3. Computer controlled cutting¶

nueval¶

- nueval

- Login with fablabs.io

- Student’s checklist -> Send Message to Instructor(in English) -> Local evaluation

- Progress -> Completed (Assignment done)

- (Local eval) Completed x 2 -> Request to Global Evaluation

- Global Evaluator will be assigned -> Global Evaluation starts

- (Global eval) Completed all + Final Presentation -> Graduate!

Google Photo¶

- Share photos

Group assignment¶

- kannai site

- repo

- Project information -> Member -> Student_name(Maintainer)

- Assessment

Document your work to the group work page and reflect on your individual page what you learned

% cd ~

% cd repo

% git clone git@gitlab.fabcloud.org:academany/fabacademy/2022/labs/kannai/site.git

% ls

site

% mv site fa2022_kannai_site

% git clone git@gitlab.fabcloud.org:academany/fabacademy/2022/labs/kannai/site.git fa2022_kannai_site

Weekly_Group_Assignments -> week3.md¶

% brew install tree

% cd repos/fa2022_kannai_site

% tree

.

├── README.md

├── agreements

│ ├── agreements_instructor_nk.md

│ ├── agreements_instructor_yt.md

│ └── agreements_labs.md

├── docs

│ ├── Instruction

│ │ ├── images

│ │ │ ├── T-shirts_grad.jpg

│ │ │ └── T-shirts_press.jpg

│ │ ├── tips

│ │ │ └── make_this_site.md

│ │ ├── tips_list.md

│ │ ├── week01.md

│ │ ├── week02.md

│ │ ├── week03.md

│ │ ├── week04.md

│ │ ├──

│ │ ├── week17.md

│ │ └── week18.md

│ ├── Machine_Building

│ │ ├── final-project.md

│ │ └── sample-project.md

│ ├── Weekly_Group_Assignments

│ │ ├── week01.md

│ │ ├── week02.md

│ │ ├── week03.md

│ │ ├── week04.md

│ │ ├──

│ │ ├── week17.md

│ │ └── week18.md

│ ├── about_my_lab

│ │ └── index.md

│ ├── files

│ ├── images

│ │ ├── avatar-photo.jpg

│ │ ├── favicon.svg

│ │ ├── home

│ │ │ ├── FabLabLannai_Logo2022-g.png

│ │ │ ├── FabLabLannai_Logo2022-tate-g.png

│ │ │ ├── FabLabLannai_Logo2022-tate-w.png

│ │ │ ├── FabLabLannai_Logo2022-w.png

│ │ │ ├── logo_slide.gif

│ │ │ ├── logo_slide_w.gif

│ │ │ ├── painting.jpg

│ │ │ └── tear_deer.gif

│ │ ├── sample-photo.jpg

│ │ ├── sample-pic-2.jpeg

│ │ └── week01

│ │ └── assignment-photo.jpg

│ ├── index.md

│ └── stylesheets

│ └── extra.css

├── mkdocs.yml

└── requirements.txt

Weekly Group Assignment¶

docs/Weekly_Group_Assignments/week03.md

docs/images/week03/photo.jpg% cd repos/fa2022_kannai_site % git pull // edit % git add . % git commit -m "add week03.md" % git push

Licenses¶

- Fusion360 (Autodesk)

- Fab academy

- Education License

- Fab Lab

- FabLab Kannai’s account

- Generative design

- FabLab Kannai’s account

- Fab academy

Preparation for next week¶

Electronics Production

group assignment:

characterize the design rules for your in-house PCB production process

extra credit: send a PCB out to a board houseindividual assignment:

make an in-circuit programmer that includes a microcontroller:

extra credit: customize the design

mill and stuff the PCB

test it to verify that it works

extra credit: try other PCB processes

MCU¶

| Family | MCU | Interface | in-circuit programmer(Assignment) |

|---|---|---|---|

| AVR | AVR-13216 | UPDI | USB-Serial board & Serial-UPDI board |

| ARM | SAMD11C | JTAG/SWD | FreeDAP board |

| Xtensa | ESP8266ESP32 | Serial | USB-Serial board |

Attention

FA2022 Trend

SAMD11C -> USB-Serial board

To Programm SAMD11C, need another DAP programmer board

(Not FTDI chip)

