Fusion 360 CAM¶

Ref. Fusion 360 Quick-Start Guide for 3018 Pro & PROver CNC’s

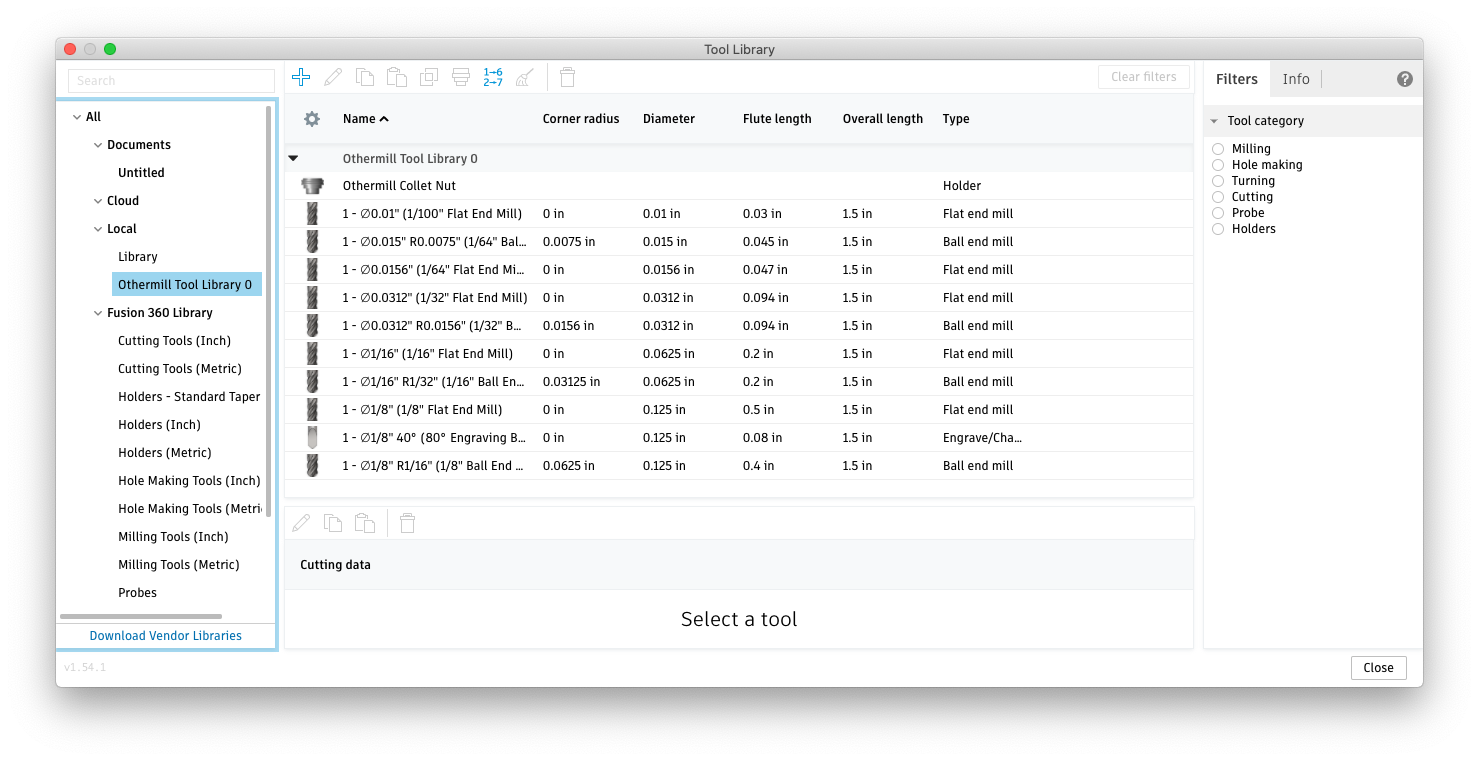

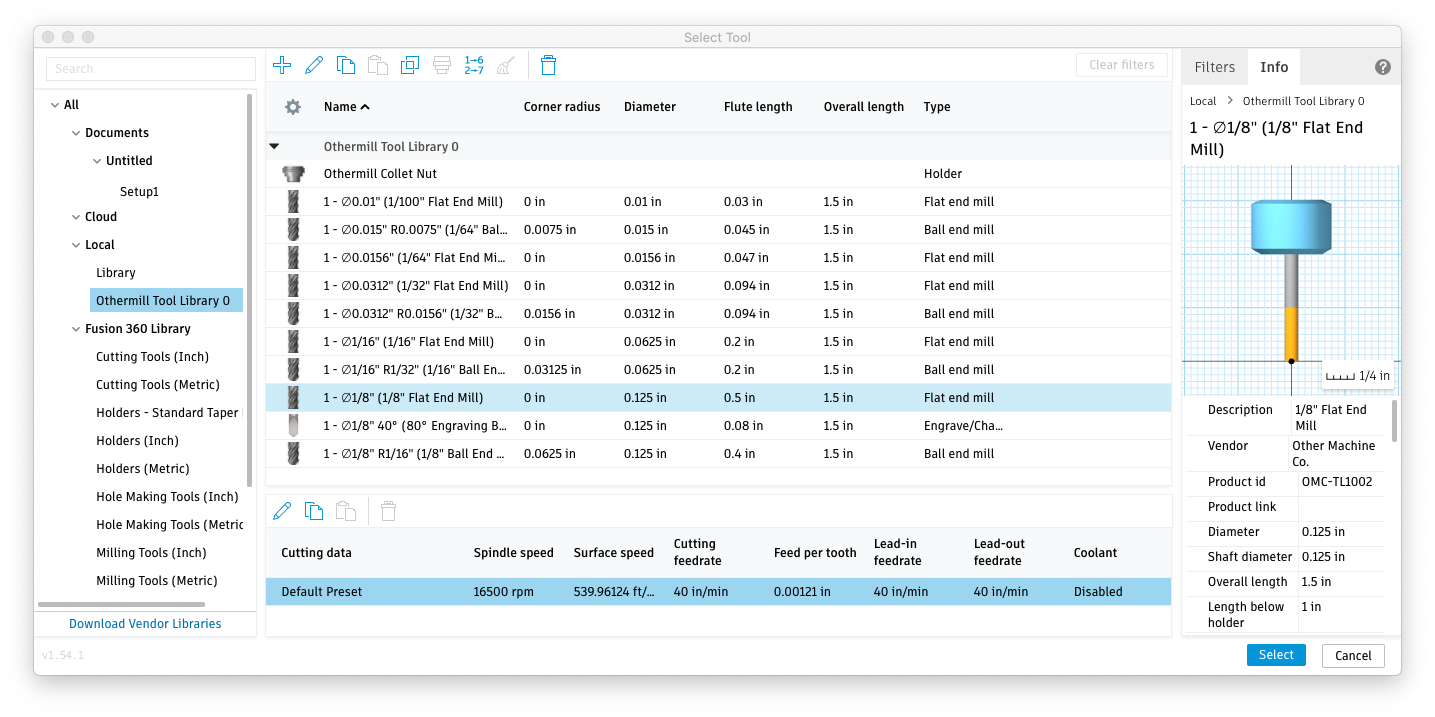

Install Tool Library¶

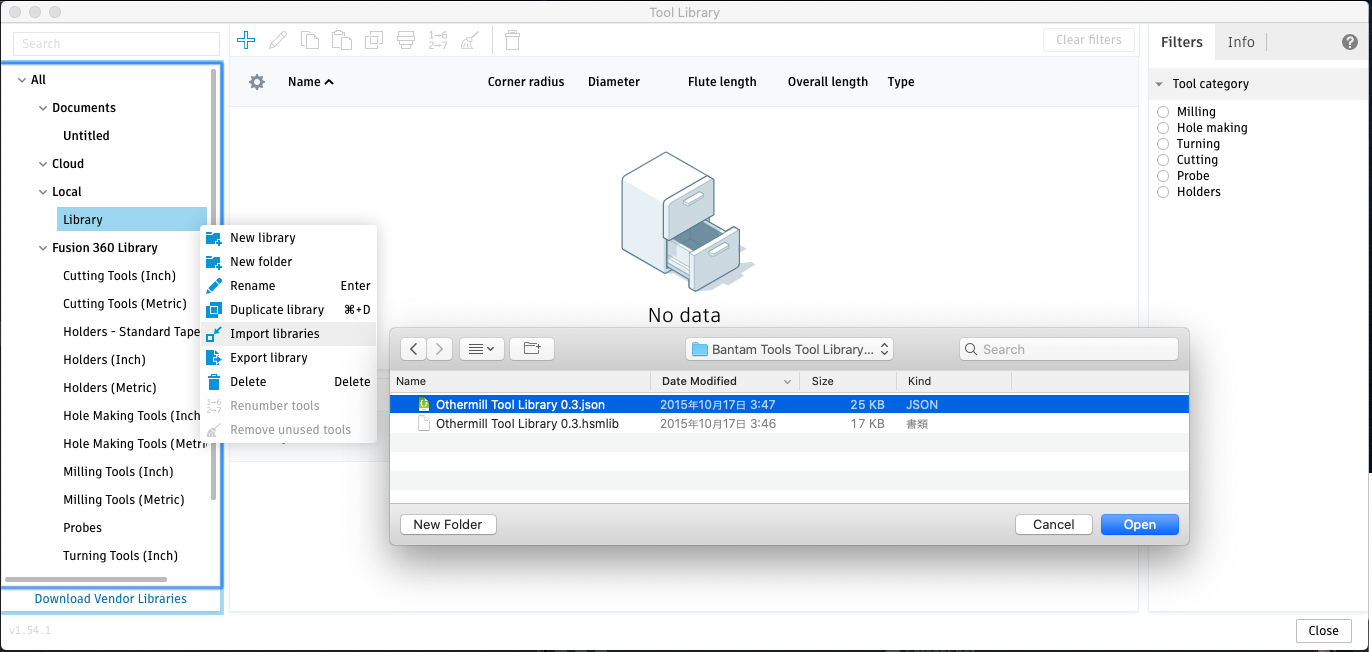

Download and unzip Fusion 360 Tool Library¶

The tool library contains definitions for the following tools:

- 1/8” Flat End Mill

- 1/16” Flat End Mill

- 1/32” Flat End Mill

- 1/64” Flat End Mill

- 1/100” Flat End Mill

- 1/8” Ball End Mill

- 1/16” Ball End Mill

- 1/32” Ball End Mill

- 1/64” Ball End Mill

- Metal Engraving Bit, 0.005”

