Wax milling with mods and Genmitsu PROVerXL4030¶

Material and Machine¶

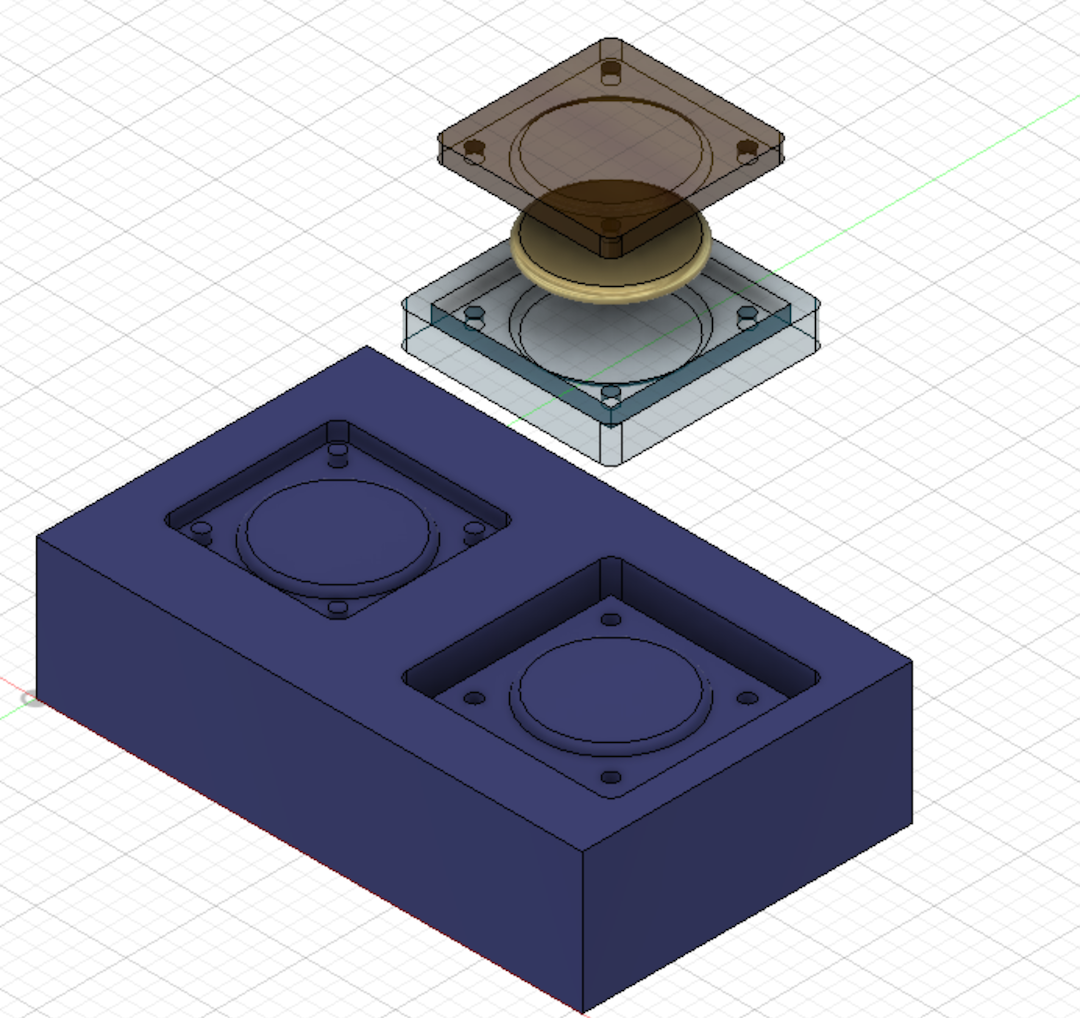

- Machinable wax

- size: 152mm x 92mm x 39mm (real size is smaller)

