-Vinul cut

I made a sticker of Fab Lab West-harima.

1. Machine I use

silhouetter CAMEO 3

Spec:

- Attachable paper size(*1 ): 304.8 mm (12inch) / 215.4mm (LETTER) / 210 mm (A4)

- cut Speed: Max 100 mm/s

- cut pressure: Max 2.1 N (210 gf)

- Number of pens that can be attached: 2

- Cuttable materials:

- [Film] Thickness 0.1 mm or less (excluding high-intensity reflective film)

- [Paper] Kent paper 157 g / m2, drawing paper, postcards, scrapbooking paper, inkjet photo paper, basil paper, 0.5 mm thick paper, inkjet photo paper, basil paper, 0.5 mm thick paper

- OS: Windows 10 / 8.1, Mac OS X 10.10 and upwards

(*1 : Supported by pinch roller switching)

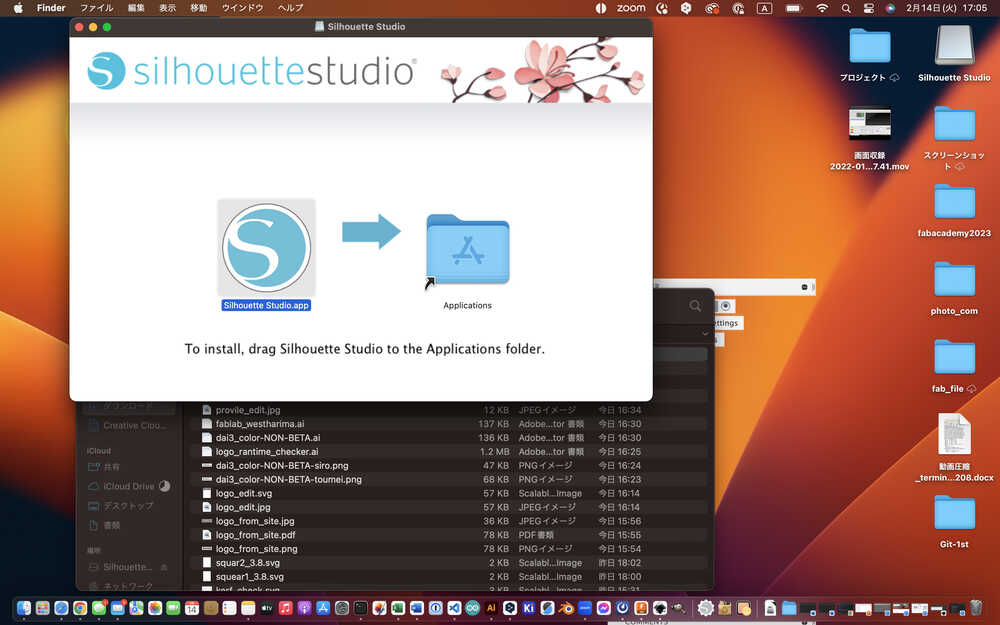

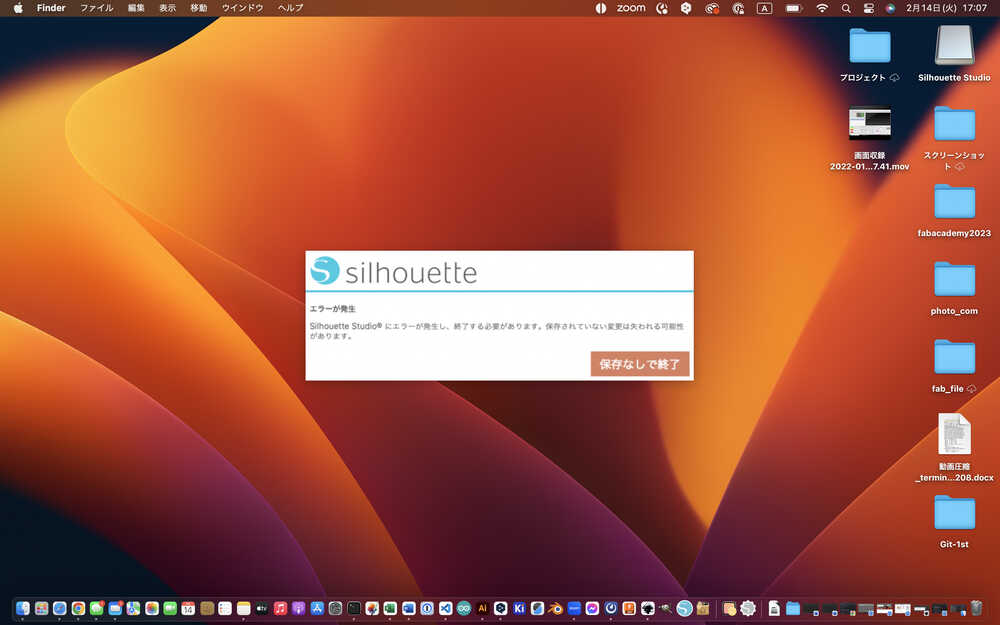

2. Installed Software

silhouettestudio

- Although silhouettestudio is available for mac M1, but it shut down as error wit just one click. I test the latest version and ex-version, both version had the same error. I was stumped and finally decided to borrow Windows in FabLab West-harima.

- error:

My action is only open silhouettestudio and just 1 click, then Error say "Silhouettestudio has an error and needs to exit". I was struggled this annoy error for 1 hour.

