H2Gen

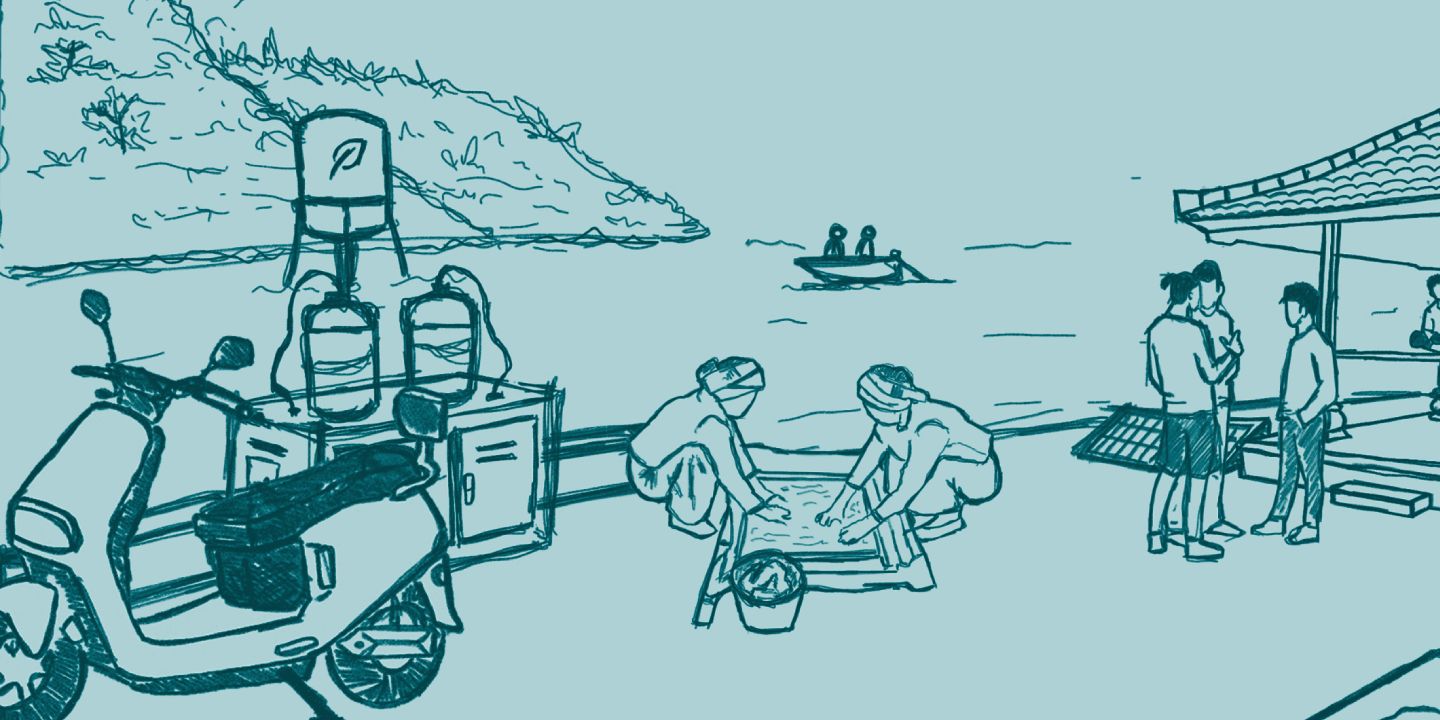

Fab Lab Bali's current flagship initiative is Hydrogen Village, a continuation and expansion of Balon-Balon Ijo, one of the Fab Island Challenge from Bali Fab Fest 2022. This initiative aims to aid Bali's attempt to achieve net zero emission by 2045 by introducing the application of hydrogen gas as a renewable energy source.

