- Molding & Casting

This page is the process for Molding and Casting, in week 12 Molding and Casting. I made the rubber feet for my final Project. The Process is below.

1. Milling Job

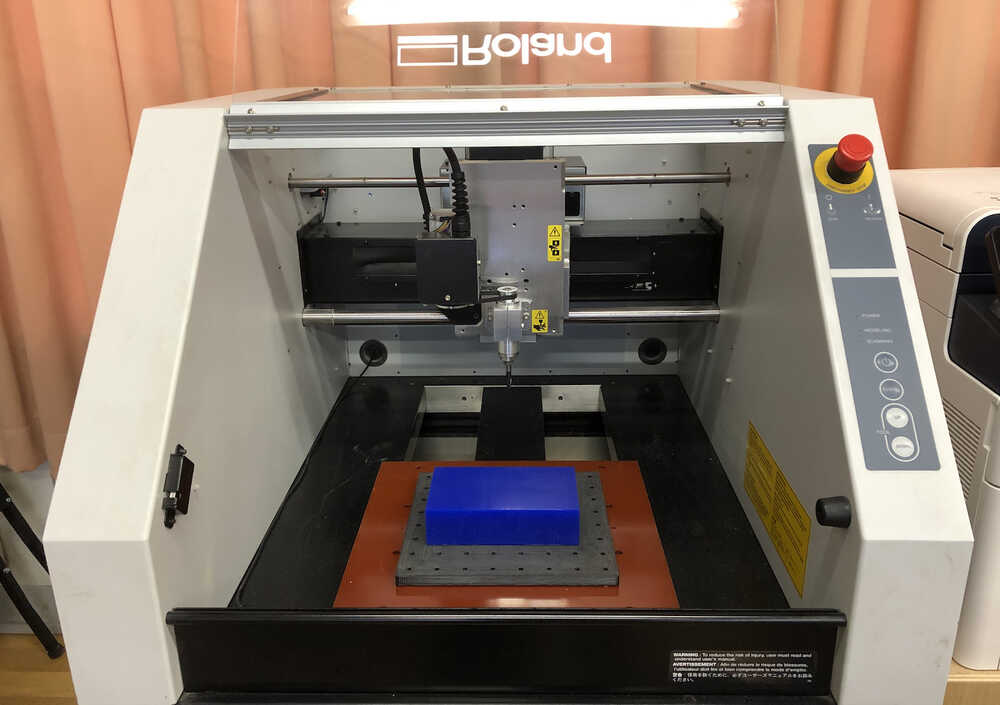

I use Roland MDX-40DA and set Molding wax(ferris File-A-Wax). About setting details, refer to Week08

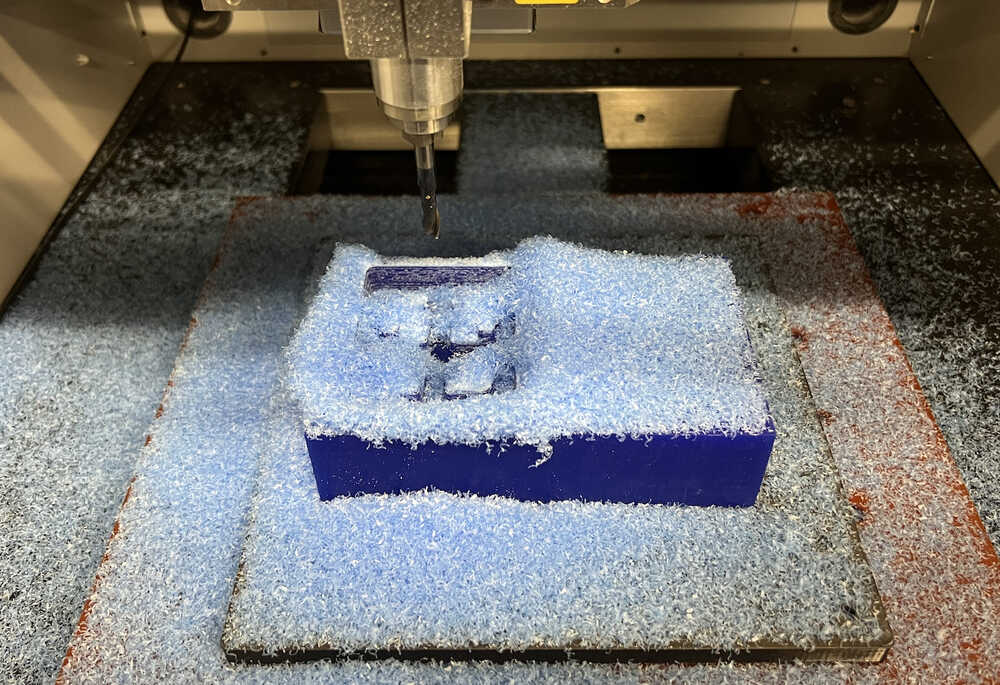

Milling with Rough Tool path by 6mm Flat end mill.

The Vacuuming is done. I was concerned about many burrs, but I continue working.

