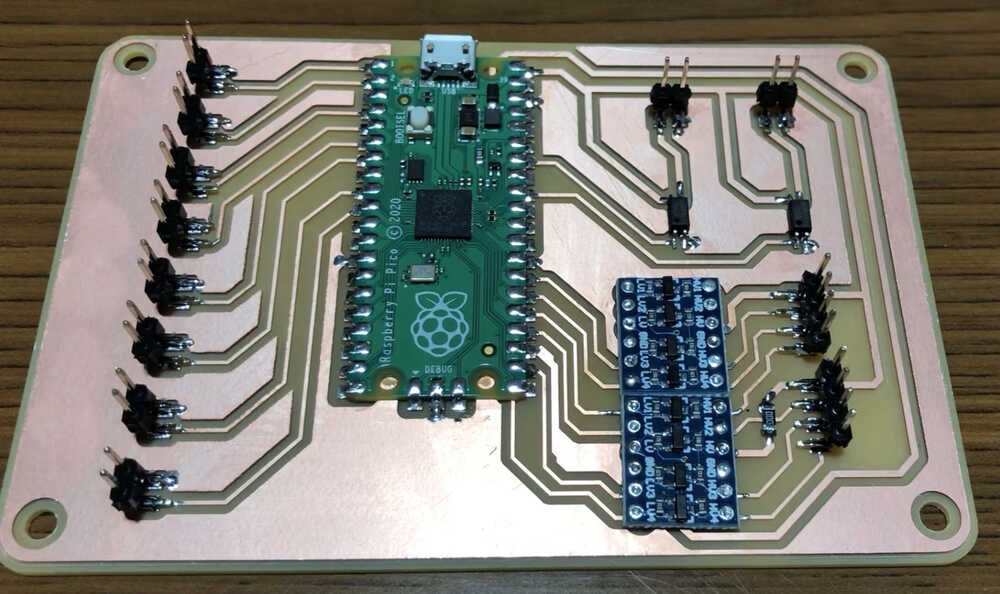

I made board design for the assignment of week10 as below. For chip, I choose Raspberry Pi Pico as it has many GPIOasse.

- Schematic by Kicad.

- PCB by Kicad

- Milling

Milling details same as Week08.

- Soldering & tester check

5. Making Control Box & Panel, by laser cutting

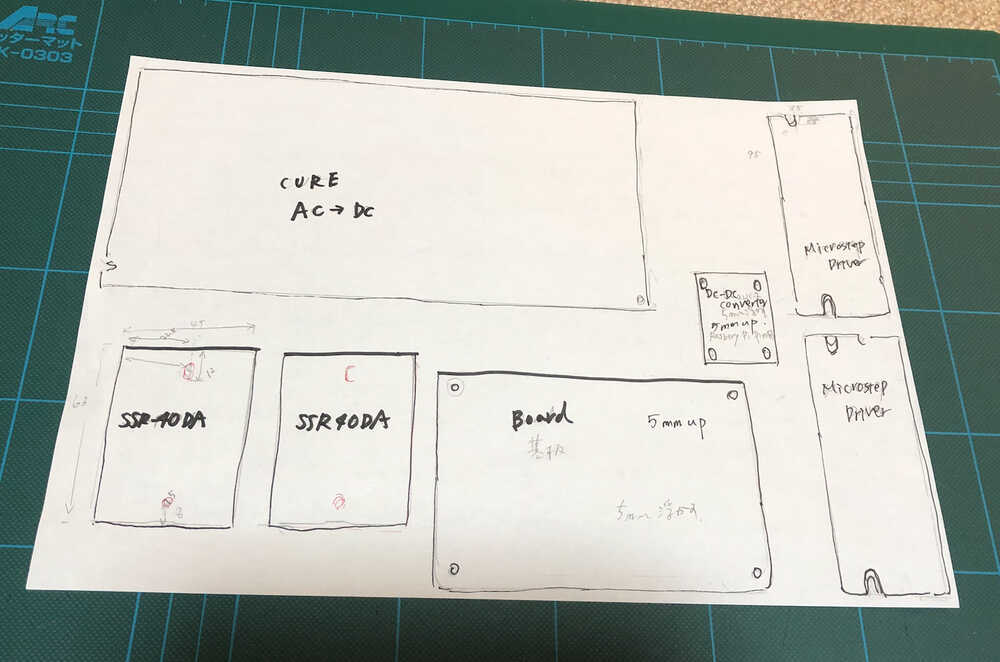

5-1) Control BOX

- Consider the position of parts and size of control box size.

- I made Control BOX, using laser cutting machine.

- Make Model

- by Fusion360 and exported in SVG format about top face.

