IV. creating and export an object¶

As in the other assignments, I used Fusion360 for creating the 3D model.

The challenge is to design and 3D print an object, that couldn’t be made substractively.

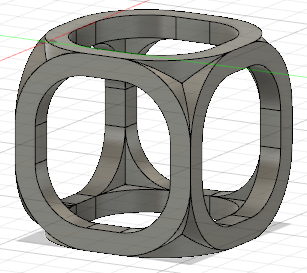

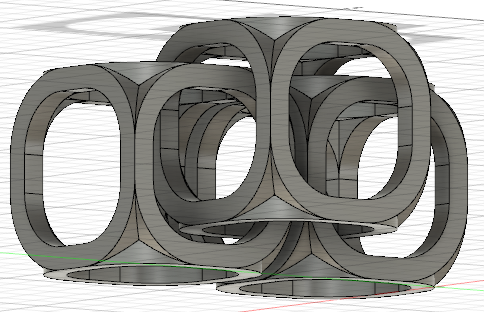

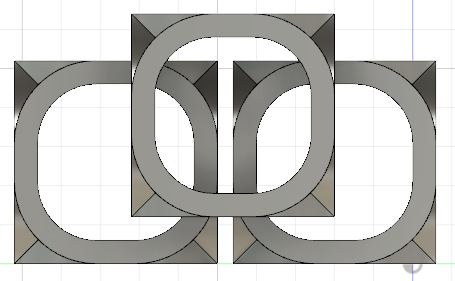

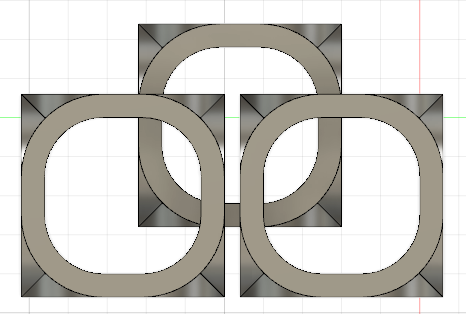

I made three nested cubes, with rounded corners. The cubes are nested inside each other and because of the nesting function and orientation, its not possible to mill between and behind the nested walls, with a milling machine.

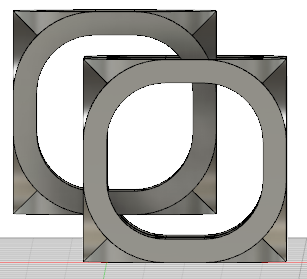

It is already not possible with only one cube to mill it with a 4-axis milling machine: The “side” walls would be left closed, because the machine is not able mill between them.

But is it really true ???

I thought a long time about my saying and so I decide to simulate it at the bottom of this page :-D

With the rounded corners, there is no need of support material for the overhangs.

The printer is able to bridge short distances, so there is only a little bit of support material needed, from the buildplate to the higher cube in the middle.

More about that later…

I’ll don’t explain it in detail here.

creating nested cubes¶

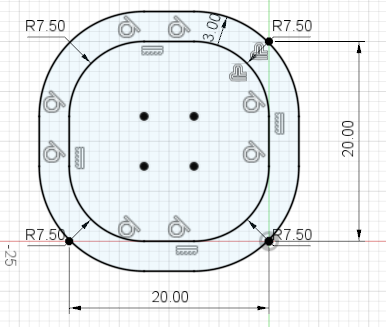

First I start sketching one side of the cube

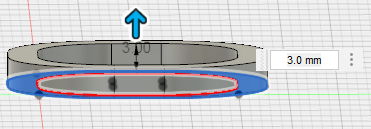

Then I extruded the sketch 3mm. So I have a ‘bar’ from 3x3mm

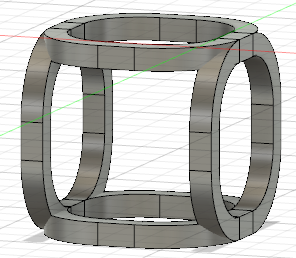

With copy & move I placed the sides

After placing all 6 sides, I combined them to one object

With copy & move I placed two more cubes

Here are the views from different views

export as stl file¶

For 3D printing, we need to export the cubes as stl file.

I decide to export only one cube and copy and place them in the slicer.