SAMD11C programming environment¶

- Use any PC and Commercial DAP to program your SAMD11C board

- Use Raspberry Pi3 (Raspberry Pi OS) as OpenOCD to program SAMD11C

- Use Raspberry Pi4 (Ubuntu) and Seeeduino Xiao as DAPLink to program SAMD11C

Preparation¶

- microUSB (16G,32G)

- Raspberry Pi3 /Raspberry Pi4

- Seeeduino Xiao

Group Assignment¶

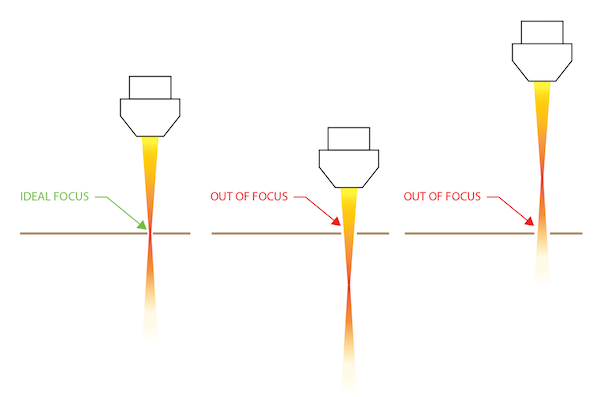

characterize your lasercutter’s focus, power, speed, rate,

kerf, joint clearance and types

Have you answered these questions?¶

- linked to the group assignment page

- Explained how you parametrically designed your files

- Documented how you made your press-fit kit

- Documented how you made your vinyl cutting

- Included your original design files

- Included your hero shots

Hero shots¶

well-taken photos, not snap shots

Laser cutter¶

Universal vls2.3

- 30W CO2

- manual

Material¶

- card board

- A3 or 300x450mm

- about 3mm thickness (need to be measured)

Todo¶

Ref. FA2021

- Focus

- Lens: 2.0 inch (2.54 x2 mm)

- Z Axis resolution 0.1mm

- Defocus +3.0, +2.5, +2.0 +1.5, +1.0, +0.5, 0, -0.5, -1.0

- Power, Speed, Rate

- Find the best parameter from this experiment

.jpg)