- and Makecase

- Laser cutting

- Machine: FABOOL Laser CO2

- Materials: veneer t=4mm

- Software: SmartDIYsCreator

- Parameter: Speed 1500, Power 40, Times 3

- Make Model

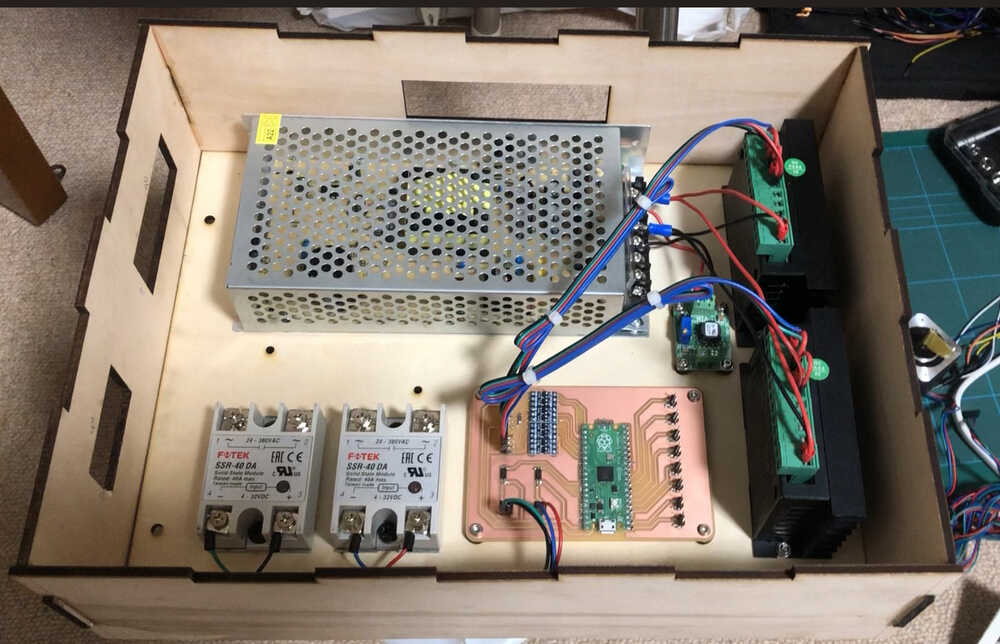

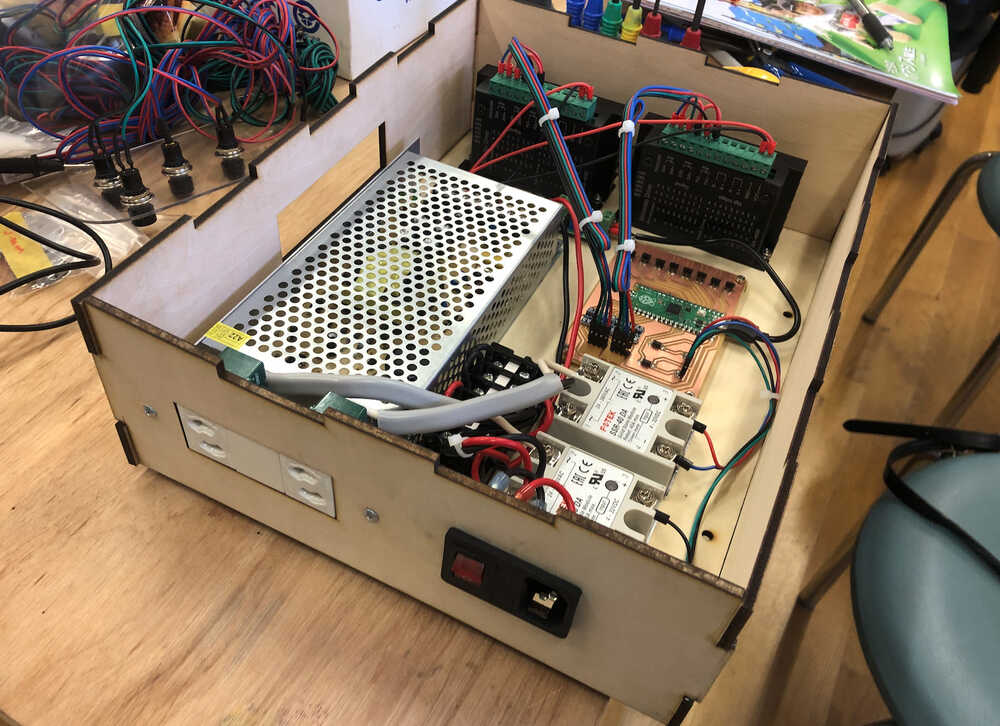

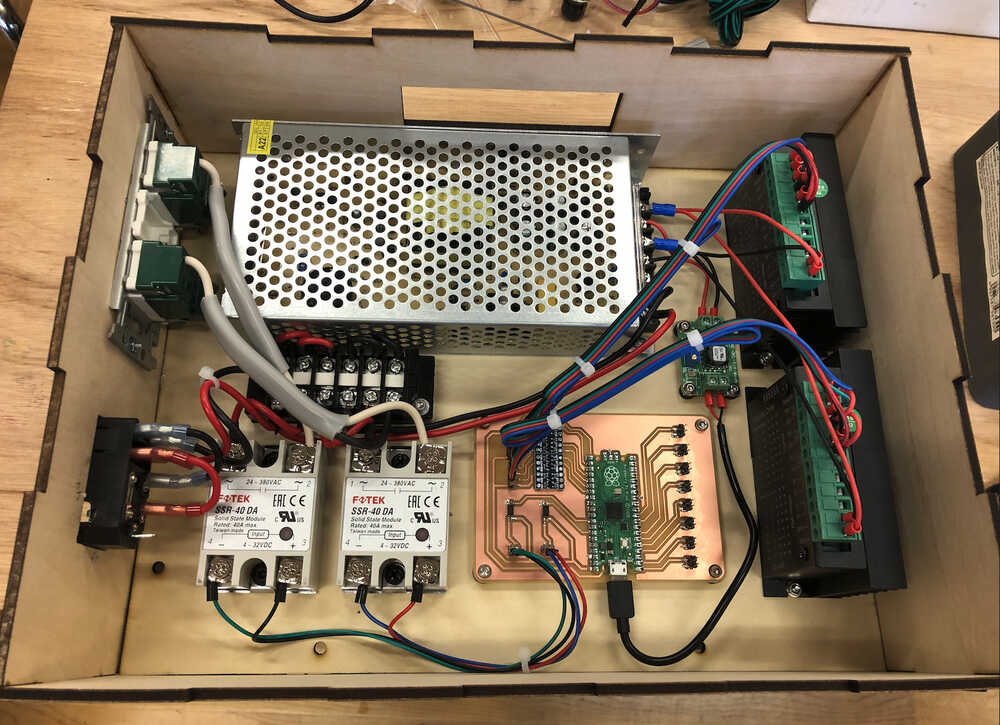

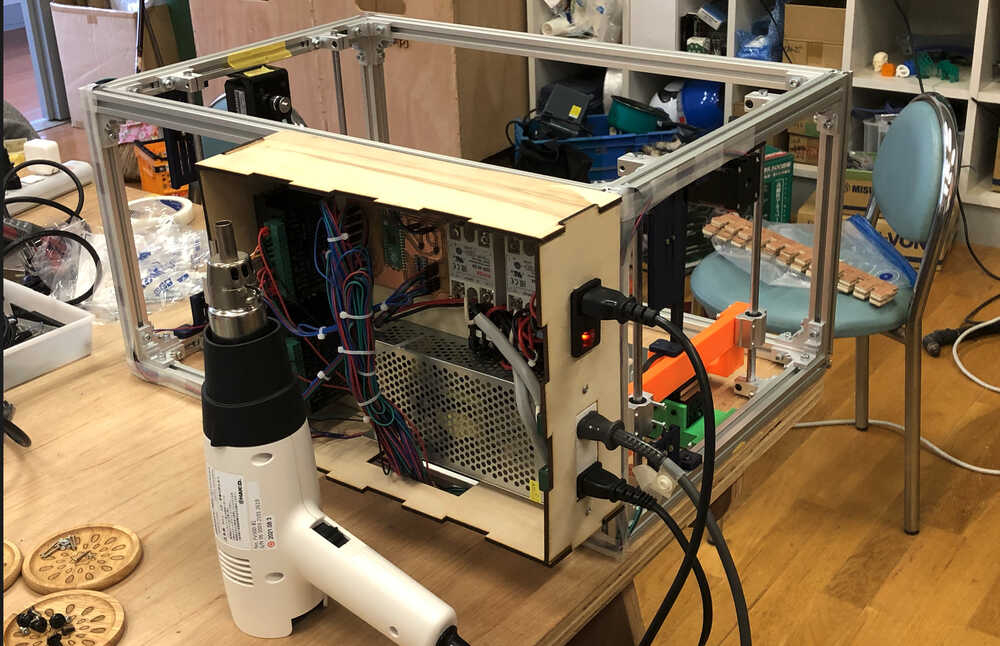

- Attach the necessary parts to the base of the Control Box.

