- Designing a mold

This page is the process for Designing my 3D mold model, in week 12 Molding and Casting.

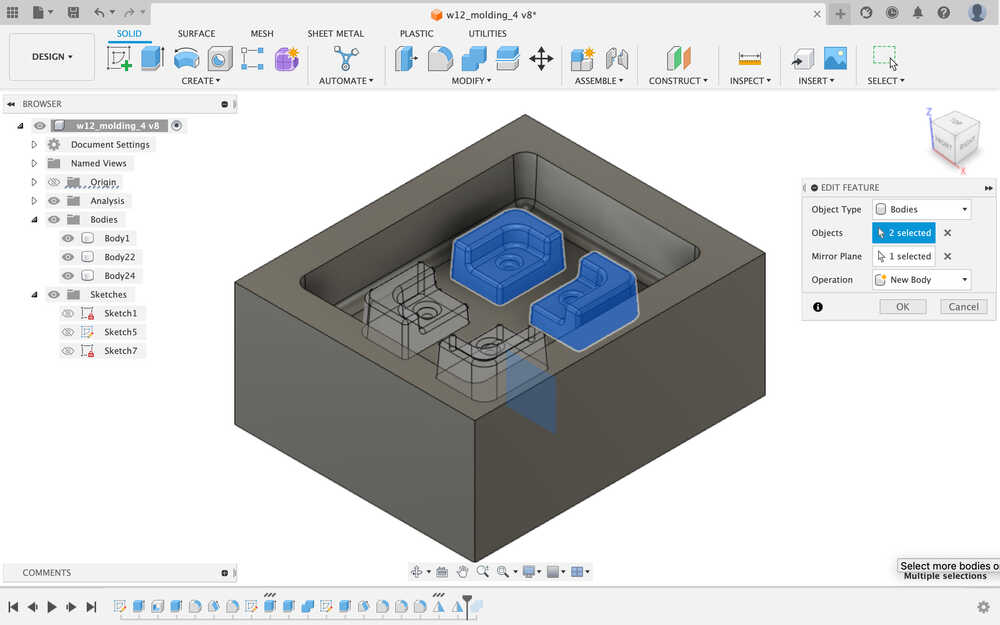

1. The Result

- I made feet (Prototype) for my final project.