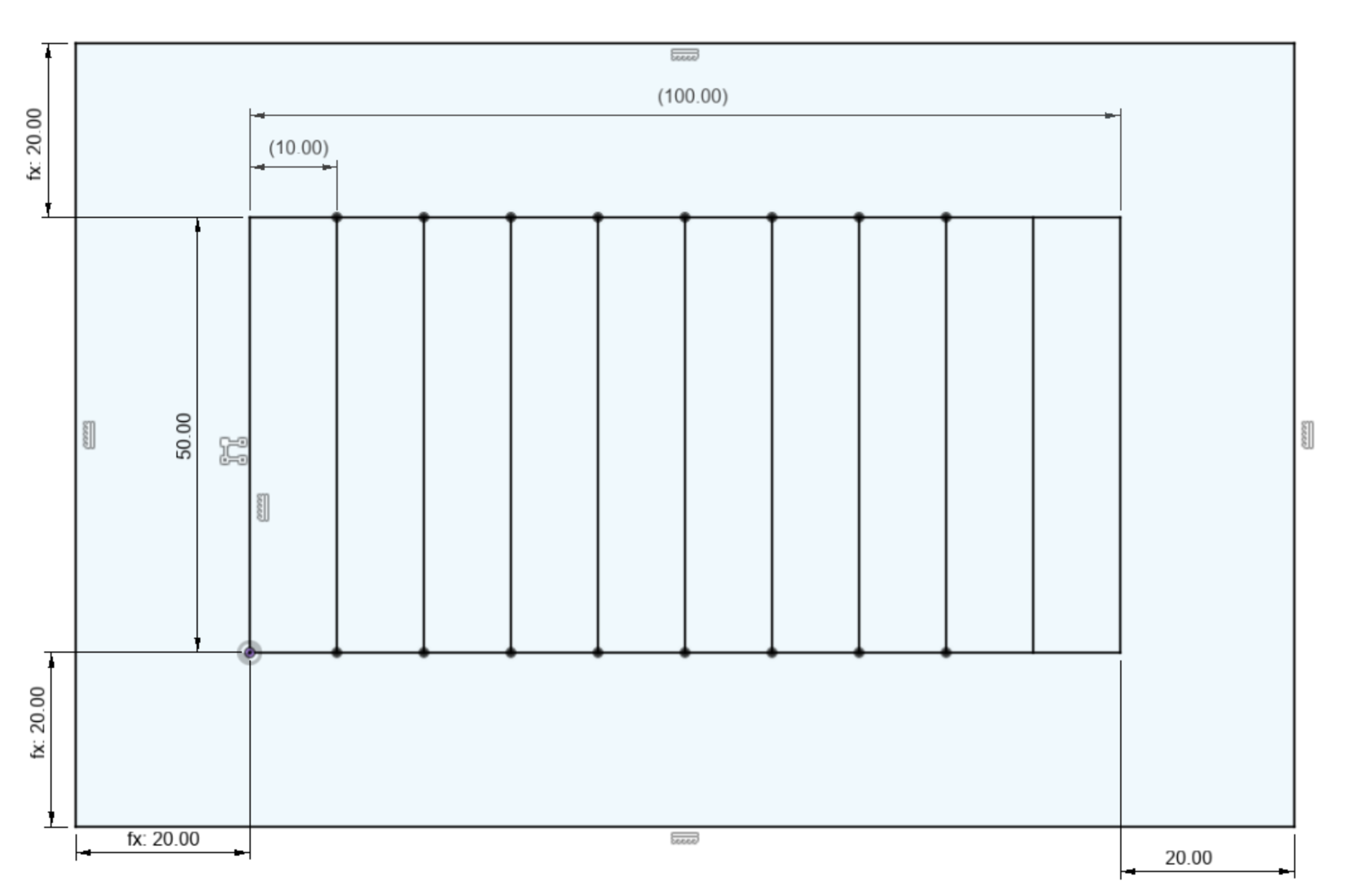

- Kerf

- 10 sticks (11 cuts)

- 1/2 + 9 + 1/2 = 10 Kerf

Download: f3d

Download: f3d

Tips

Markdown

[](path/to/link.f3d "mouse-over-text")

