Final Project Ideas

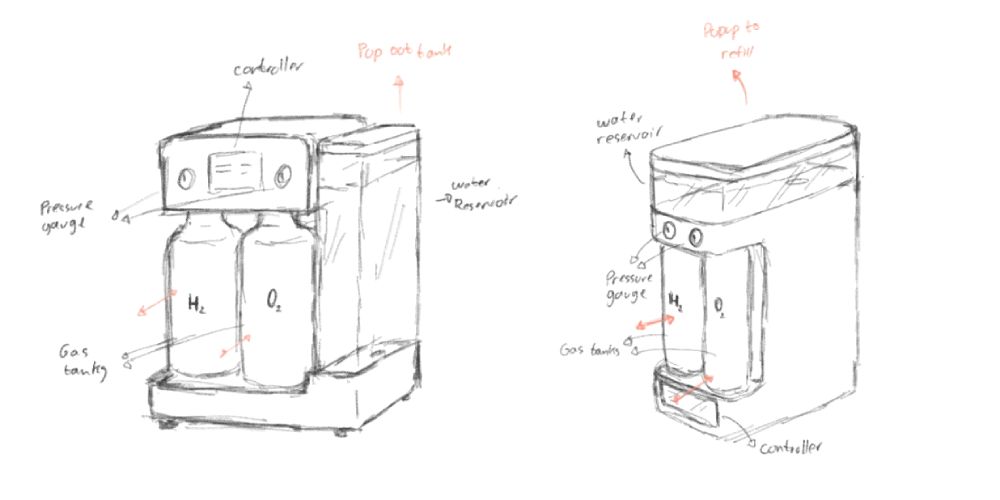

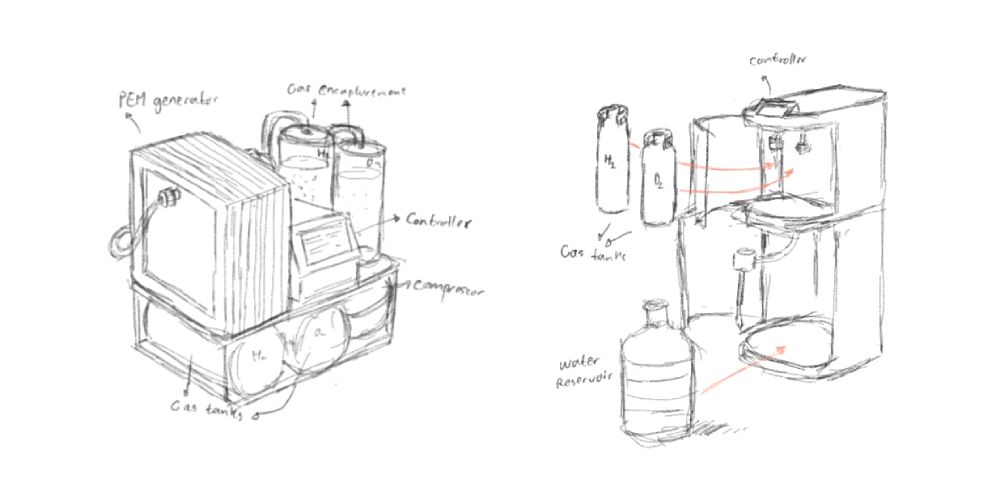

Compact Hydrogen Generator

Fab Lab Bali's current flagship initiative is Hydrogen Village, a continuation and expansion of Balon-Balon Ijo, one of the Fab Island Challenge from Bali Fab Fest 2022. This initiative aims to aid Bali's attempt to achieve net zero emission by 2045 by introducing the usage and application of hydrogen generated from the sea. For the pilot project, we are working together with the local community to deploy it in their area, a small island in the Bali region named Serangan. But this project has the potential for a positive impact on people living in coastal areas not just in Bali but all over Indonesia since we are the biggest archipelago nation in the world with more than 17,000 islands.

Indonesia is still a developing country, and outside of major cities like Jakarta, Bandung, or Surabaya, many areas still have limited access to electricity due to the significant investment required to build the infrastructure. This results in a heavy reliance on diesel generators for electricity for a large segment of citizens living in those areas. While there is a big push from the government to transition to solar energy, which is a positive move, not many realize the negative implications from the mining operations required to produce all the batteries to store the electricity produced by solar in an off-grid system.

Hydrogen generators already exist, but they are mostly industrial scale (which is massive), or too simplistic (usually used for demonstration purposes). My aim is to build a compact hydrogen generator for household or small neighborhood scale that can be constructed mostly using materials that are relatively easier to source, following the philosophy of distributed innovation.