- Machines

- Genmitsu PROVerXL

- work area: 400mm × 300mm × 110mm

- Genmitsu PROVerXL

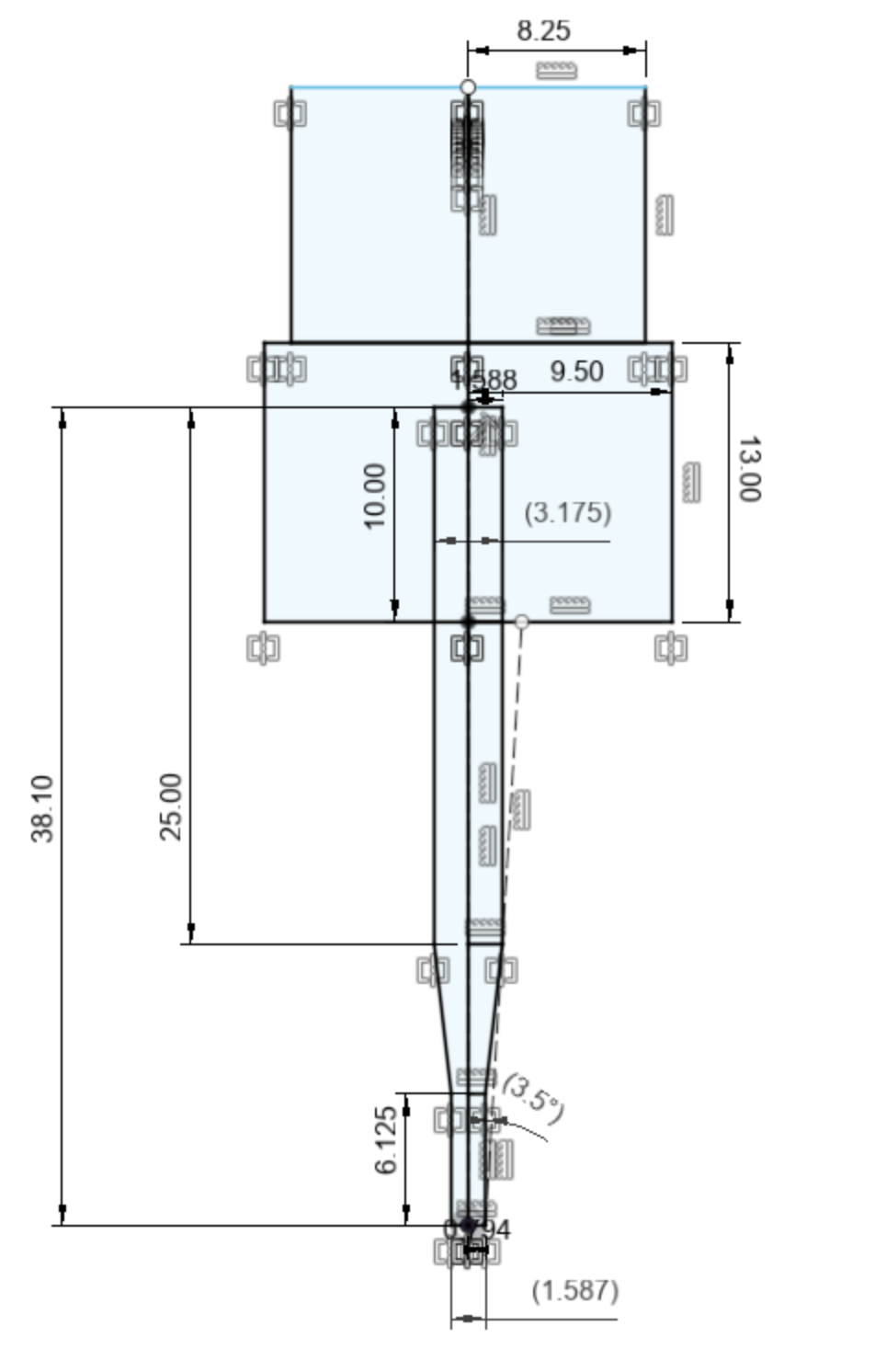

- Endmill

- Rough cut

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

- Tool_dia: 1/8” =3.175mm