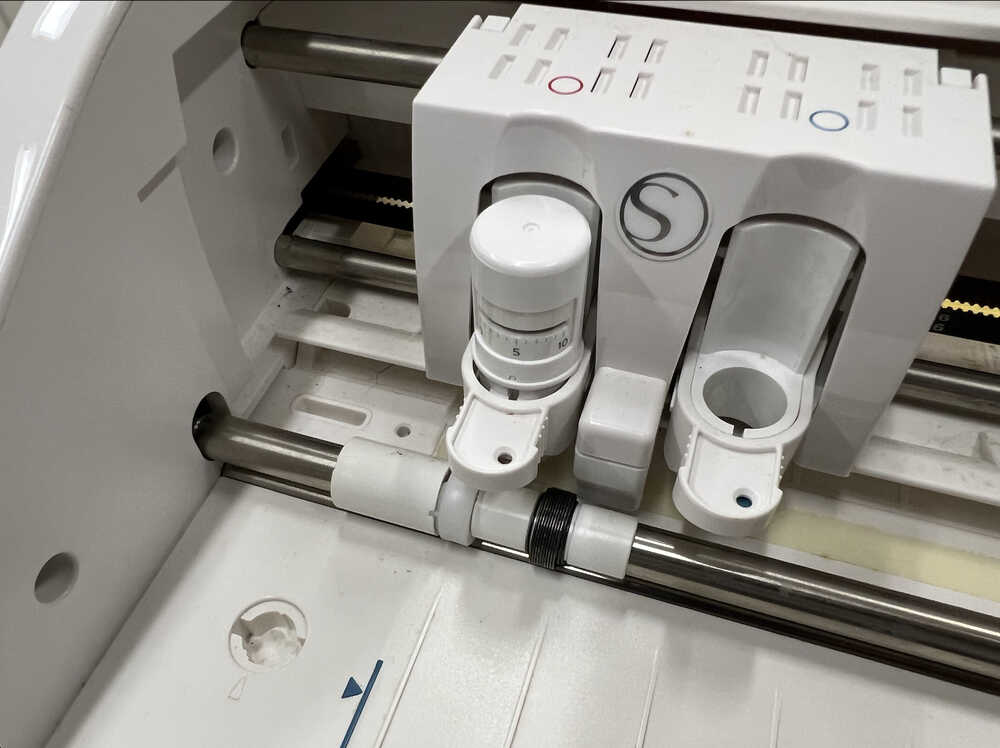

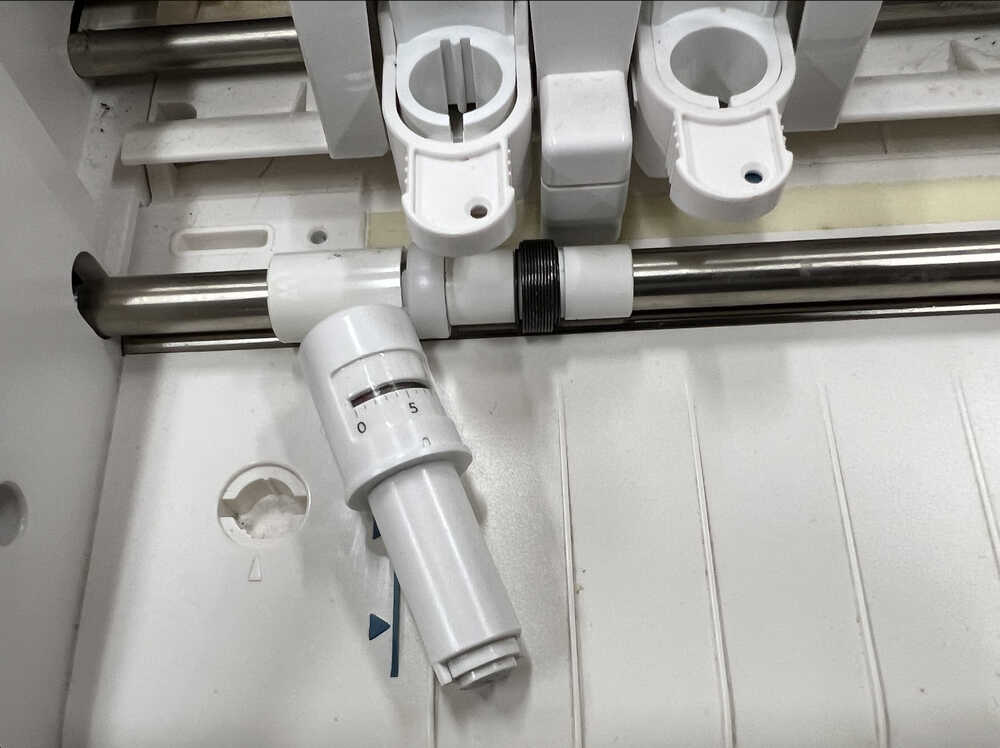

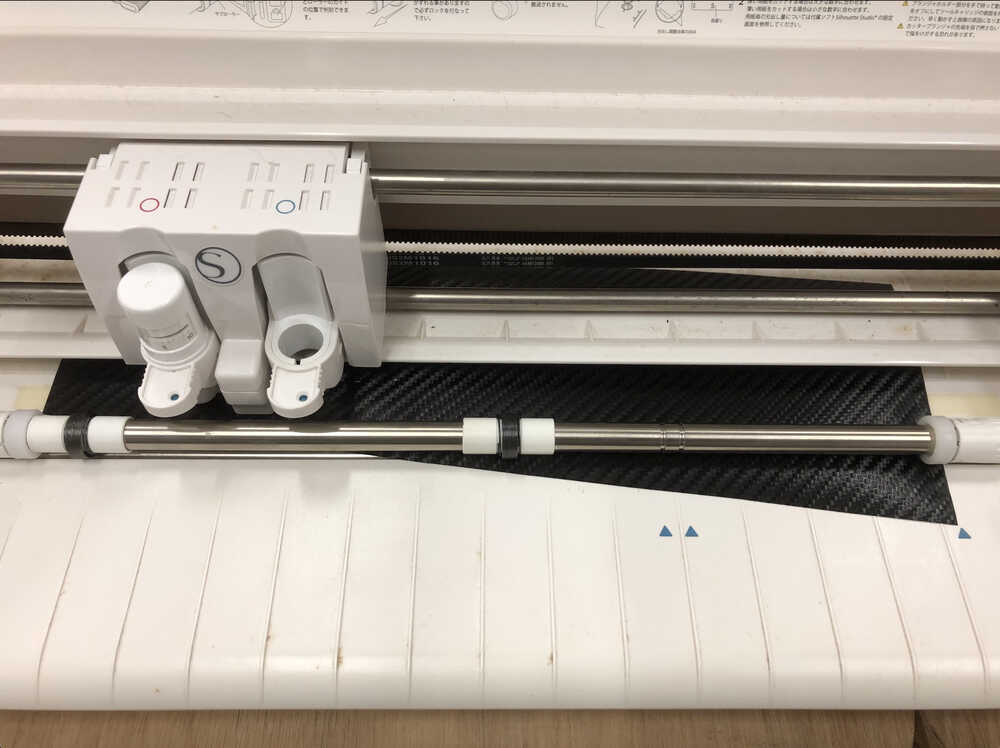

3. The machine part

I looked at the blades and parts to get to know the machine better.

- Pen holder

- pen holder can remove

- Blade:It had a small blade to cut the film.