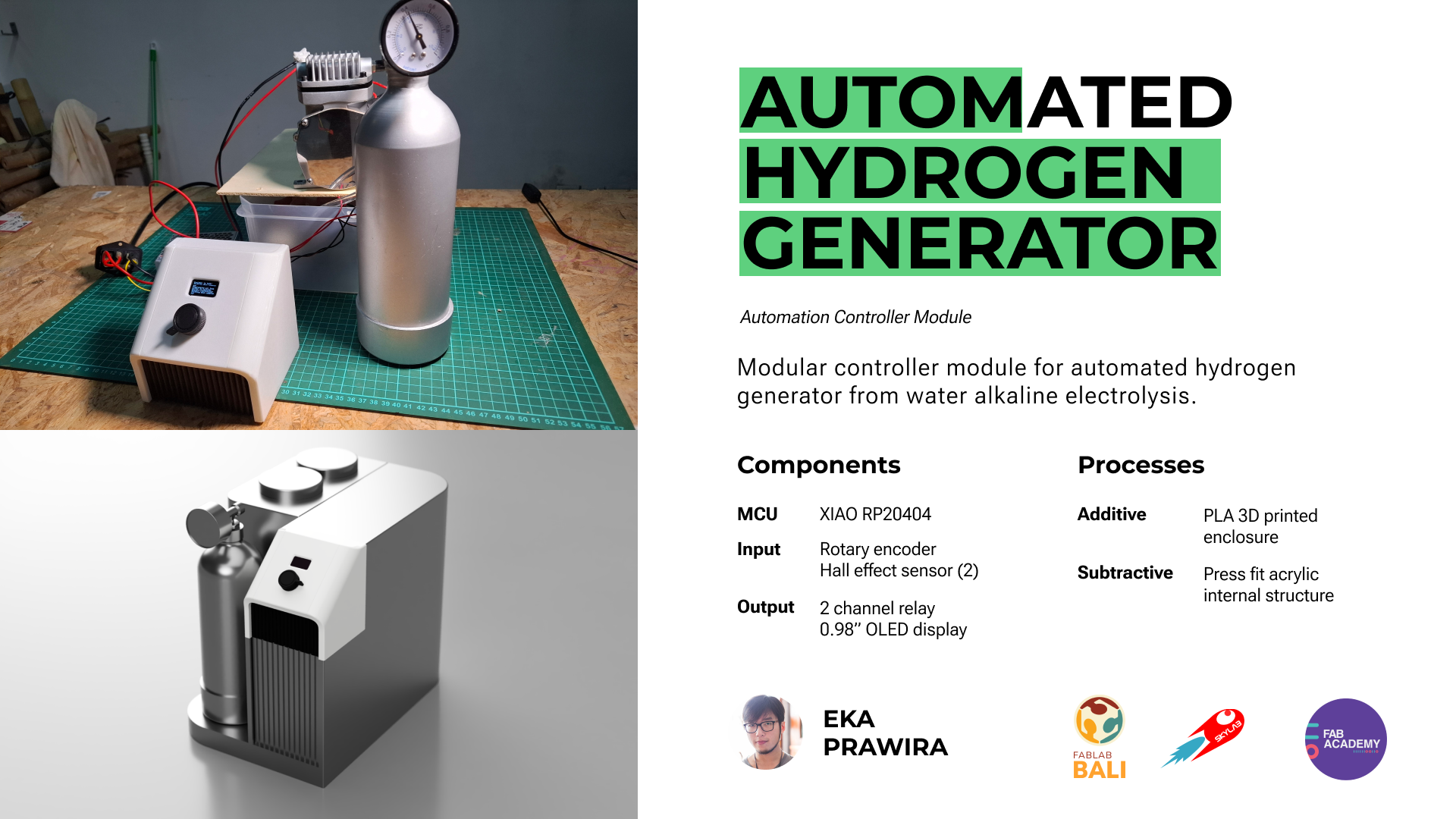

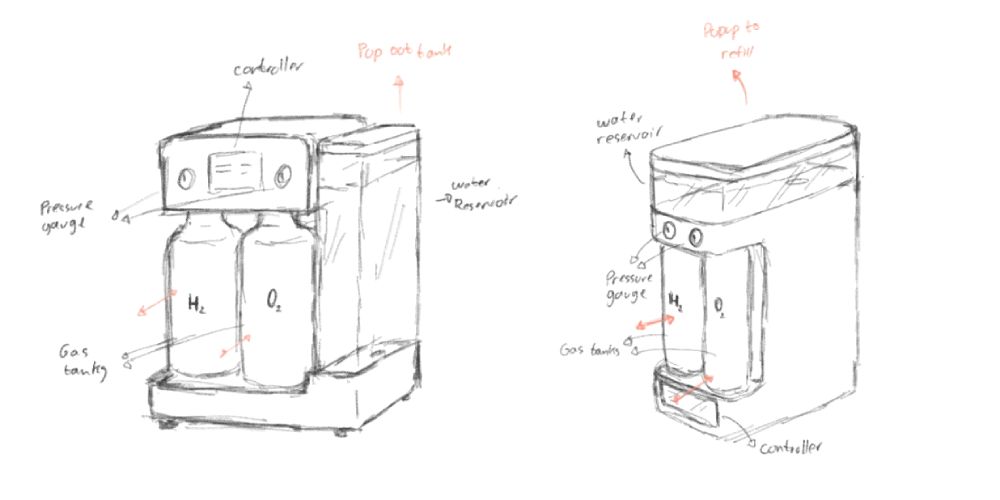

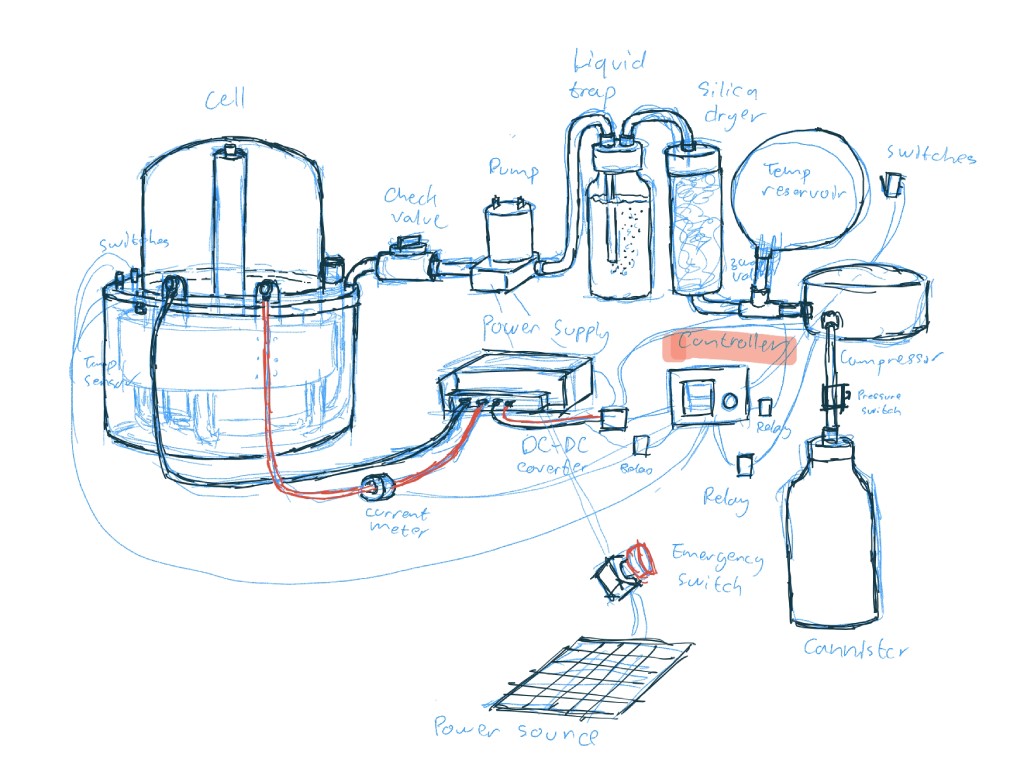

This project is called H2Gen, a compact automated hydrogen generator from seawater using alkaline electrolyser to be used for household or small neighborhood scale. This final project is focused only on the automation controller module because the scale and complexity of the project as a whole are too much for the limitted time we have in Fab Academy.