- OverAll Length: 2-1/4”(2.25”) =57.15mm

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

- Finish cut

- 0.0625” DIA 2FL SE AlTiN 1/16

- Tool_dia: 1/16” =1.5875mm

- OverAll Length: 1-1/2”(1.5”) =38.1mm

- 0.0625” DIA 2FL SE AlTiN 1/16

- Rough cut

3D Design¶

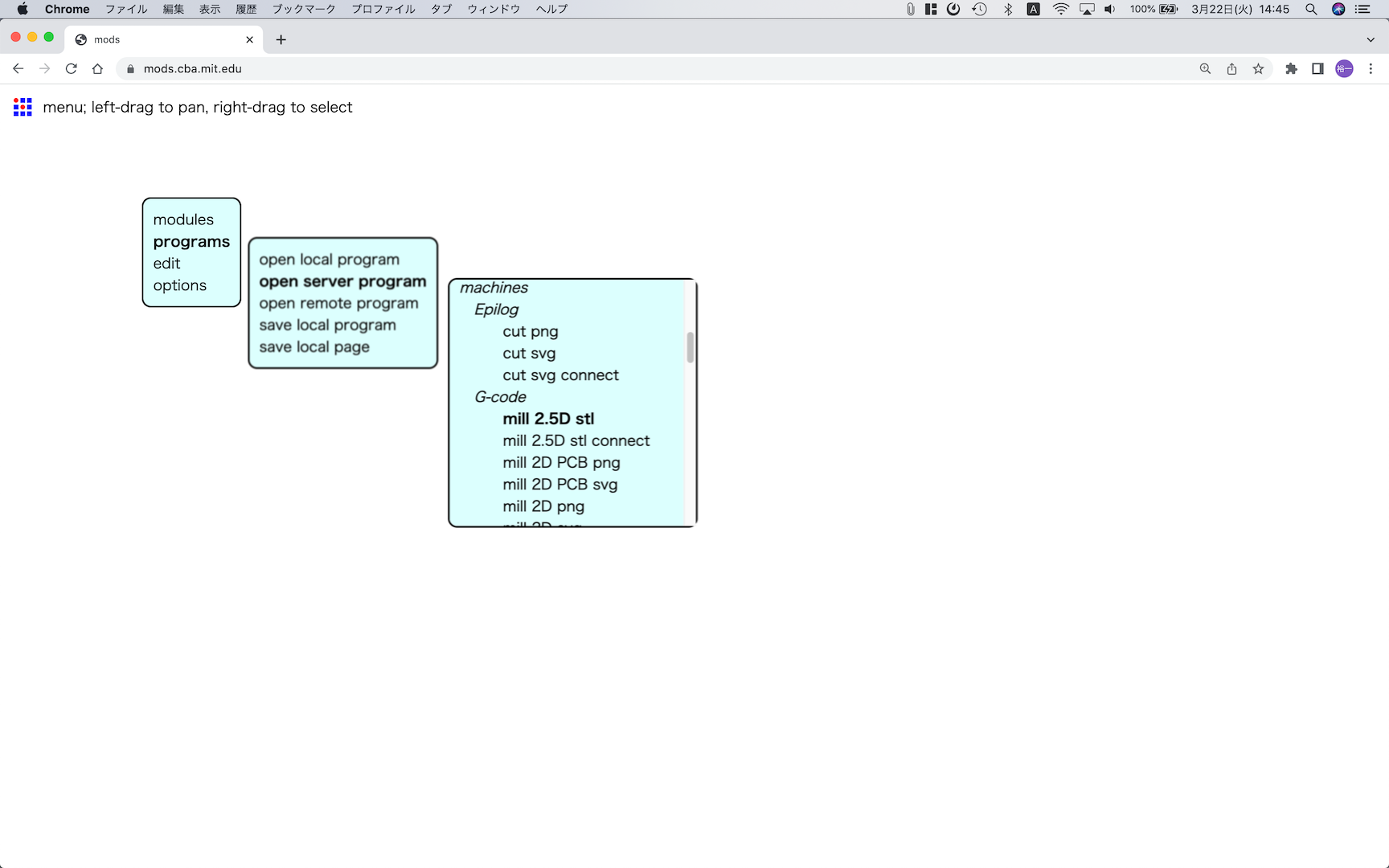

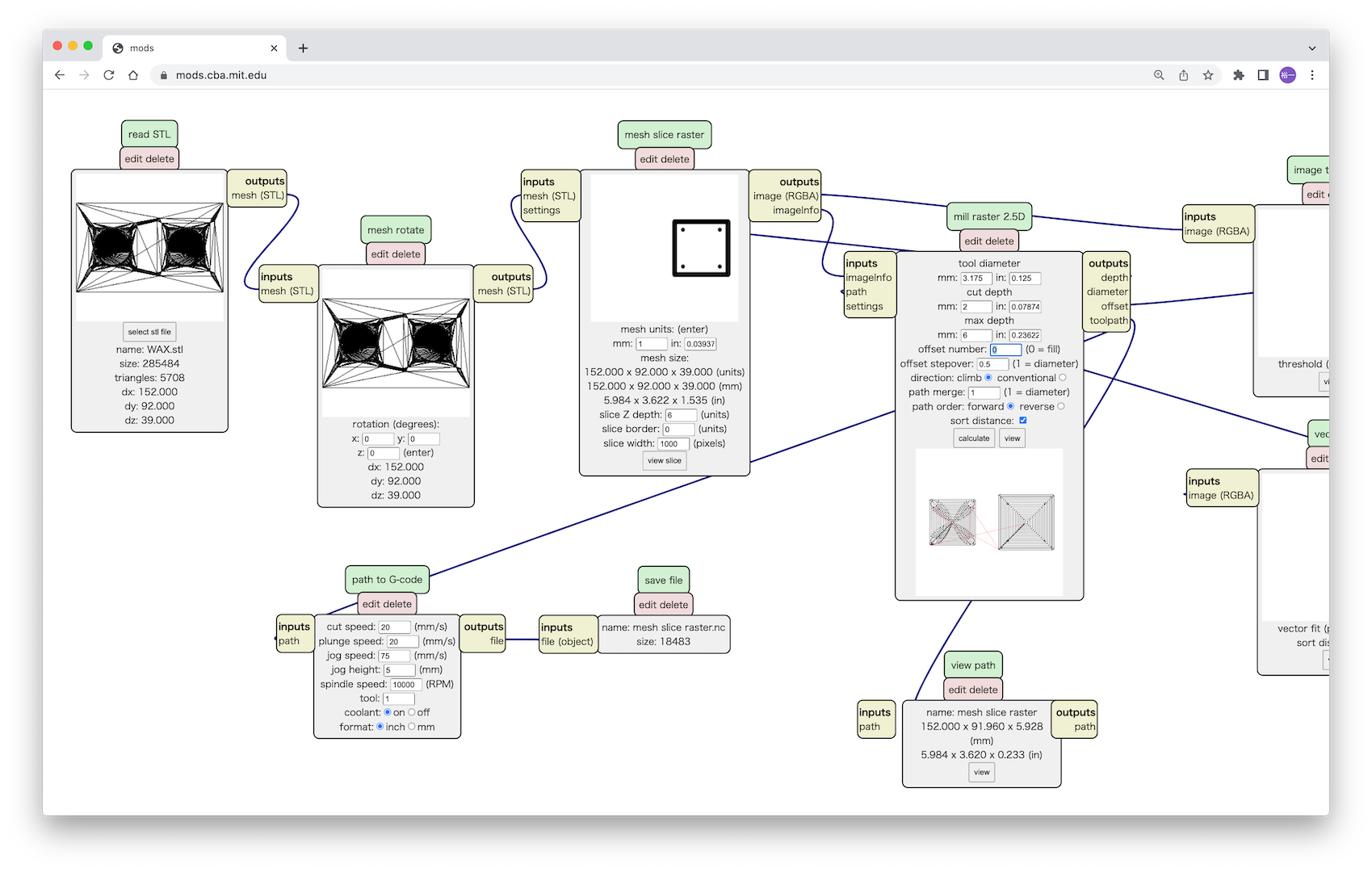

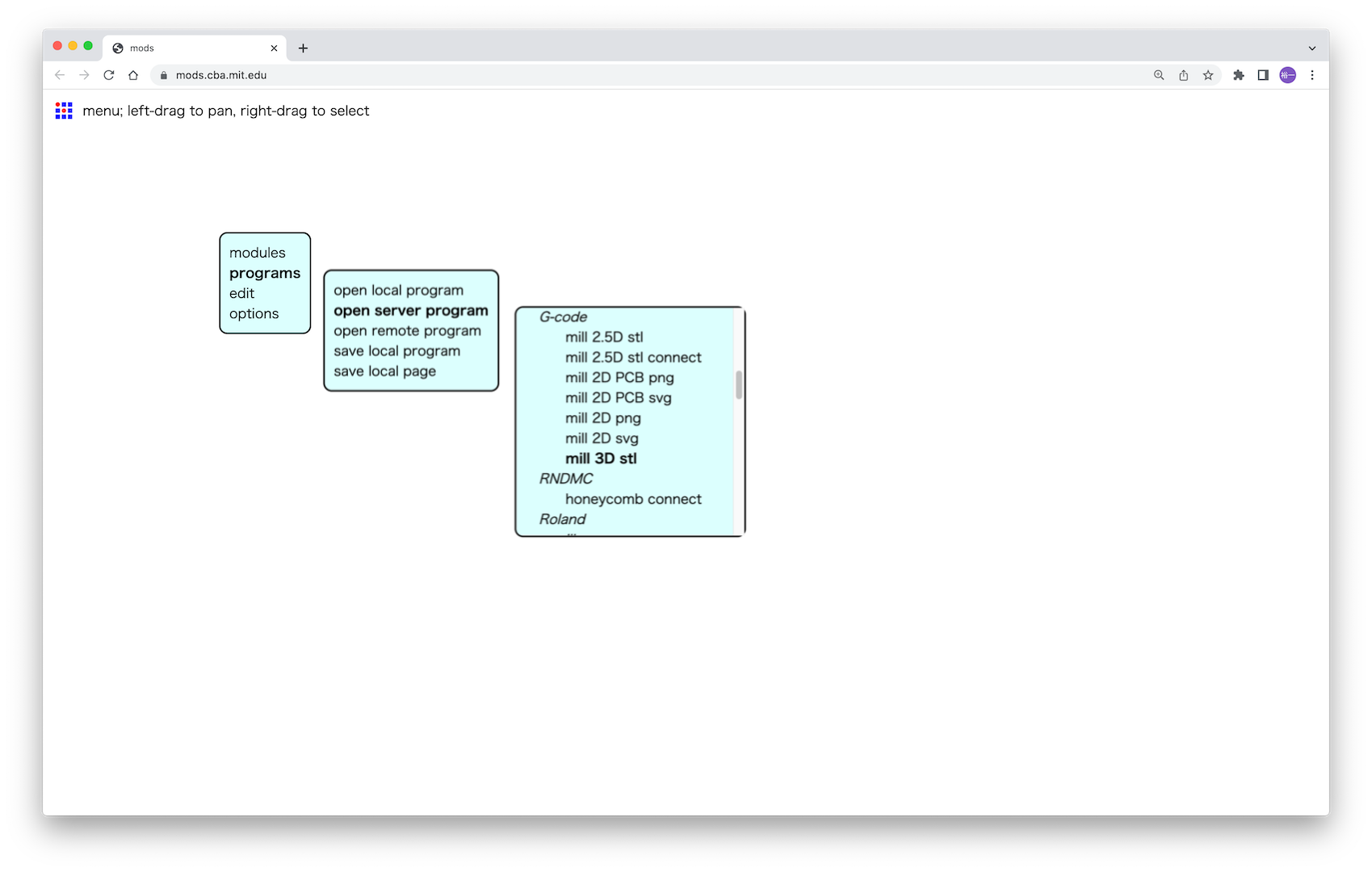

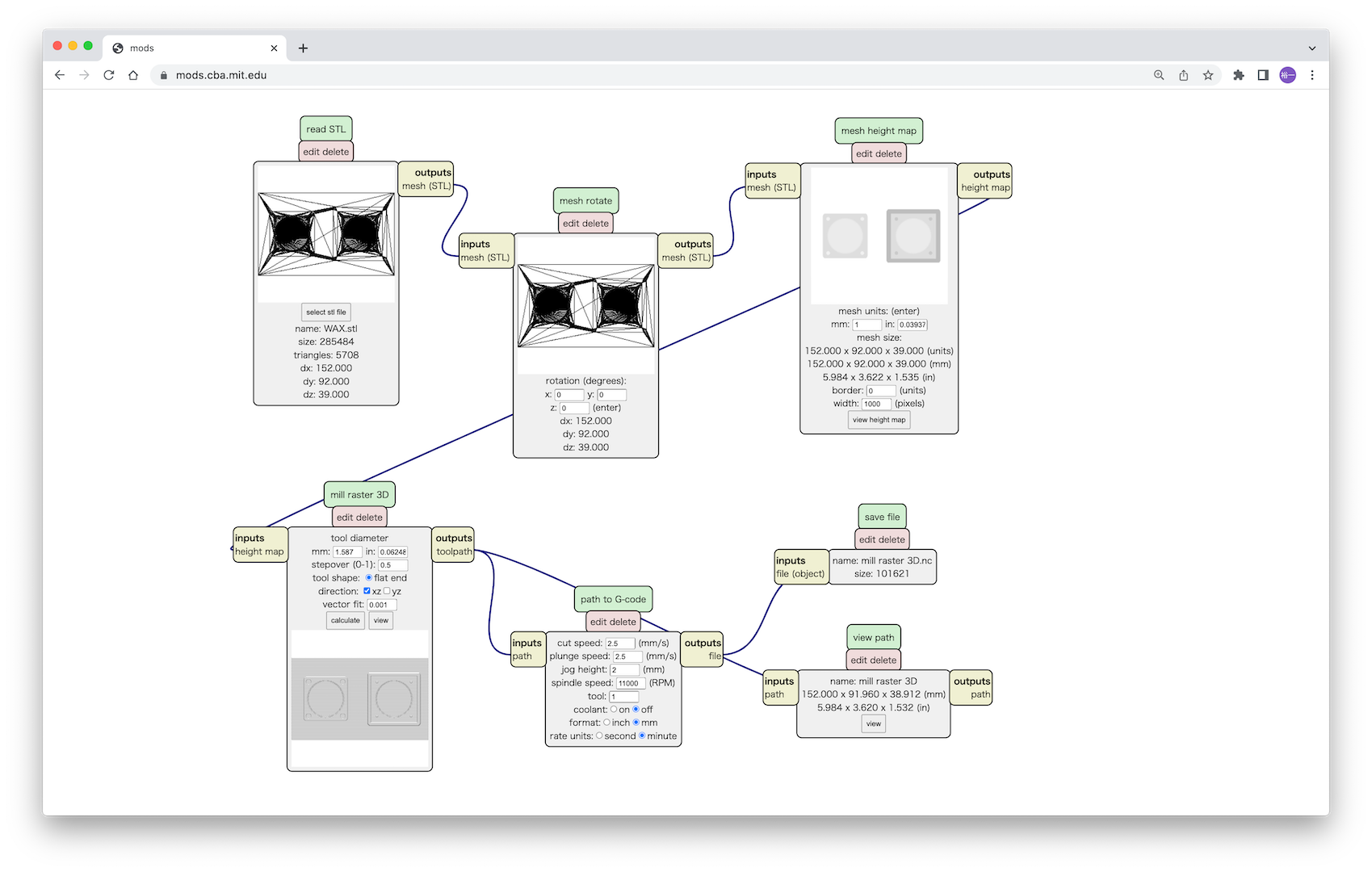

mods¶

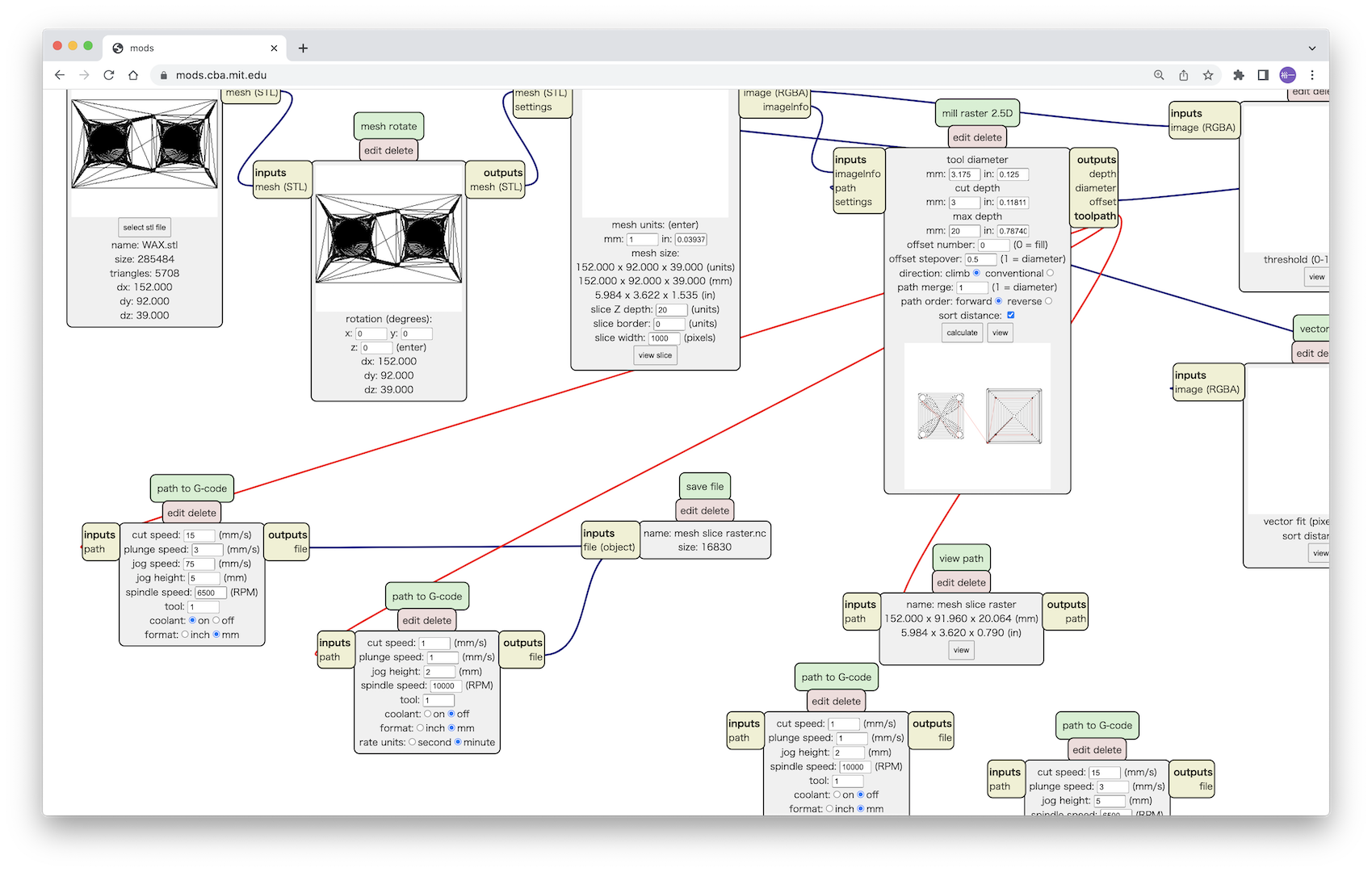

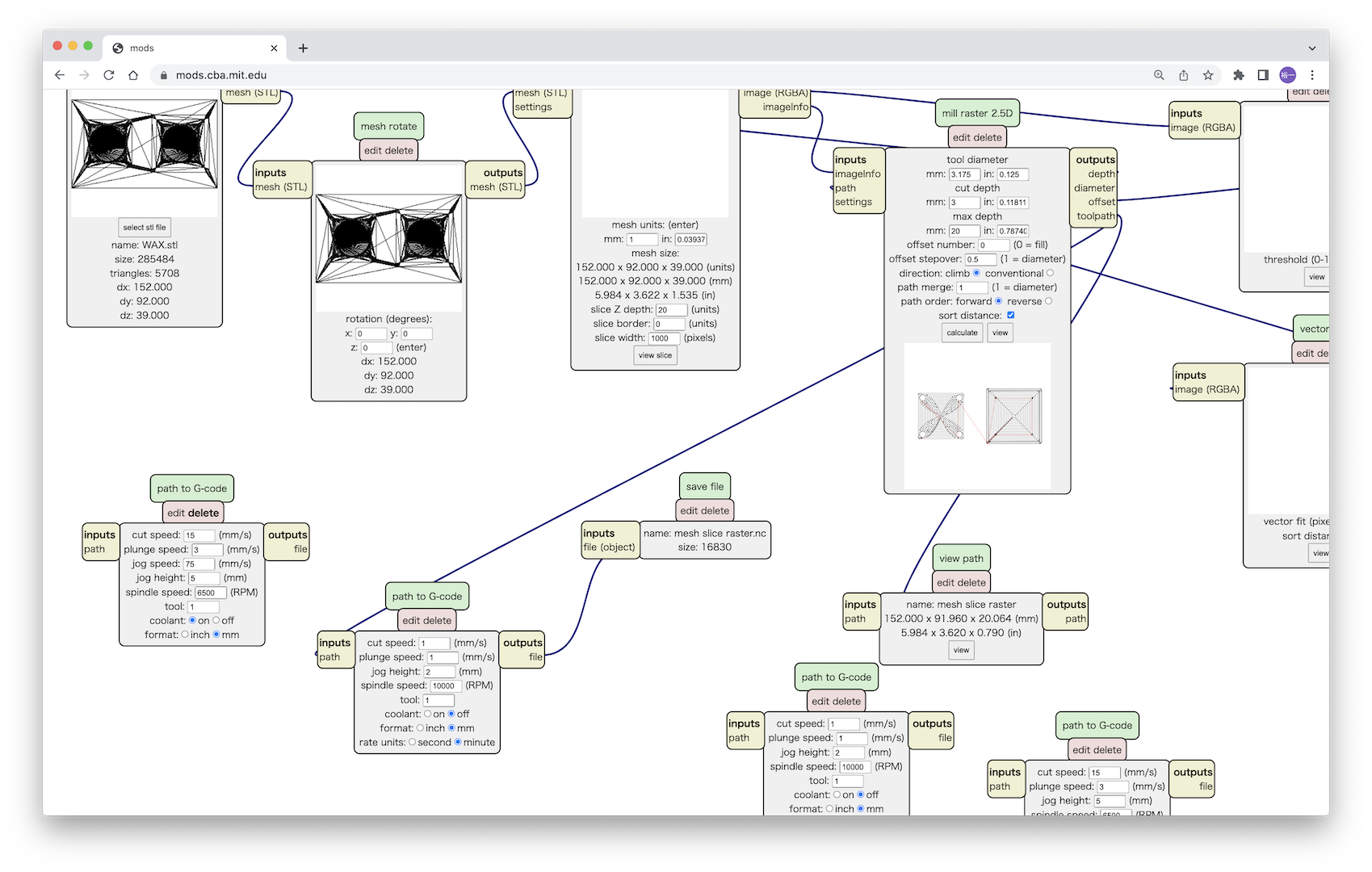