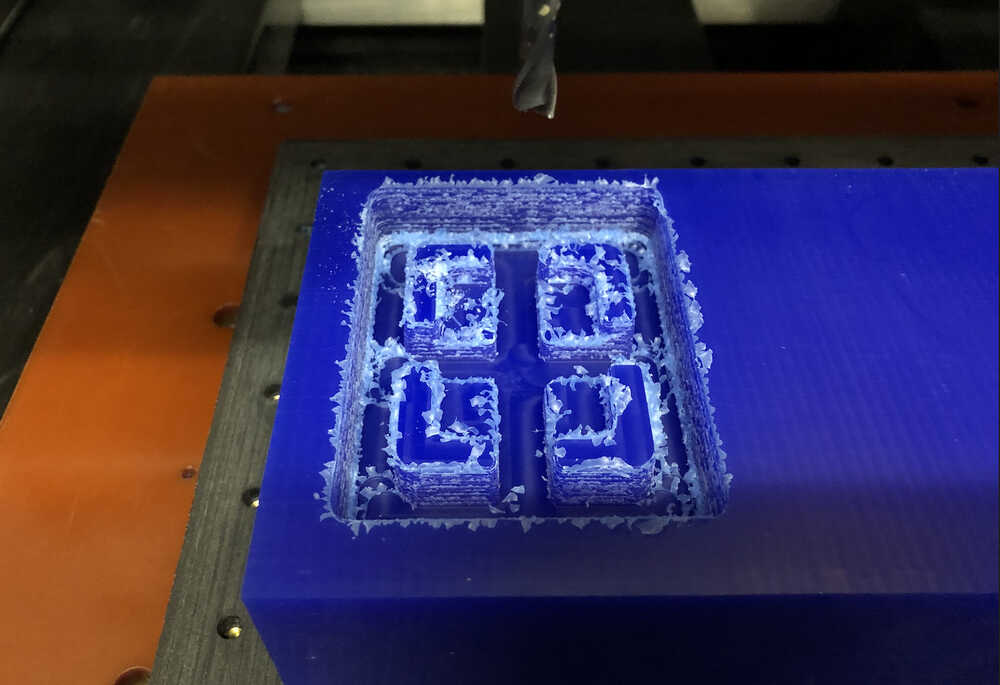

Start Milling by Finish Tool path by 2mm Ball end mill.

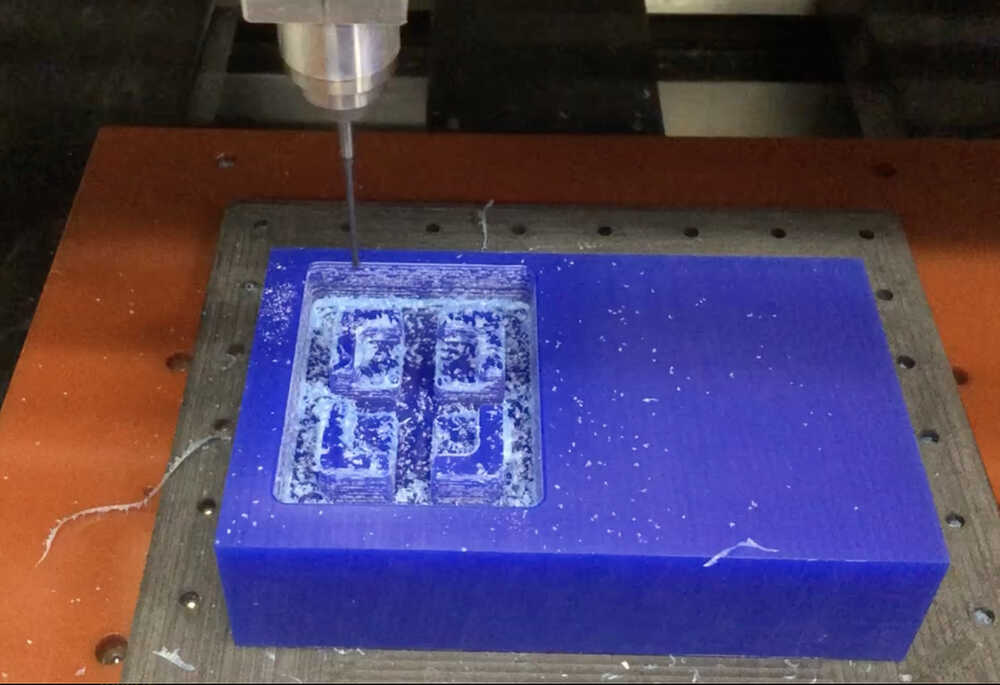

Done.