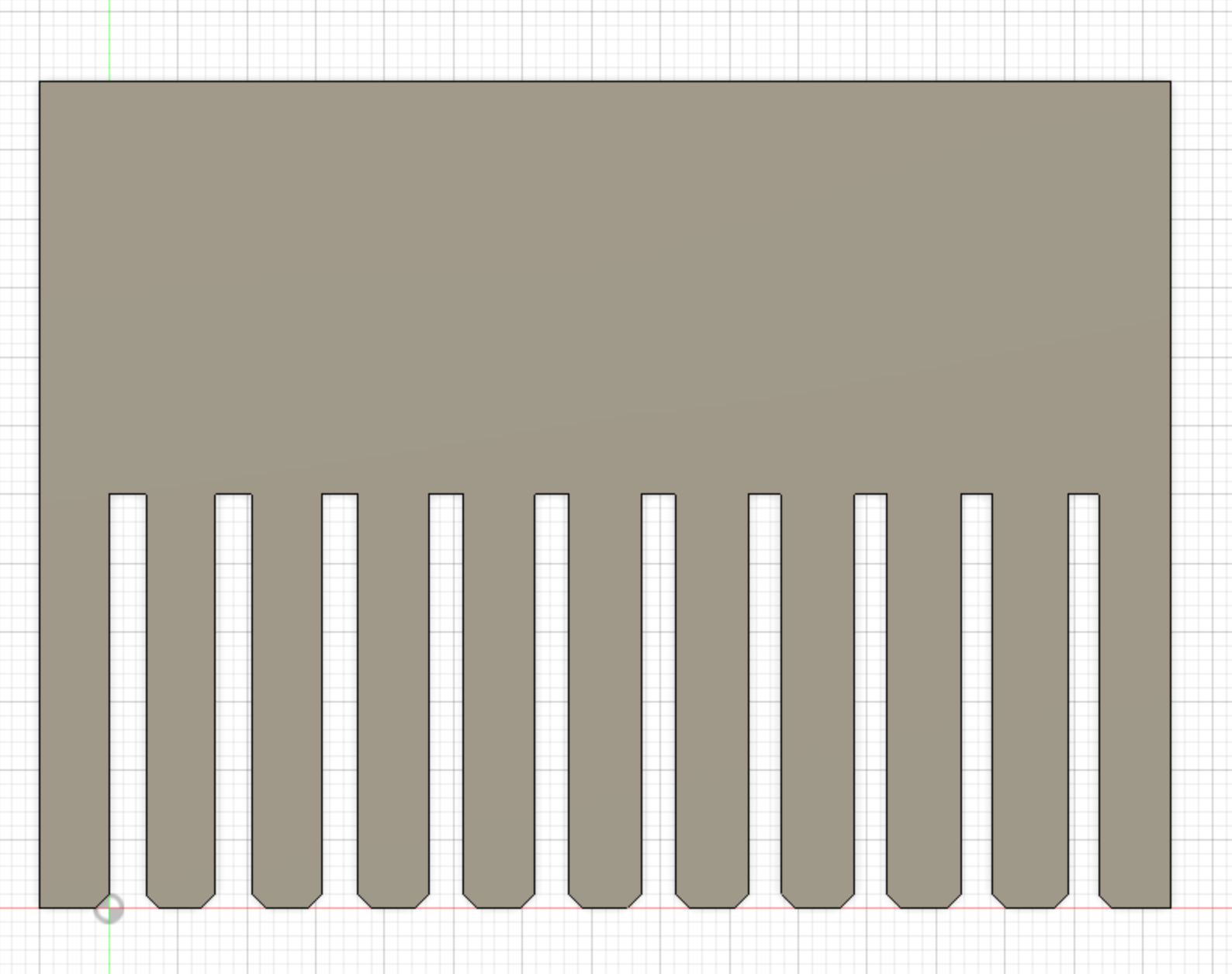

- Joint Clearance fro pressfit

- Comb

Download: f3d

Download: f3d

- Comb

Individual Assignment¶

cut something on the vinylcutter

design, lasercut, and document a parametric construction kit,

accounting for the lasercutter kerf,

which can be assembled in multiple ways,

and for extra credit include elements that aren’t flat

what you learned from Group assignment¶

- Add link of this week’s group assignment page

- Add What you learned from Group assignment

ToDo¶

Parametric construction kit¶

-

Fusion360

- parametric design

- Kerf

- Clearance

- Joint

- parametric design

-

elements that aren’t flat

- Kerf bending

- Inkscape Extension: Living Hinge Creator

- Kerf cut: Trotec Wood and acrylic sheets bending applications

- Kerf bending

Vinylcutter¶

silhouette CAMEO

Silhouette Studio

- Download images from web or design your original

- Cut Vinyl sheet

- Laptop Sticker

- Sand Blast Stencil > Glass

- Ref. last year

- Cut Rubber sheet

- Heat Press > T-shirt