IV. Milling the Shelf¶

At the HRW Fablab I got a short access to a LongMill.20 Benchtop CNC from Sienci Labs.

Preparing the gcode¶

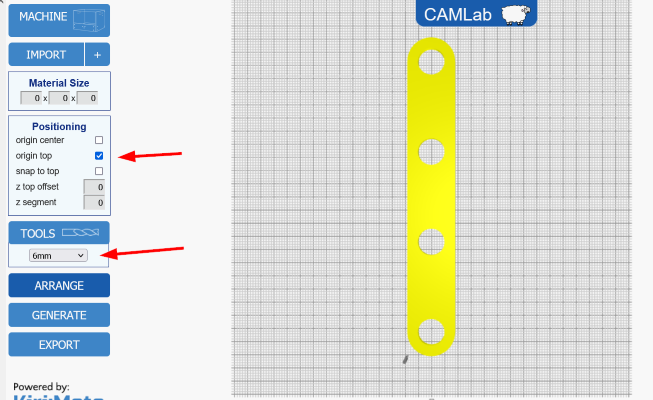

The gcode has to be prepared with an online tool called CAMLab

After opening the tool, a pixel sheep welcomed me… :-D

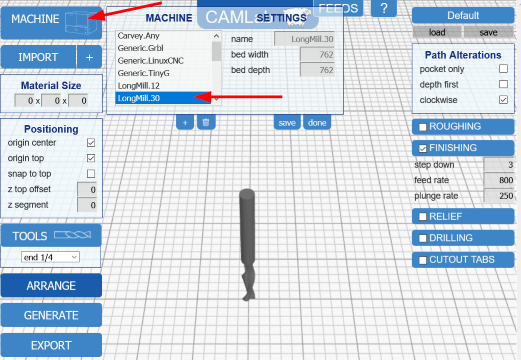

First I had to select the Machine I would like to use

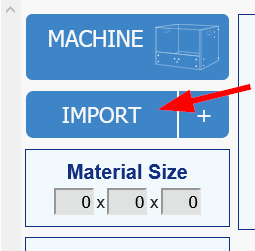

And then import the model

The next step is to select origin top and choose the end-mill I would like to use