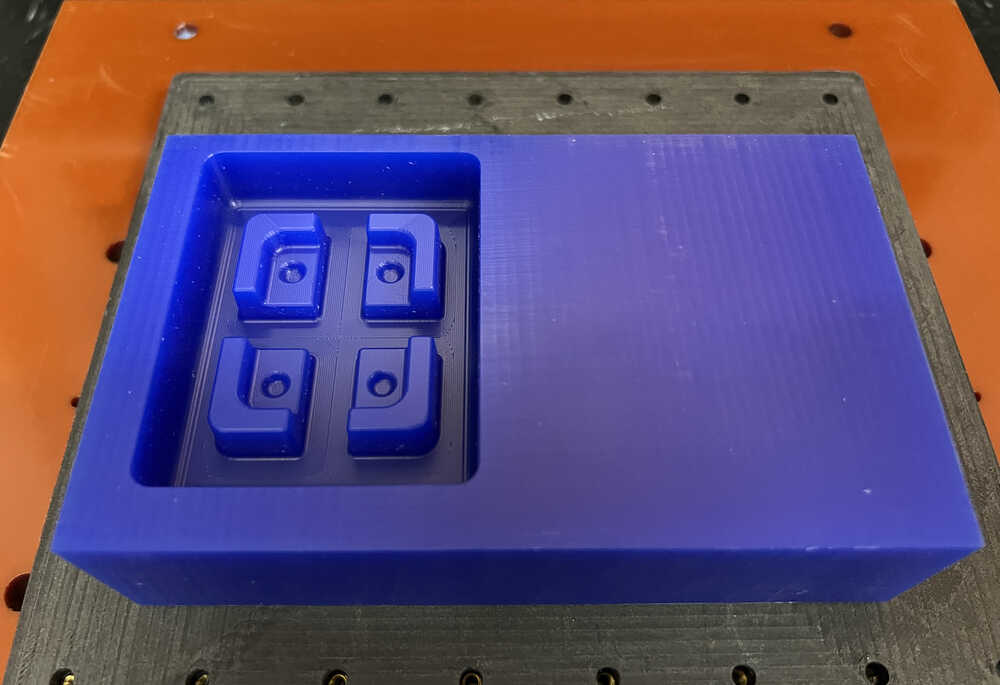

2. Molding

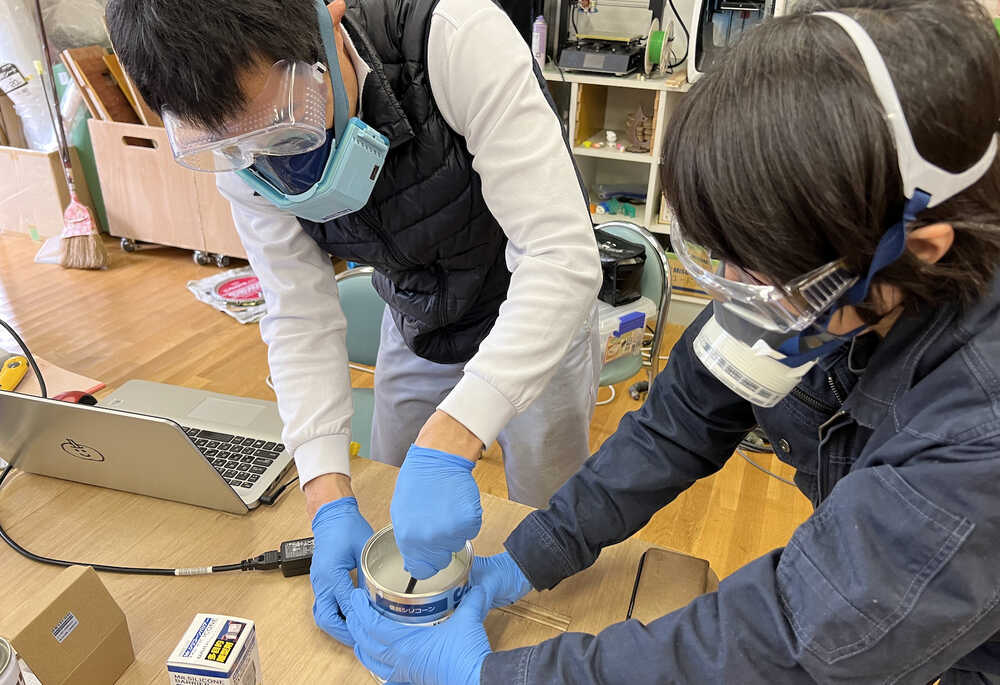

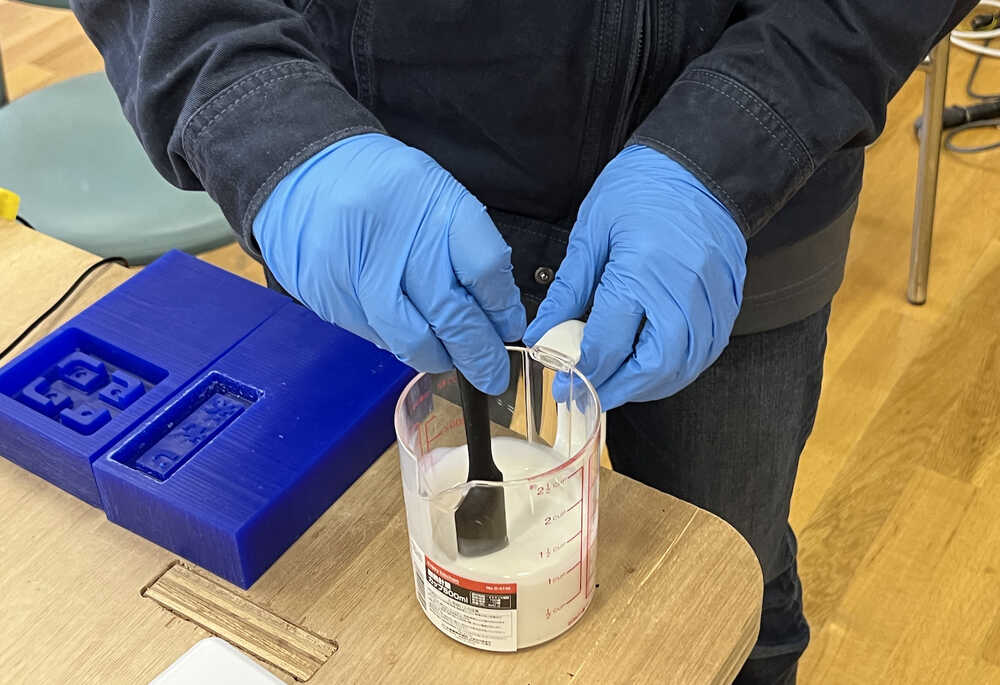

Mixed the silicone (KE-17) gently. The sediment was hard and took a long time to mix.