4. How I made the sticker?

- Get the logo of "Fab Lab West-harima" (PNG file)

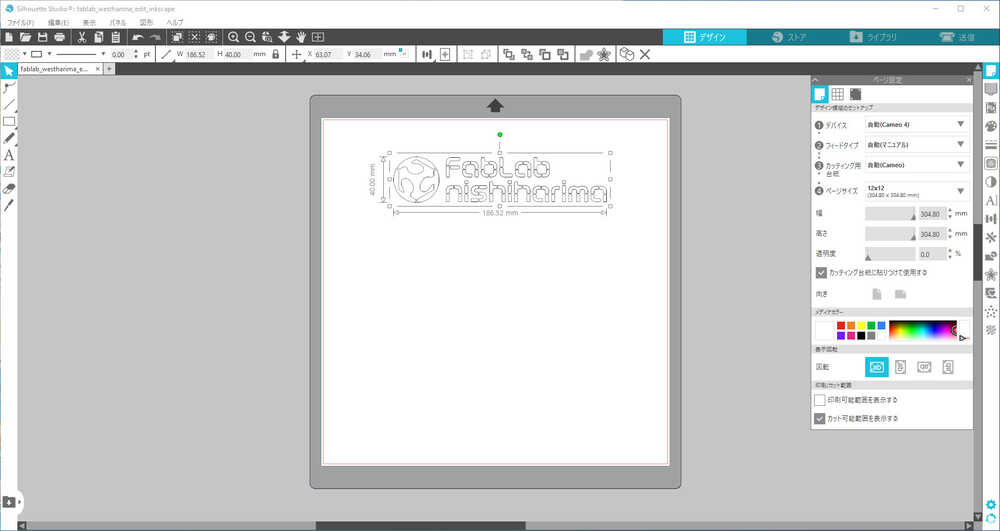

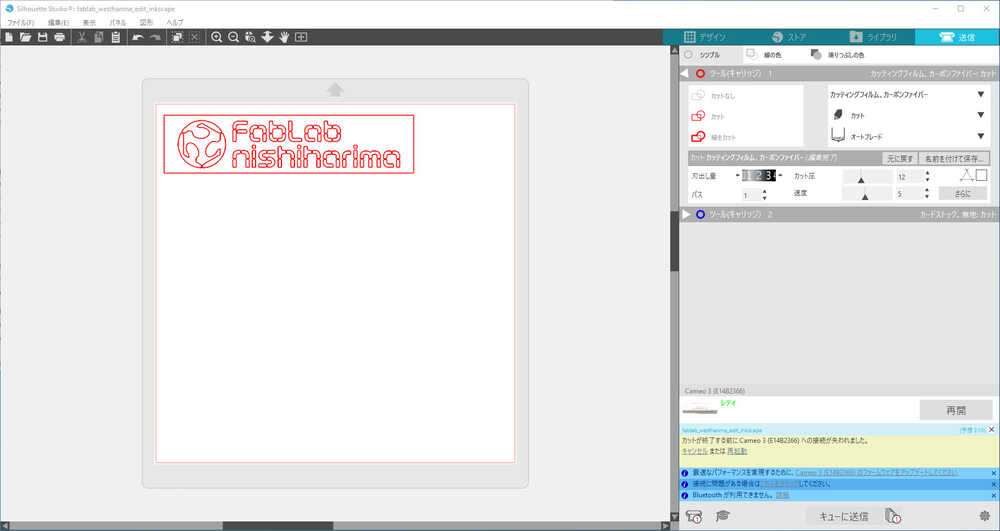

- Outline with Inkscape, and export with DXF file. (the format should be DXF for silhouetter CAMEO)

-

Import DXF file to Silhouettestudio.(If size change, do it this )