- Collet Nut

├── Bantam Tools Tool Library 0.3

│ ├── Othermill Tool Library 0.3.json

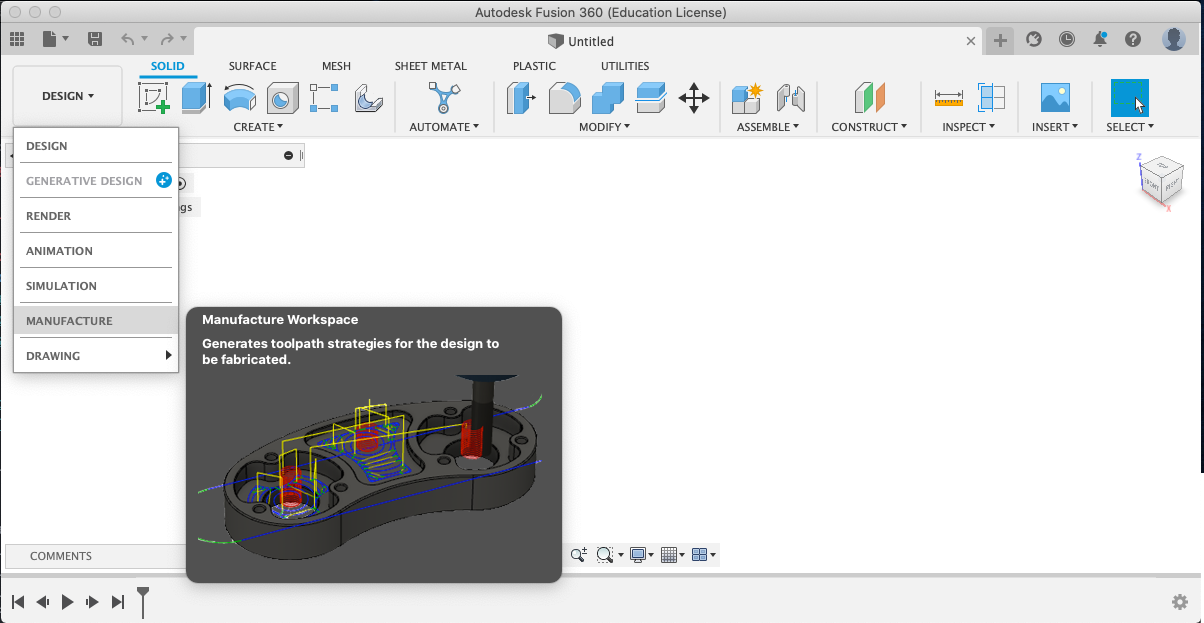

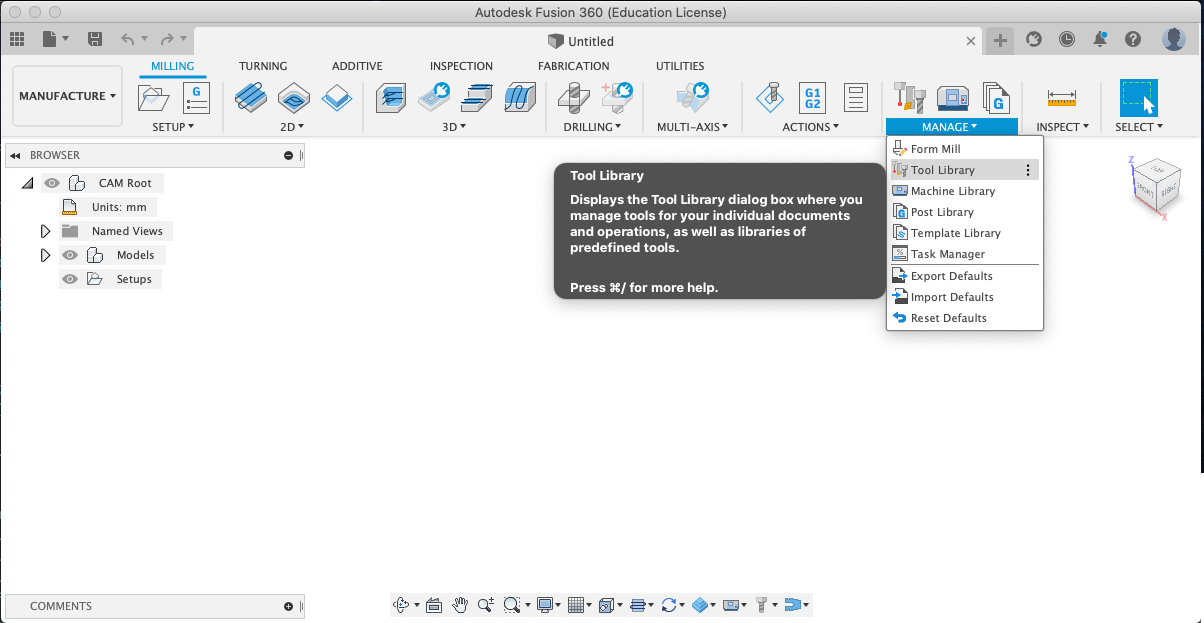

Install to Fusion 360¶

Switch to Manufacture workspace

Manage -> Tool Library

Local -> library -> Import libraries -> .json -> Open

Imported Tools

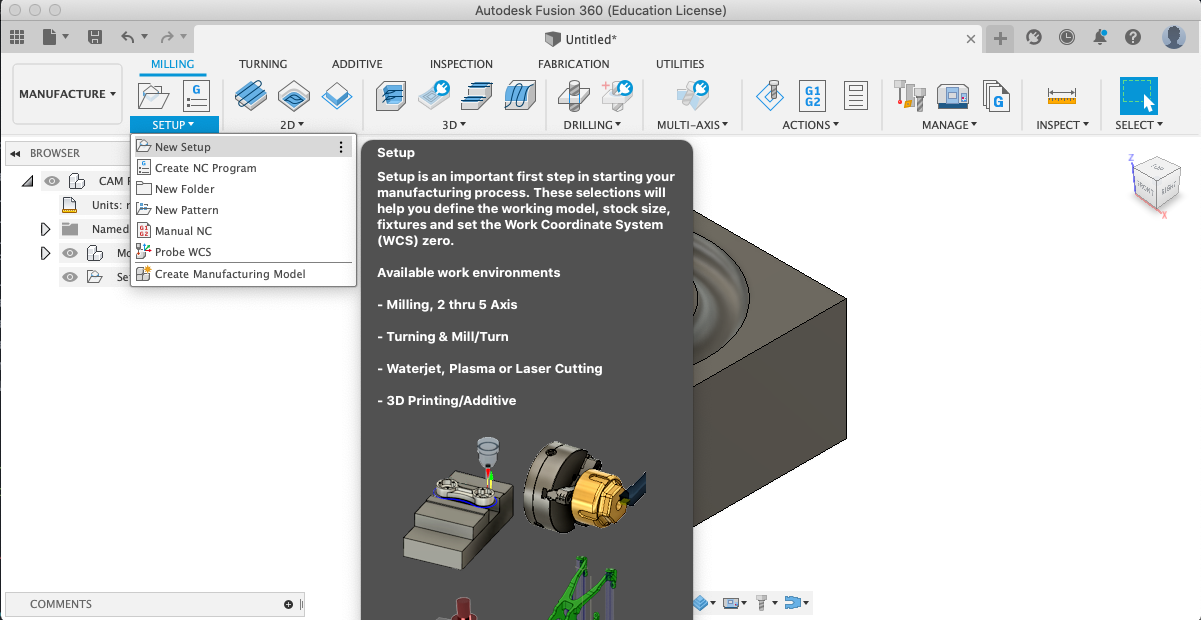

Make tool path¶

Ref. BANTAM TOOLS

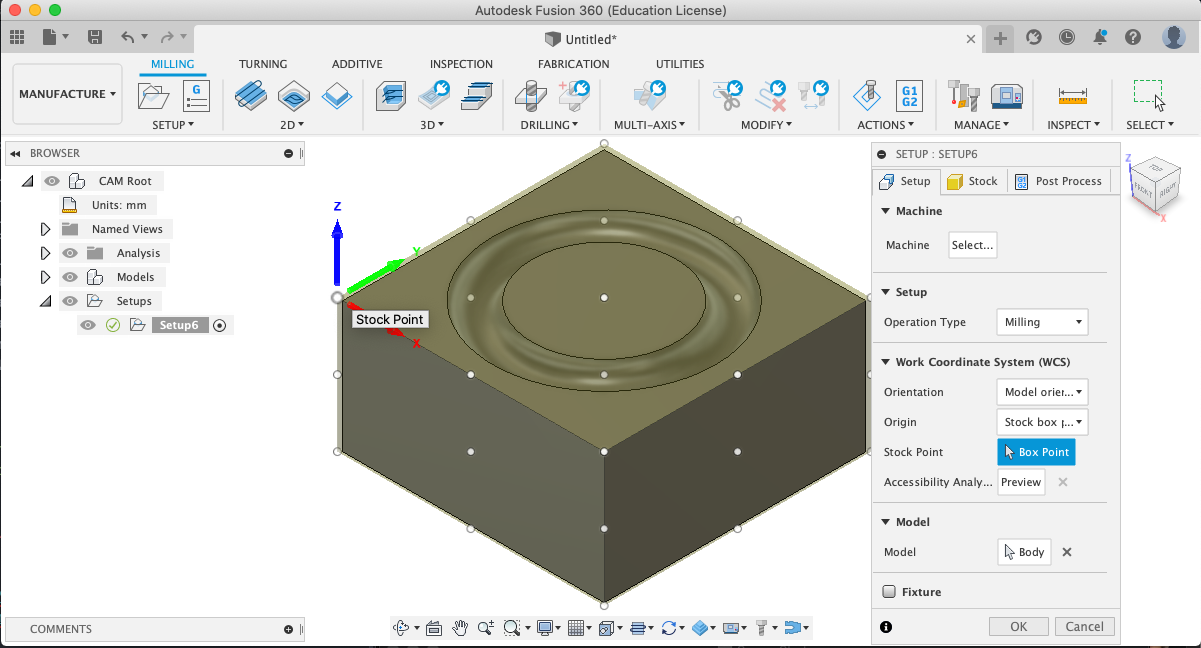

Setup origin¶

Set the Stock Point to top, front, left corner of the model

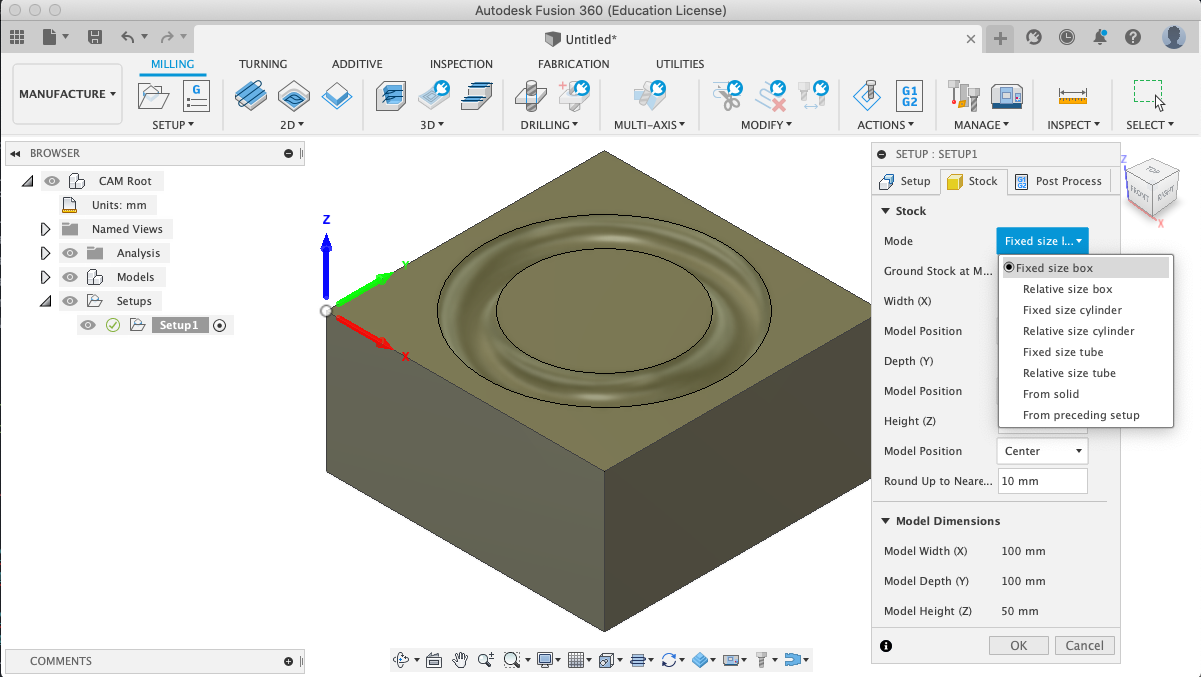

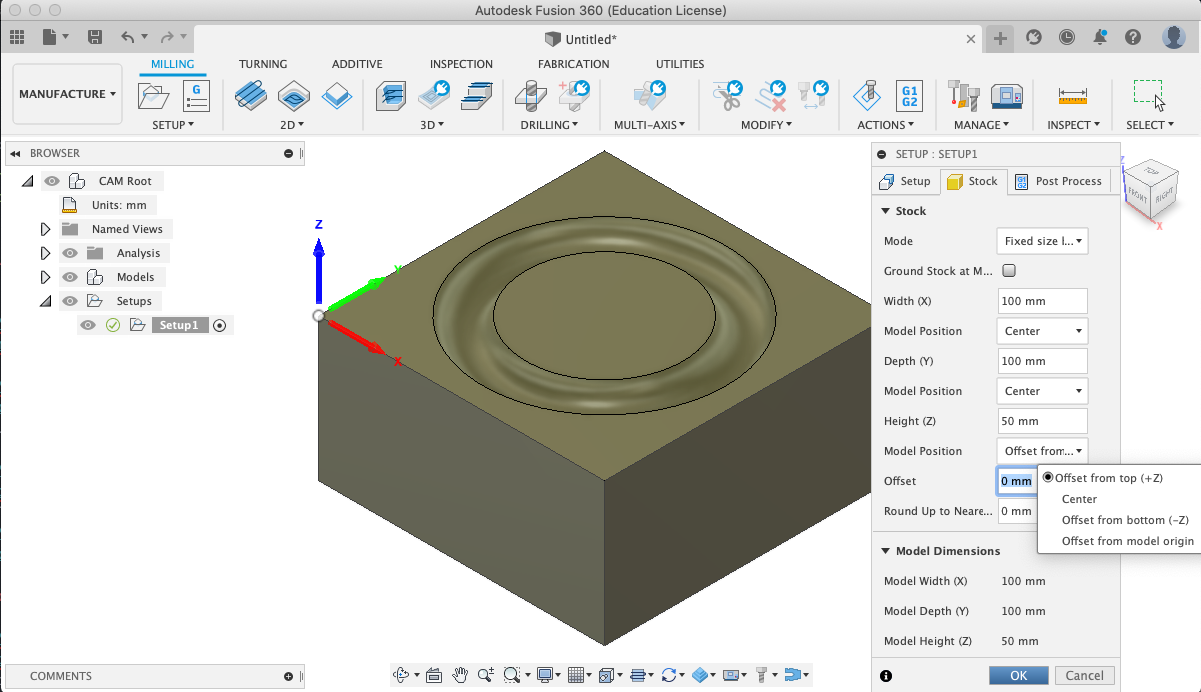

Stock -> Model -> Fixed size -> Set the material Dimension Width(X), Depth(Y) and Height(Z)

