9. Molding and casting¶

Machine Building¶

Possibly Collaborate with

- Dilijan (Dilijan, Armenia)

- Schedule

- Apr 06: mechanical design, machine design (Class)

- Apr 09(Sat): local session

- Apr 13: break (no class)

- Apr 16(Sat): local session

- Apr 20: input devices (1 min presentation)

nueval¶

- Local evaluation

Preparation for next week¶

Output Devices

group assignment:

measure the power consumption of an output device

individual assignment:

add an output device to a microcontroller board you’ve designed,

and program it to do something

for final project¶

- LED illumination of the back cover depending on the air quality

When the Air Quality is good (CO2 is low, temperature is comfortable…), the light turns green..

When the Air Quality is bad (CO2 is high, temperature is too hot or cold…), the light turns red..

Color LED¶

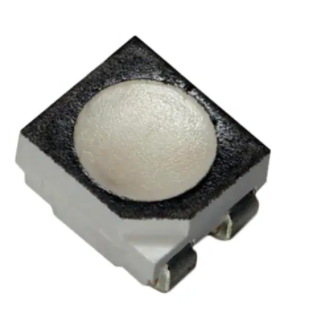

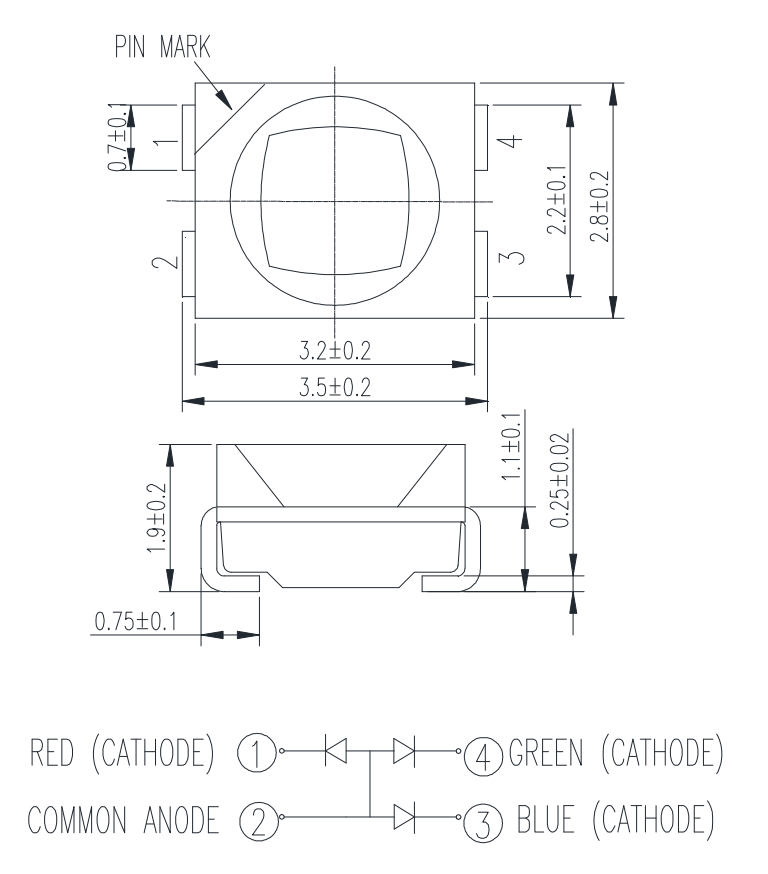

RGB LED¶

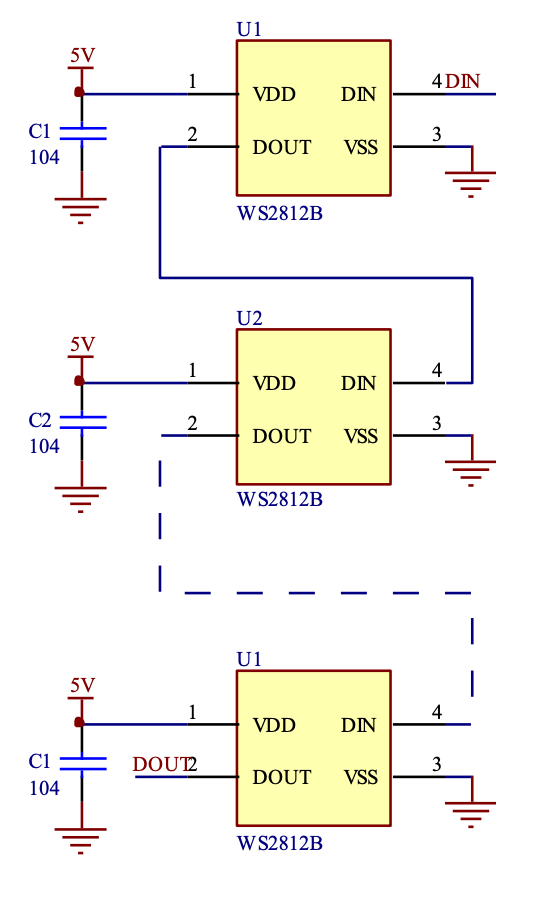

NeoPixel(WS2812)¶

C1 104 = 100nF = 0.1uF

Ref. uf-nf-pf-capacitor-conversion-table

![]()

neon (EL wire)¶

- EL: Electroluminescence

- Ref. How to make EL-wire blink?(Arduino)