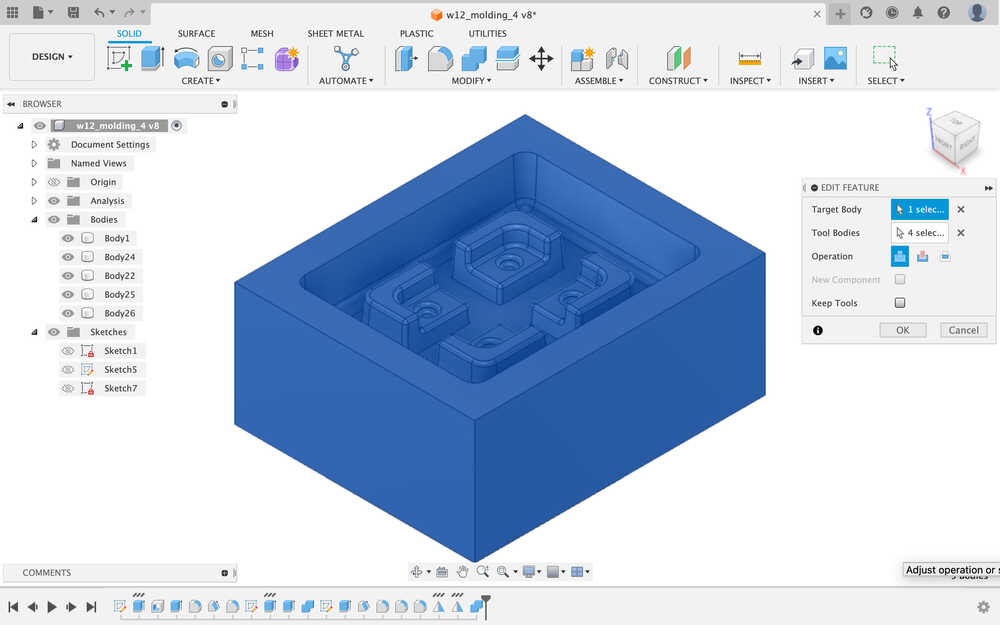

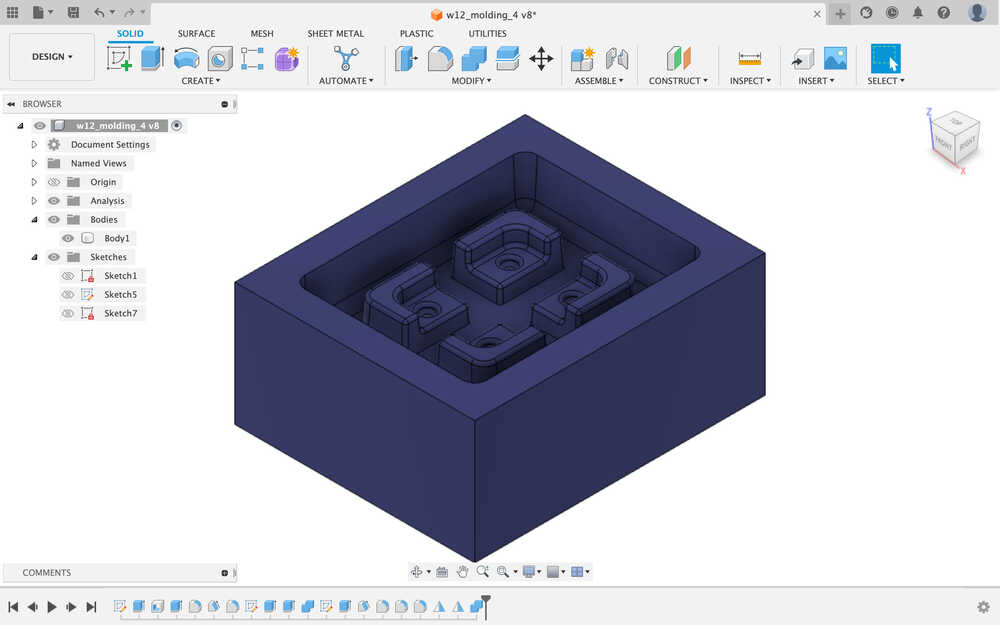

- This is my 3D complete mold model. The model size 92(W)x76(D)x39(H) mm, half of size of material.

2. How I designed

- To make the design of the mold I use Fusion360.

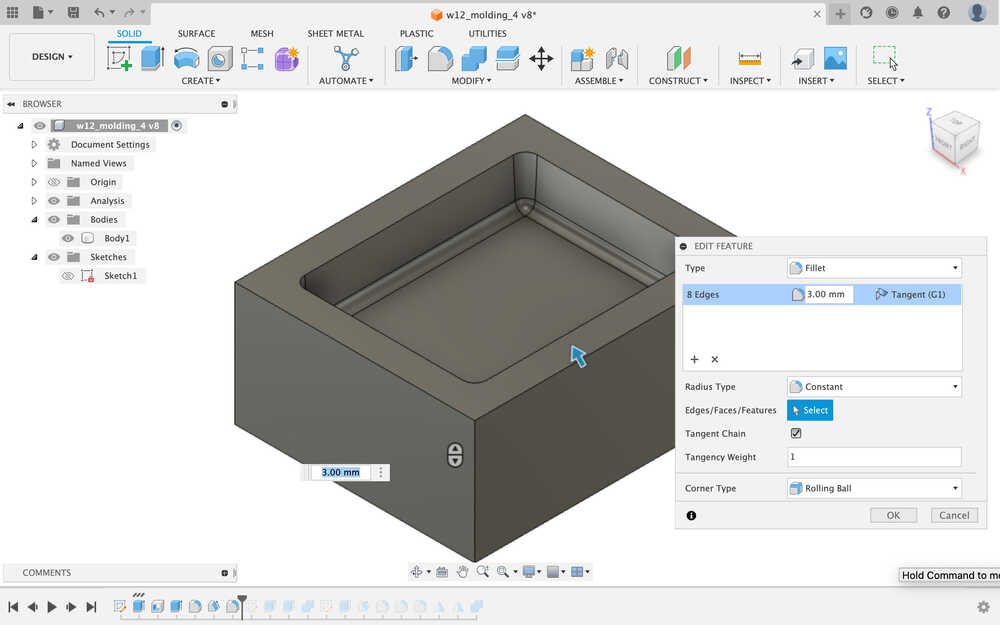

- I learned that design a mold need Vertical walls need slightly angled. And right-angled corners should be filleted, to consider pull out Silicone mold easily.