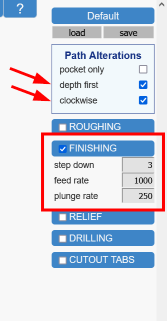

On the right side, we activate depth first and clockwise and set the feedrate

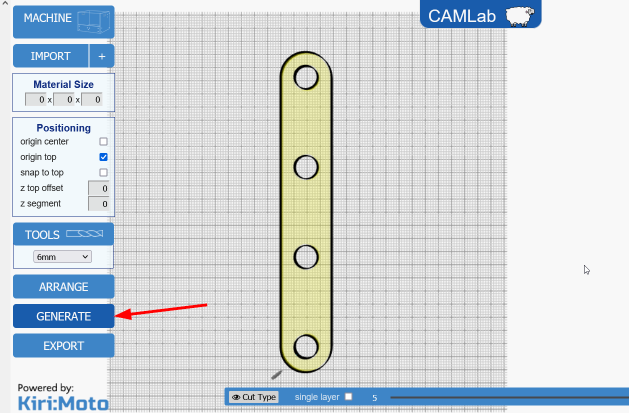

After a click on GENERATE a preview is shown

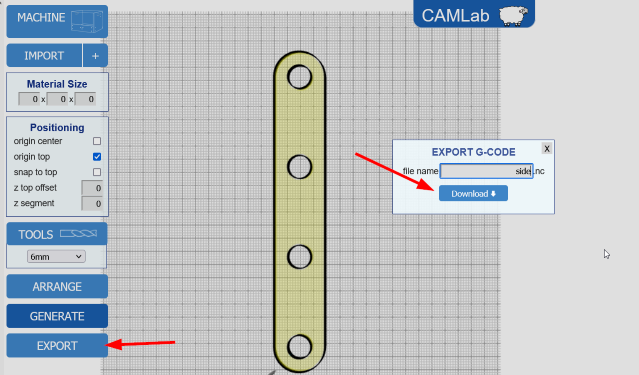

Then we have to EXPORT and Downloadthe generated gcode

The milling process¶

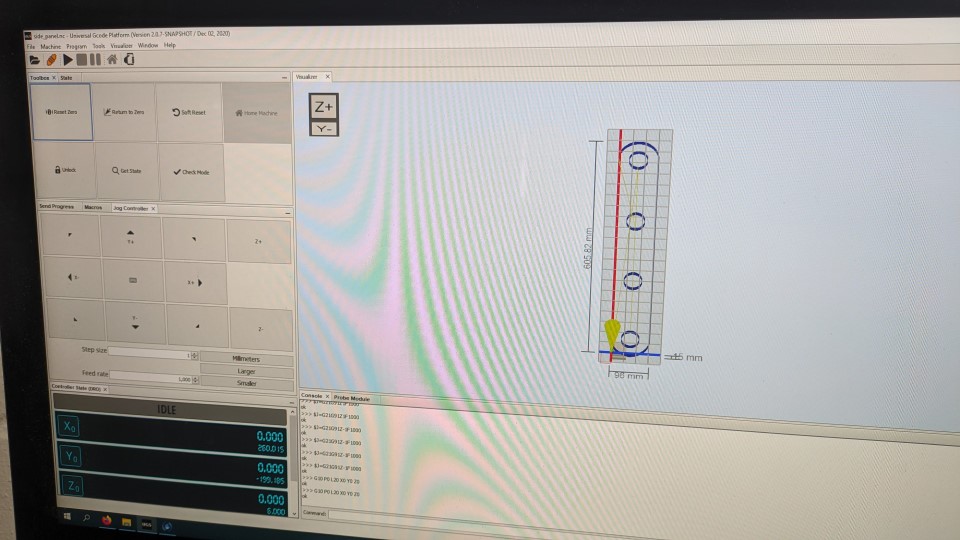

The generated gcode has to open in the UGS - Universal Gcode Sender

With the navigation buttons, I placed the spindle on the bottom left corner and on top of the wood. Here you can see also, that I fixed my workpiece with screws on the sacrifice board

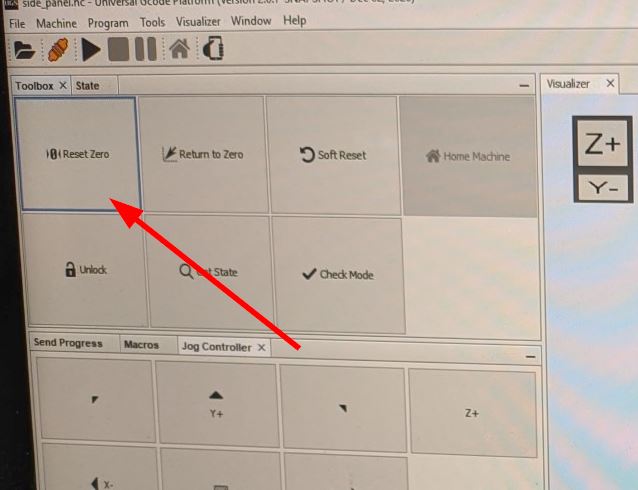

The the zero point has to be set by clicking Reset Zero

Now I put on ear and eye protection !!!

I lift up the spindle a bit. It can not be controlled automatically, so I had to turn it on.

I closed the safety cover and started the milling job

final result¶

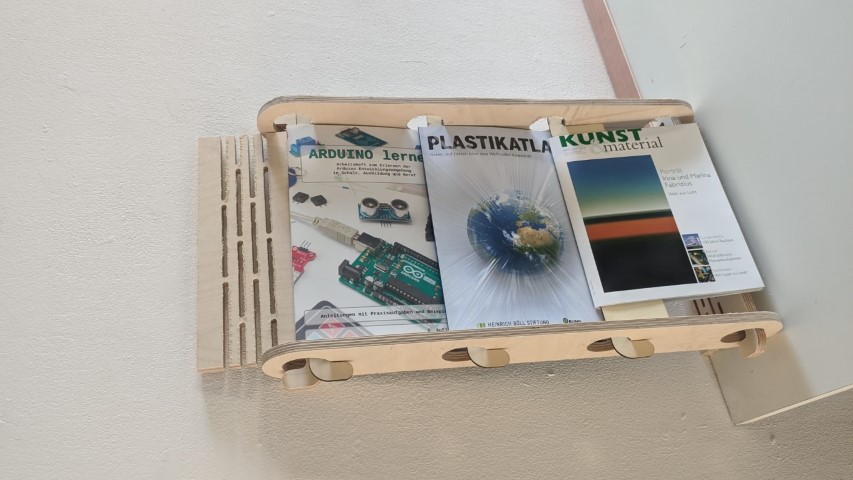

The pieces are pluggable. Normally the top part has to be screwed on a wall, but I just leaned it on, to show the result here.

All the parts could need sanding a little bit, but I didn’t.

And this is the final result…