-

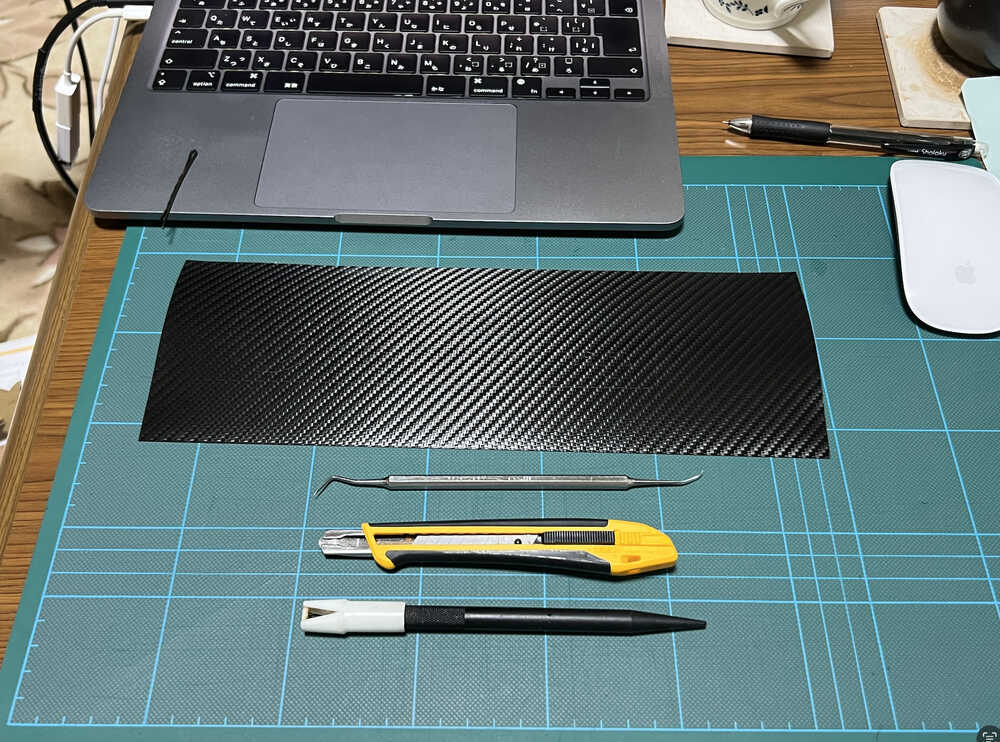

Set the material (follow the datum line)

If the material is not good position, Loosen the fixing knob and reset the material to the correct position.

-

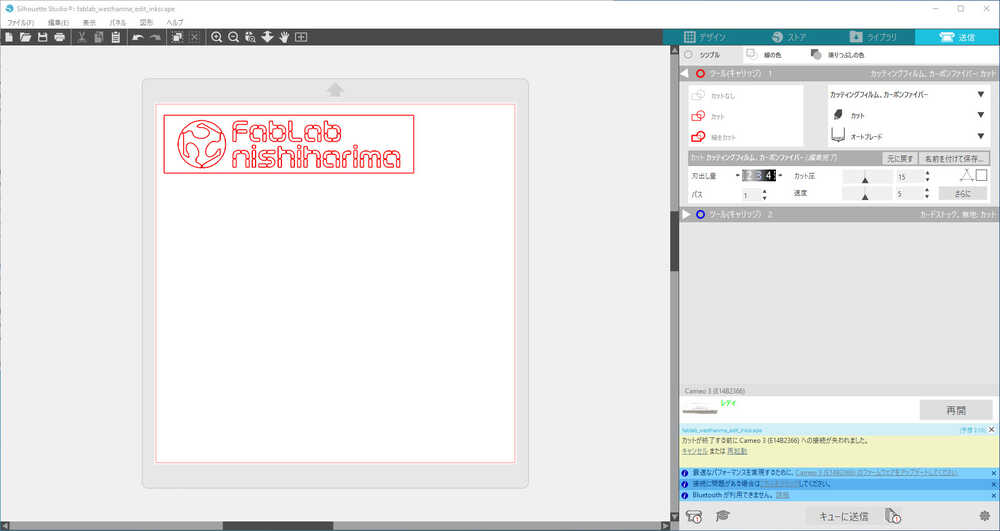

Set initial settings (blade out, cutting pressure, path, speed) and Test cut.

In testing, the manufacturer's recommended setting values tended to be overcut, so I use recommended settings by FabLab West-harima, and did Test cut (1cm square size). -

Cut

Push sending data through USB code, and Cut the film (cutting sheet).