2-1) Outer frame

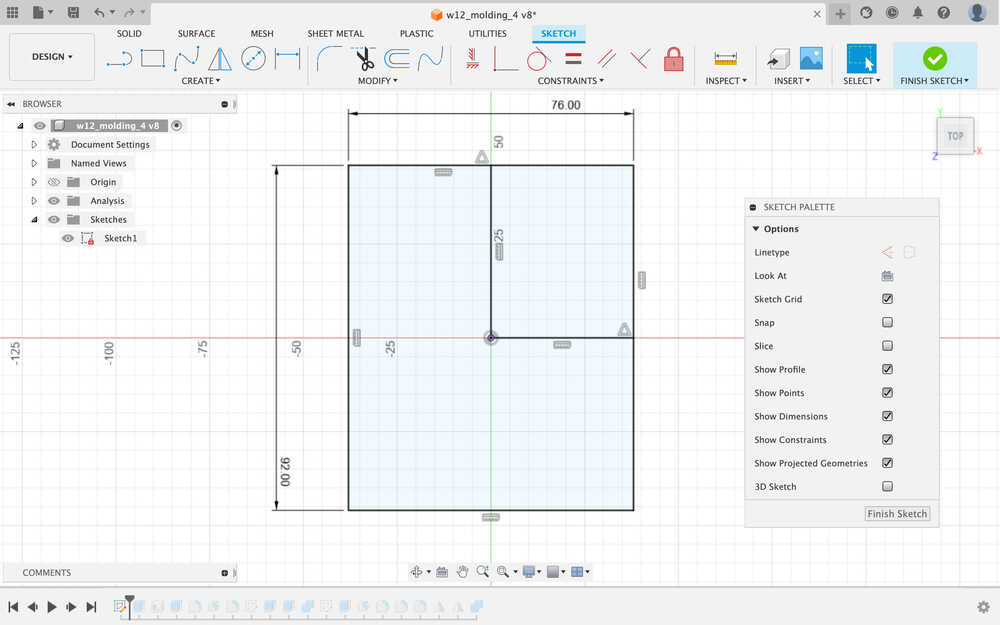

Sketch

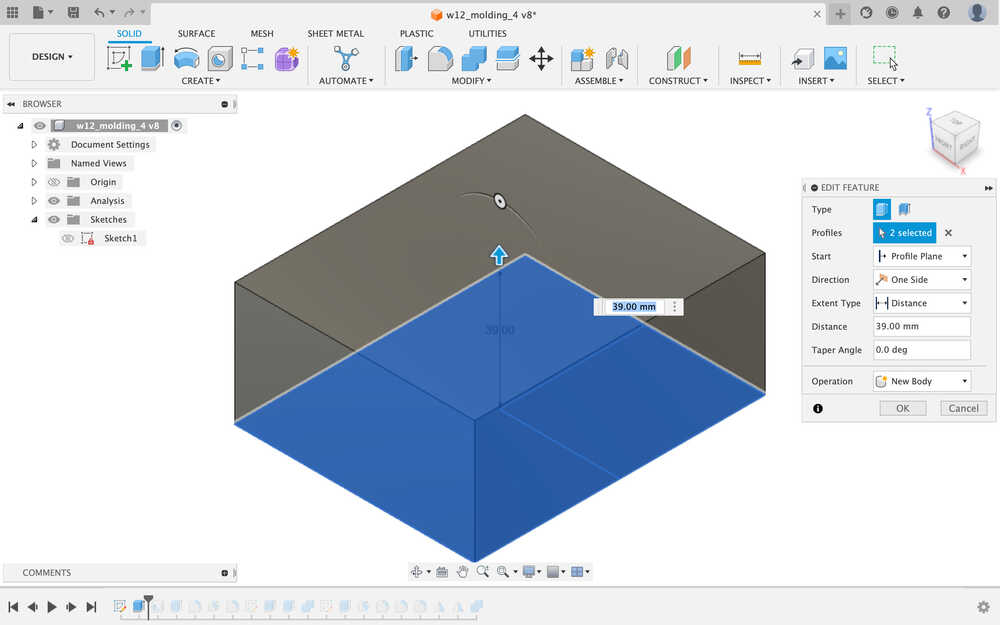

Extrude

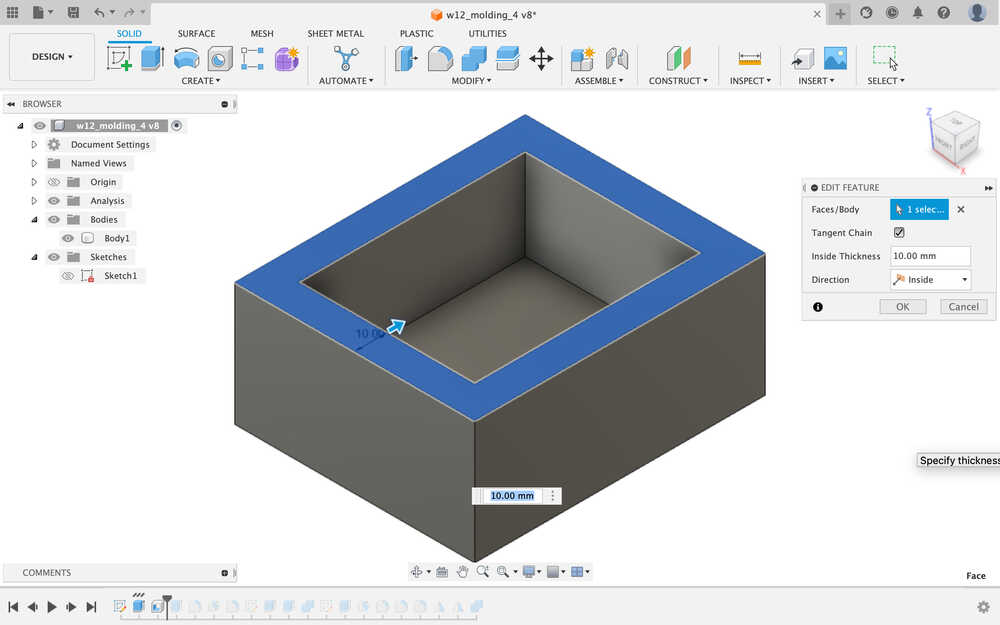

Shell