Model Position(Z) -> Offset from top(+Z) -> Offset 0mm

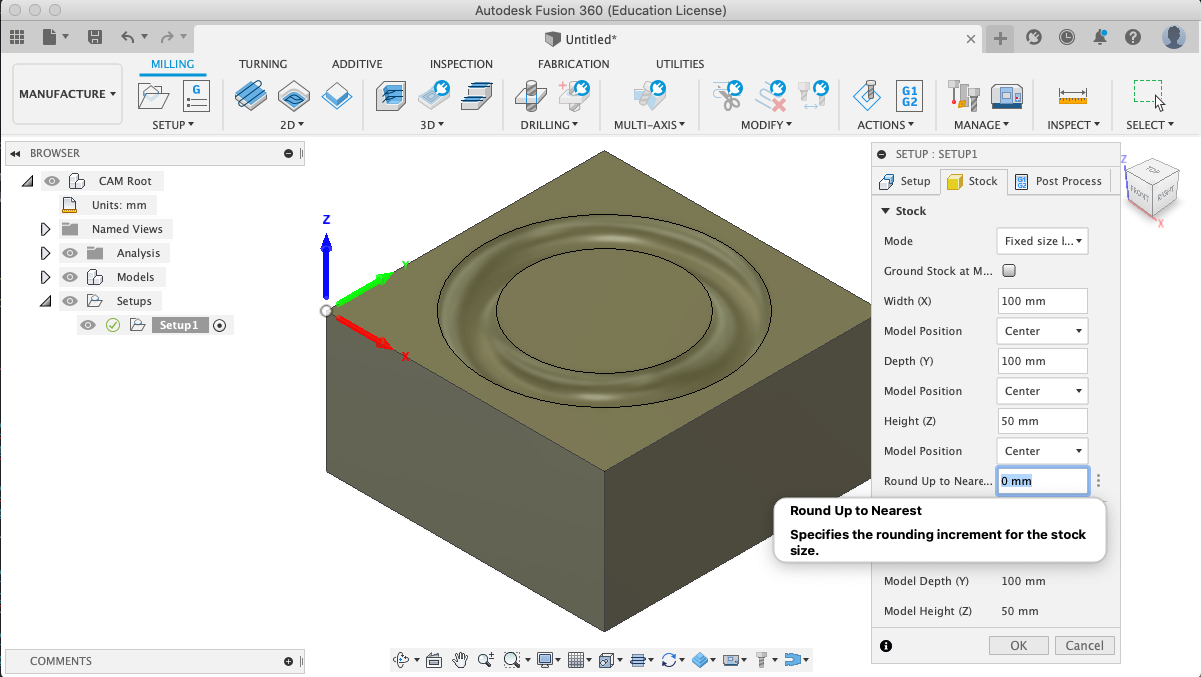

“Round up to Nearest” to 0

Note

By default, Fusion 360 will place your model in the exact center of your stock. Depending on the size of your stock and the CAM strategies you wish to use, you may want to align your model to the surface of your stock or offset it by some absolute amount. To do this, choose the “Model Position” for the dimension you want to align to, choose the side you want to offset from, and fill in the Offset field with the amount you want to offset by. Entering 0 will align your model flush to that face of your stock.