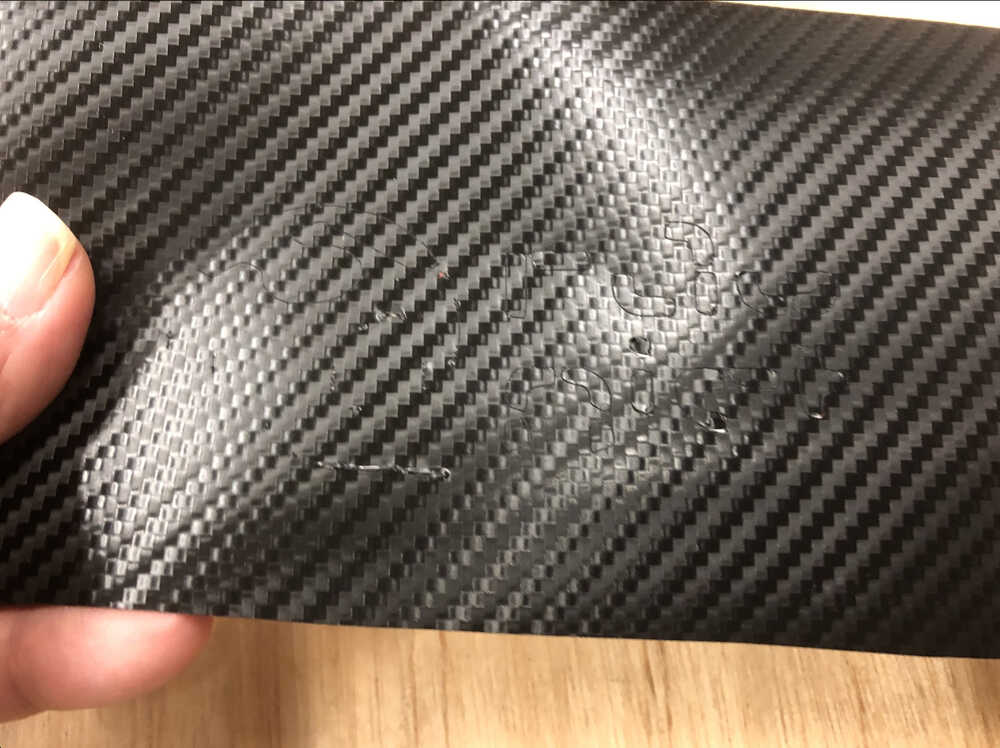

1st cut:

the setting is same as test cut. (blade out:3, cutting pressure:15, path:1, speed:5)

The materials are not enough length, so the material was slanted during the process.

From the mistakes, I learned that it is important not to be stingy with materials.

Also, I found the pressure seemed to be too strong.

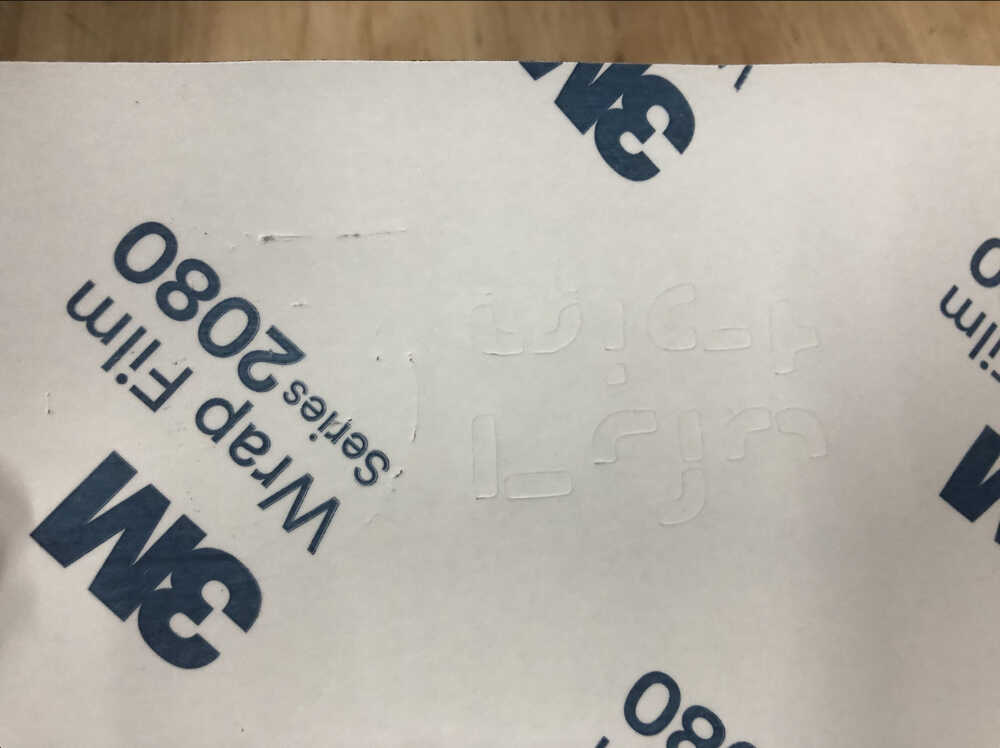

2nd cut: Success

The setting (blade out:2, cutting pressure:12, path:1, speed:5)

-

Remove unwanted parts.

- Transfer

I use Transfer paper.

Transfer logo to PC is complete.

5. My impression

- Errors were hard to make in the absence of time.

- It was difficult to transfer, because the logo was divided into smaller parts.