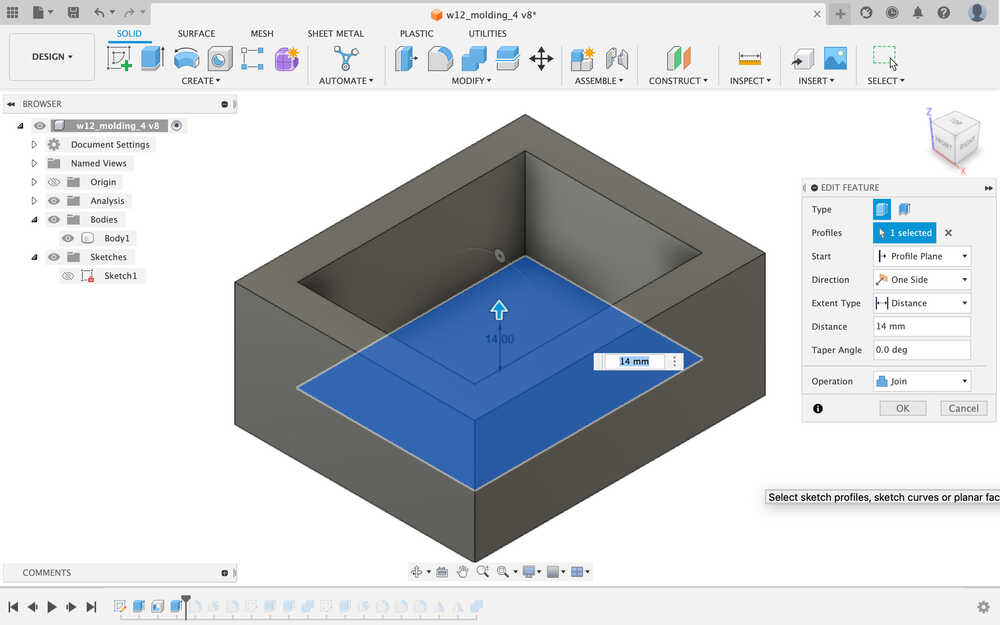

Extrude

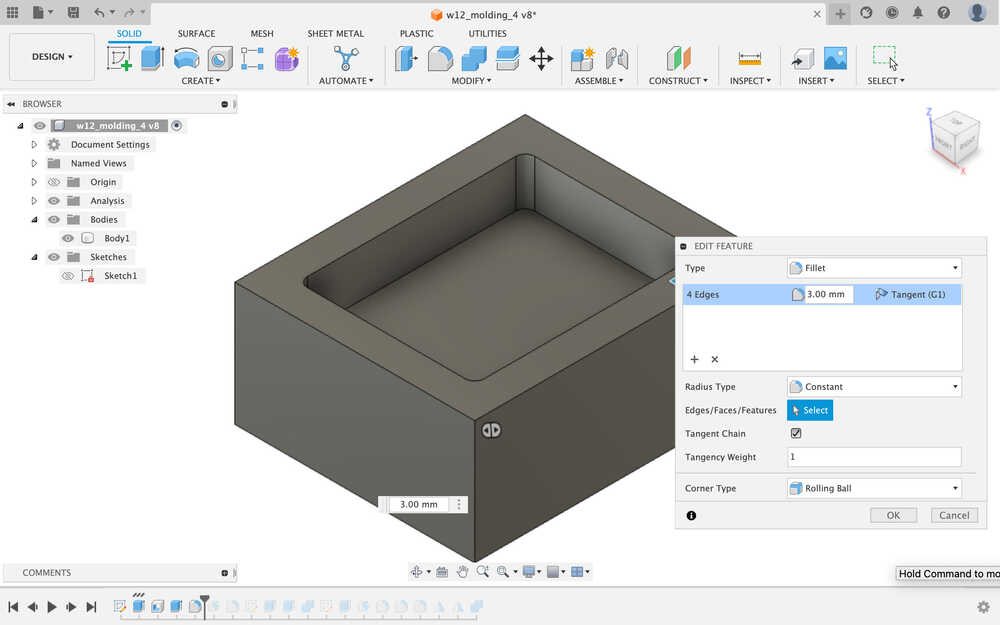

Fillet

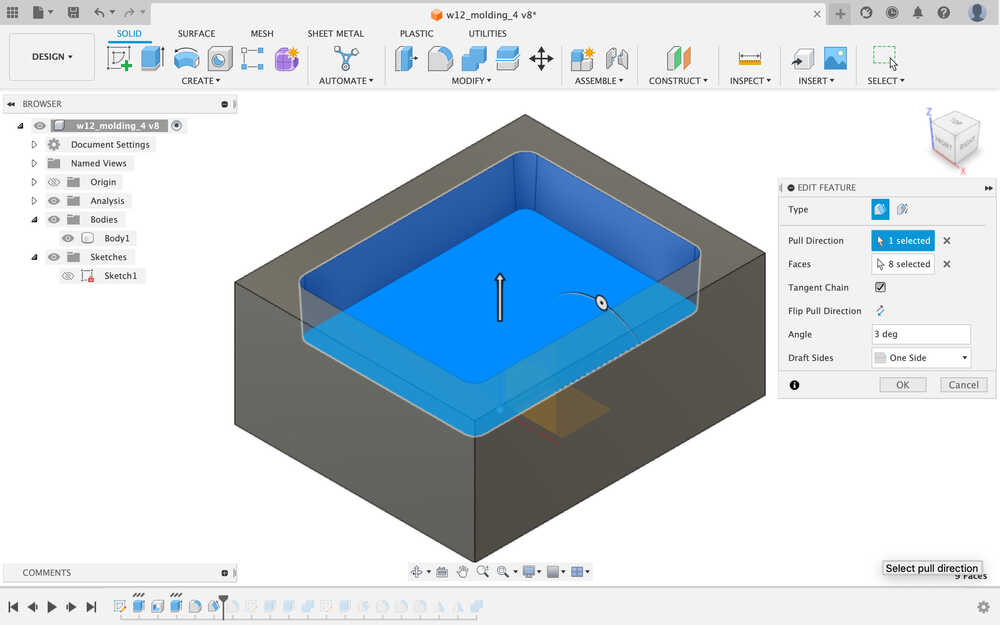

Draft

Fillet

The next I made the model of rubber feet parts.