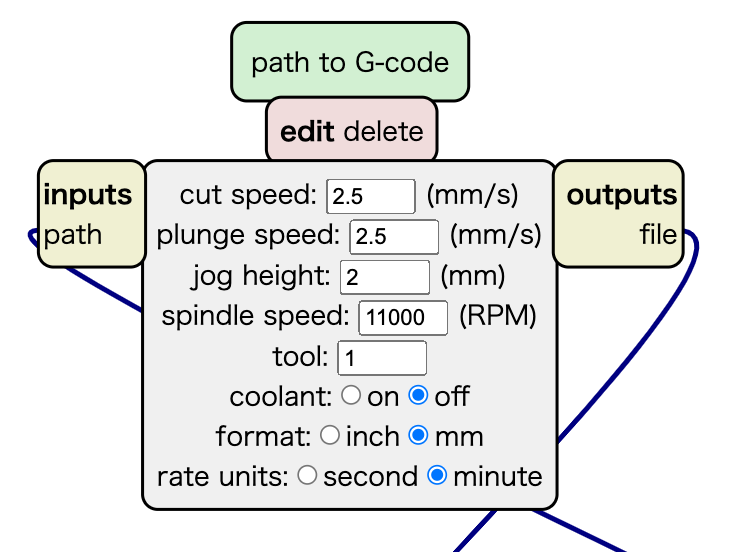

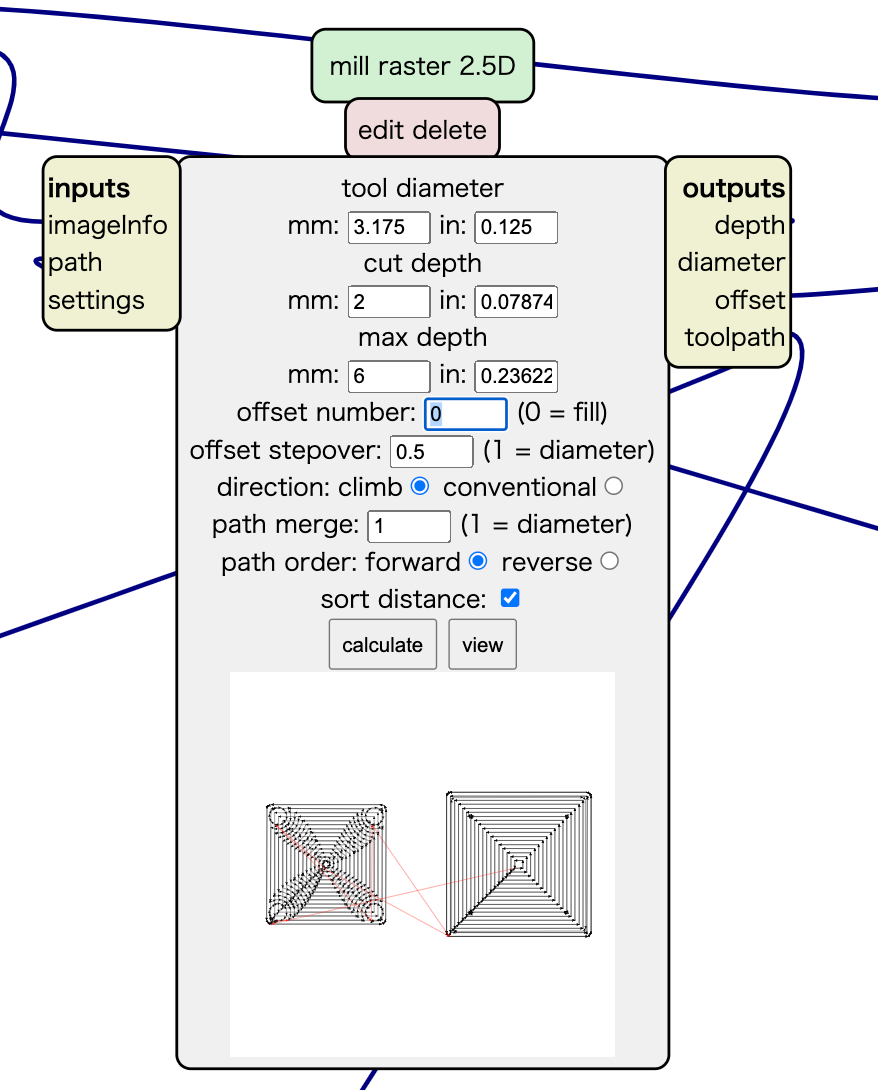

Rough cut¶

Click calculate to make path and download .nc file

Note

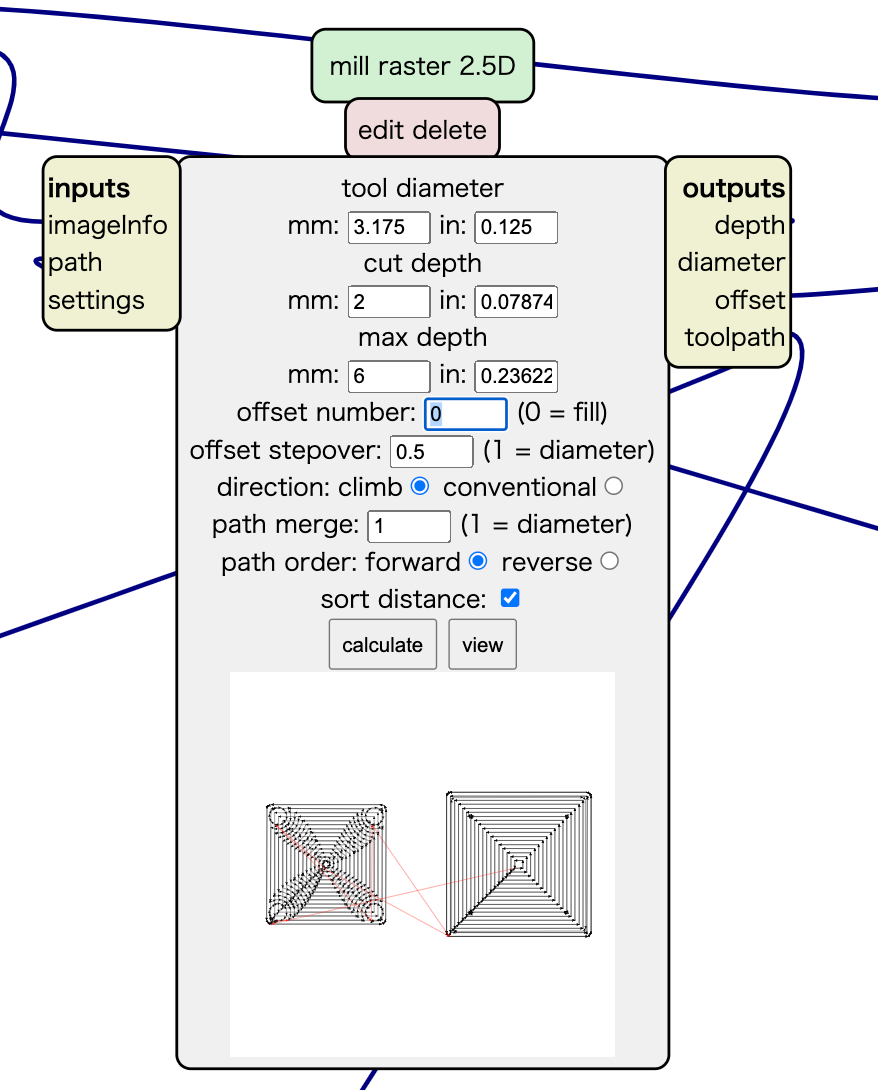

In mill raster 2.5D node, Set offset number: 0 ( 0 =fill)