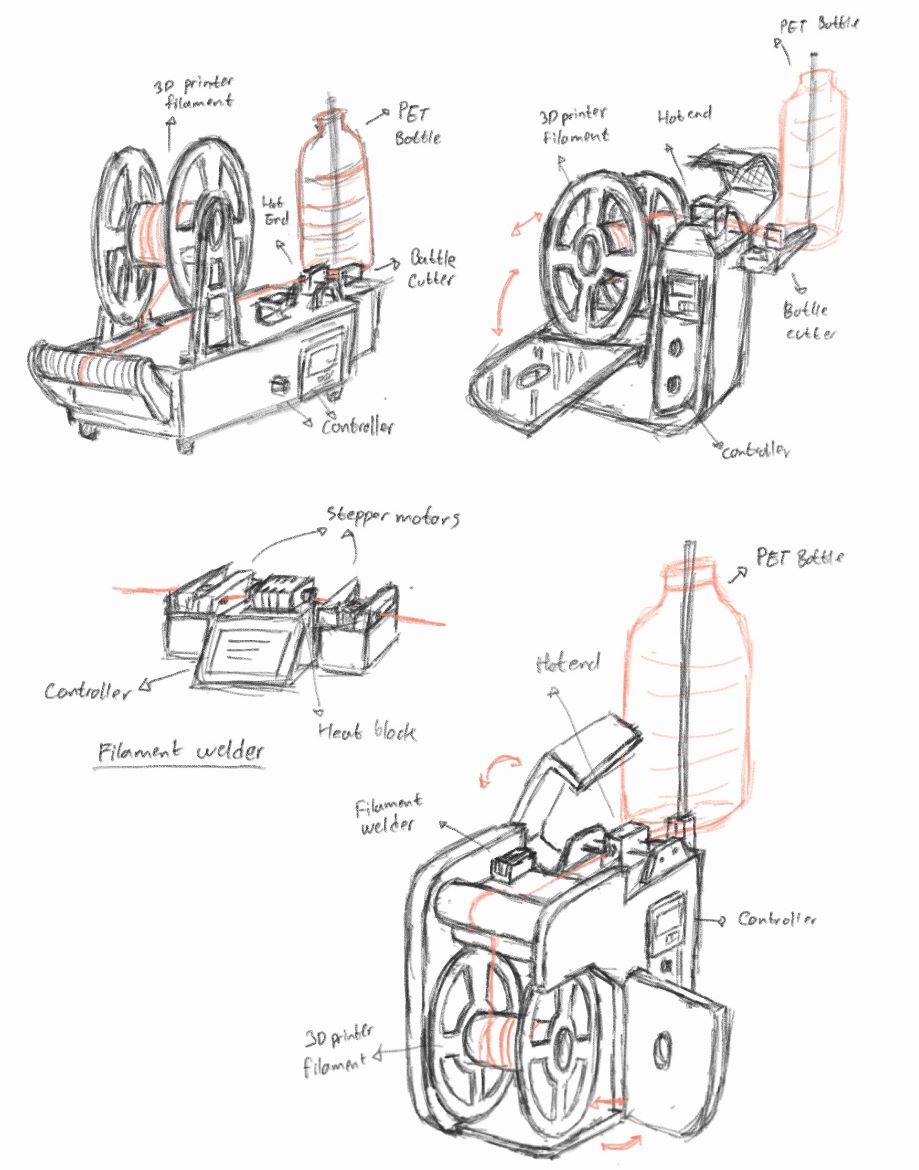

PET Filament Maker

3D printers are very ubiquitous among makers nowadays, resulting in a massive amount of filaments being used daily for various purposes, from prototyping to small-scale manufacturing. Unfortunately, in Indonesia, most filaments are still imported primarily from China. To my knowledge as of 2023, there is only one filament factory in Indonesia. Although filaments come in many different colors and properties these days, they are generally thermoplastics in the form of 1.75mm strings. Wouldn't it be great if we could produce our own filaments from our plastic waste? This would greatly propel us forward towards the ideal of distributed innovation and reduce our reliance on the global distribution chain.

This idea is not new, and in fact, there has been a renaissance of this trend in recent years. Some notable projects in this area include Recreator, Polyformer, PetMachine, RePet, PetBot, and many more. However, the problem I have with most of them is that they are quite bulky, which is fine if you plan to have the machine stationary on top of a table. However, our lab is located a bit far from others in Bali, and we often need to go to other places to hold workshops, demonstrations, etc. It would be difficult to move around if the machine is bulky. Therefore, the goal of my design is to make it more compact and easily transportable.