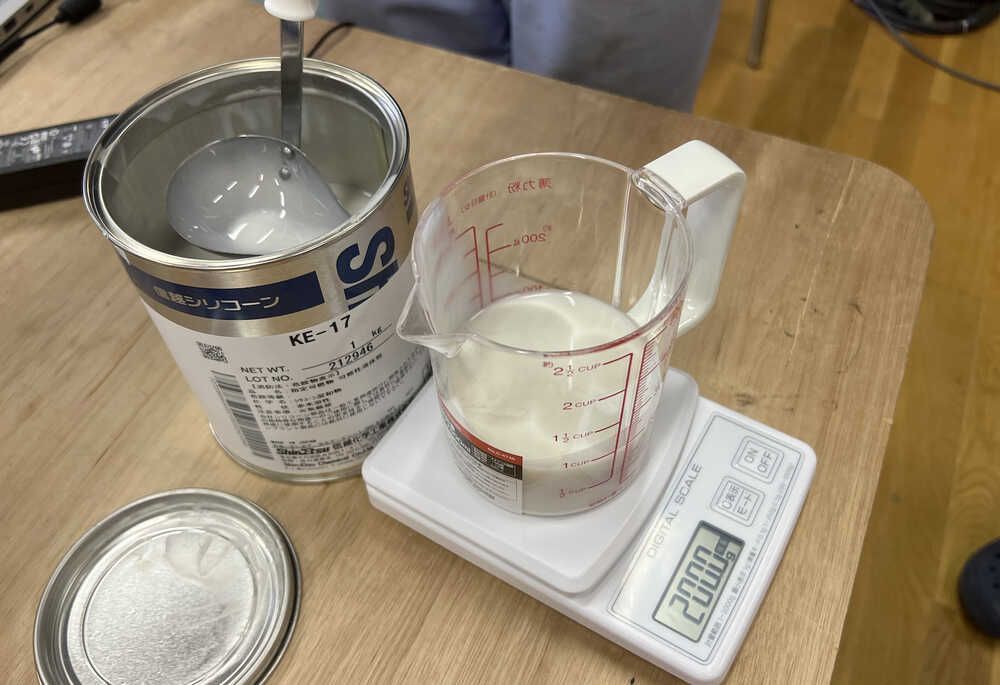

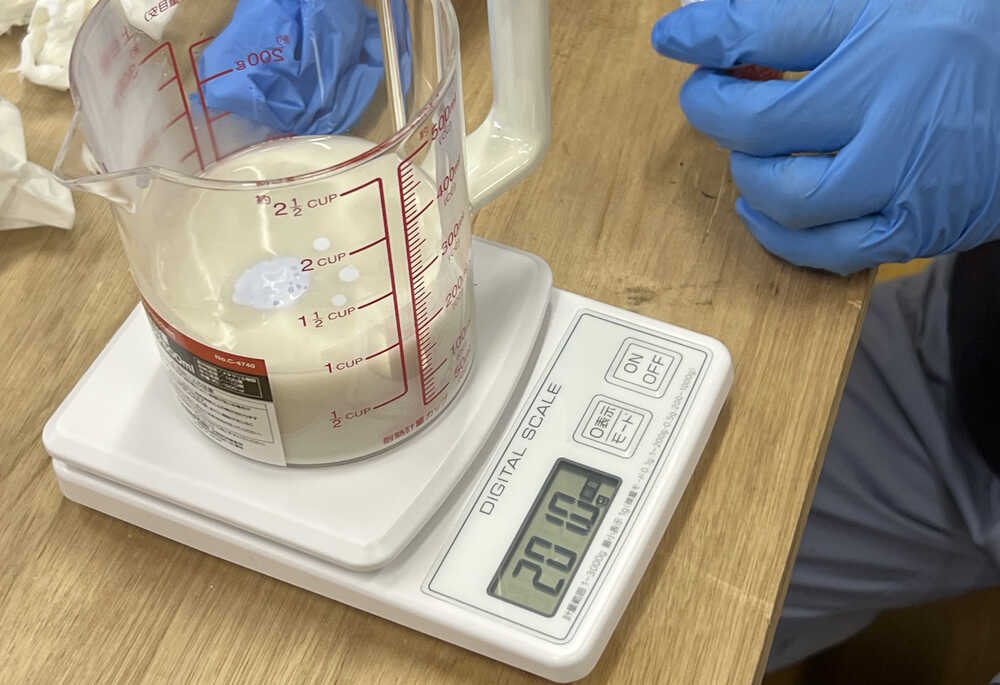

Measure the silicone.

Mixed with the curing agent. Mixing ratio of the agent to silicon is 0.5 %.