- Install the outer frame of the control box

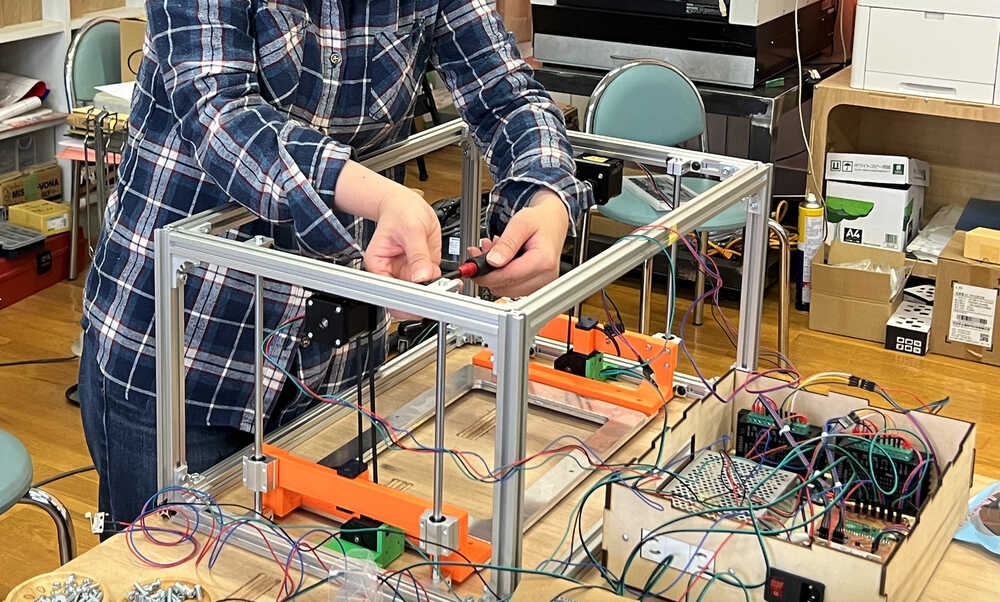

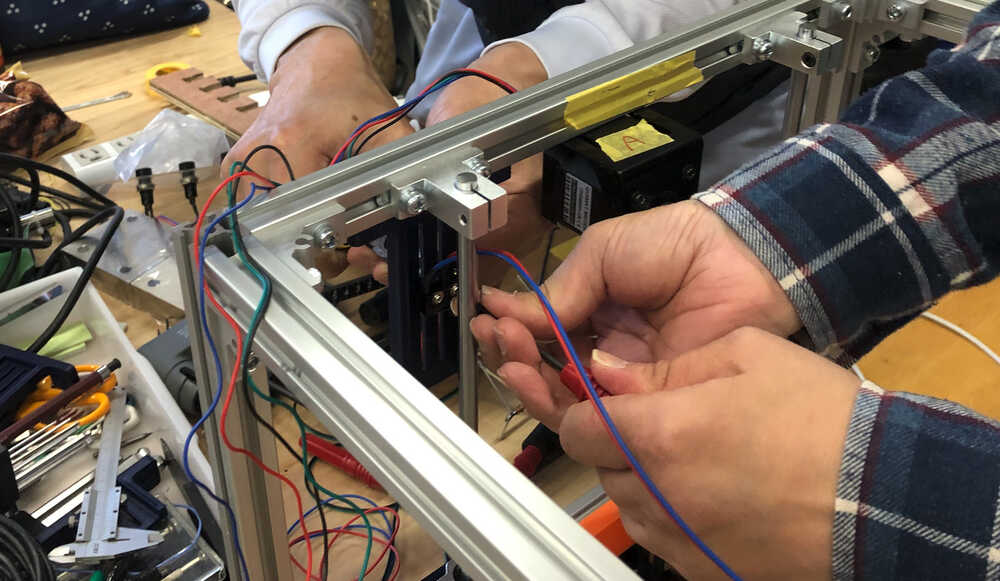

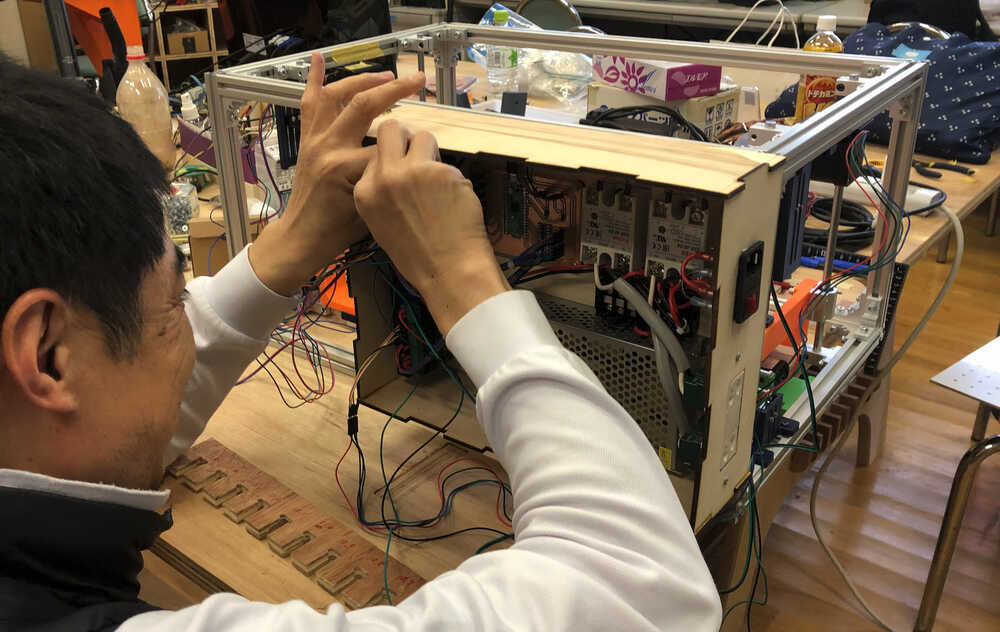

Then, It's time to wire for the prototype.

