VII Linetest with CNC3018¶

Of course my first attempts were not exactly successful :-D

So this category should be renamed into “outtakes”, like in movies.

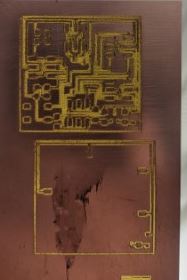

My first attempts to mill a pcb with a v-bit ended with a broken tip.

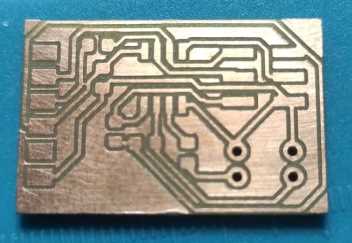

These are the pcb’s milled with the v-bit

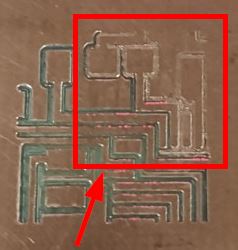

After changing my strategy using a 0.4mm mill tool, I got better results, but my first linetest was still not very good.

I find out, that the spindle was to shaky on the z-axis. After inspecting the cause I’ve seen, that the 4x LM8SUU linear bearings had too much play.

So I changed the 4x LM8SUU with 2x LM8UU Drylin bearings and that was much better

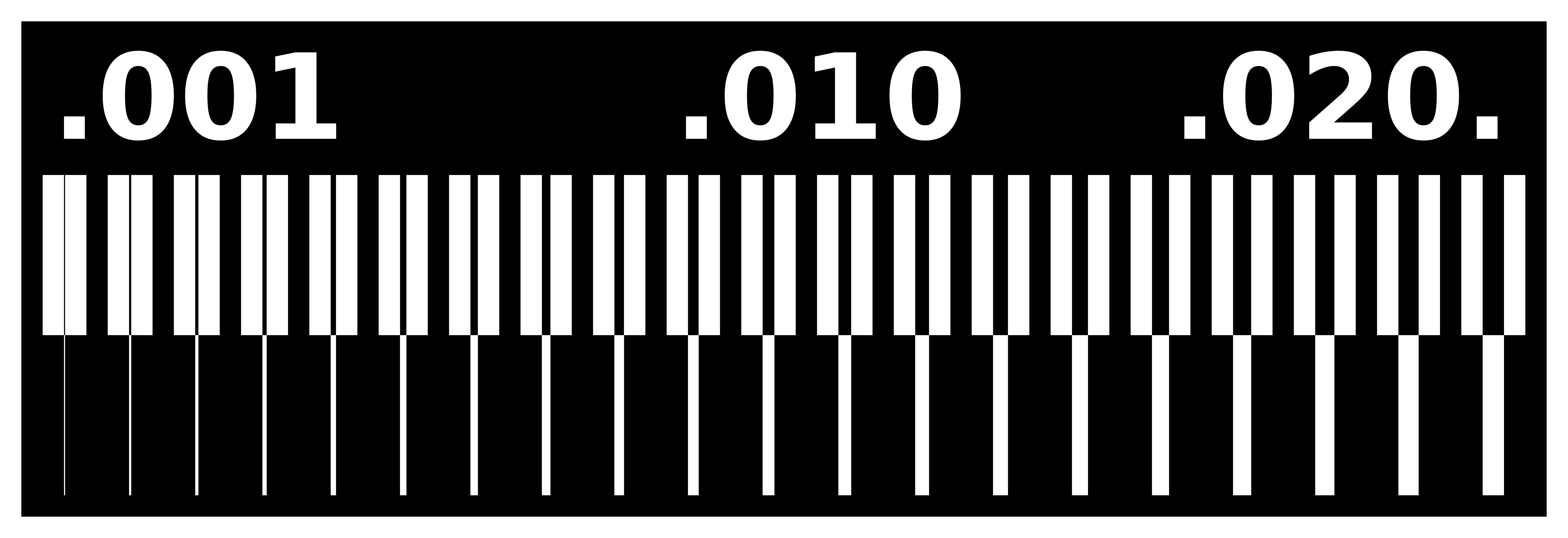

I used the linetest template from Jacopo Dimatteo

and milled it with the following parameters

| cut speed | spindle speed | Plunge speed | Cut Depth | Tool |

|---|---|---|---|---|

| 20 mm/s | 8000rpm | 20 mm/s | 0.20 mm | 0.4mm mill |

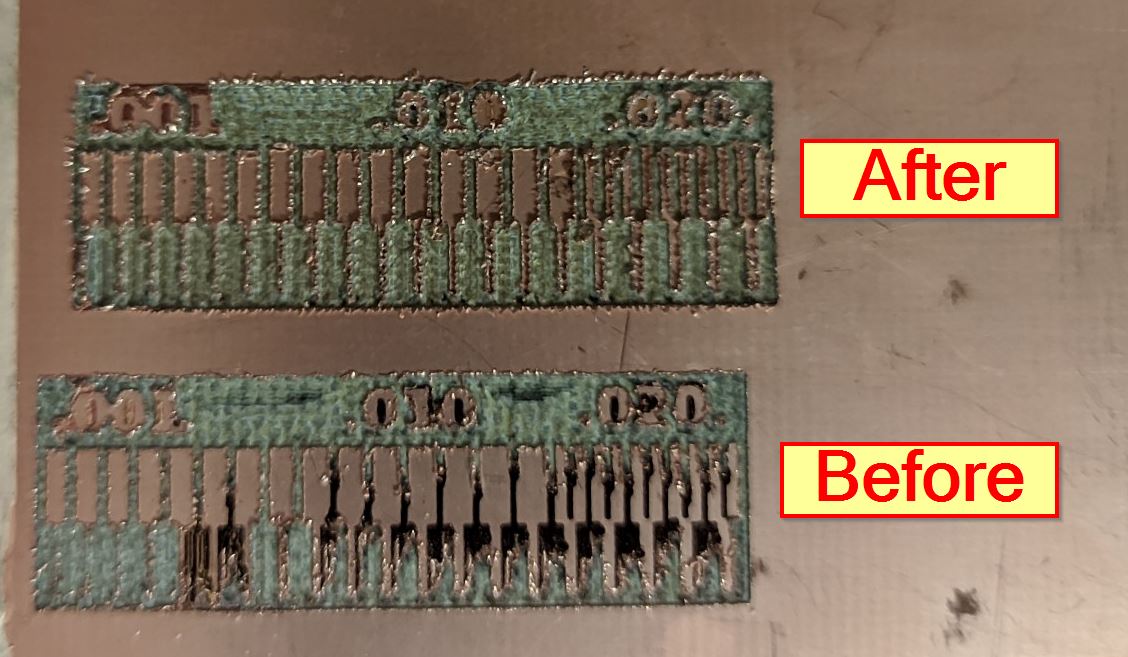

Here is the result

I’ve order more bits and I hope that they will deliver in in the upcoming days. Then I’ll make more tests.

In the meantime I made really good experiences with the 0.4mm end-mill for the traces and a 1.0mm end-mill for the cut-outs.

Because of that, I have to have a look at the design rules in KiCad / Eagle to use a Clearance and Track Width with 0.4mm