Ref. BANTAM TOOLS

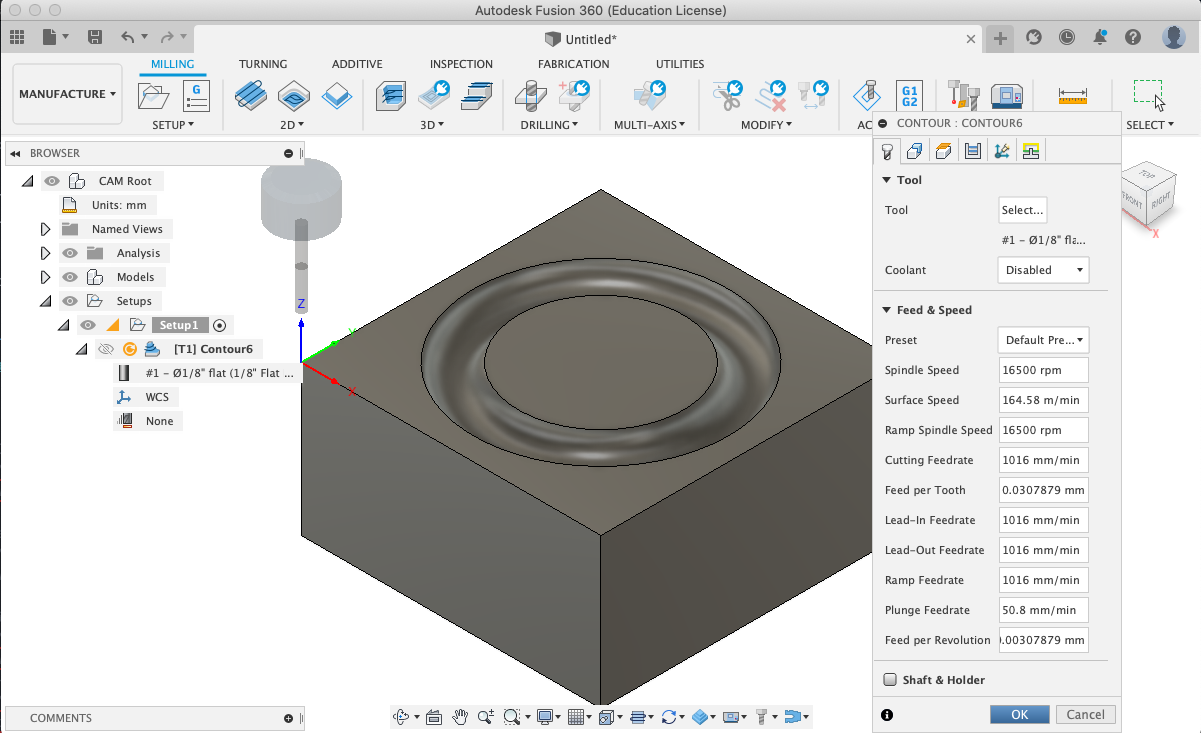

Rough Cut¶

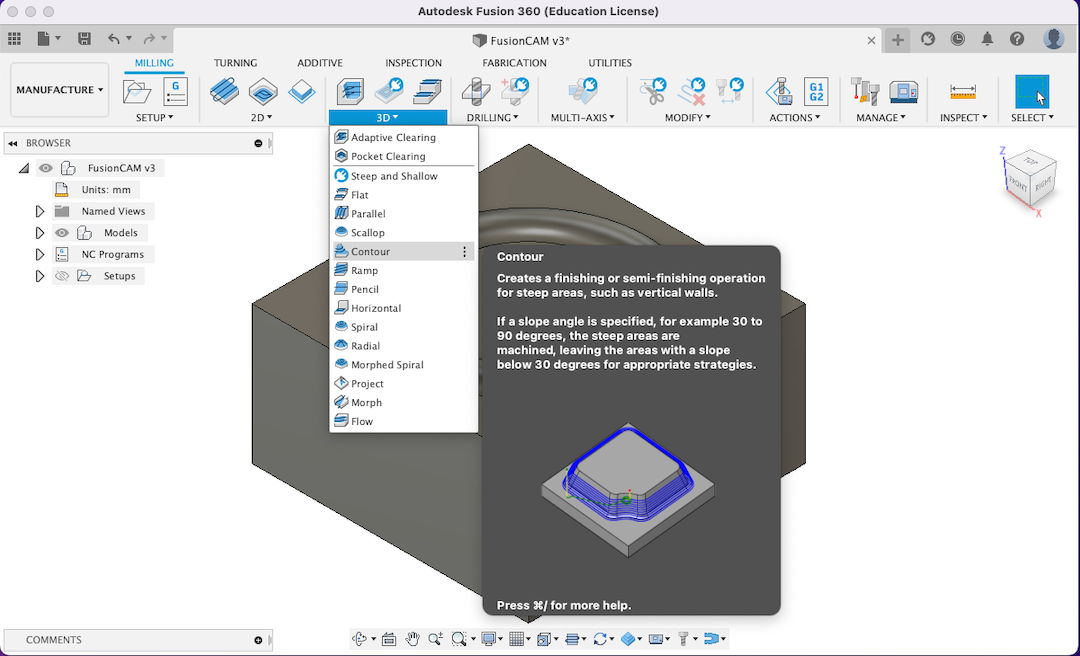

3D -> 3D Contour

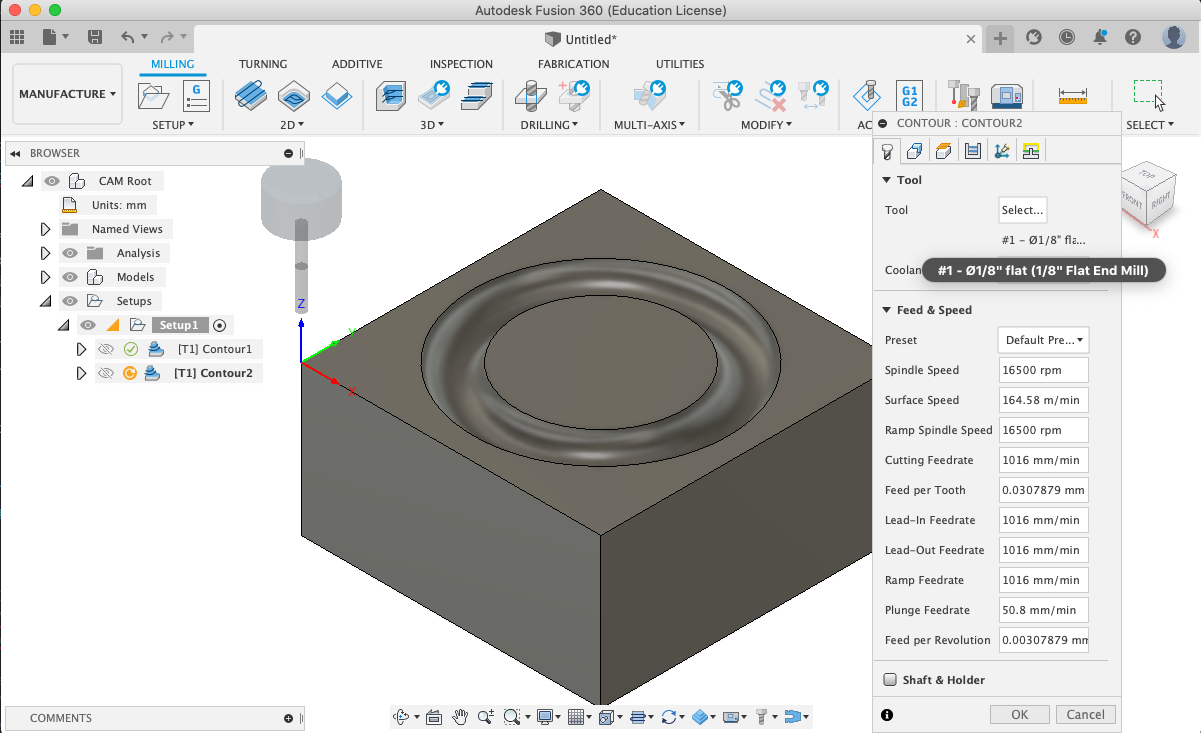

Tool -> Select

Select 1/8” Flat End Mill

OK

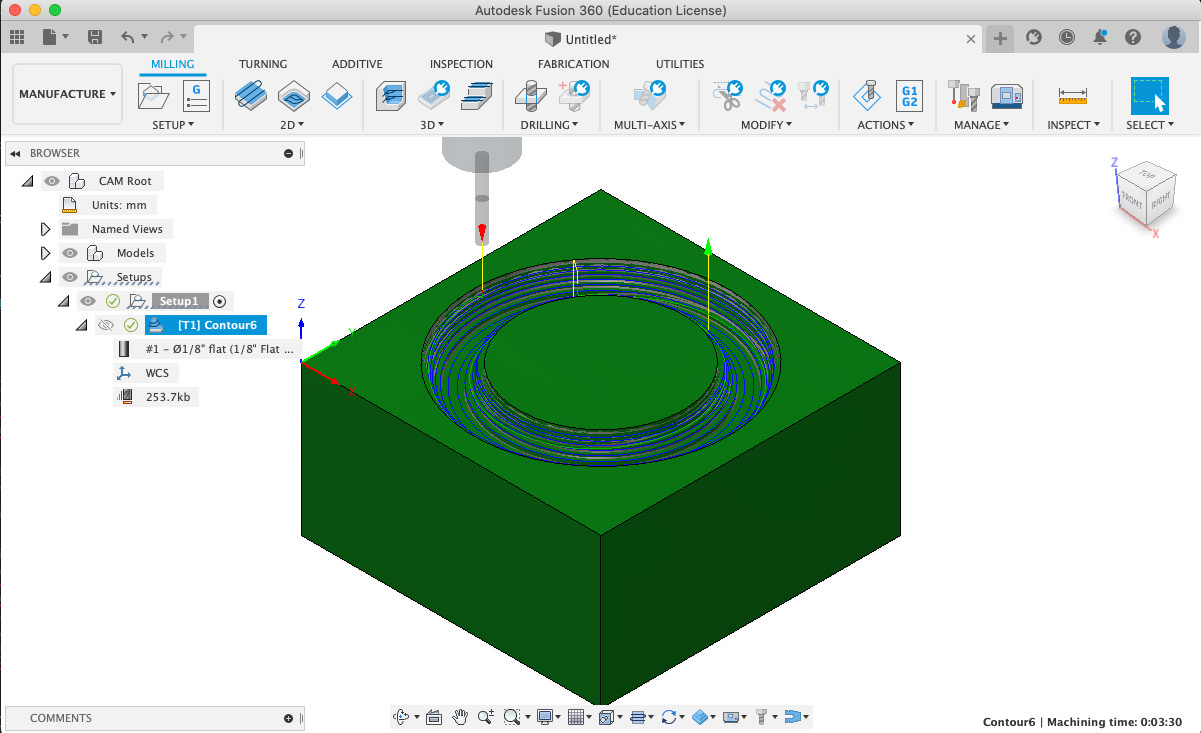