EL sheet¶

- Ref. monotaro

Lumisheet RGB¶

- Ref. Lumisheet RGB

for Machine Building¶

Stepper motor¶

- Moter driver

Servo motor¶

DC motor¶

- Moter driver

Preparation¶

none

Group Assignment¶

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

extra credit: try other molding and casting processes

Materials¶

-

machinable wax, modeling wax

-

Silicone rubber

- Mold Star 31T 0.9KG Trial Kit

- Smooth-on SDS

- SDS_JP

- Mix ratio by Volume: 1A:1B

- Mix ratio by Weight: 1A:1B

- pot life: 5 min

- cure time: 23 min

- color: Translucent

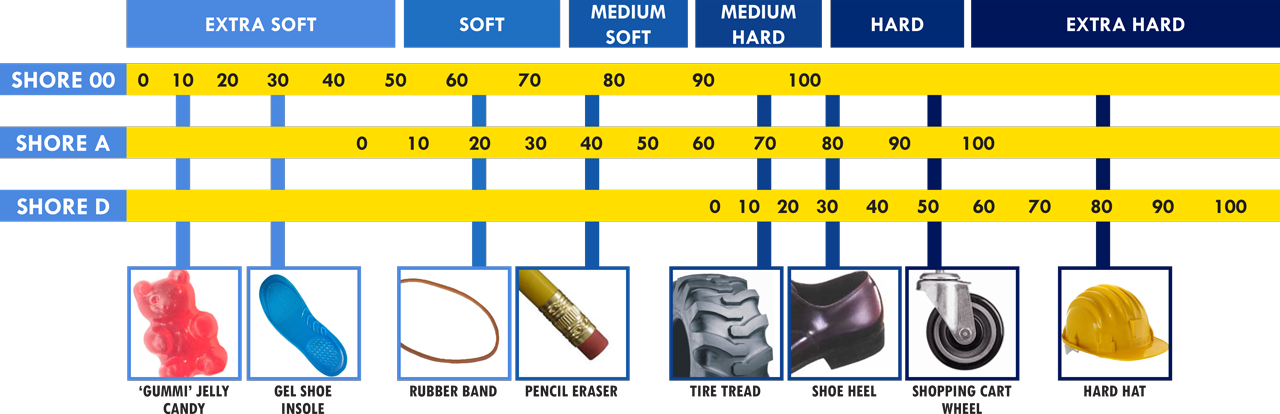

- Share Hardness: 30A

-

Urethanes resin

- Smooth-Cast 320 0.86KG Trial kit

- Smooth-on SDS

- SDS

- Mix ratio by Volume: 1A:1B

- Mix ratio by Weight: 100A:90B

- pot life: 3 min

- cure time: 10 min

- color: Off white

- Share Hardness: 70D

-

So-strong