2-2) The rubber feet parts

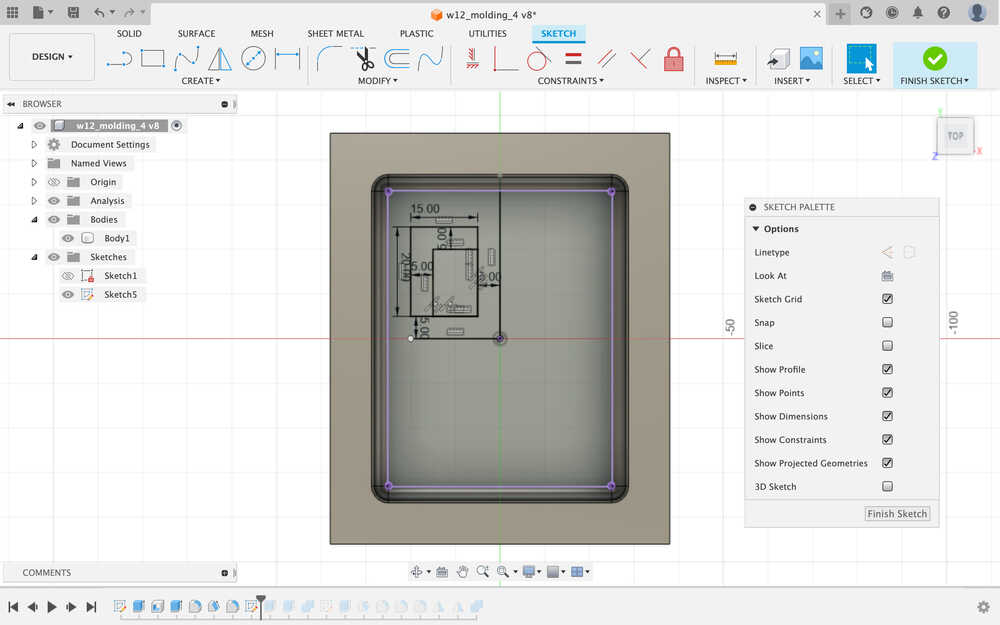

Sketch

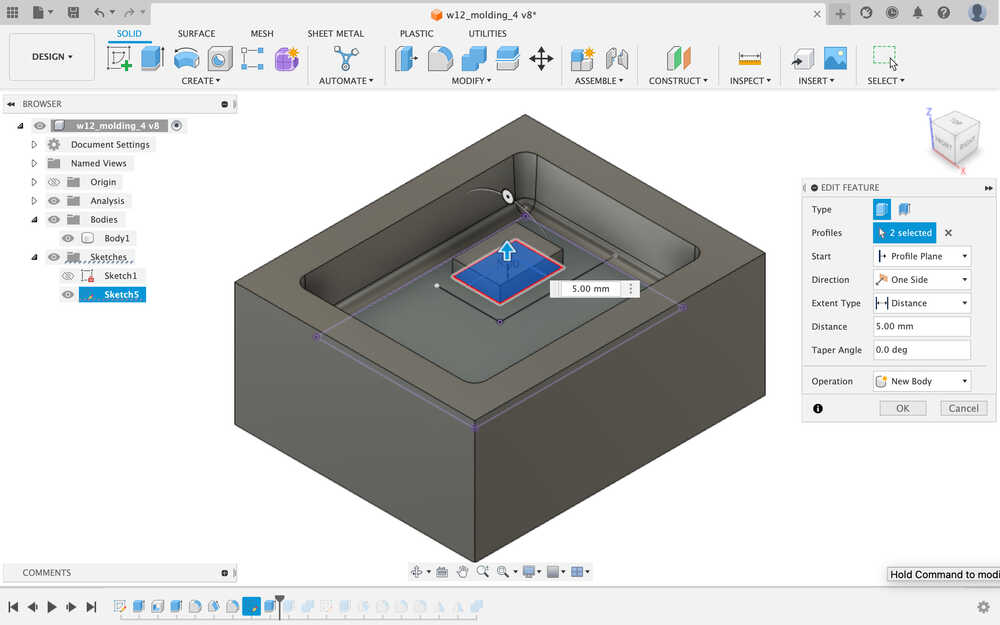

Extrude

