Reflection

Well, this week is the first week I finally feel in control. I finished all my individual assignments early with a quality that I am happy with. I didn't have to rush to do them, unlike previous weeks. This might be due to me being fairly familiar with the 3D printing topic, but I also feel like I finally found the rhythm of my workflow that I'm able to manage while juggling my other responsibilities. I also felt like I discovered my own voice when doing documentation. Instead of trying to replicate past student documentations, now I look at them only as references, especially the technical parts.

Things I Learned

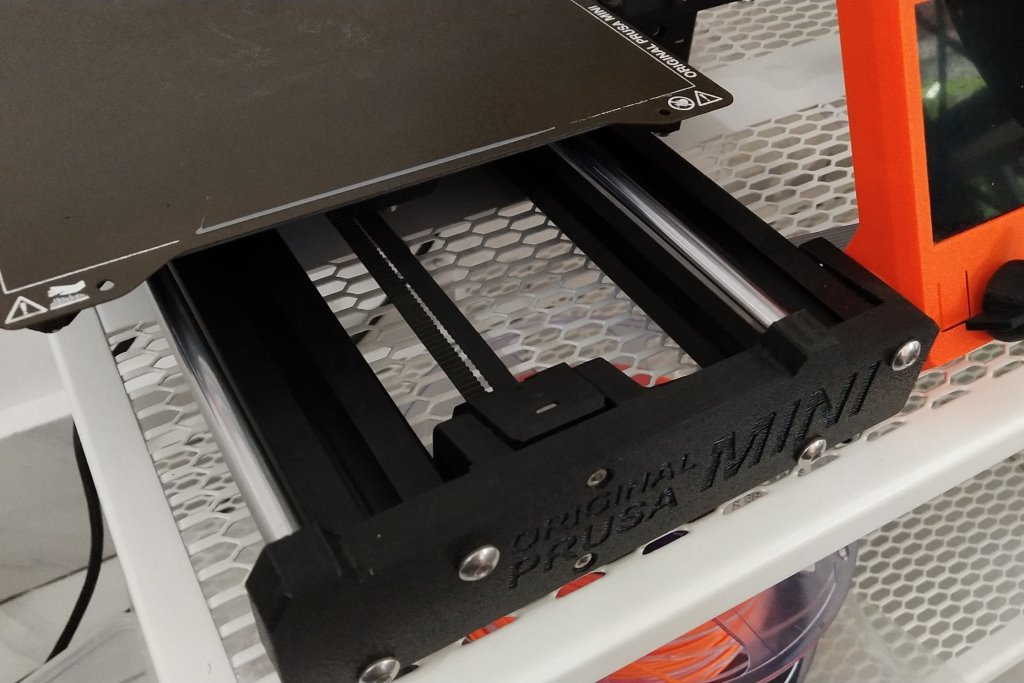

For the 3D printing assignment (both group and individual), I didn't learn a great deal of new things. We are using my personal printer, a Prusa Mini that I bought since October 2019. I haven't used it as much as I'd like to because in my primary job as a web developer, there is close to zero need for physical objects! However, I have used it to learn CAD and product design on my own, and as a result, I have learned quite substantially about 3D printing technology.

However, this week I was reminded that these machines are still far from plug and play like many other consumer devices. Though some are more sophisticated than others, they still require regular maintenance, regular cleaning, etc. When we were printing our test prints, the Y-axis timing belt slipped and resulted in a shifted layer. Luckily, Prusa has amazing documentation and it covers almost every aspect of the machine, including troubleshooting many possible issues like this.

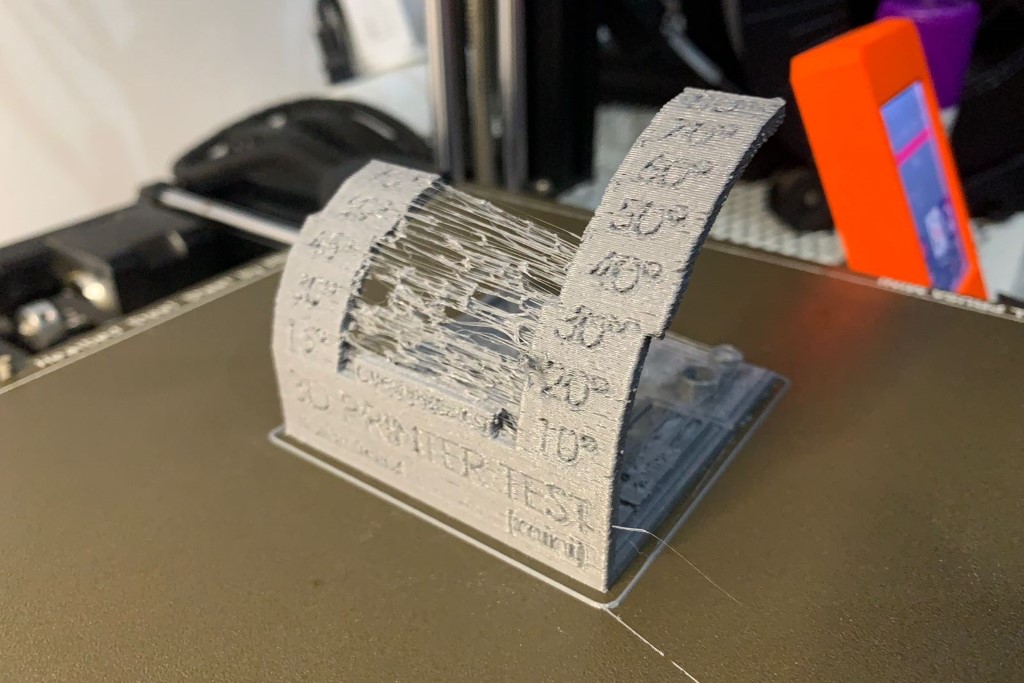

Another thing is the lifespan of filament, how hygroscopic they are, and how much it affects the print quality. Bali is located in a tropical area and therefore the humidity is very high - 70% to 80% on average. It definitely is not ideal to leave filament in the open air. Plus, the PLA filament we have available, though it has only been recently opened, I have had it since about three years ago. The first test print results look like an aftermath battle between Spiderman and another Spiderman from another universe!

We don't have a filament dryer, so we tried to rejuvenate the filament by a very clever trick I learned from this YouTube video using only left over filament box and a 3D printer heated bed. It definitely improved the print quality a little bit. There are fewer popping sounds from the nozzle, less under-extrusion happening, but the stringing is almost impossible to be fully removed unless we calibrate the retraction and temperature settings specifically for this filament by doing comprehensive tests.

What Can be Improved

- Although I finished things on time, I still strayed a bit from my planned SSTM. I need to review it so I can gauge and better plan for the next coming weeks.

- Having a heated filament dryer would be a great help.