Mixed the silicone and curing. (Workable time of KE-17: About 60 mins)

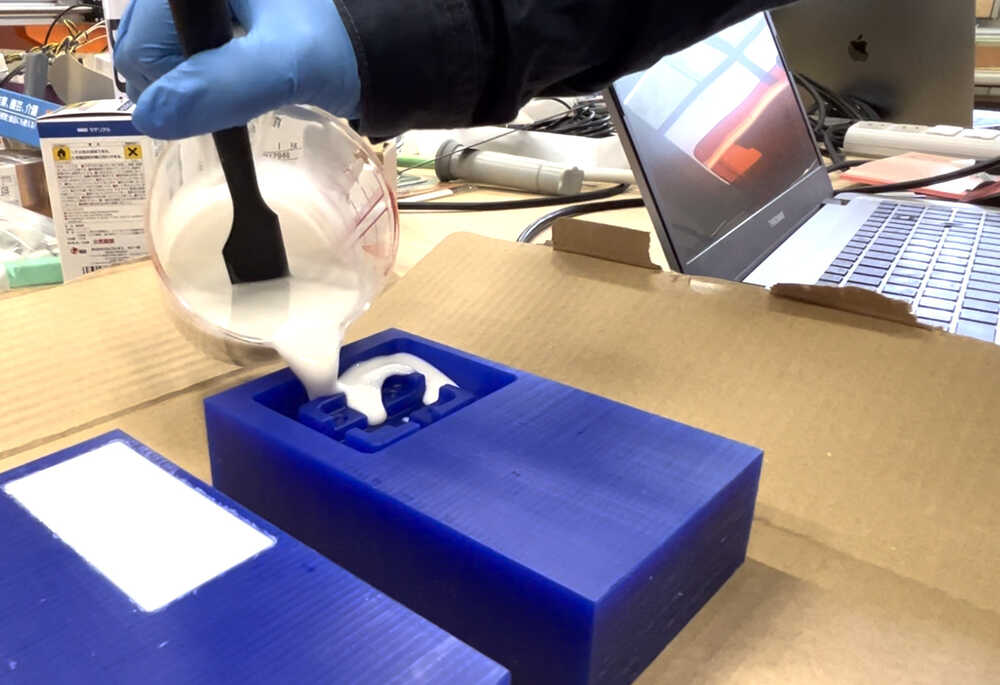

Gently poured the silicone on to the wax mold.

Also poured it into a mold made by vacuum forming for Week 10 production.

