5. 3D Scanning and printing¶

Instruction¶

Group Assignment

- test the design rules for your 3D printer(s)

- Document your work and explain what are the limits of your printer(s) (in a group or individually)

- Document your work to the group work page and reflect on your individual page what you learned

Individual Assignment

What I did in Week5¶

- Test the 3D Printer : Angle, Overhang, Bridge, Wall-thickness, hole test → In this page

- Design and 3D print an object → individual page

- 3D scan an object, try to prepare it for printing → individual page

The 3D Printer we used : Creality Ender-3 V2¶

Technical Specifications (Ender-3 V2 FDM 3D Printer Properties)

| index | Technical Specifications |

|---|---|

| Modeling Technology | FDM(Fused Deposition Modeling) |

| Printing Size | 220x220x250mm |

| Filament | PLA/TPU/PETG |

| Working Mode | Online or SD card offline |

| Supported OS | MAC/WindowsXP/7/8/10 |

| Filament Diameter | 1.75mm |

| Slicing Software | Simplify3d/Cura |

| Machine Size | 475x470x620mm |

| Product Weight | 7.8KG |

| Package Weight | 9.6KG |

| Power Supply | Input AC 115V/230V; Output DC 24V 270W |

| Layer Thickness | 0.1-0.4mm |

| Print Precision | ±0.1mm |

| Hotbed Temperature | ≤100° |

Angle Test¶

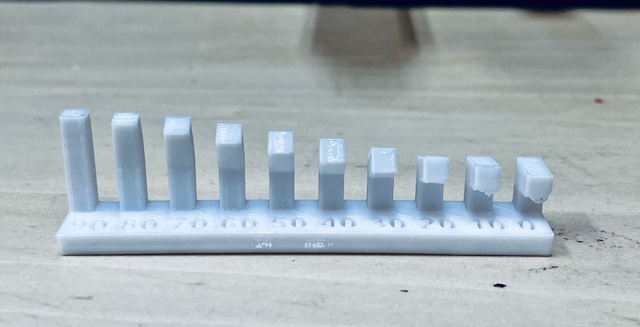

Printed by 3d Printer

Angle test conclusion:

Angles greater than 30 degrees CAN be printed fine.

20 is borderline, and Angles less than 20 degrees CANNOT be printed fine.

→Bending should be limited to 60 digree angle.

Overhang test¶

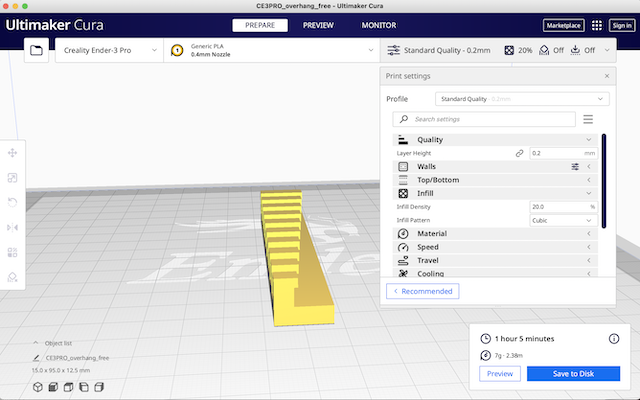

download and convert to gcode by cura

| index | Settings |

|---|---|

| Quality | Standard Quality |

| Quality/Layer height | 0.2mm |

| infill | 20.0% |

| Generate Support | Uncheck |

- printed by 3d Printer

Overhang Test Conclusion:

overhang which length is under 0.2mm can be printed fine.

overhang which length is over 0.3mm cannot be printed fine.