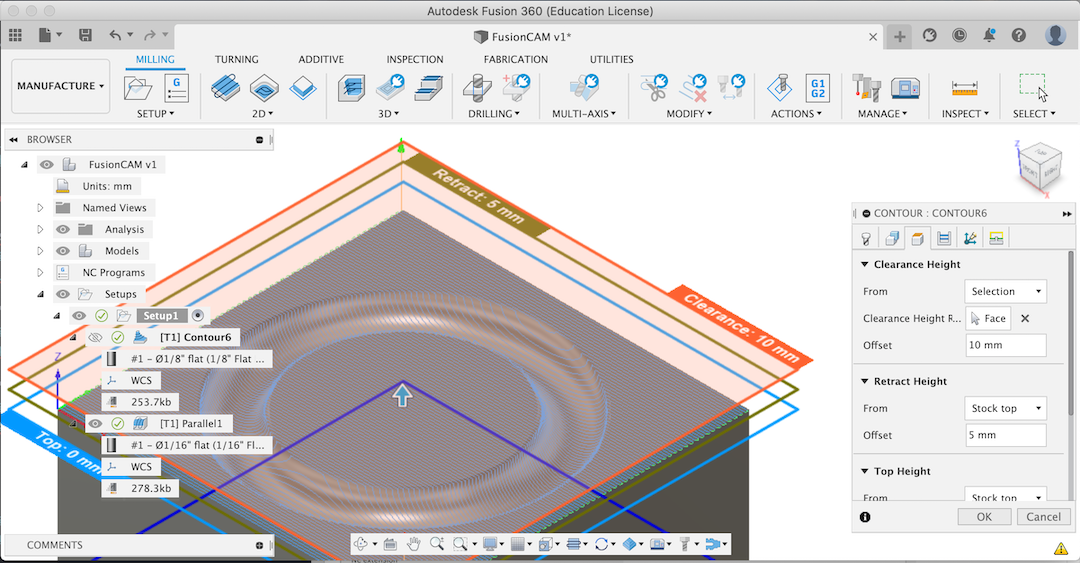

Path made

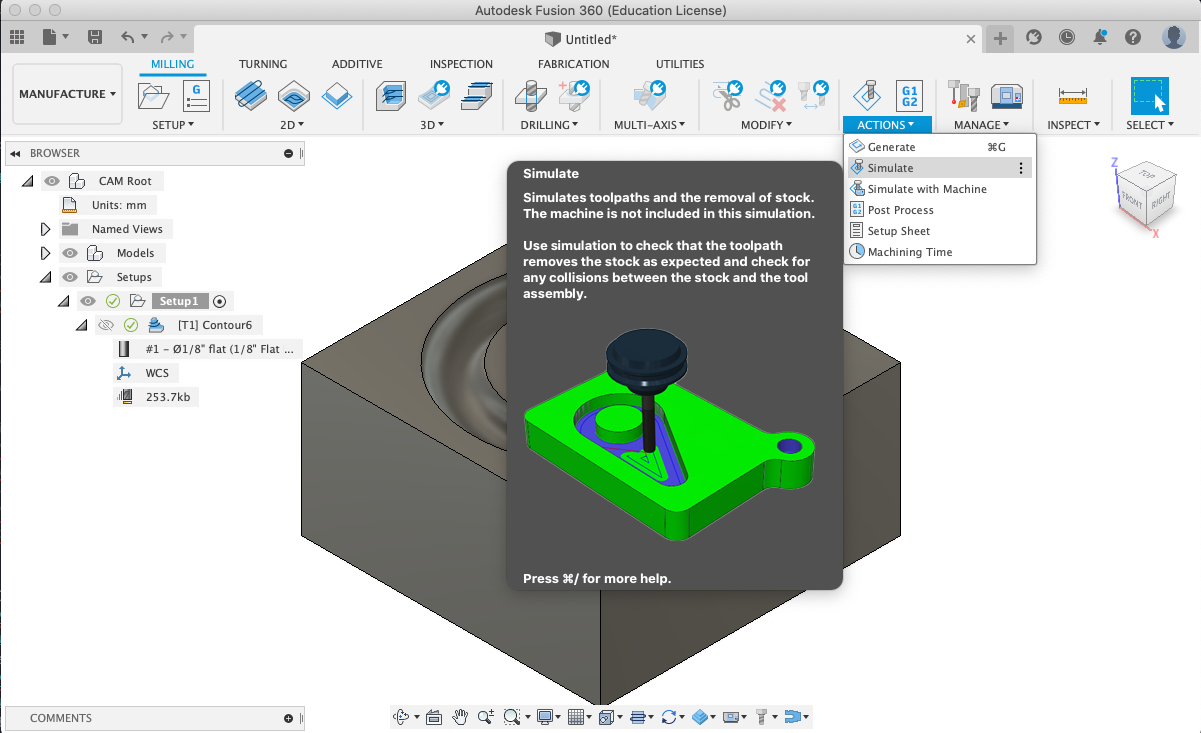

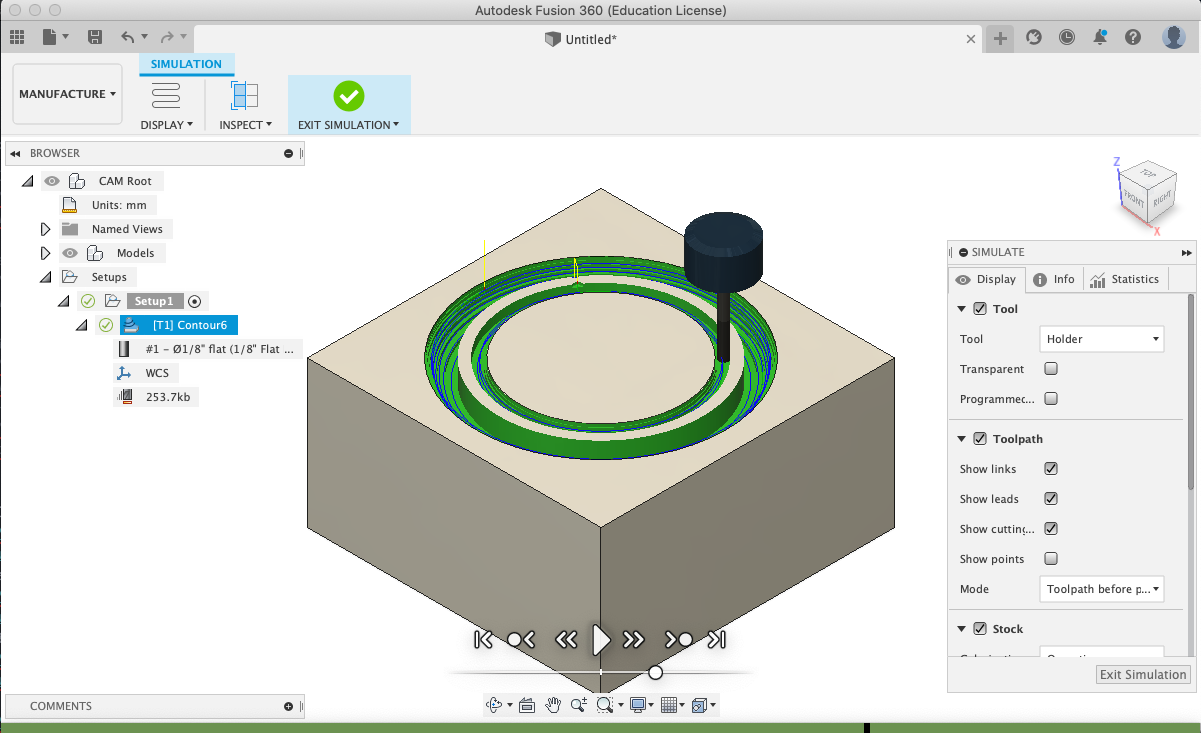

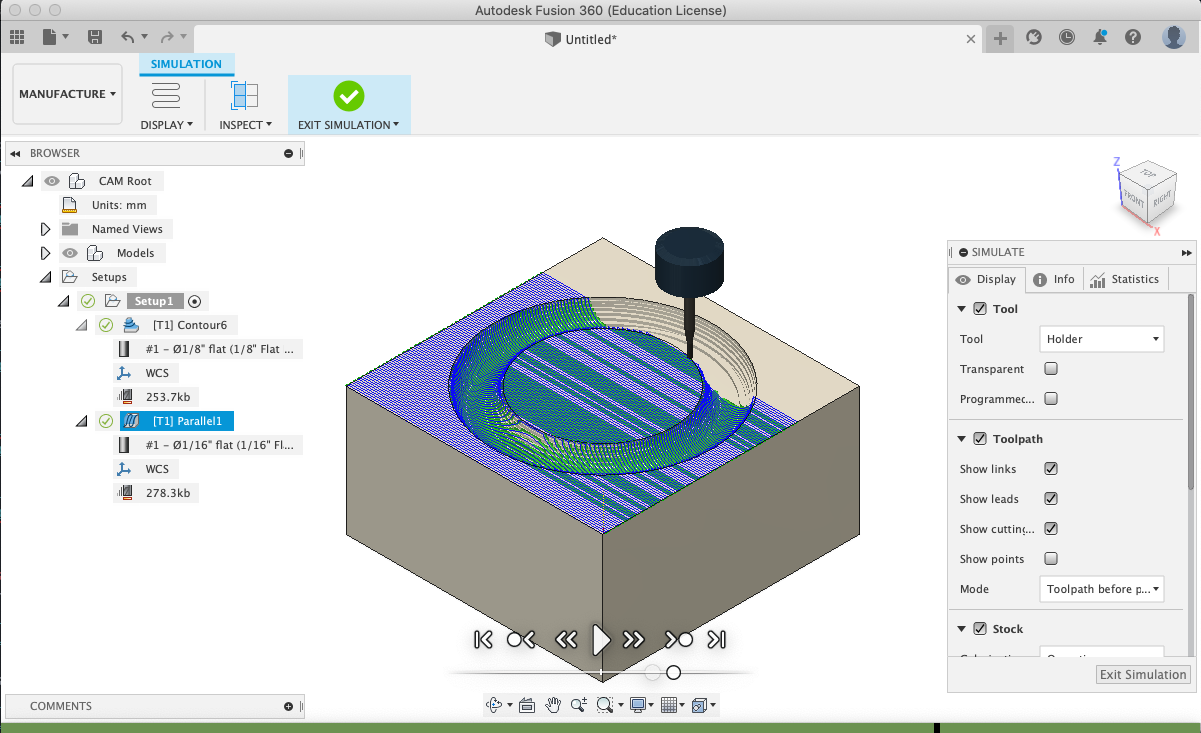

Simulate

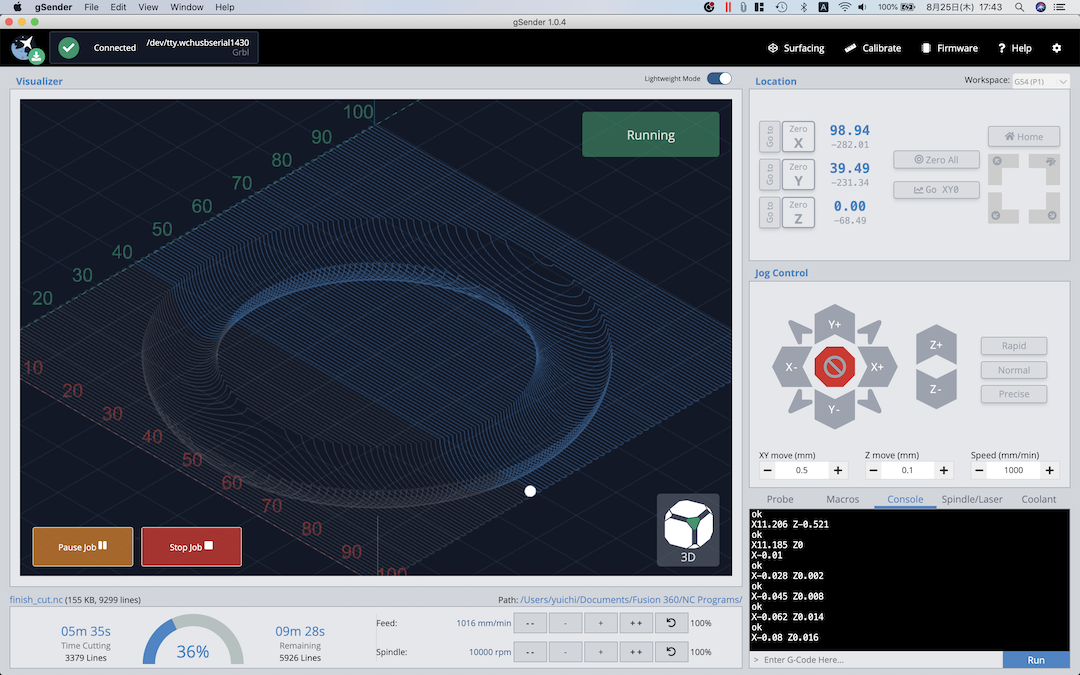

Simulate Running

Simulate Running

Finish Cut¶

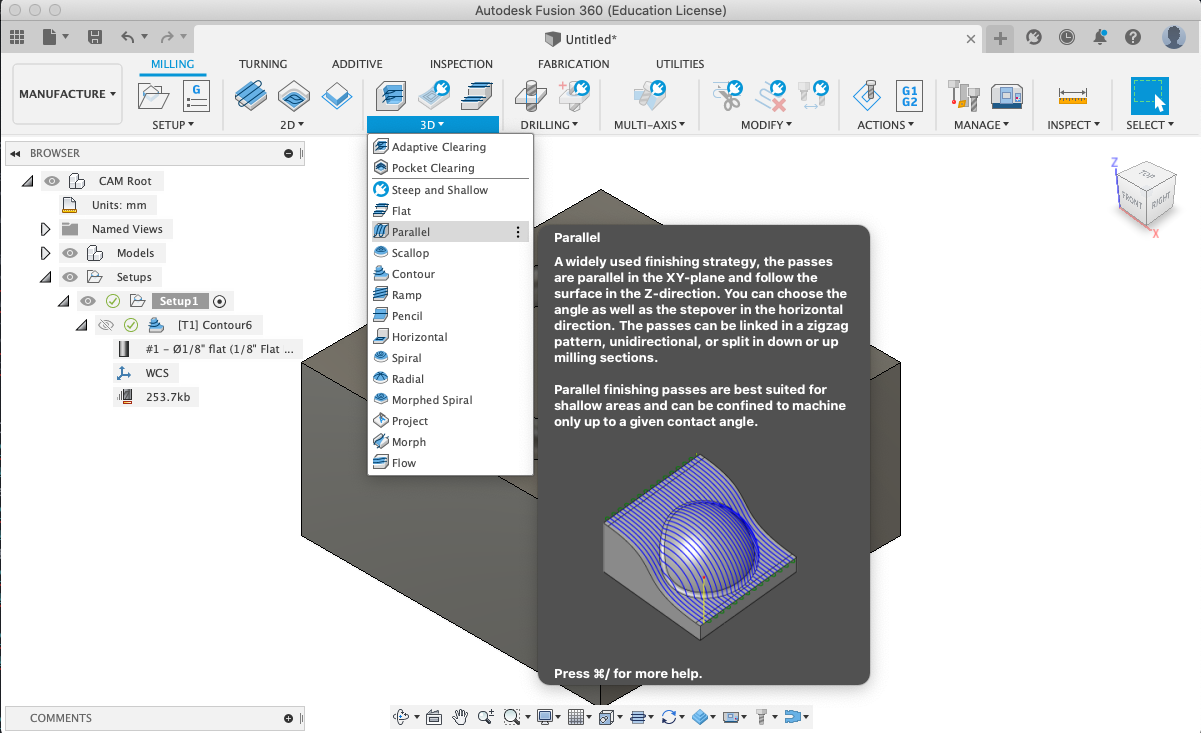