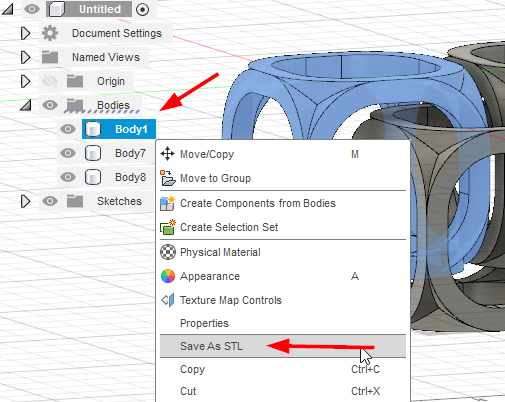

With a right click on the body there is an option to save as stl

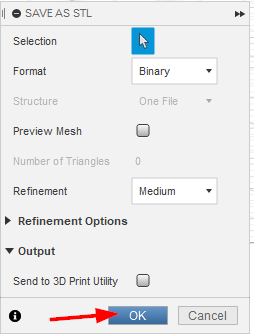

Just confirm the upcoming window with ok

And that’s it.

The fusion360 file can be downloaded here

The cube.stl can be downloaded here

milling simulation¶

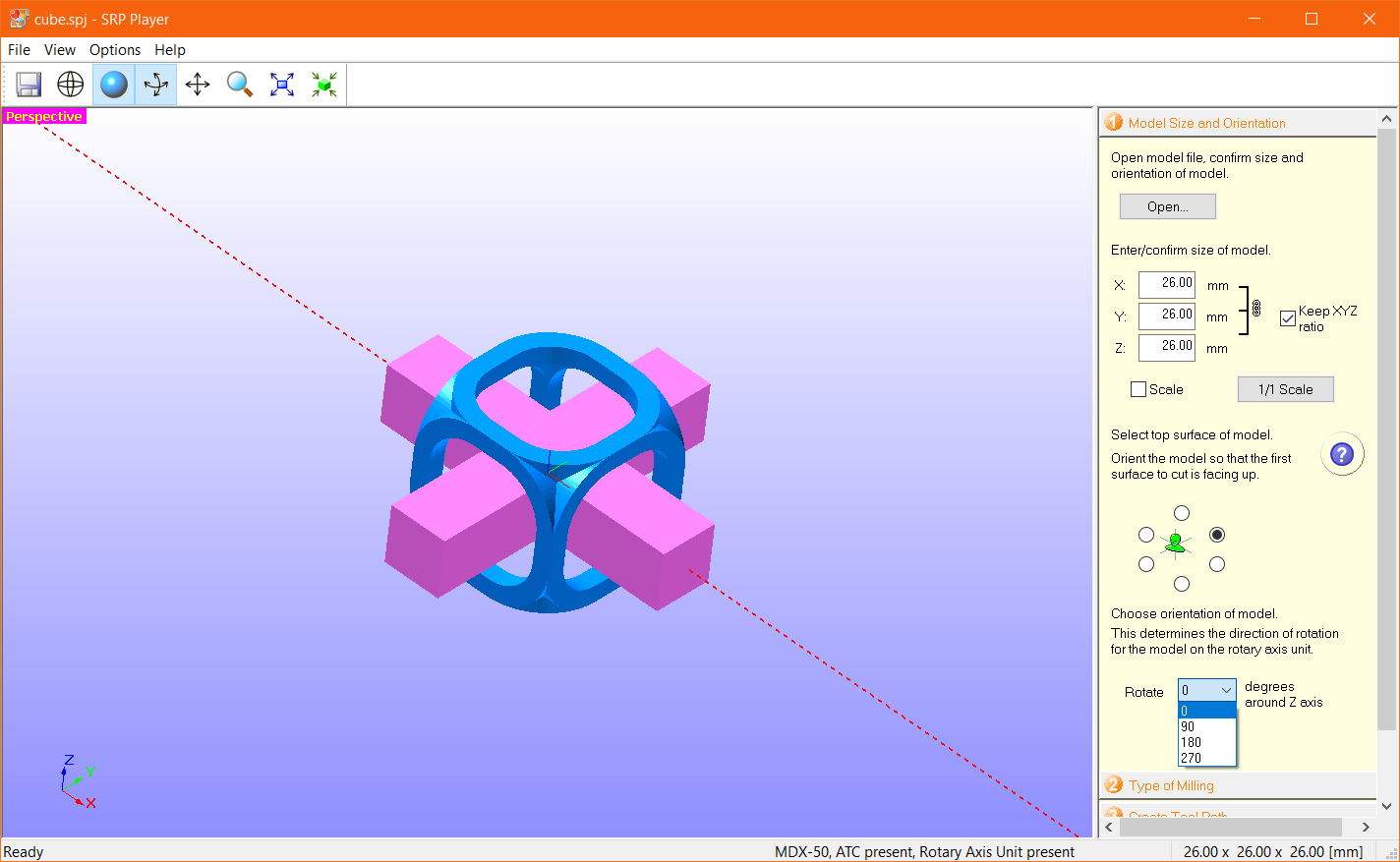

I tried to import just one of the cubes into the SRP-Player for the Roland MDX-50.

In week 11. Molding and Casting I described more about it.