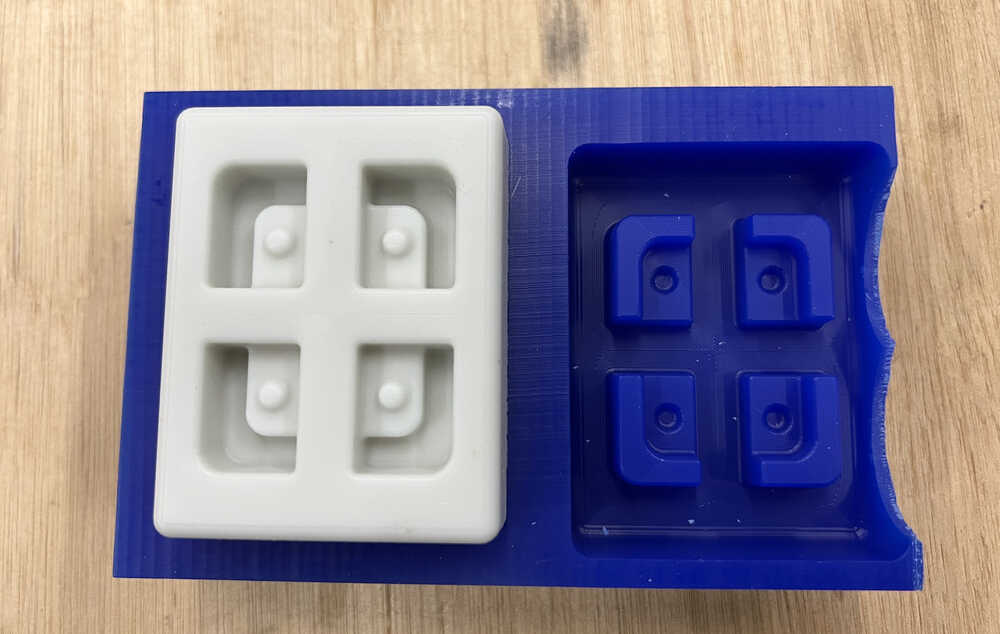

About a day and a half after the work was poured, I removed the silicone of vacuuming mold. The silicone cure well.

Silicone in molding wax proved difficult to remove.

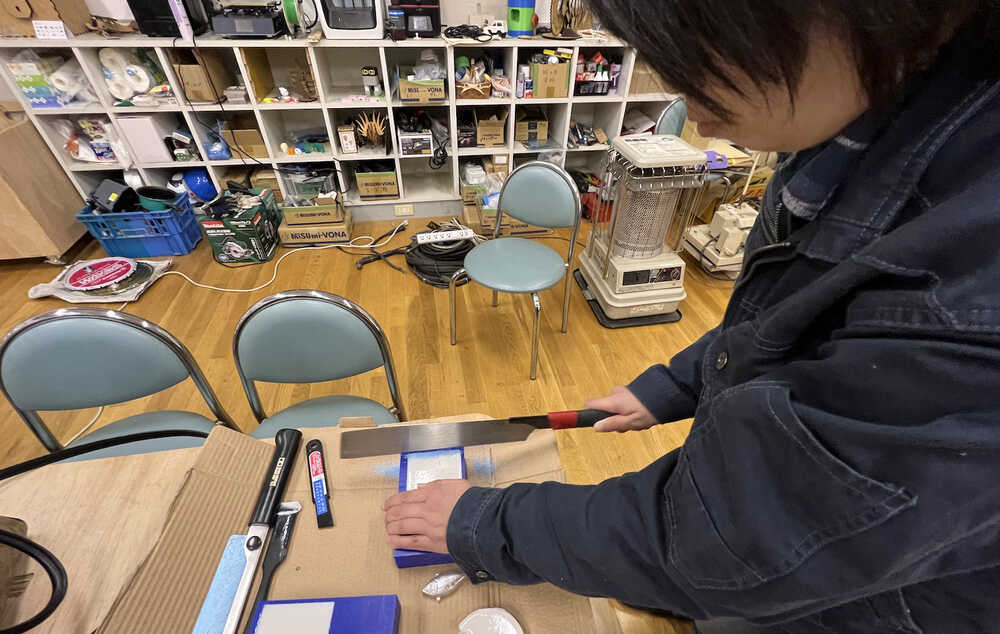

I cut the molding wax a little.

Then remove the silicone.

The silicone remove, and cure well.