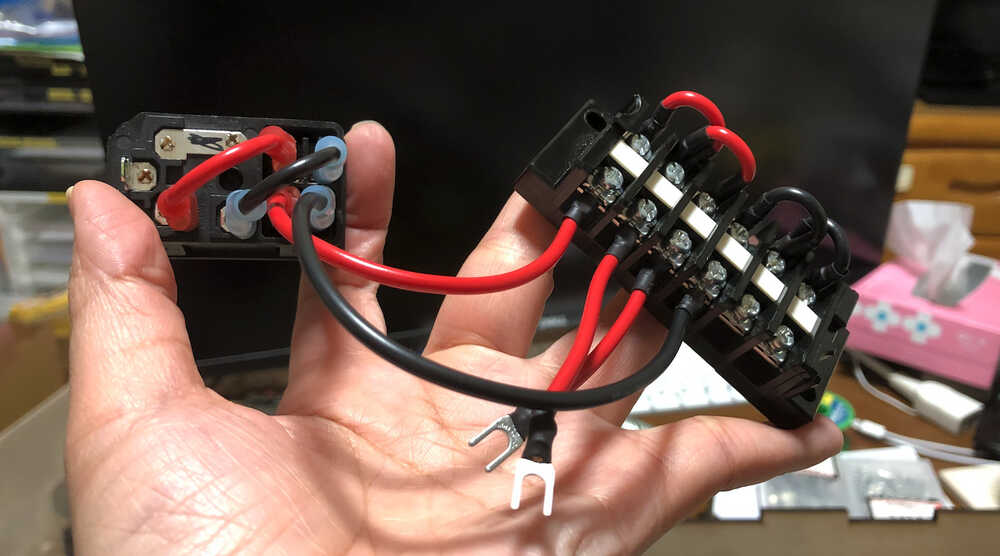

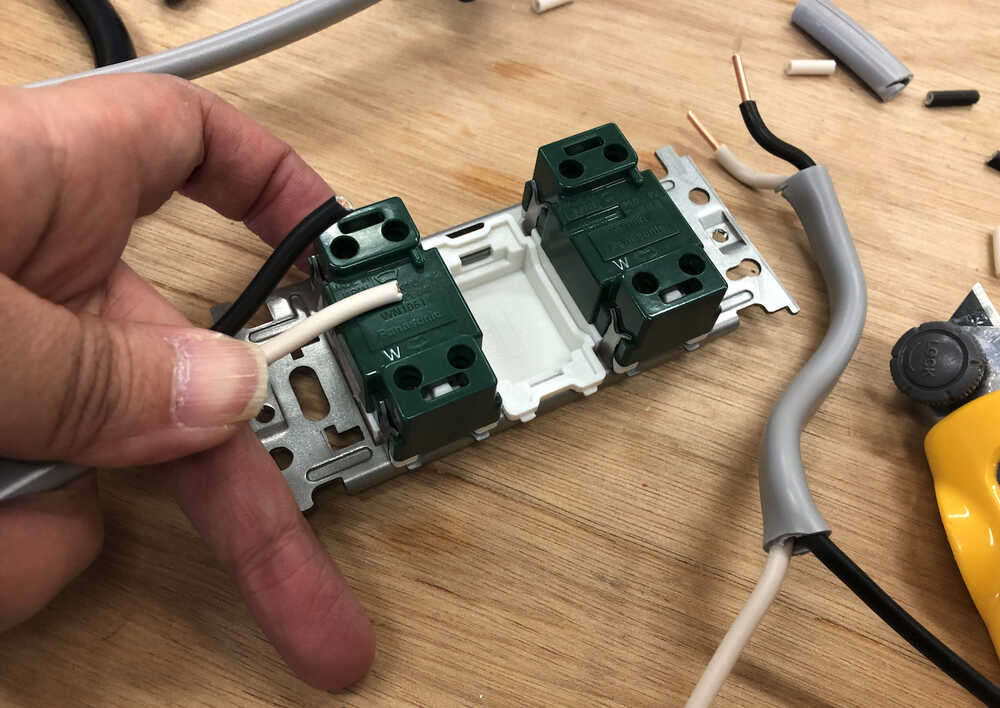

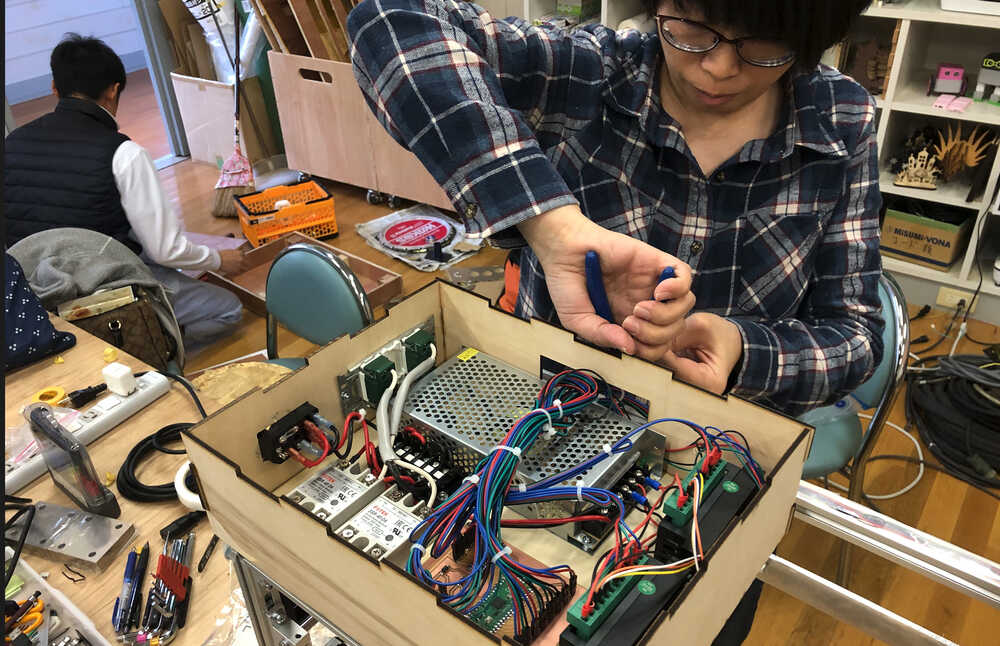

5-2) Wiring

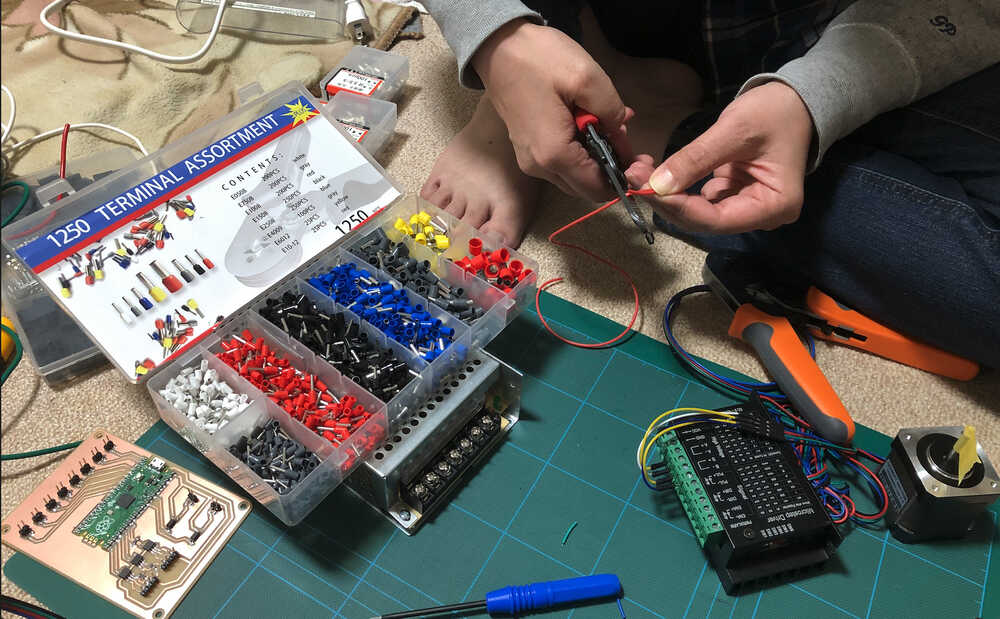

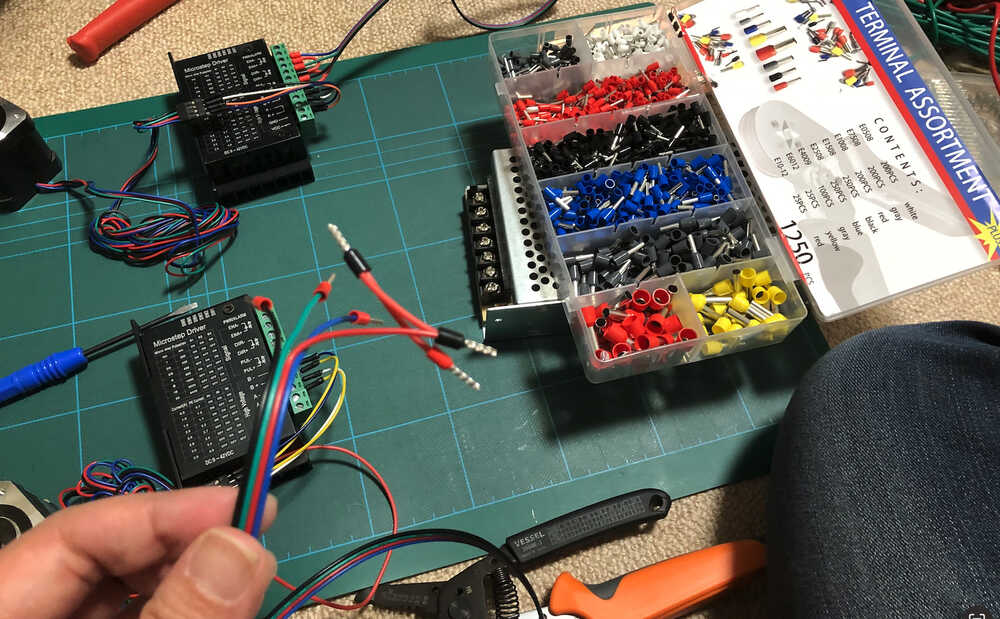

