Week15. Wildcard week

1. Assignment and Result

About the process, I made new page and made links are below, because the long page makes me confuse.

| INDIVIDUAL ASSIGNMENT | THE RESULT |

|---|---|

| Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to) |

- Create Movable frame base by Welding -> Process - TRY plaster composites using 3d printing mold -> Process |

2. HERO SHOT (Welding)

As a result, Movable frame base is made by welding with the steel materials using TIG and MIG, finished it with a grinder, added casters, and made it mobile.

Unpainted, but it is already worked well as a Movable frame base for MDX-40A.

Unpainted, but it is already worked well as a Movable frame base for MDX-40A.

MIG

MIG

TIG

Grinder

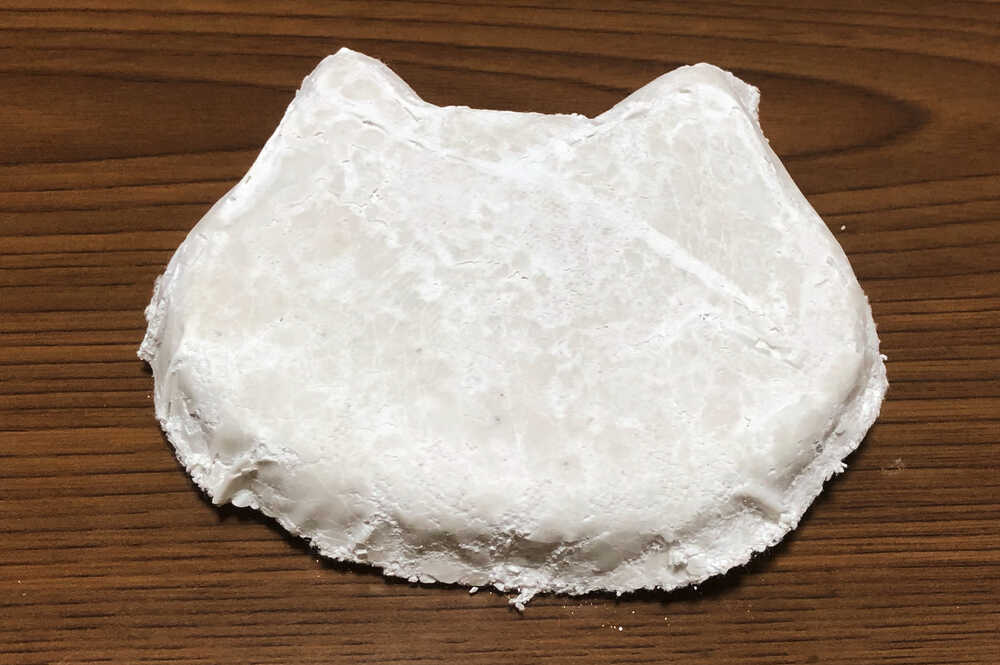

3. Failure (Composites's Result)

I tried composites (Plaster and FRP), using 3d printing mold.

The plaster did not soak into the Indian cotton fabric very well and did not harden properly. From Failure, I learned, the plaster need several layers. About Fiber, Fiber with gaps, such as hemp, is more suitable. It was hard to remove the mold, as Plaster hardens but is brittle and peels off in pieces.

FRP was hard to remove the mold, too. I learned when making hard composites, Soft molds is suitable.

FRP was hard to remove the mold, too. I learned when making hard composites, Soft molds is suitable.

4. Plan

4-1 Welding

In Fab Lab West-harima, As we didn't have a frame base for the Roland MDX-40, So we decided to build a sturdy frame trestle out of steel material and welding.

The Main Flow

- Safety Training

- Create model by Fusion 360

- Purchase the material and Protection

- Practice of Welding

- Actual performance Welding and Grinder

5-1 Composites

Try make composite product using vacuum forming, and using clamping Male and Female mold.

- Prepare material and read datasheet

- Research composite with ex-student

- Create model by Fusion360, and output by 3d printing

- Try composite

5. My thought

Welding:

- It is good experience that it is the first time to do welding.

- I thought welding is very hard work, both physically and mentally, and need a profoundly disciplined skill.

- Mentally : To prevent electric shock, burns, and other hazards, you must always pay attention to precautions and work accordingly.

- Physically: The work with dust masks and helmets, and then welding, and torch become heavy during work. And it is tough work of grinder, too.

- The TIG is beautiful finish and less grinder. Add wire is extremely difficult.

- The MIG (SUZUKID ARCURY80 NOVA (100V, NO GAS)) is fast to weld, and it add wire automatically, so easier. But rough finish. With my image, the machine is good for hobby user.

Composites:

- It is good experience that it is the first time to do composites.

- I thought it took a lot of skill to layer and cut the composite cloth (fiber).

- The composites need research well, how do it correctly.