- Color Tints for Urethane

- Smooth-on SDS

- 0.01% to 3% of total system weight

- Metal

- Bismuth Based Alloy Ingot

- Tin

- 231.9 C

Safety¶

- ventilation

- open windows, fans…

- protection

- glass

- groves

- disposal

- finish chemicals reaction before dispose -> heat

- dispose cups and Stir bars directly into bin

- change groves

- do not touch any uncovered place, chair, desk…

Individual assignment:¶

design a mold around the stock and tooling that you’ll be using,

mill it (rough cut + three-axis finish cut),

and use it to cast parts

extra credit: use more then two mold parts

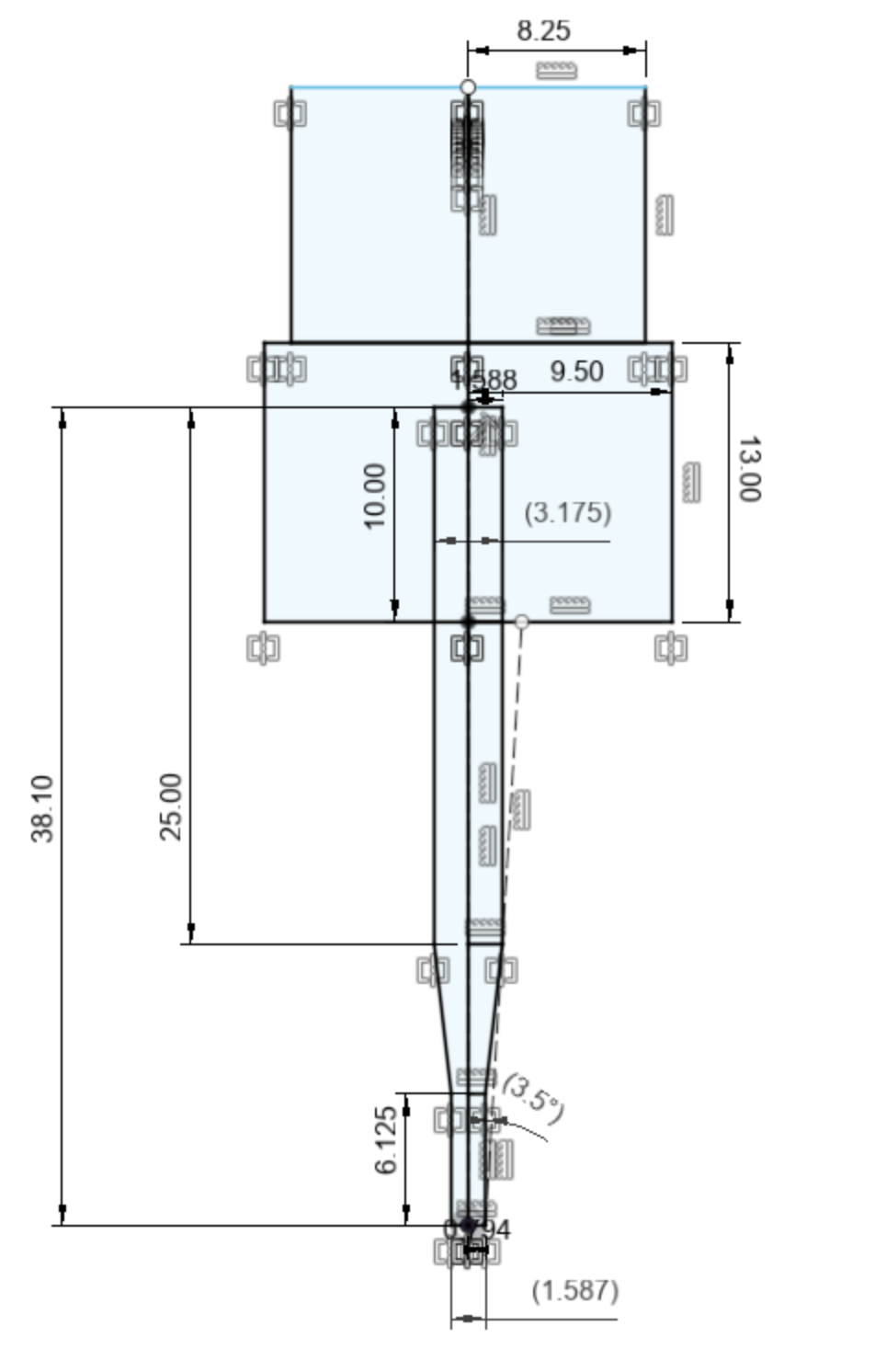

Sizes¶

Attention

- Check all material and tool sizes in whole process

- 3D model should be arranged with these sizes

- start milling

- Machinable wax

- size: 152mm x 92mm x 39mm (real size is smaller)