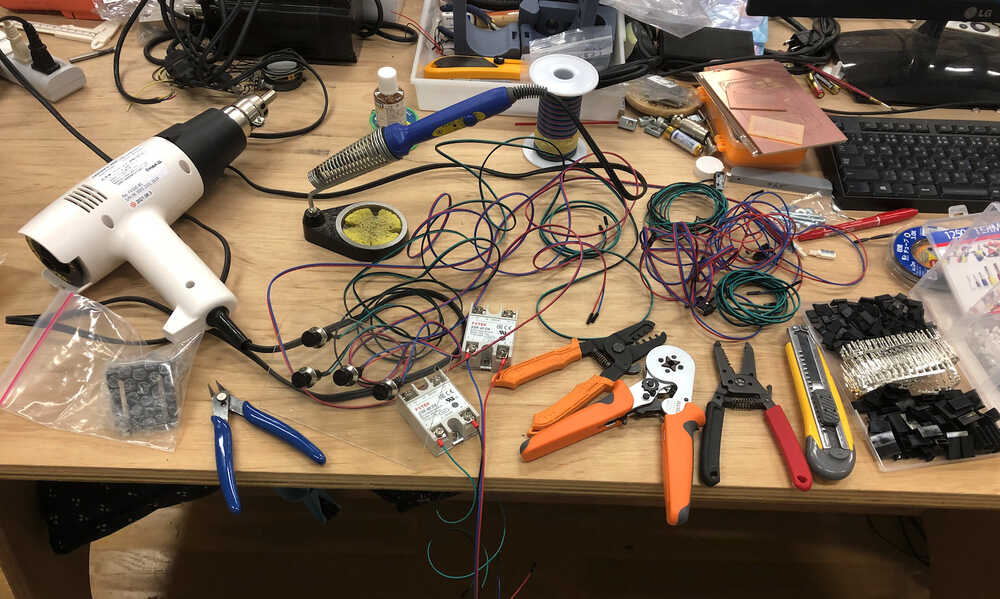

Wiring is done using many tools and terminal assortment.

During wiring work.

During wiring work.

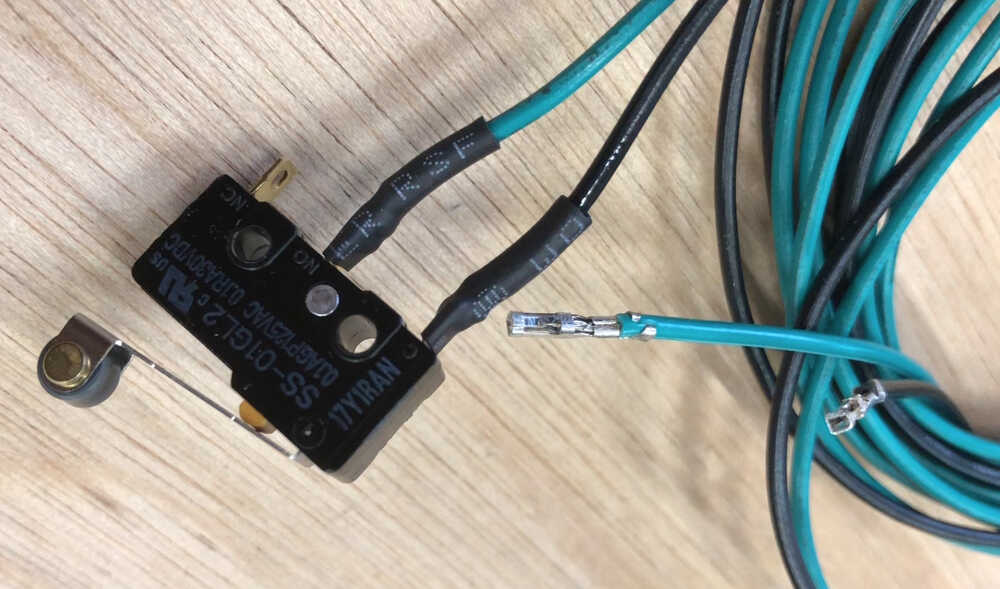

- Limit Switch