License

This project is licensed under Creative Commons Attribution-ShareAlike 4.0 International License. This means you are free to share and adapt this project under these circumstances:

- Attribution: You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

- Share a like: If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.

- No additional restrictions: You may not apply legal terms or technological measures that legally restrict others from doing anything the license permits.

Bill of Materials

The approximate total cost of the components and materials listed below are IDR 336,920 or about USD 21. All of them are sourced from as little number of sellers possible on Tokopedia, Indonesian largest marketplace.

| Quantity | Price | Total | |

|---|---|---|---|

| XIAO ESP32-C3 | 1 | IDR 127.500 | IDR 127.500 |

| LM2596HVS Buck Converter | 1 | IDR 11,200 | IDR 11,200 |

| Relay 5V 2 channel | 1 | IDR 10,500 | IDR 10,500 |

| 0.96" OLED screen | 1 | IDR 26,500 | IDR 26,500 |

| KY-40 rotary encoder | 1 | IDR 6,500 | IDR 6,500 |

| KY-003 hall effect sensor | 2 | IDR 5,000 | IDR 10,000 |

| Female straight header - 7 pin | 2 | IDR 700 | IDR 1,400 |

| JST XH right angle - 2 pin | 1 | IDR 1,000 | IDR 1,000 |

| JST XH right angle - 3 pin | 4 | IDR 1,500 | IDR 6,000 |

| JST XH right angle - 4 pin | 1 | IDR 2,000 | IDR 2,000 |

| JST XH right angle - 5 pin | 1 | IDR 2,500 | IDR 2,500 |

| JST XH right angle - 7 pin | 2 | IDR 3,000 | IDR 7,000 |

| JST XH straight - 4 pin | 1 | IDR 1,700 | IDR 1,700 |

| KF2EDG right angle terminal block - 2 pin | 3 | IDR 2,500 | IDR 7,500 |

| Screw terminal block - 2 pin | 3 | IDR 1,750 | IDR 5,250 |

| Capacitor 1206 - 100 nF | 7 | IDR 400 | IDR 2,800 |

| Resistor 1206 - 1 kΩ | 14 | IDR 150 | IDR 2,100 |

| Resistor 1206 - 470 Ω | 2 | IDR 150 | IDR 300 |

| Transistor NPN SOT-23 | 2 | IDR 400 | IDR 800 |

| Schottky Diode | 1 | IDR 250 | IDR 250 |