Important

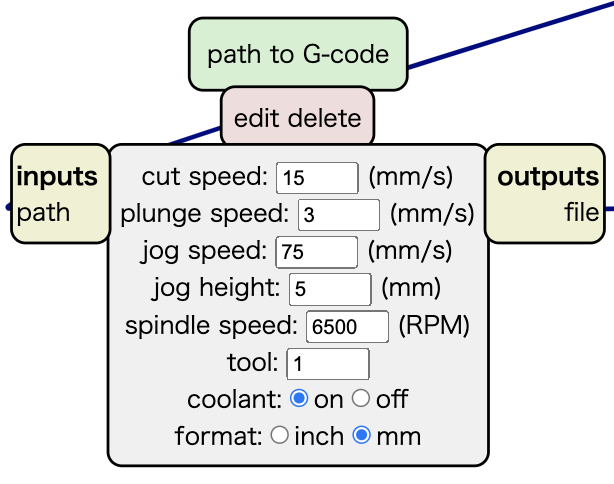

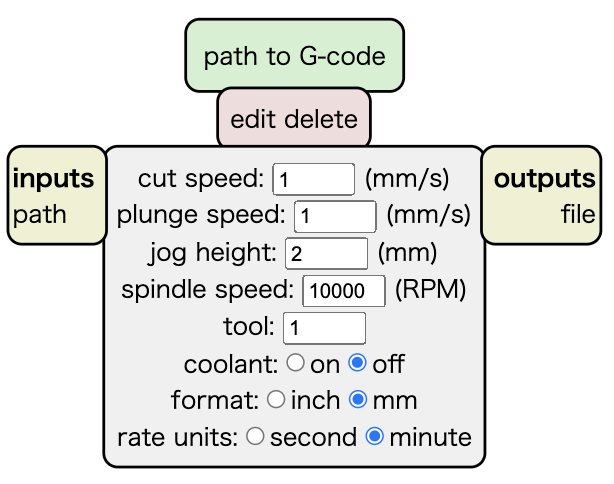

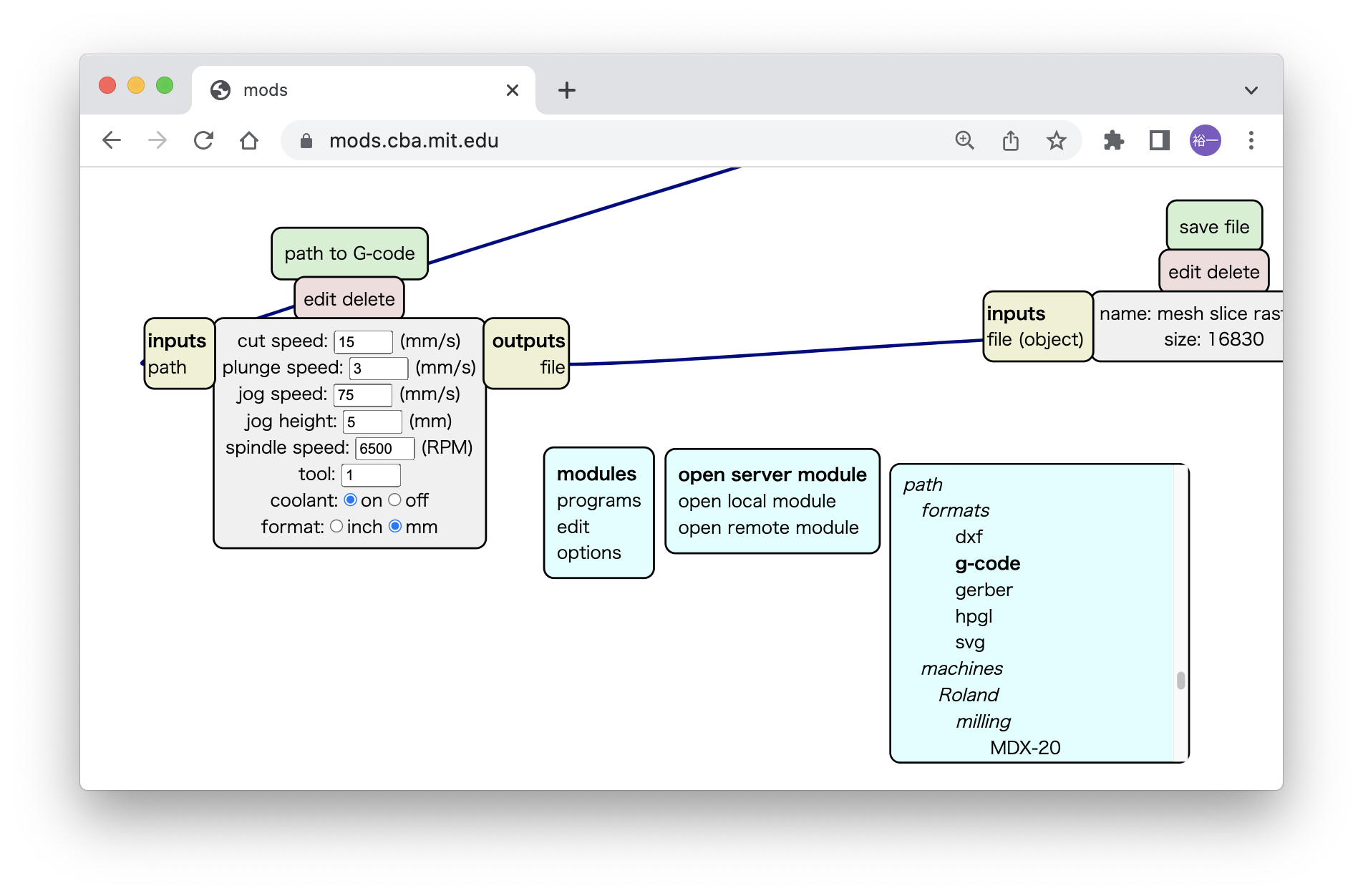

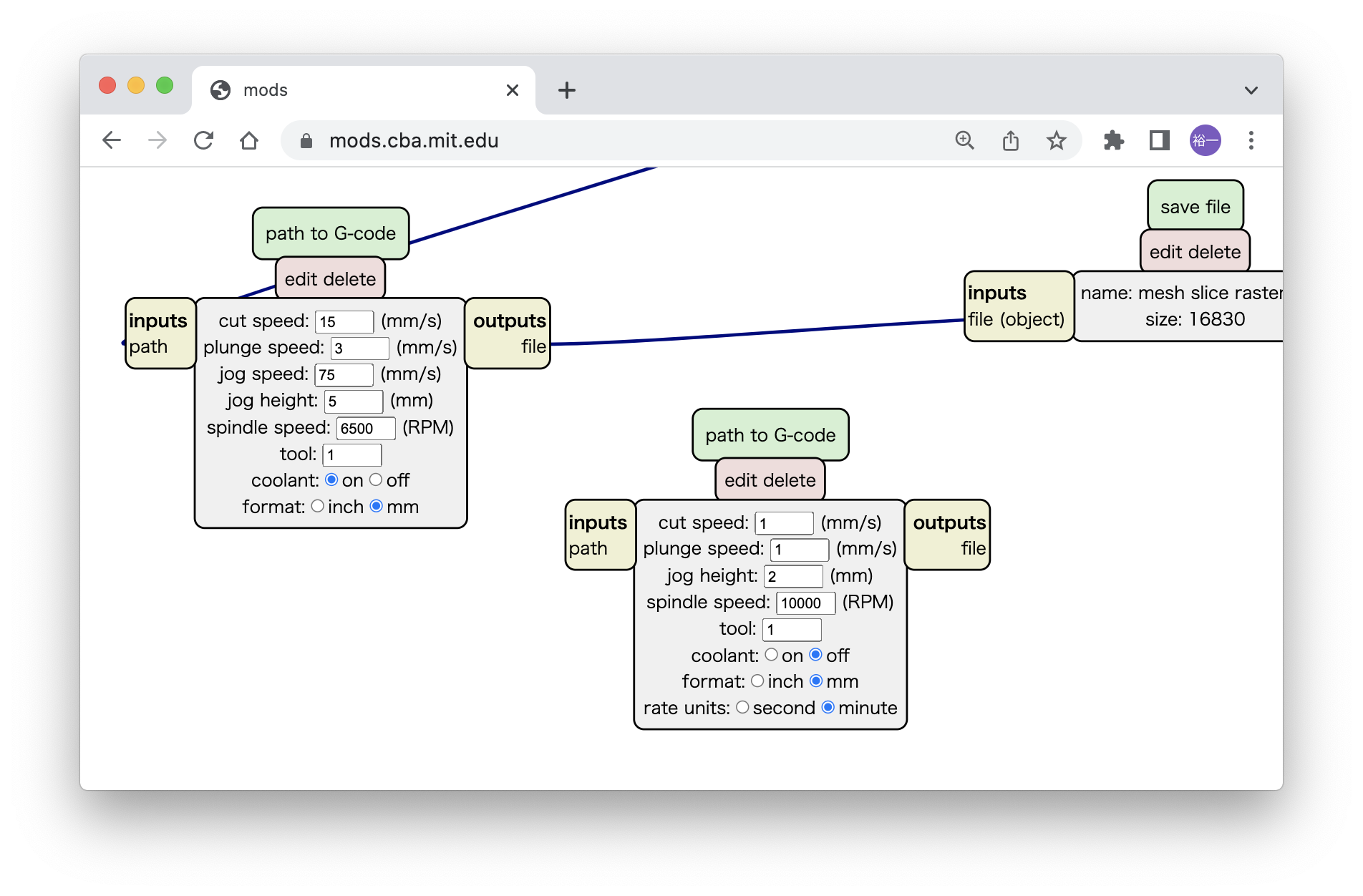

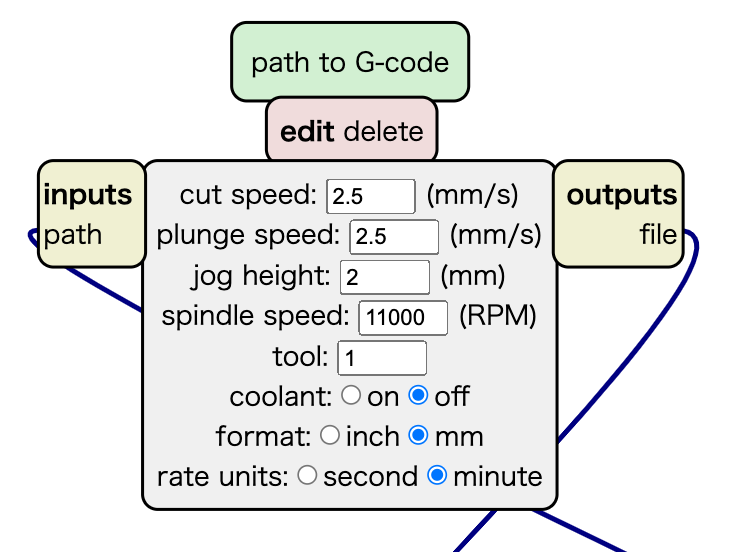

path to G-code node need to be replaced.

| Before | After (replaced) |

|---|---|

|

|

rate units is missing |

How to replace nods¶

Add node¶

Connect and disconnect lines¶

Simply click input path on path to G-code node and output toolpath on mill raster 2.5D node to connect and disconnect.

Also outputs fileon path to G-code node and inputs file on save file node

Delete node¶

click delete on unused node

Attention

As mentioned in this tip,

G04 P1000 need to be commented out for this machine, otherwise machine will stop on this line.