- Machines

- Genmitsu PROVerXL

- work area: 400mm × 300mm × 110mm

- MDX-15

- work area: 152.4mm × 101.6mm × 60.5mm

- Genmitsu PROVerXL

- Endmill

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

- Tool_dia: 1/8” =3.175mm

- OverAll Length: 2-1/4”(2.25”) =57.15mm

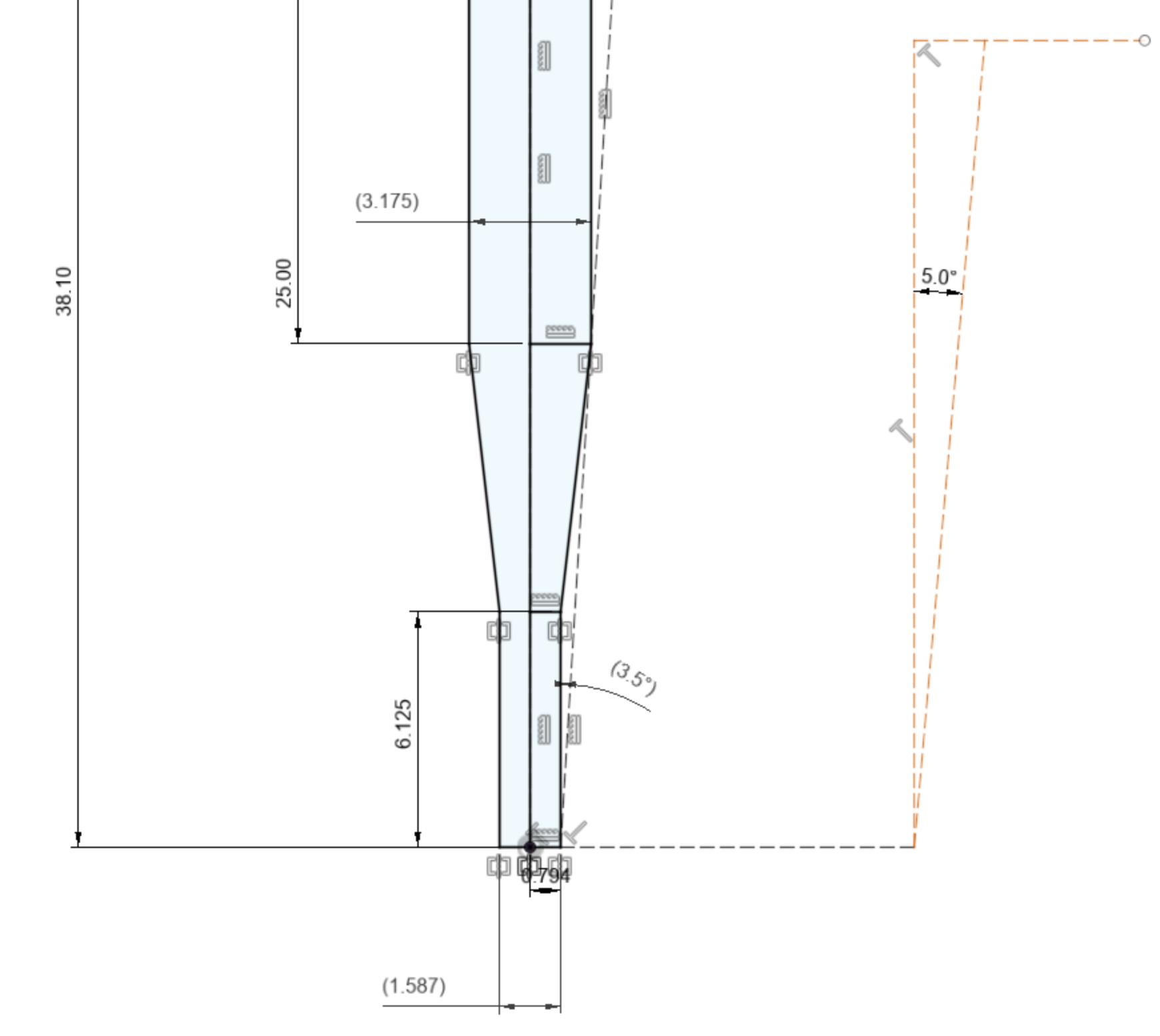

- Rough cut

- 0.0625” DIA 2FL SE AlTiN 1/16

- Tool_dia: 1/16” =1.5875mm

- OverAll Length: 1-1/2”(1.5”) =38.1mm

- Finish cut

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

Design restriction from these sizes¶

- XY size -> real wax size

- Final Part size < (real wax size - wax_wallx2 - mold_wallx2)

- distance between bumps (凸 and 凸) > 1.58mm(1/16”) > 0.79mm(1/32”)

- width of dent 凹: tool size > 1.58mm(1/16”) > 0.79mm(1/32”)

- Z depth

- tool: 1/16_endmill_lemgth=38.1mm -in_collet_lenght=10mm = 28mm

- machine: genmitsu_z=110mm - Wax_height_39mm = 71mm > tool_length

- machine: MDX-15_z=60.5mm - Wax_height_39mm = 21.5mm

- 2 sides mold: 21.5mm each = 43mm_max

- 1 side mold: 21.5mm_max

- prevention of hitting by tilt

- 1/16_endmill

Design for casting¶

- Registration (for alignment)

- ref. How to Make Molds

- Registration Key

- nest (recommend)

- sprue -> lower position

- runner

- air vent -> higher position

- parting line -> edge/surface -> deburring

Process¶

- 1 side molding/ 2 sides molding or more

- negative/positive

- 3D modeling process

- sample

- design final part (positive)

- design molds to make final part (negative)

- design wax to make molds (positive)

- casting process

- pour liquid silicone rubber into wax to cast molds (negative)