3D -> Parellel

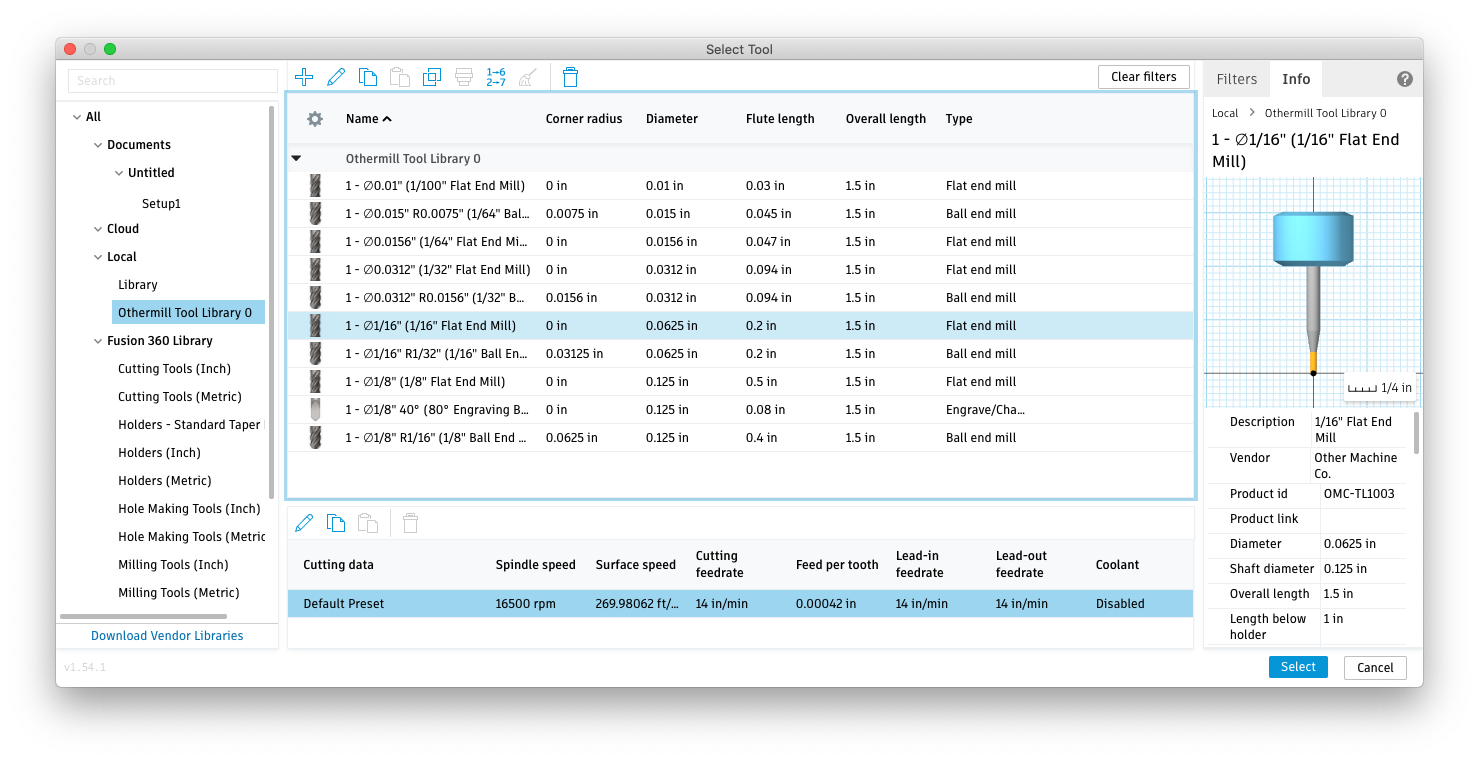

Tool -> select -> 1/16” Flat End Mill

Stepover

- Endmill 1/16” = 1.5875

- Steopver 50% = 1.5875 x0.5 = 0.79375

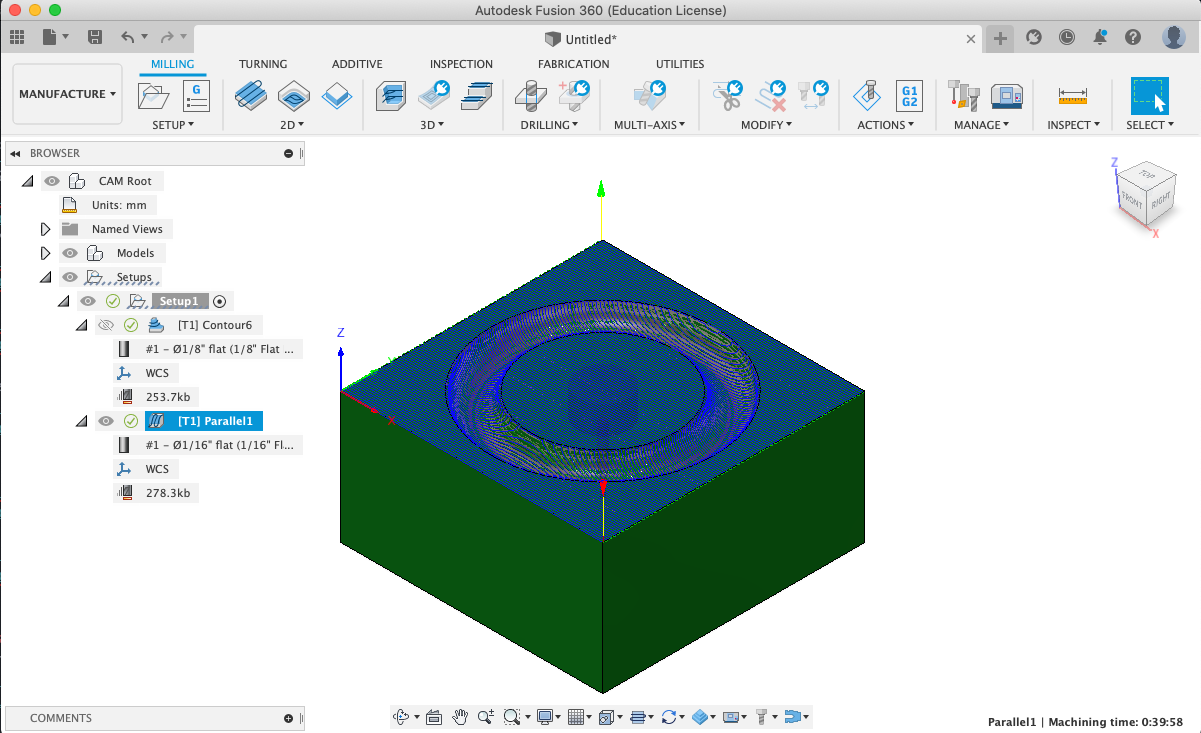

Path made

Simulate

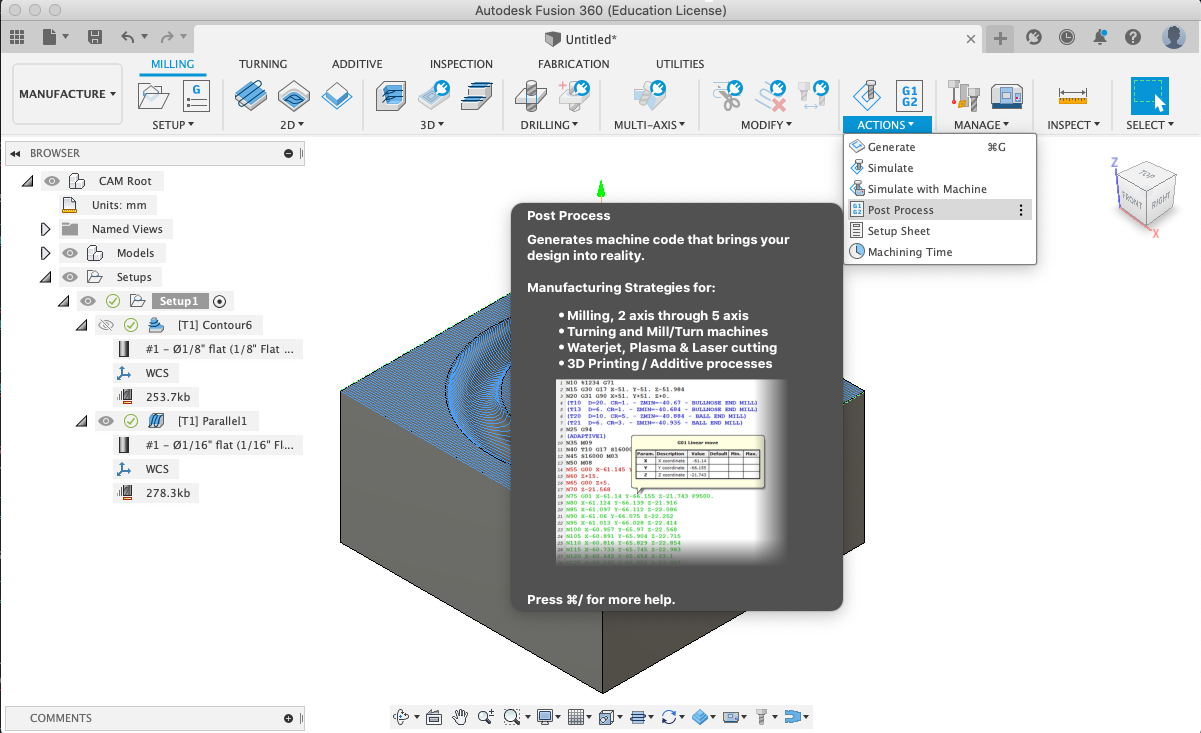