| Signal cable | 1 m | IDR 9,900 | IDR 9,900 |

| Cable 16 AWG | 20 cm | IDR 9,500 / m | IDR 1,900 |

| Cable 18 AWG | 20 cm | IDR 6,500 / m | IDR 1,300 |

| Cable 20 AWG | 30 cm | IDR 4,500 / m | IDR 1,350 |

| M3 screw - 6 mm | 22 | IDR 400 | IDR 8,800 |

| M3 screw - 12 mm | 2 | IDR 400 | IDR 800 |

| M4 screw - 8 mm | 10 | IDR 500 | IDR 5,000 |

| M4 screw - 20 mm | 2 | IDR 650 | IDR 1,300 |

| M3 nylon spacer - 6 mm | 18 | IDR 590 | IDR 10,620 |

| FR1 PCB board - 10 x 10 cm | 1 | IDR 4,000 | IDR 4,000 |

| PLA filament | 350 g | IDR 154,000 / kg | IDR 53,900 |

| 3 mm Acrylic sheet - 10 x 15 cm | 150 cm2 | IDR 23 / cm2 | IDR 5,250 |

| Total | IDR 336,920 |

Development & System Integration

Ideation

Conception

Midterm Review

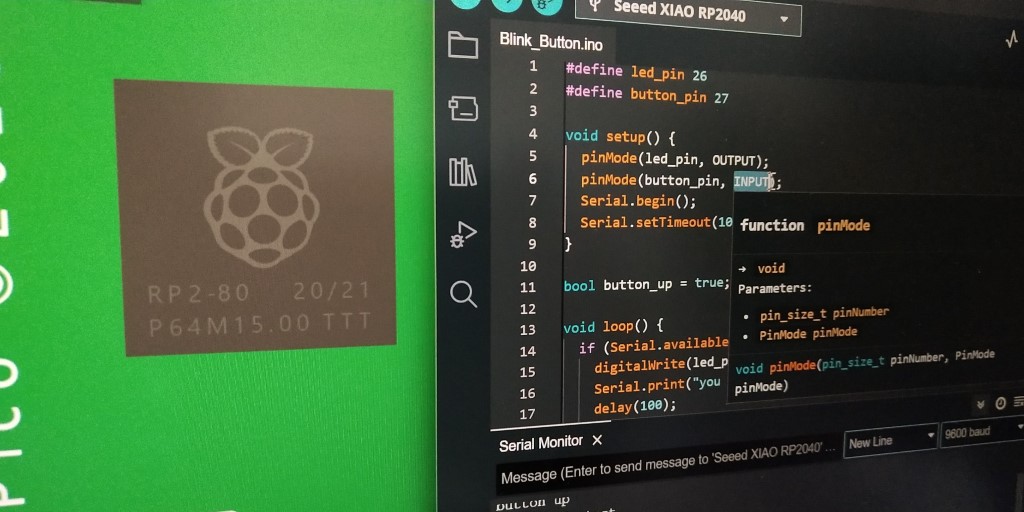

Embedded Programming

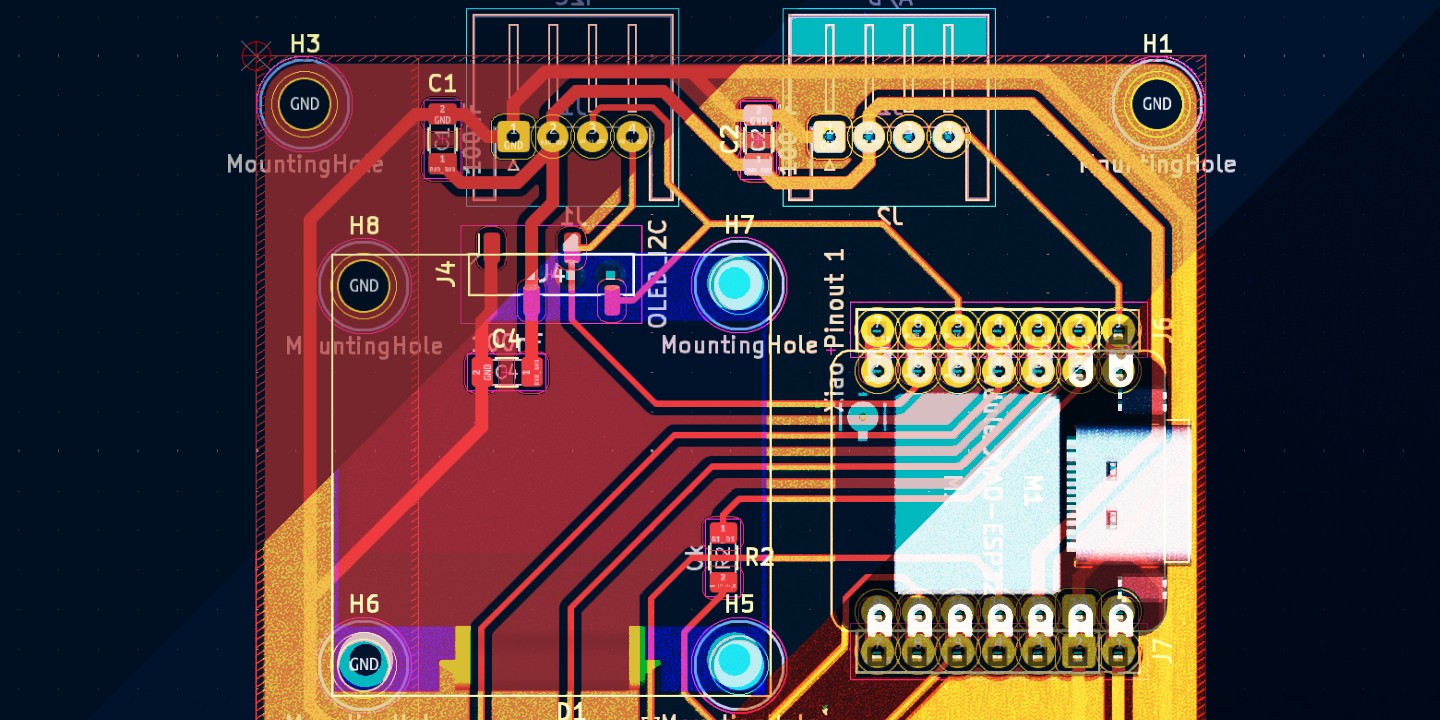

Electronic Design

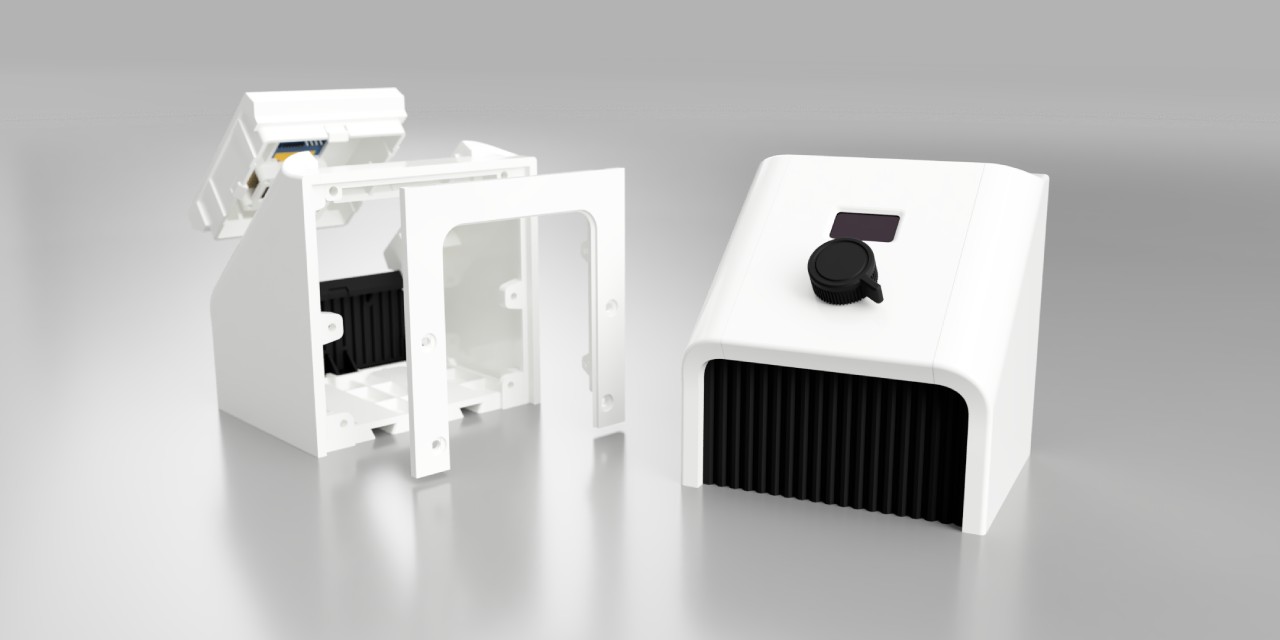

System Integration

Application & Implication