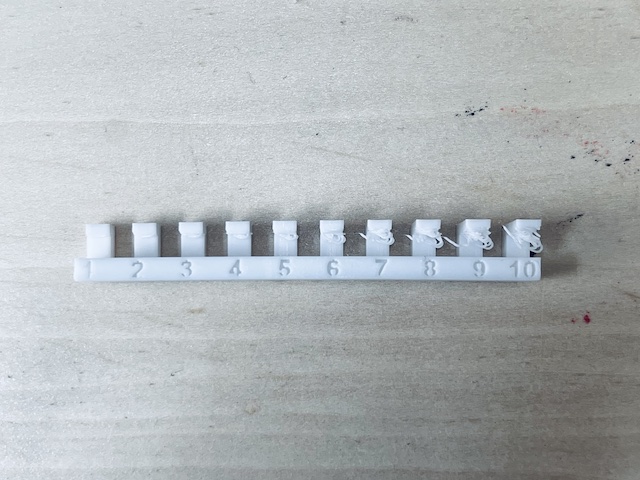

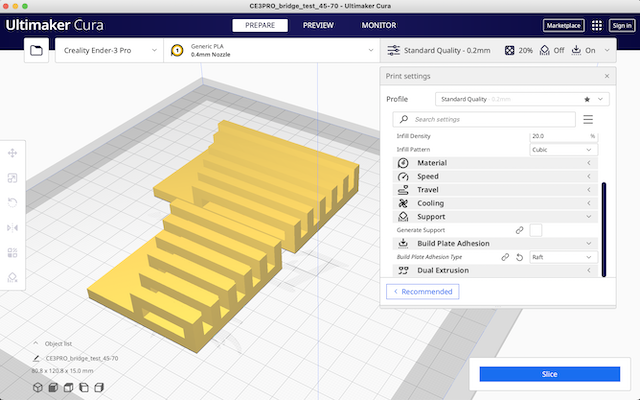

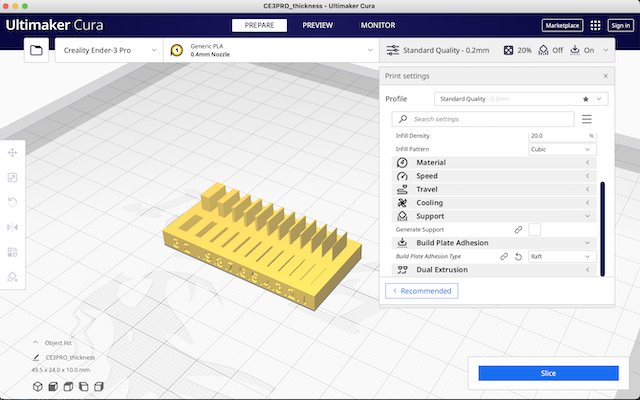

Bridge Test¶

Design the object in Fusion 360 and export to Cura

inside dimensions : 20, 25, 30, 35, 40, 45 mm + 45, 50, 55, 60, 65, 70 mm

Printed out and check wether they can be printed expextedly

Bridge Test Conclusion:

~45mm : printed very clearly just as I intended

50~60mm : printed clearly to some extent

65mm~ : printed bad-looking

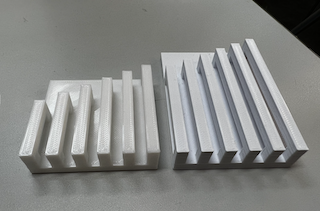

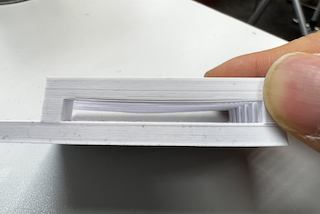

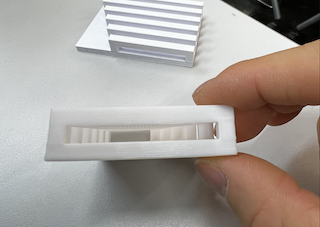

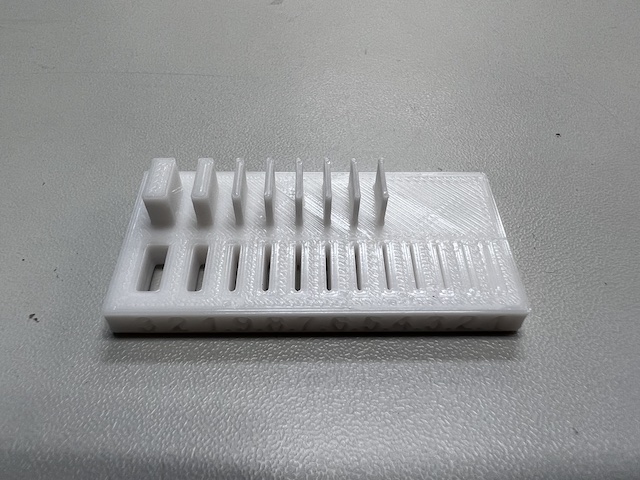

wall_thickness Test¶

Conclusion:

Upper row (Fence) : Shapes less than 0.4 mm thick are not output. Output is available for sizes larger than 0.5 mm.

Downer row (Grooves) : grooves smaller than 0.3mm cannot be output. thicker than 0.4mm are ok

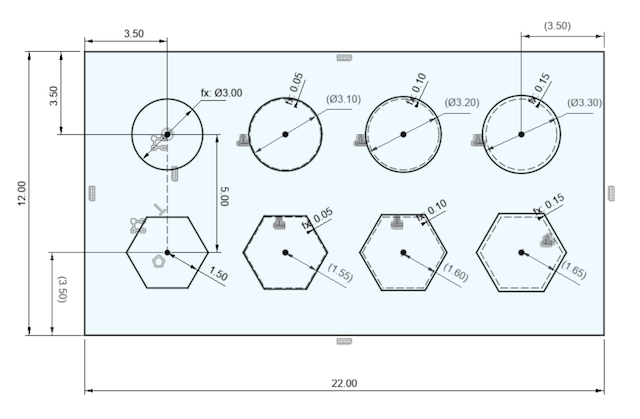

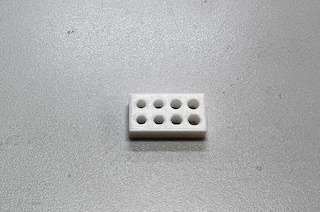

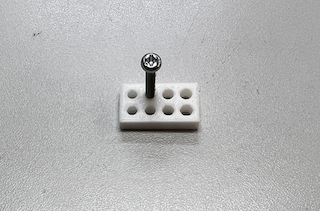

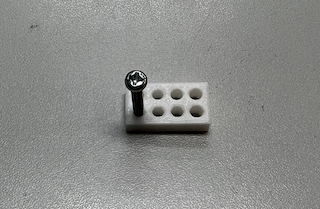

M3_hole_test¶

printed out

Conclusion:

the shape of circle (upper row) : the hole of second from left (3.1, fx : 0.05) is just-fit

the shape of hexagon (lower row) : the hole of the first from left (3.0) is just-fit