After opening the Cube I saw directly, that it’s not possible to mill it, in that way.

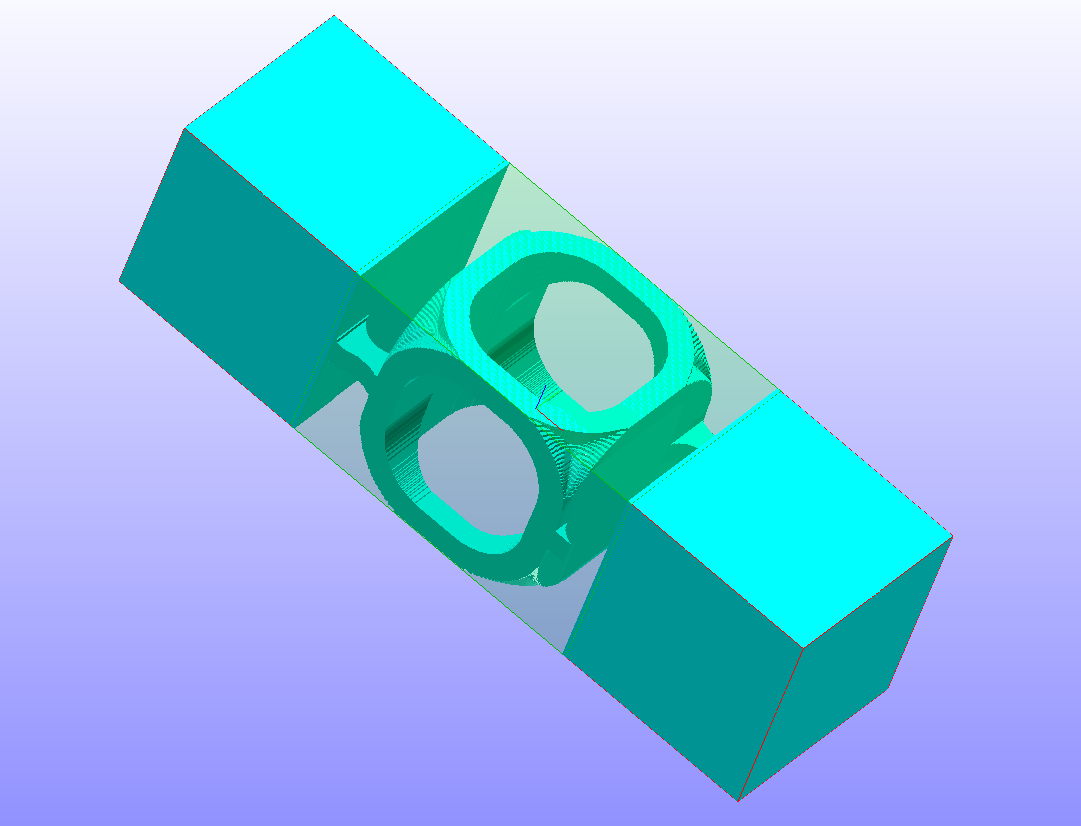

Neverminded, I tried to optimize the support and added milling jobs in 0, 90, 180 and 270 degrees on the rotary unit and this is what I got from the preview

As I expected, the side walls wouldn’t be milled correctly. The SRP-Player is very limited arranging the models. Maybe I could get a better result, if I could arrange the model with ‘userdefined’ degrees.