Imagine if you could bring this machine, recycle plastic bottles on the spot, and print something with it immediately (yes, I also need a portable 3D printer, and I am already planning to build one). What do you think we should print on the spot? How about parts of this machine itself to make the same machine and leave it behind for the local community to use? That's what we envision doing in Bali to spread the concept of distributed innovation by creating mini labs across Bali through the Banjar network.

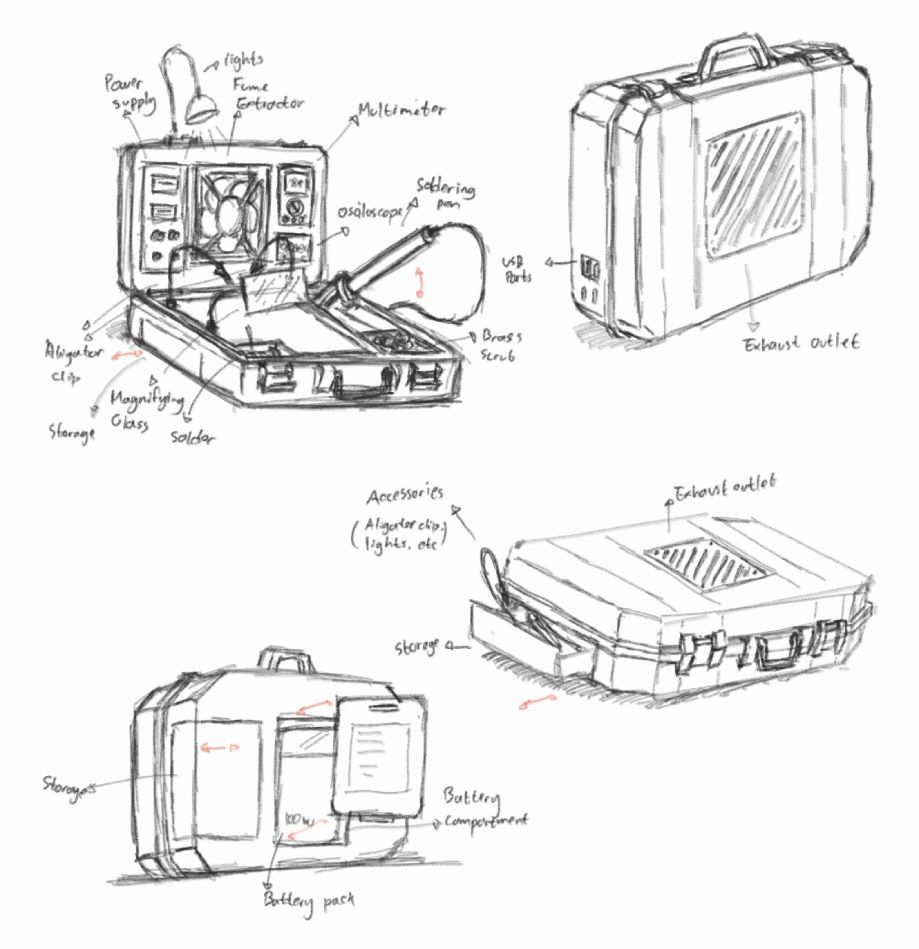

Mobile Fab Lab - Electronic Module

Building on my previous idea, one of the initiatives I propose in Fab Lab Bali is to develop a Mobile Fab Lab. Our discussions have expanded significantly, starting with the idea of having a van, but then we started tossing around ideas like a bike lab, a floating fab lab, a flying fab lab, or even a space fab lab just for fun! Regardless of the form of transportation, the core idea remains simple: to have a lab that is mobile and easily transportable.

With that in mind, I had the idea to build the lab as modular units. This way, the mobile lab can be adjusted to focus on different areas depending on the lab's needs. The goal of this idea is to create the simplest module as a first stepping stone towards our bigger vision. It's an electronic lab module that can compact into a single briefcase, housing a soldering workstation, power supply, oscilloscope, multimeter, reflow hot plate, and more.

As I am still very new to electronic design, I anticipate that this project will evolve along the way as I learn more about it if I choose to make this my final project. But just imagine the convenience of having everything neatly packed in a single case. You wouldn't need to worry about forgetting any tools or components because everything would have its own compartment and be ready for you to just grab and go.