Export G-code¶

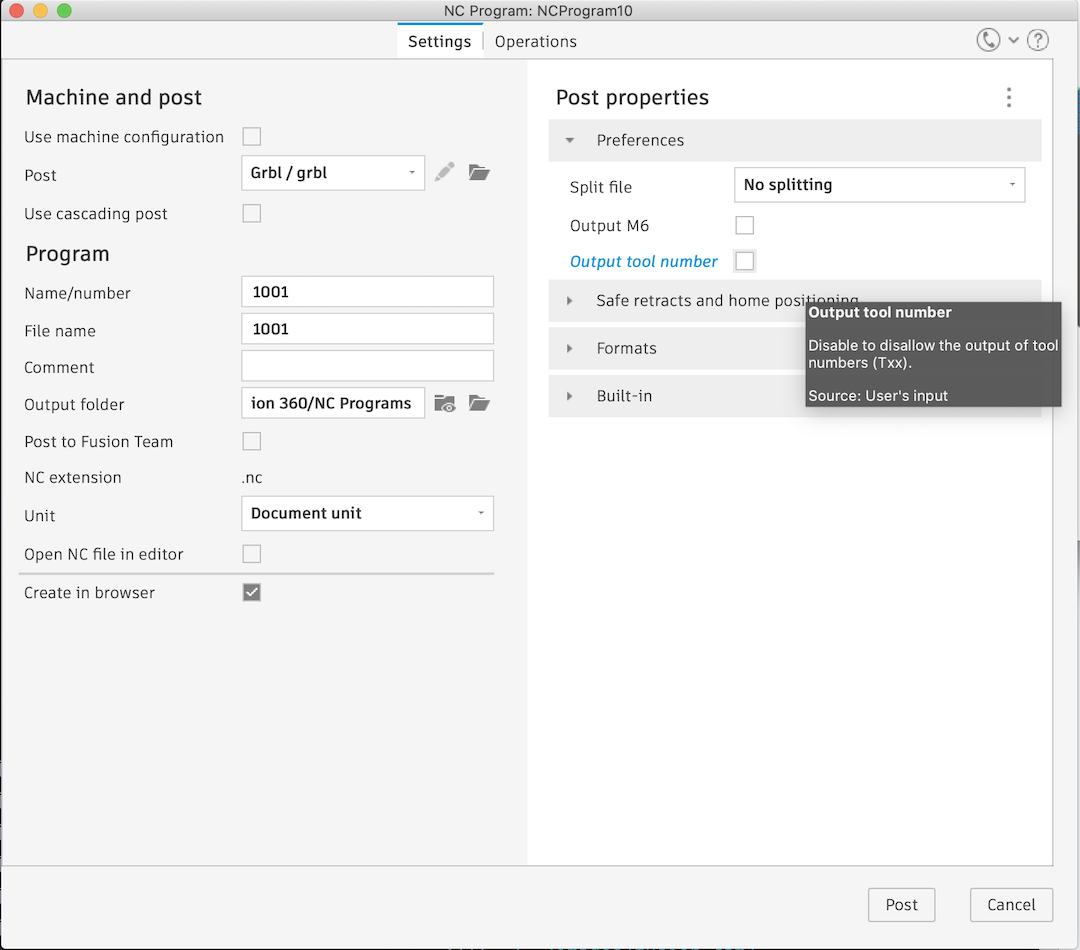

Action -> Postscript

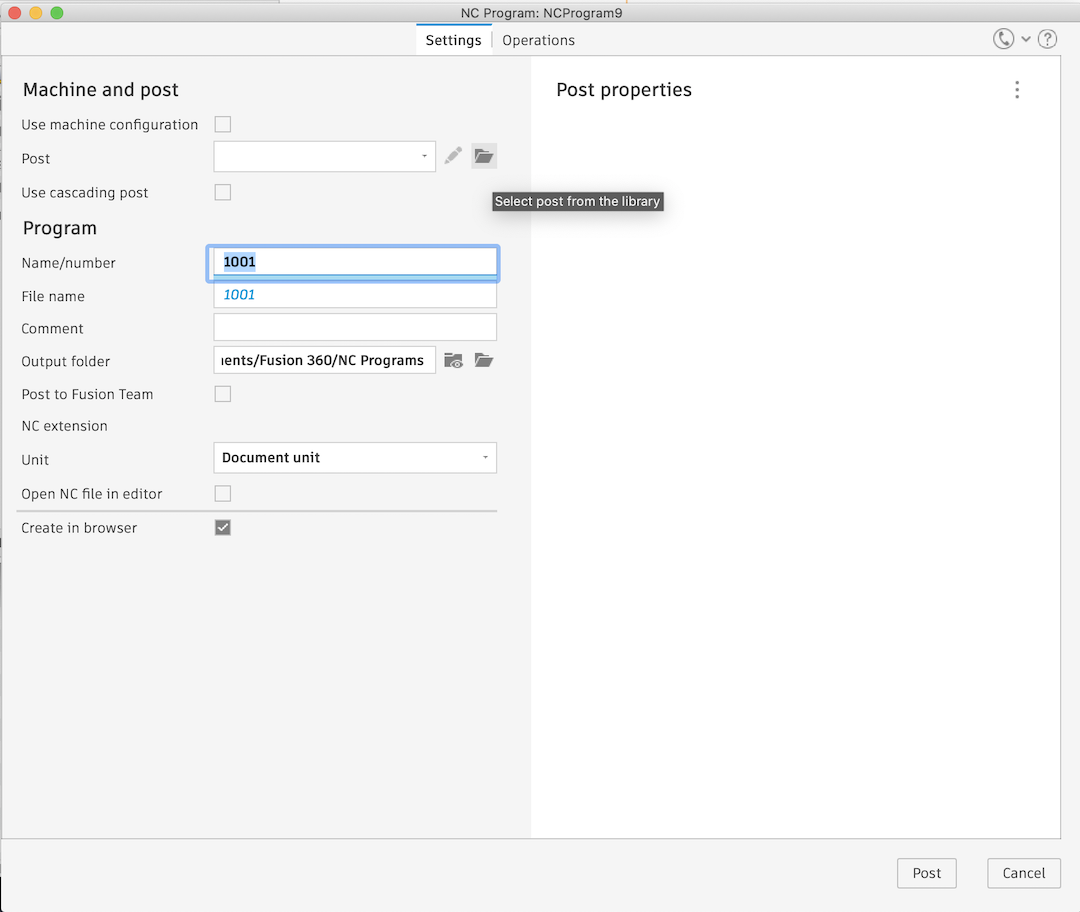

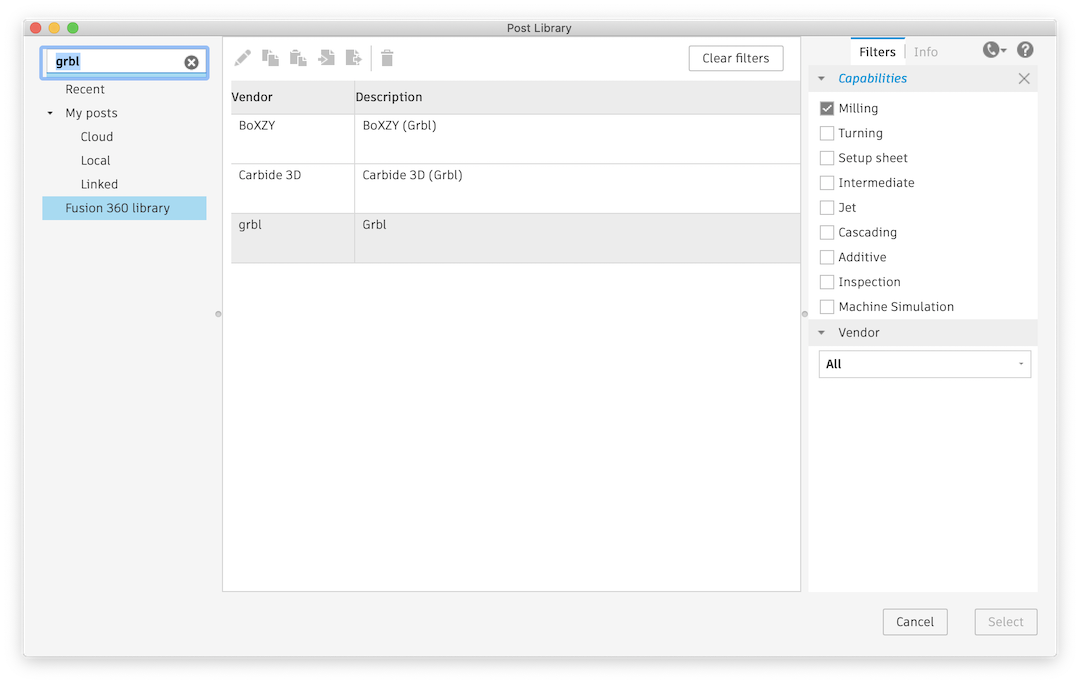

Select “Post” from Library

Search “grbl” and select Grbl

Uncheck both “Output M6” & “Output Tool Number”