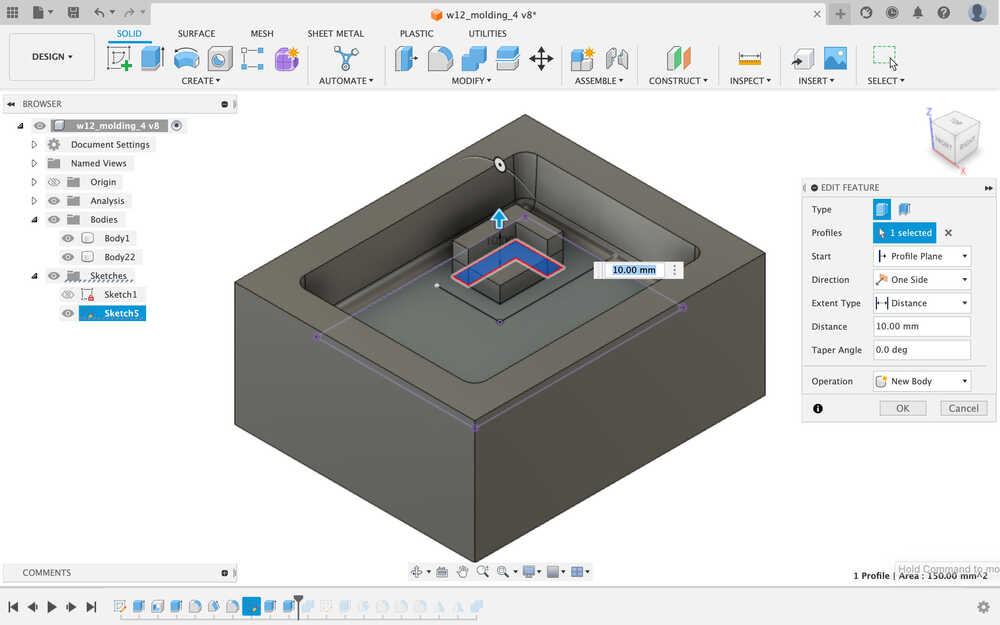

Extrude2

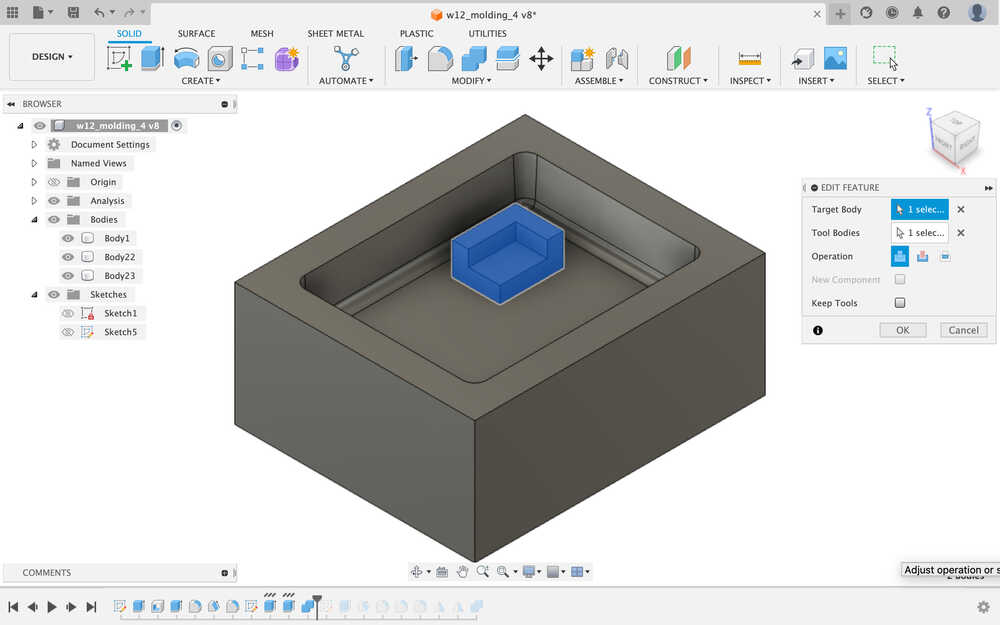

Combine

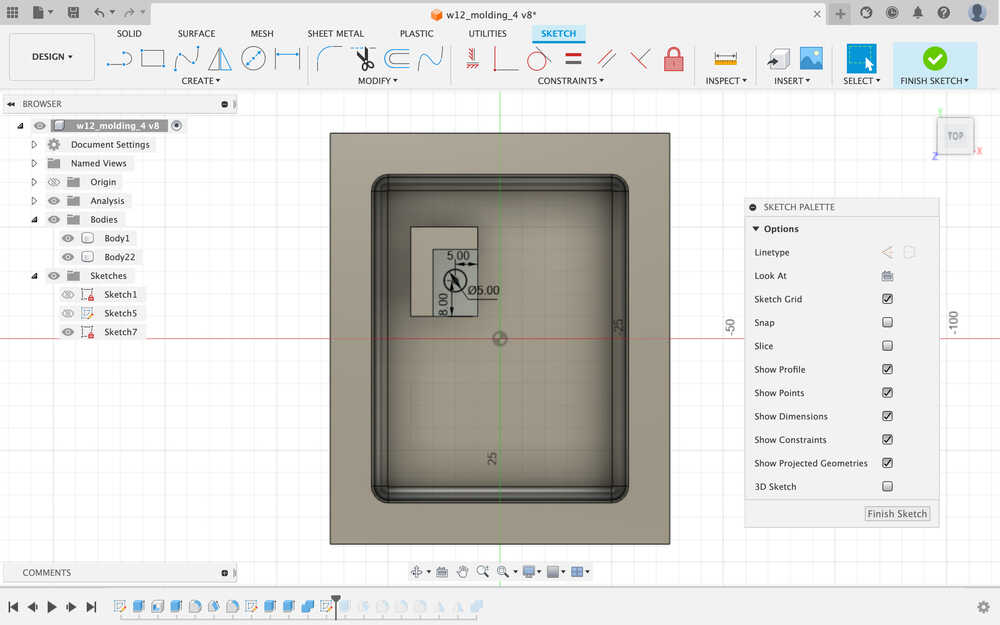

Sketch