- pour liquid resin into molds to cast final part (positive)

- 3D modeling process

ToDo¶

Design¶

- Fusion360

- Final_part

- model including smooth tilted or curved surfaces instead of “steps” towards axis Z

- Silicon_mold

- model Silicon_block

- combine > cut

- Silicone_block - final part = Silicon_mold

- Wax

- model Wax_block

- combine > cut

- Wax_block - Silicone_mold

- add

- Sprue

- Air vent

- Registration key

- Final_part

Milling¶

- genmitsu ProVerXL

- Tips: Wax milling with mods and Genmitsu PROVerXL4030

- rough cut

- finish cut

- Stepover

- class

- as little stepover as possible

- 10% may be good

- 50% still see features

- class

- Stepover

// mill 3D stl -> mill raster 3D node

var w = evt.data.width

var xmin = evt.data.xmin

var xmax = evt.data.xmax

var diameter = evt.data.diameter

var stepover = evt.data.stepover

var mmunits = evt.data.mmunits

var step = Math.floor(stepover*diameter*w/(mmunits*(xmax-xmin)))

Casting Silicone mold¶

- Silicone rubber: Mold Star 31T

- weight 1A:1B

- Mix

- pot life

- Cure

- cure time -> longer in low temperature

- 2 sides molds -> cure completely otherwise stick together

Casting material¶

- Urethane resin

- Weight 100A:90B

- Mix

- pot life

- Cure

- cure time -> longer in low temperature

- Metal

- talk

- Mold Star 31T: heat resistant up to 232°C

- Bismuth Based Alloy (138 C)

- Tin (231.9 C)

- Silicone rubber

- release agent

- Food

- Silicone rubber is not food safety -> do not eat

Assessment¶

FAQ

What does 3-axis milling mean?

Answer: You should have smooth tilted or curved surfaces instead of

“steps” towards axis Z.