- Power line (AC inlet) and Terminal block.

- Wall outlet:

peel the cover of code about the length of guide on the outlet.

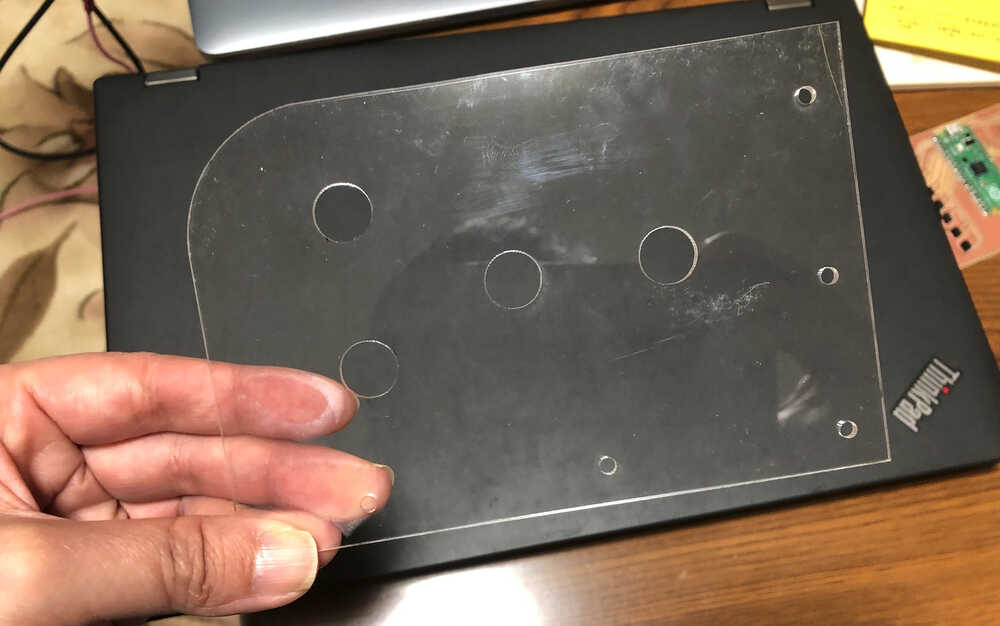

5-3) Panel

I made Push-button switch panel, using laser cutting machine.