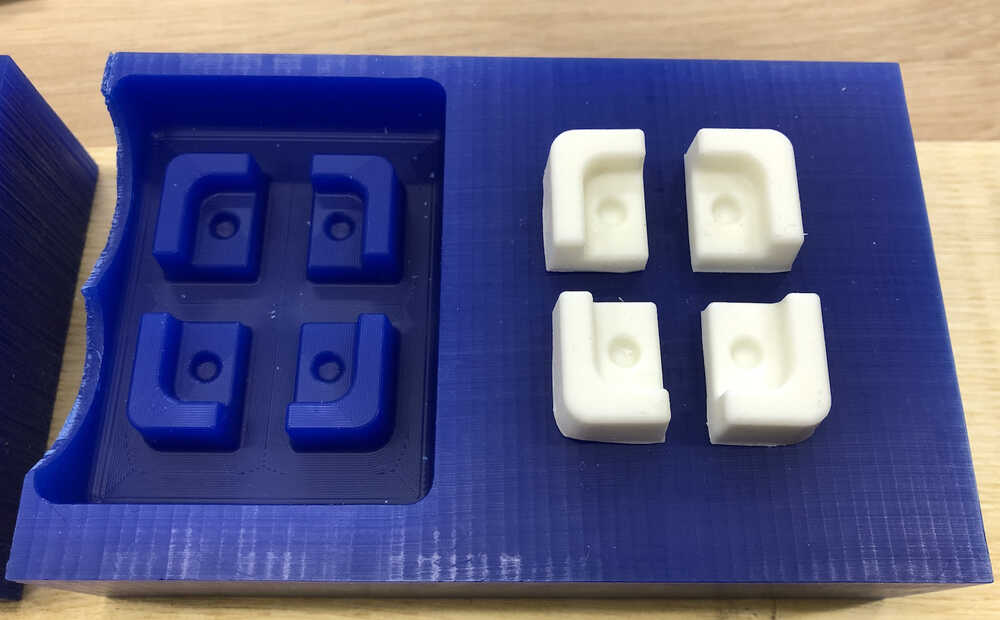

3. Casting

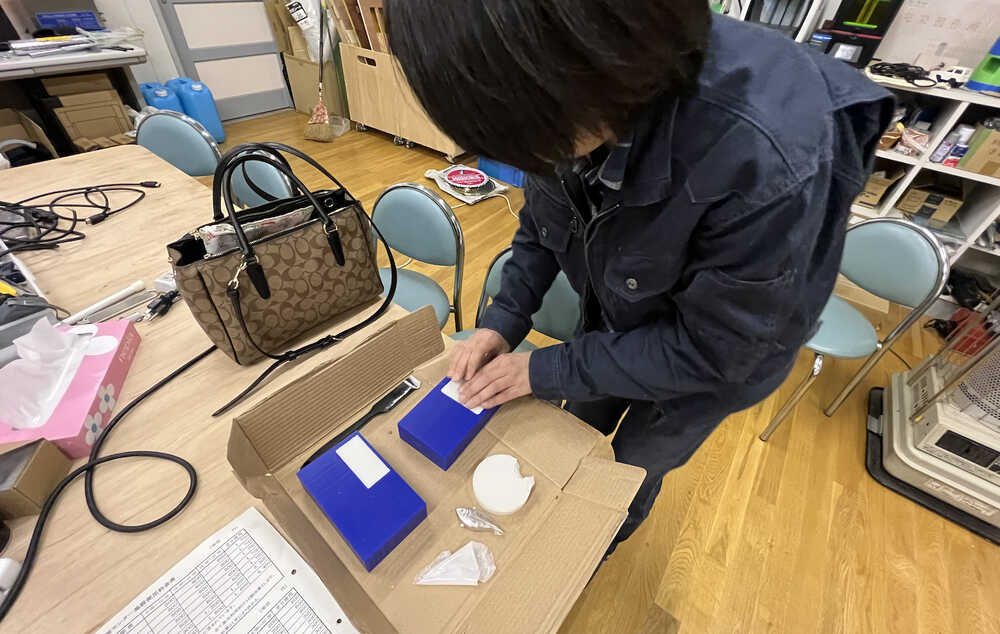

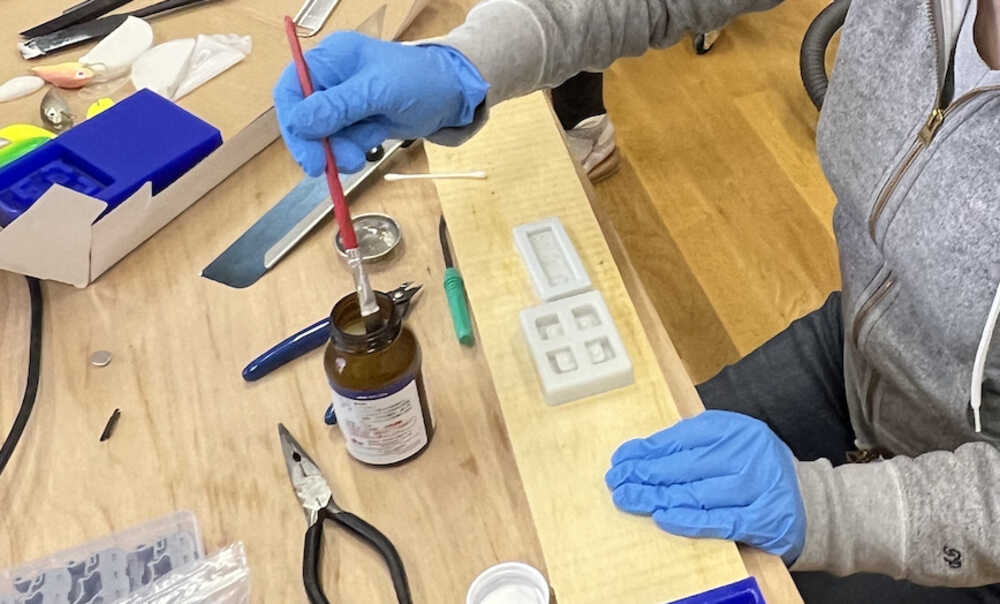

Apply Mr. silicone barrier to silicone mold.

We prepare liquid A and the liquid B of polyurethane resin.

According to the instruction, proper mixture ratio is 1 : 1. So We measured the weight with a digital scale.