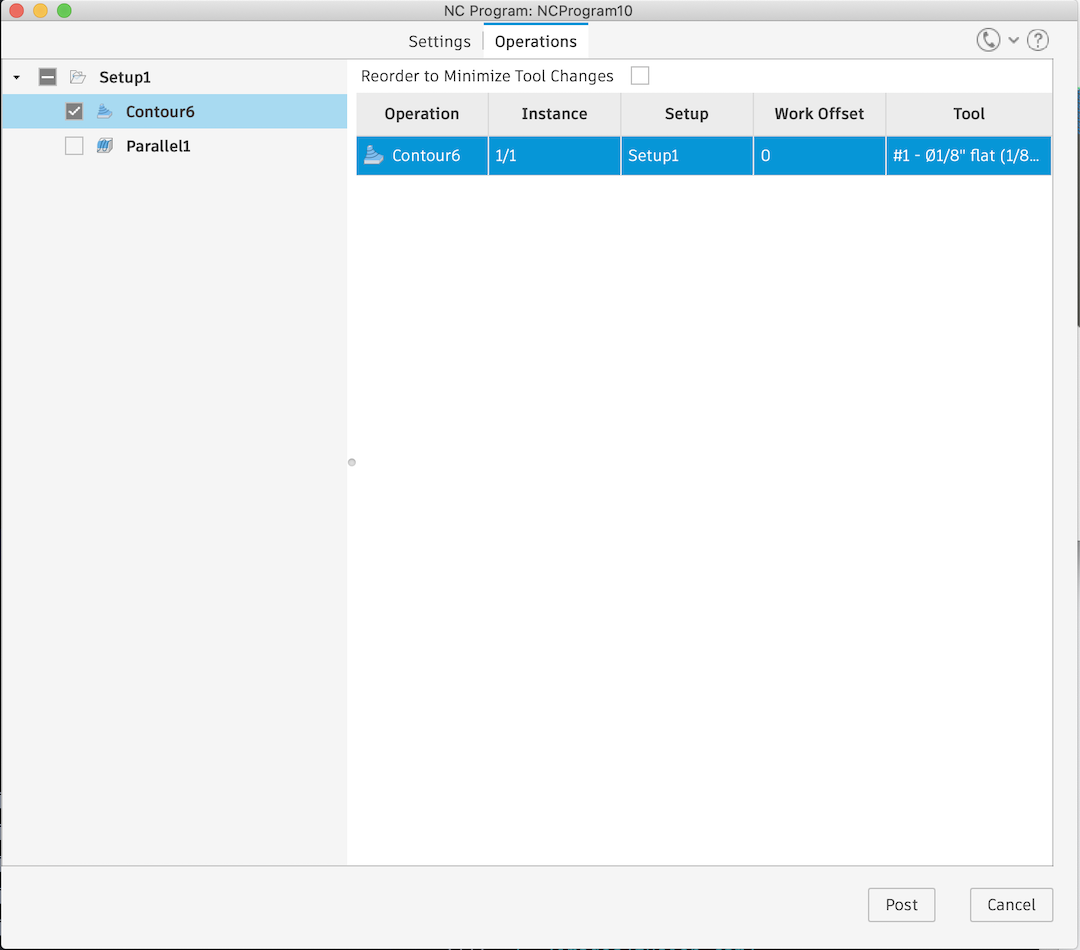

Operation tab -> select setup(s) to use

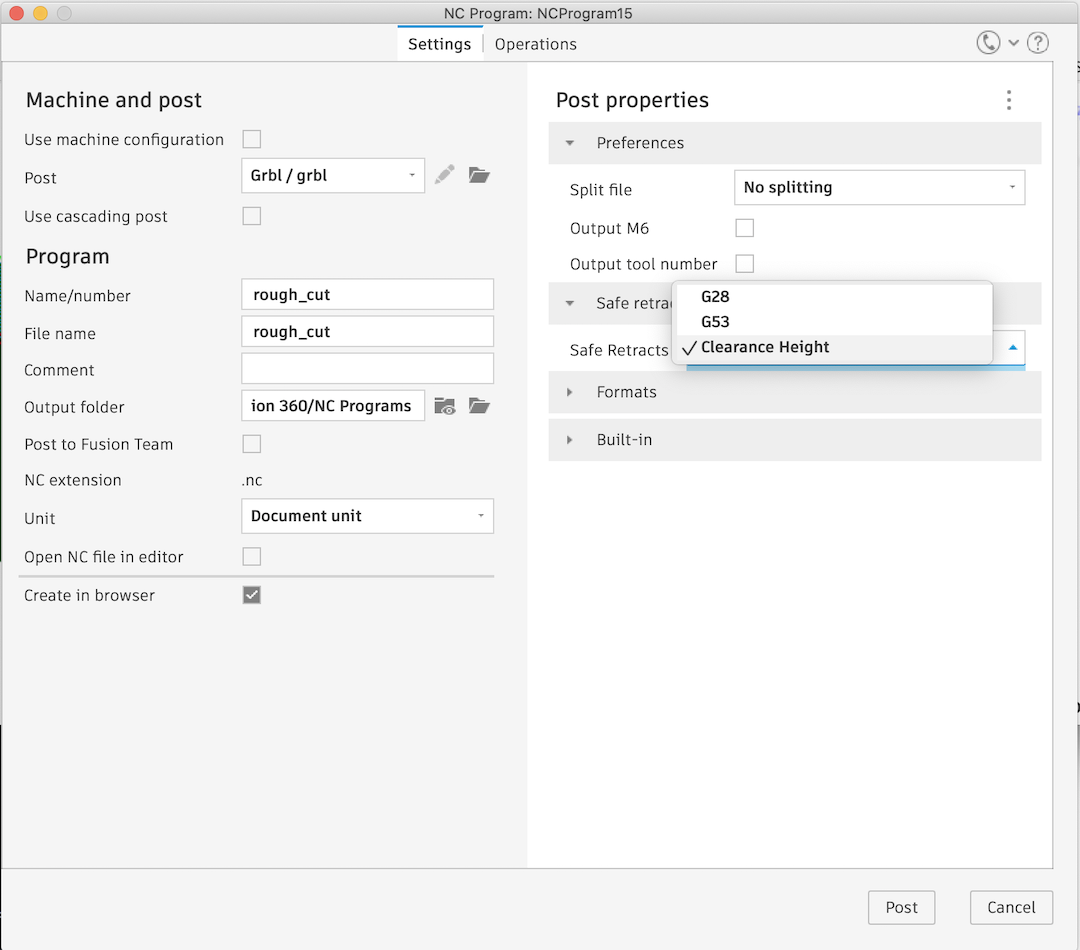

Safe retracts and home positioning -> Clearance Height

Name: rough_cut -> Post to Save .nc file

Clearance Height is set in here

Attention

Do not select them

G28: 機械原点復帰 (Return to Machine Zero Point)

G53: 機械座標系設定 (on-Modal Machine Coordinate Selection)

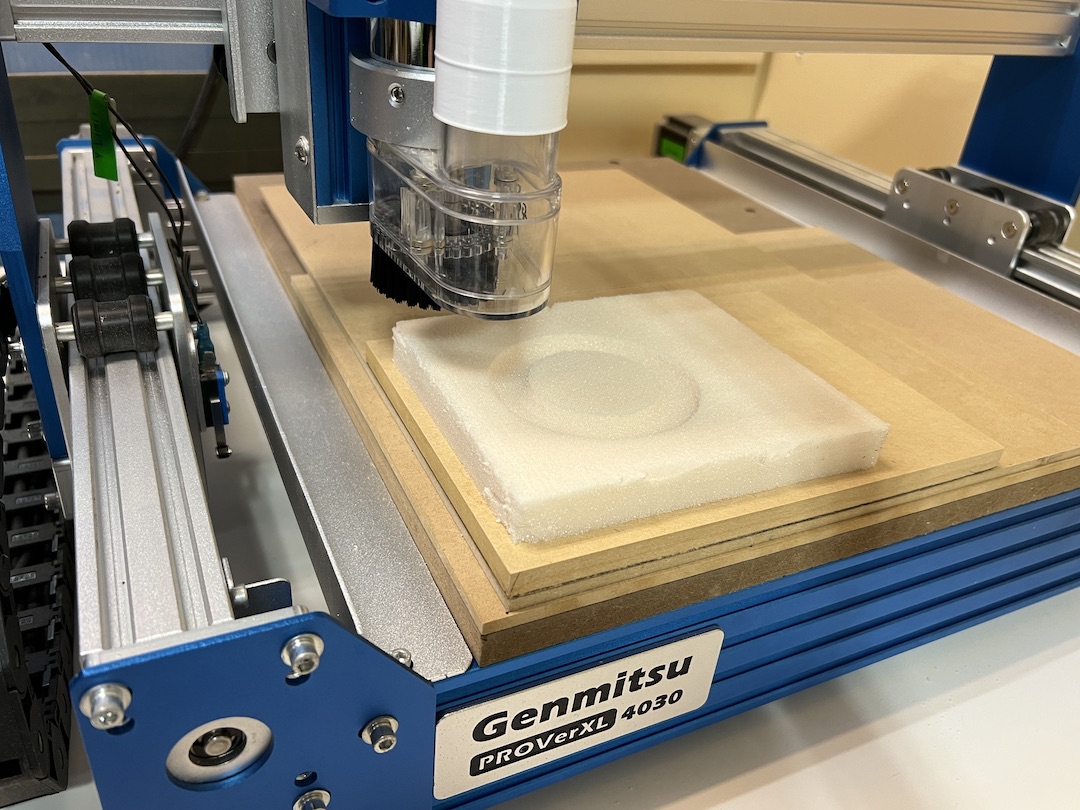

Mill¶

G-sender¶

Mill in this order

- rough_cut.nc

- finish_cut.nc

Milled¶