- Make Model

- by Fusion360

- exported in SVG format about top face.

- Laser cutting

- Machine: FABOOL Laser CO2

- Materials: acrylic board

- Software: SmartDIYsCreator

- Parameter: Speed 900, Power 60, Times 2

Then I install Push-button switch to panel.

Then I install Push-button switch to panel.

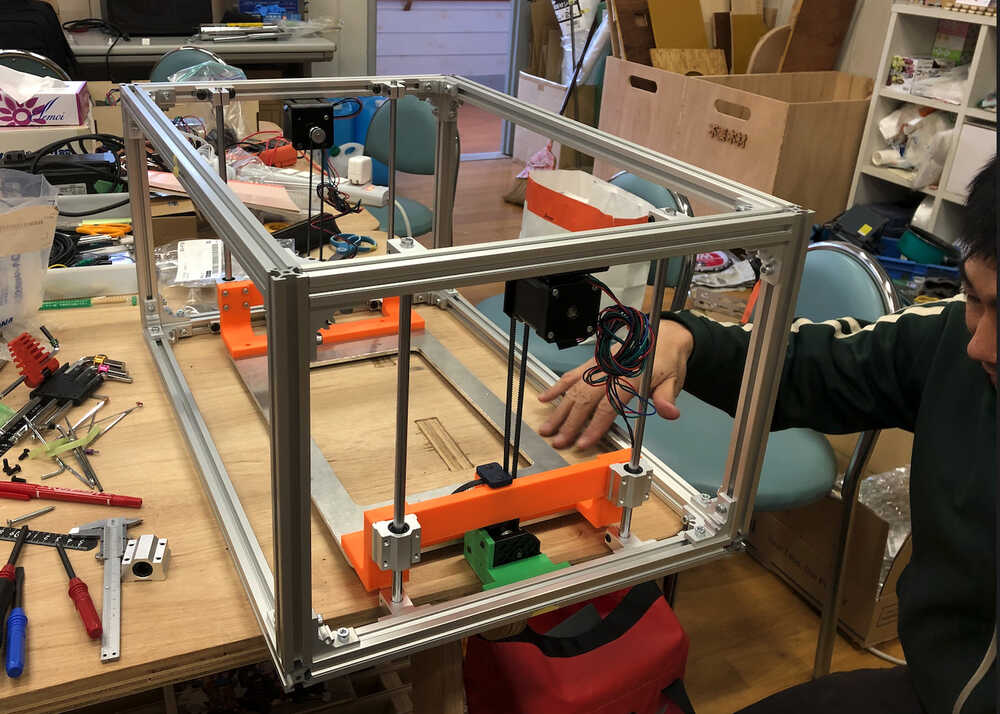

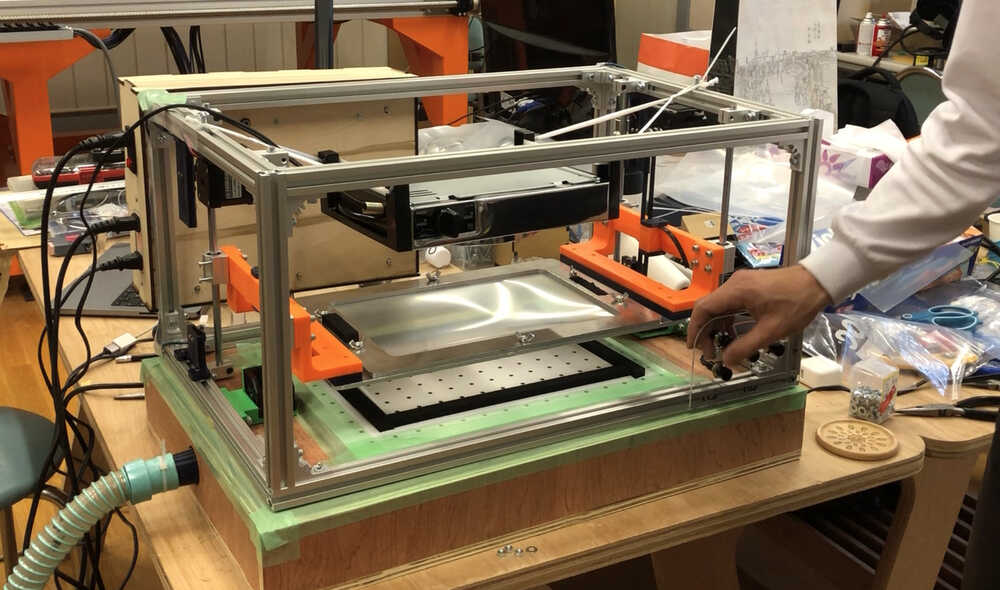

6. Assembly

It's time to assemble. Masuoka-san and I work for assemble together.

Install Motor

Install Limit Switch

Install Control box

Install Panel

Bundle the wires

Prototype1 assembly is Done.

After test ON 11-April, We choose electric heating stove to heat.