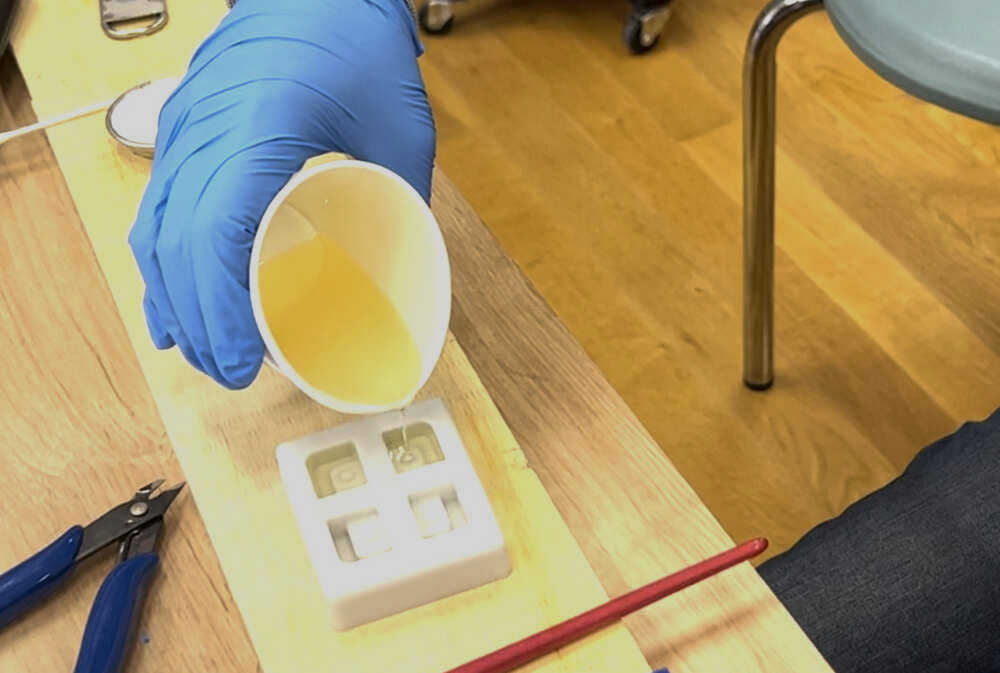

Pour the mix Liquid A + B to silicone mold. It seems that the amount of resin will be reduced slightly, We aim for the amount of surface tension.

Pour the mix Liquid A + B to silicone mold. It seems that the amount of resin will be reduced slightly, We aim for the amount of surface tension.

Looks overflowed a little, but the mix Liquid is filled, so it is OK.

Looks overflowed a little, but the mix Liquid is filled, so it is OK.

Cure start about 300 seconds. The product said that it starts curing in 180 seconds, but today's low temperature (about 13 degrees Celsius) seems to have lengthened the curing start time.

Cure start about 300 seconds. The product said that it starts curing in 180 seconds, but today's low temperature (about 13 degrees Celsius) seems to have lengthened the curing start time.

It seems the mix liquid become hot, during the cure. We wait the silicone mold is cool, and remove the cast resin.

It seems the mix liquid become hot, during the cure. We wait the silicone mold is cool, and remove the cast resin.

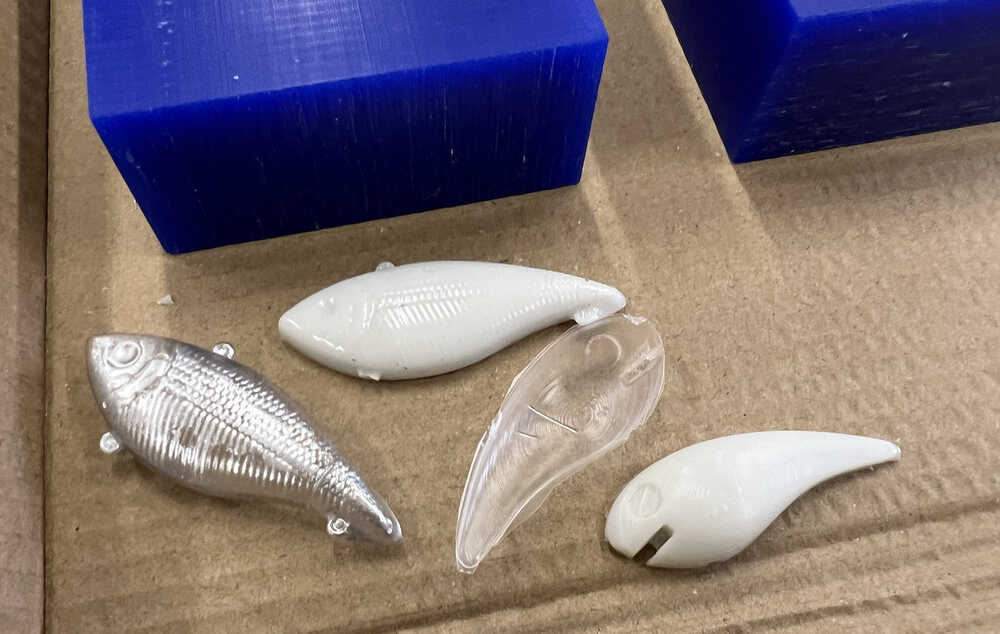

Cut the protruding part, then finish casting!

Cut the protruding part, then finish casting!

I am happy that My Prototype of rubber feet for my final Project can made by molding and Casting.

I am happy that My Prototype of rubber feet for my final Project can made by molding and Casting.