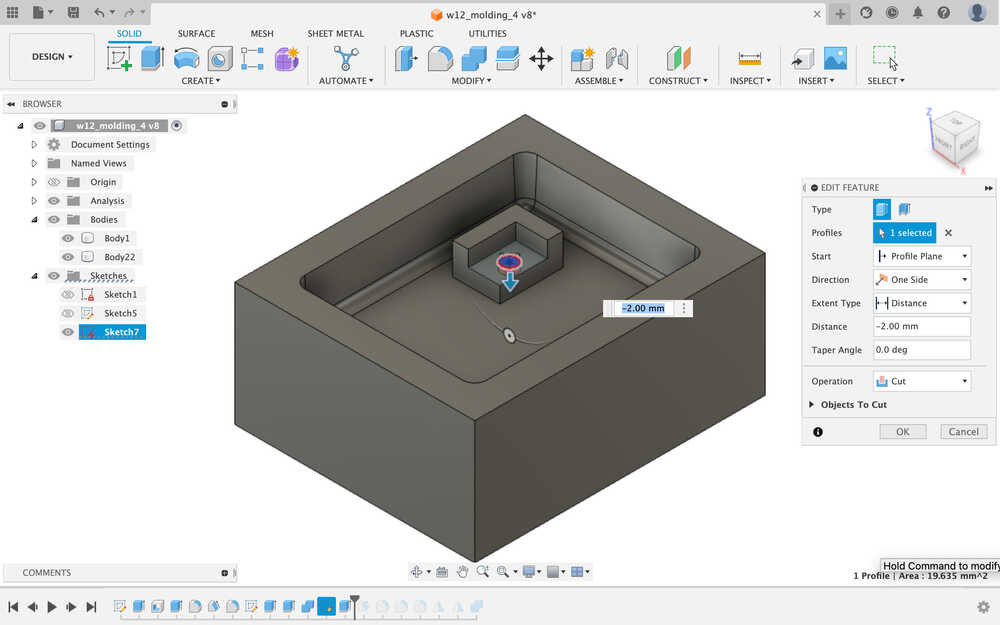

Extrude

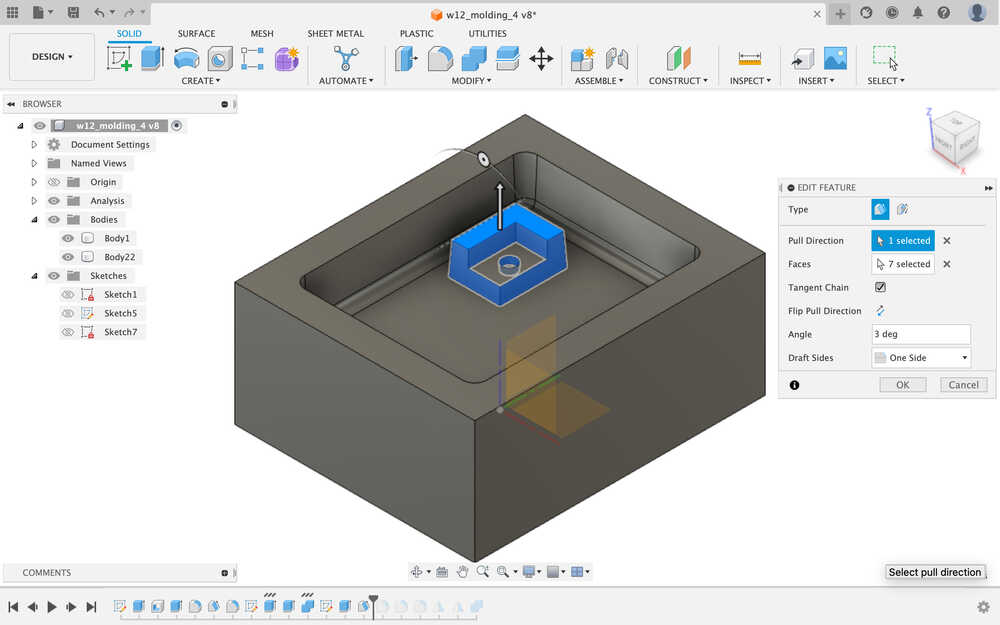

Draft

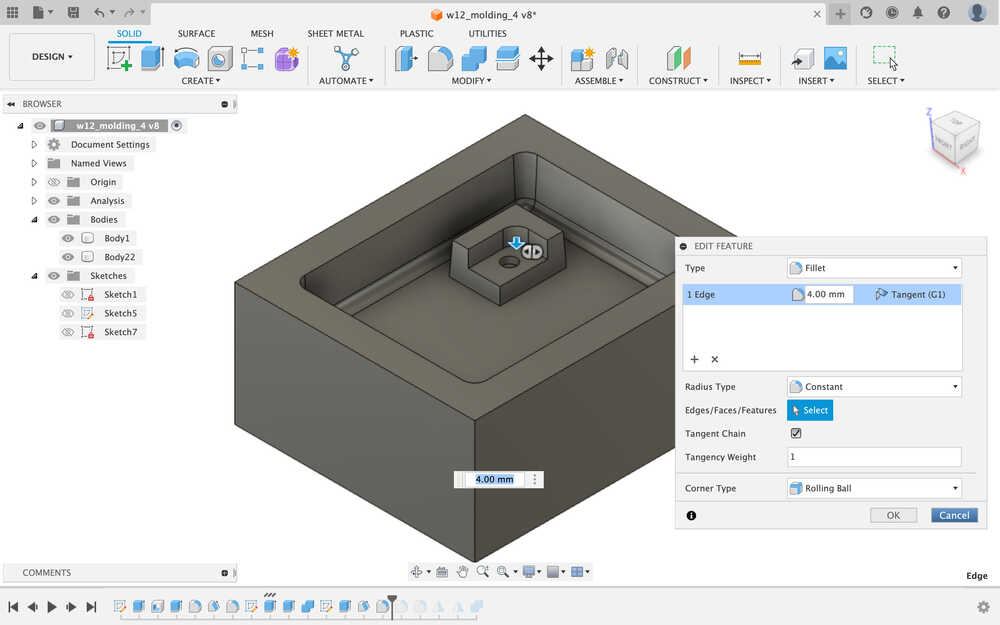

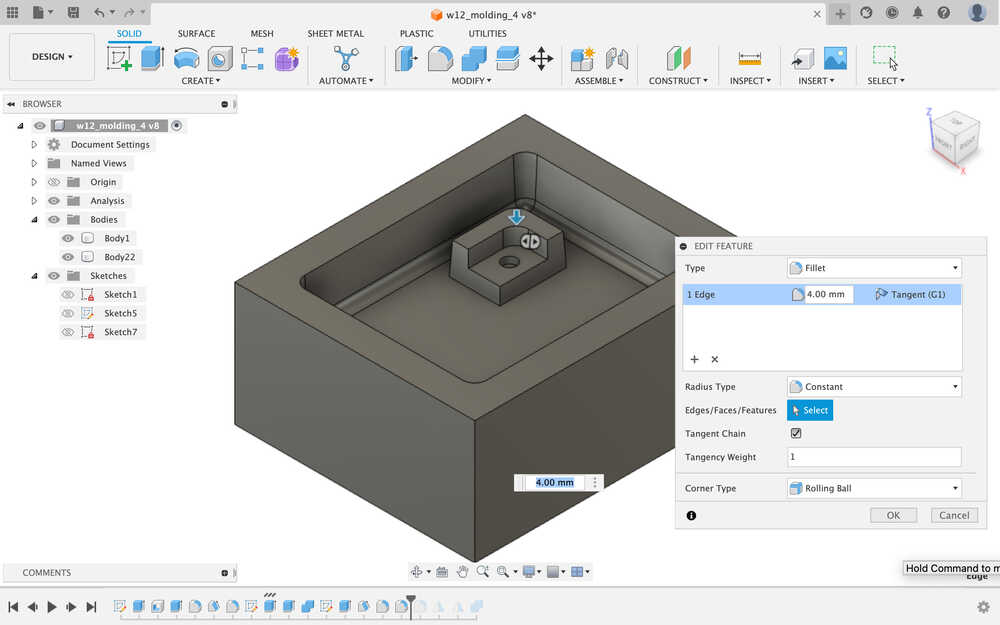