Install electric heating stove (Work on Progress)

7. Programming code

The completion code is as follows

// Pin definitions for stepper motors A and B

const int motorA_PUL = 16;

const int motorA_DIR = 17;

const int motorA_ENA = 18;

const int motorB_PUL = 19;

const int motorB_DIR = 20;

const int motorB_ENA = 21;

// Pin definitions for sStart button and limit switch

const int limitSwitchAPin_up = 0;

const int limitSwitchBPin_up = 1;

const int limitSwitchAPin_down = 2;

const int limitSwitchBPin_down = 3;

const int upButtonPin = 4;

const int downButtonPin = 5;

const int heatButtonPin = 6;

const int startButtonPin = 7;

// Pin Definition for Relay

const int heater_relay = 27;

const int vacuum_relay = 28;

// Stepping motor step count and delay time

const int stepsPerRevolution = 200;

const int stepDelay = 200000 / stepsPerRevolution; // MicroSec

void setup() {

// Setting of Pin

pinMode(motorA_DIR, OUTPUT);

pinMode(motorA_PUL, OUTPUT);

pinMode(motorA_ENA, OUTPUT);

pinMode(motorB_DIR, OUTPUT);

pinMode(motorB_PUL, OUTPUT);

pinMode(motorB_ENA, OUTPUT);

pinMode(upButtonPin, INPUT_PULLUP);

pinMode(downButtonPin, INPUT_PULLUP);

pinMode(startButtonPin, INPUT_PULLUP);

pinMode(heatButtonPin, INPUT_PULLUP);

pinMode(limitSwitchAPin_up, INPUT_PULLUP);

pinMode(limitSwitchBPin_up, INPUT_PULLUP);

pinMode(limitSwitchAPin_down, INPUT_PULLUP);

pinMode(limitSwitchBPin_down, INPUT_PULLUP);

// Setting of Relay pin

pinMode(heater_relay, OUTPUT);

pinMode(vacuum_relay, OUTPUT);

}

void loop() {

// (1)When the up button is pressed

if (digitalRead(upButtonPin) == LOW) {

// Enable stepper motors

digitalWrite(motorA_ENA, HIGH);

digitalWrite(motorB_ENA, HIGH);

//Rotate both stepper motors

if (digitalRead(limitSwitchAPin_up) == HIGH) {

rotateMotor_cw(motorA_DIR, motorA_PUL);

}

if (digitalRead(limitSwitchBPin_up) == HIGH) {

rotateMotor_cw(motorB_DIR, motorB_PUL);

}

}

// (2)When the down button is pressed

if (digitalRead(downButtonPin) == LOW) {

// Enable stepper motors

digitalWrite(motorA_ENA, HIGH);

digitalWrite(motorB_ENA, HIGH);

//Rotate both stepper motors

if (digitalRead(limitSwitchAPin_down) == HIGH) {

rotateMotor_ccw(motorA_DIR, motorA_PUL);

}

if (digitalRead(limitSwitchBPin_down) == HIGH) {

rotateMotor_ccw(motorB_DIR, motorB_PUL);

}

}

// (3)When the heating button is pressed

if (digitalRead(heatButtonPin) == LOW) {

// Enable stepper motors

digitalWrite(motorA_ENA, HIGH);

digitalWrite(motorB_ENA, HIGH);

// Rotate both stepping motors until both limit switches A and B are pressed

while (digitalRead(limitSwitchAPin_up) == HIGH || digitalRead(limitSwitchBPin_up) == HIGH) {

if (digitalRead(limitSwitchAPin_up) == HIGH) {

rotateMotor_cw(motorA_DIR, motorA_PUL);

}

if (digitalRead(limitSwitchBPin_up) == HIGH) {

rotateMotor_cw(motorB_DIR, motorB_PUL);

}

}

// Heater relay ON when both limit switches A and B are pressed

digitalWrite(heater_relay, HIGH);

//Heating OFF when start button is pressed

if (digitalRead(startButtonPin) == LOW) {

digitalWrite(heater_relay, LOW);

}

}

// (4)When the start button is pressed

if (digitalRead(startButtonPin) == LOW) {

// Enable stepper motors

digitalWrite(motorA_ENA, HIGH);

digitalWrite(motorB_ENA, HIGH);

// Rotate both stepping motors until both limit switches A and B are pressed

while (digitalRead(limitSwitchAPin_down) == HIGH || digitalRead(limitSwitchBPin_down) == HIGH) {

if (digitalRead(limitSwitchAPin_down) == HIGH) {

rotateMotor_ccw(motorA_DIR, motorA_PUL);

}

if (digitalRead(limitSwitchBPin_down) == HIGH) {

rotateMotor_ccw(motorB_DIR, motorB_PUL);

}

}

// Vacuum relay ON for 10 seconds when both limit switches A and B are pressed

digitalWrite(vacuum_relay, HIGH);

delay(10000);

digitalWrite(vacuum_relay, LOW);

delay(1000);

}

}

// function definition

void rotateMotor_cw(int motor_DIR_cw, int motor_PUL_cw) {

digitalWrite(motor_DIR_cw, HIGH); // Rotate in clockwise direction

digitalWrite(motor_PUL_cw, HIGH);

delayMicroseconds(stepDelay);

digitalWrite(motor_PUL_cw, LOW);

delayMicroseconds(stepDelay);

}

void rotateMotor_ccw(int motor_DIR_ccw, int motor_PUL_ccw) {

digitalWrite(motor_DIR_ccw, LOW); // Rotate in counterclockwise direction

digitalWrite(motor_PUL_ccw, HIGH);

delayMicroseconds(stepDelay);

digitalWrite(motor_PUL_ccw, LOW);

delayMicroseconds(stepDelay);

}

Reference code

In my case, I had a very hard time with the program code. The following sites and others helped me.

-

TB6600 Stepper Motor Driver

-

"INPUT_PULLUP" of arduino IDE

- OttoBlockly Sample code

- Arduino IDE Sample code

- ChatGPT

8. My Thought

- I am in charge of Making Control system for Machine building. It was very wonderful experience for me.

- There was so much to do for machine building that there was no time at all. (connections, programming, and wiring work, etc)

- Space for installing Control Box components is small. For future work, I leaned the outbox size should made it wider.

- Wires are disconnected and debugging is frequent, so I changed to caulking terminals that are difficult to disconnect.

- I've also learned that wiring with long length can result become inconvenience.