Fillet

Fillet

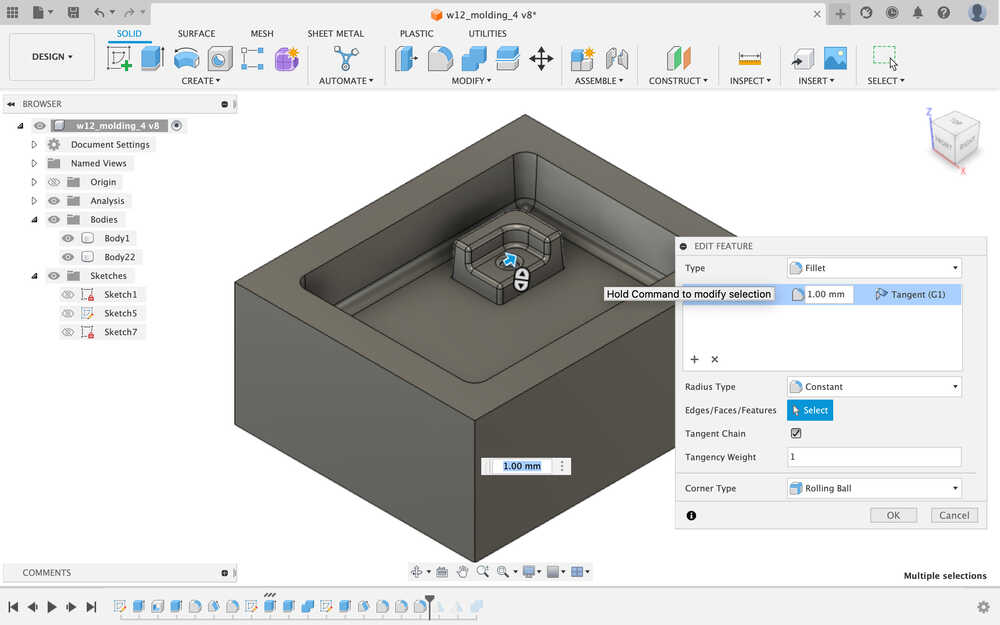

Fillet

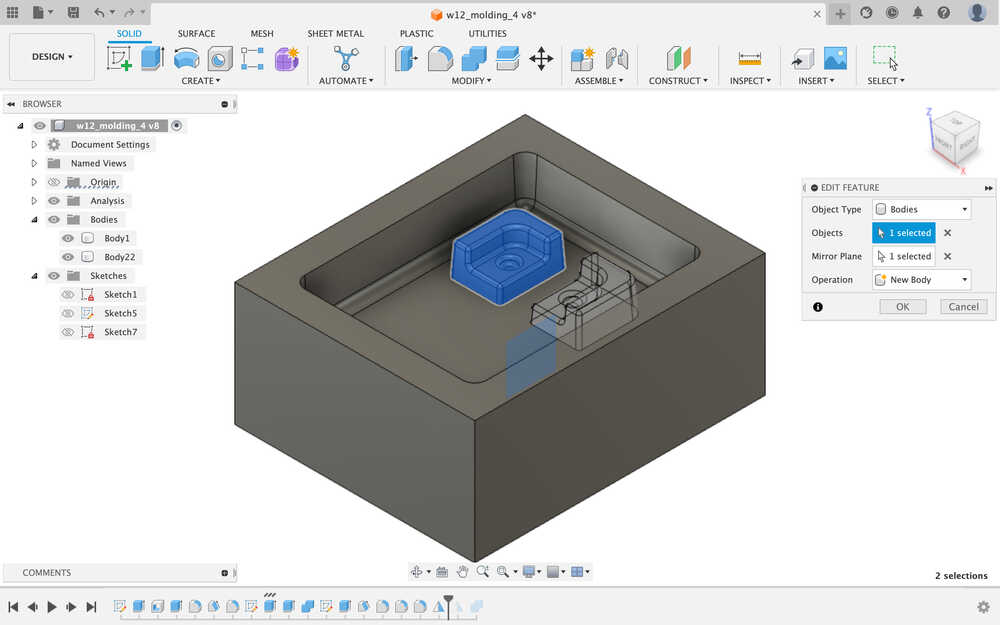

Mirror

Mirror2

Combine