T1M06 may be also need to be commented out. This happened when wchusbserial1440 did not appear in the device list to connect. Possibly CH340 driver may not be installed successfully.

edit -> comment out as below

//str += "T"+tool+"M06\n" // tool selection, tool change..................comment out

//str += "G04 P1000\n" // give spindle 1 second to spin up................comment out

//str += "G04 P1\n" // give spindle 1 Millisecond to spin up..............comment out

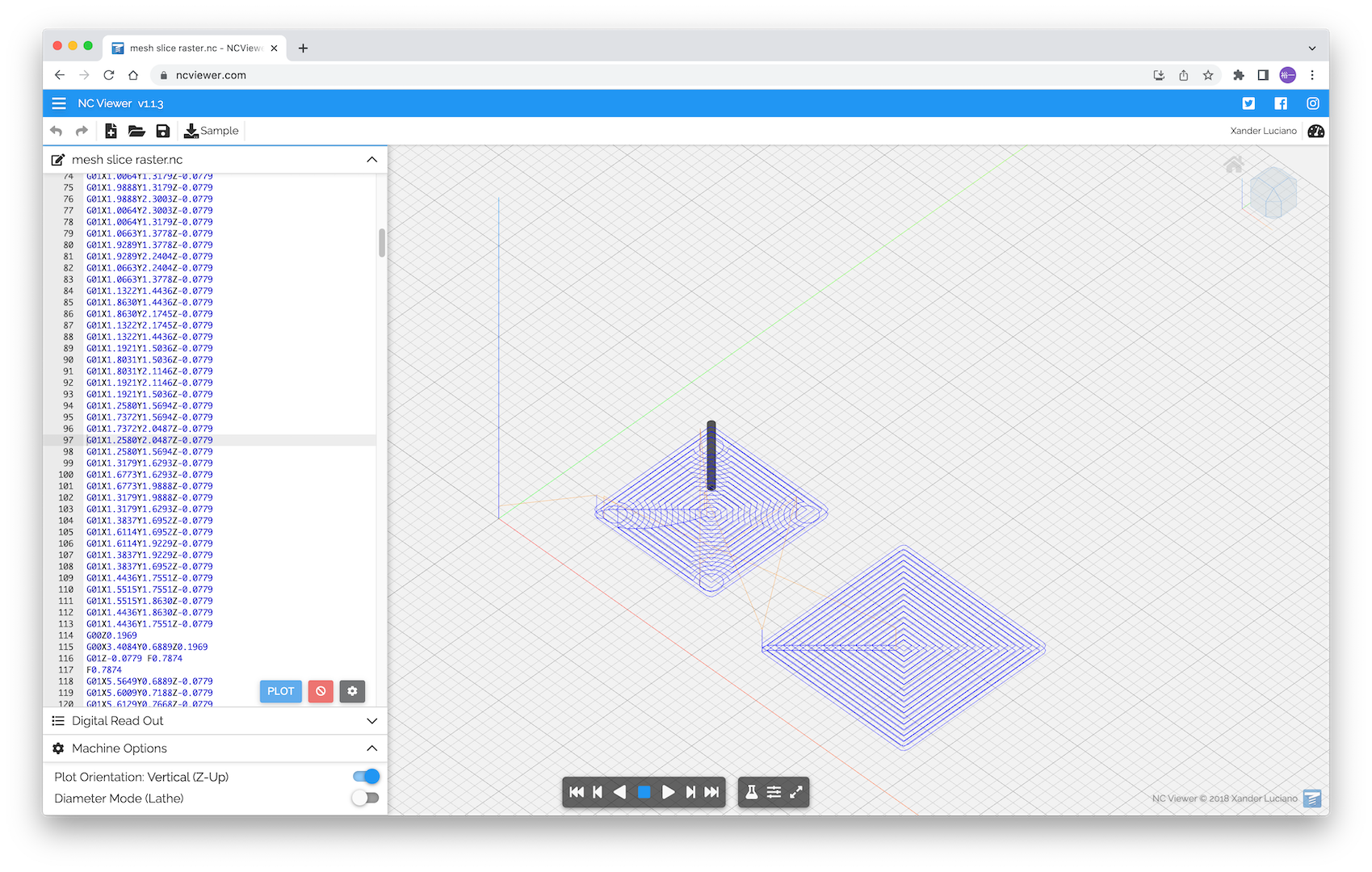

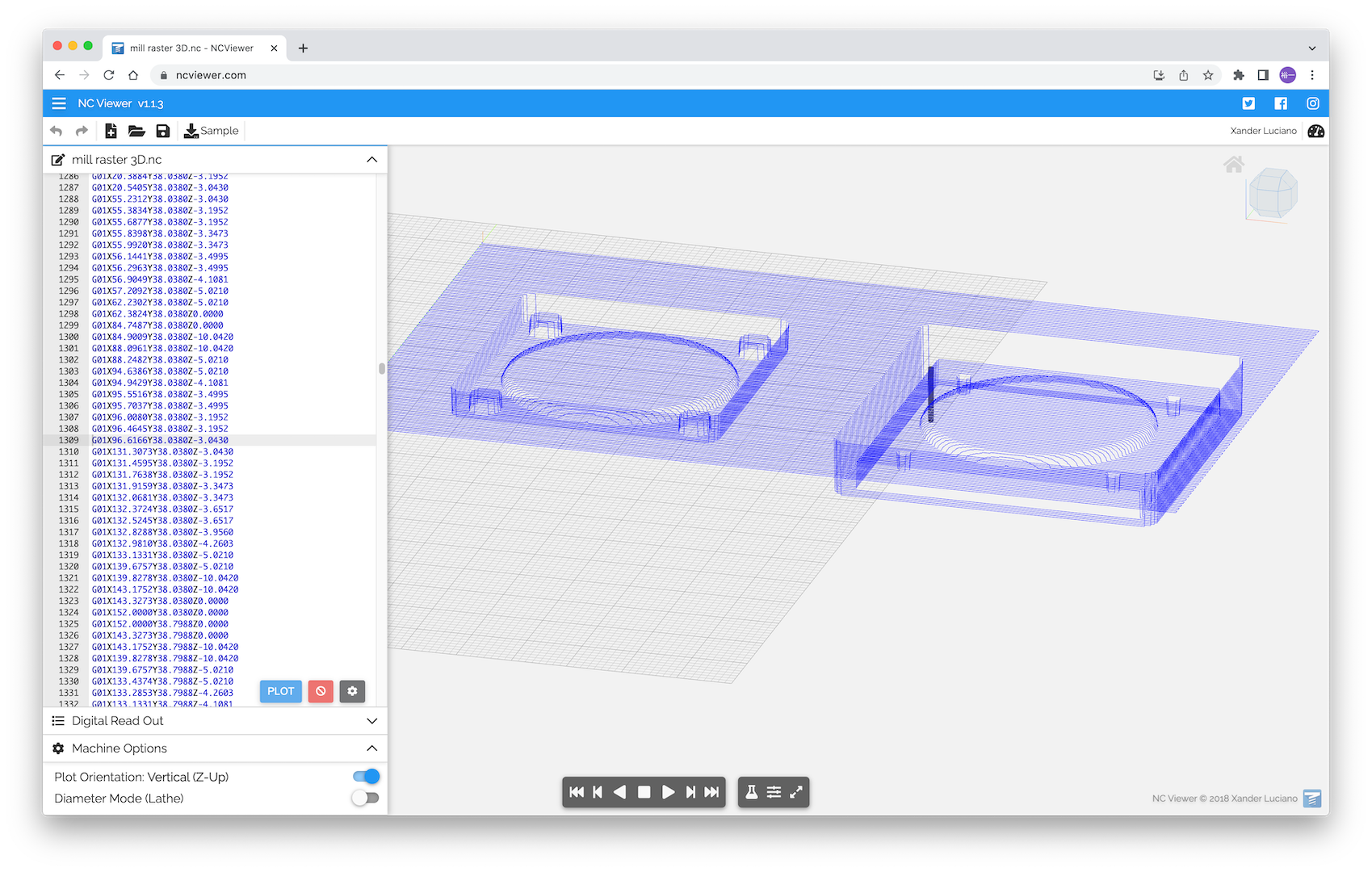

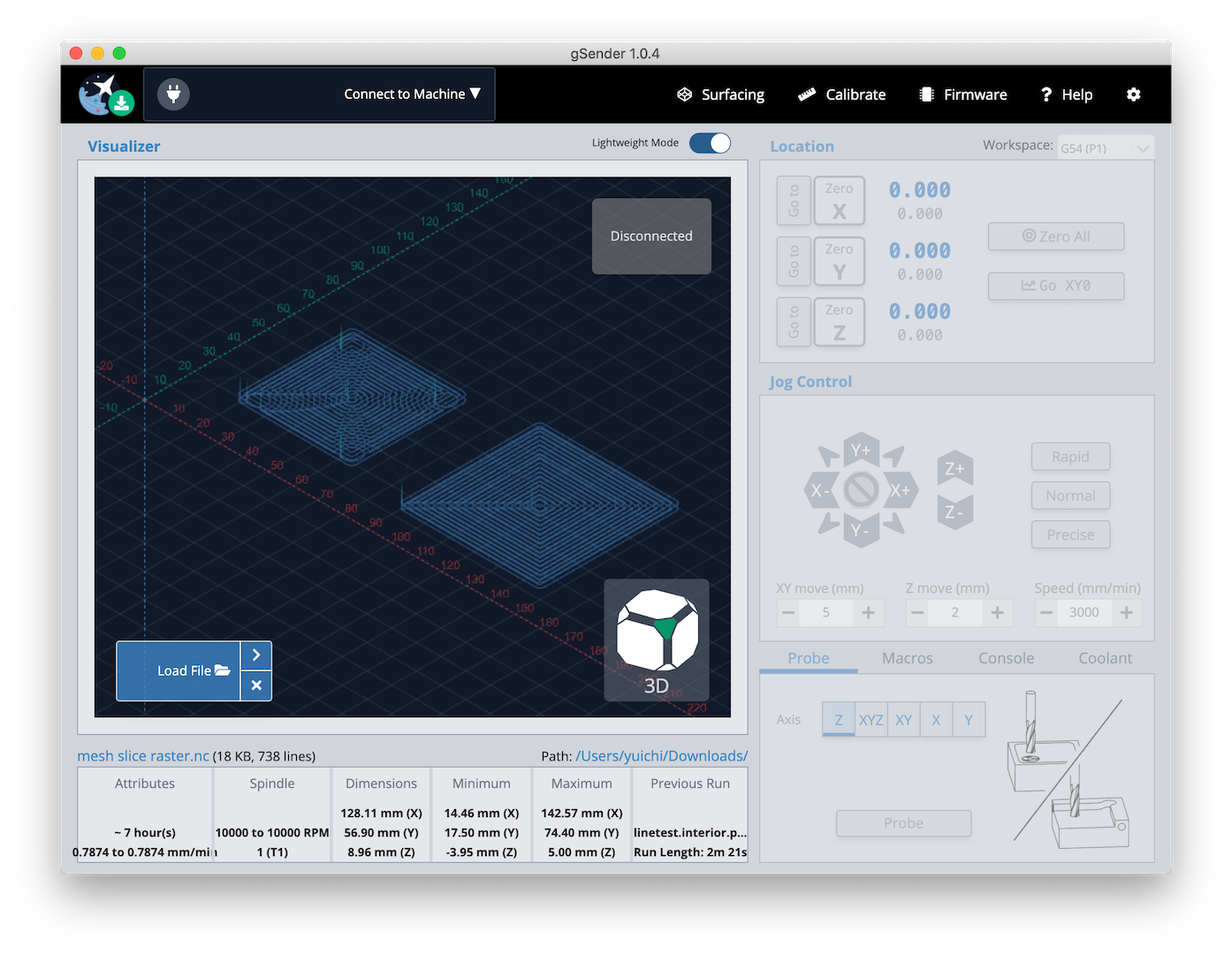

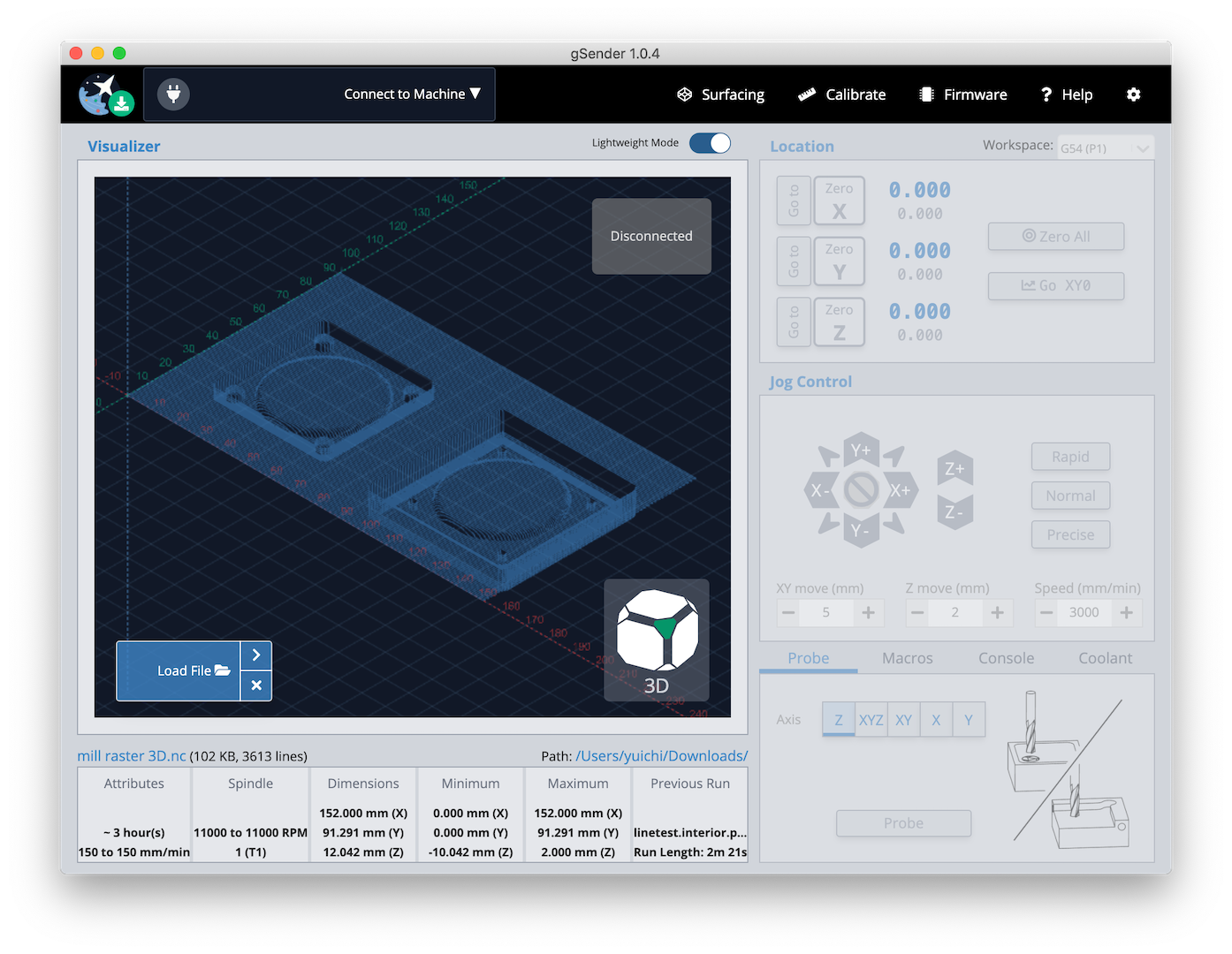

Check the g-code¶

- handy online tool for quick visualization

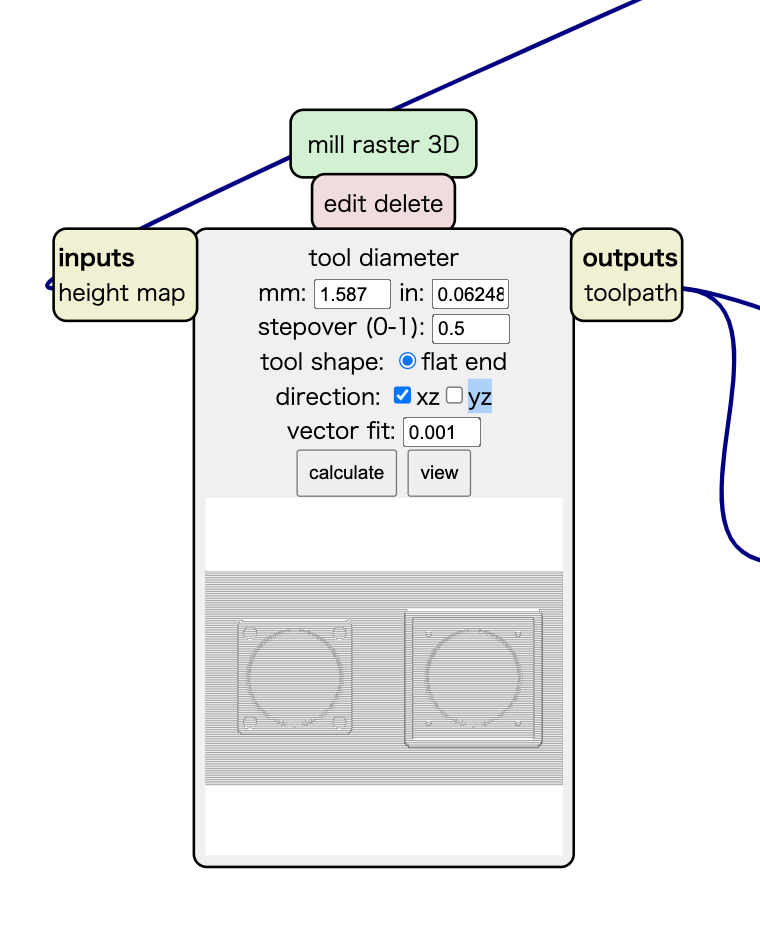

Finish cut¶

Note

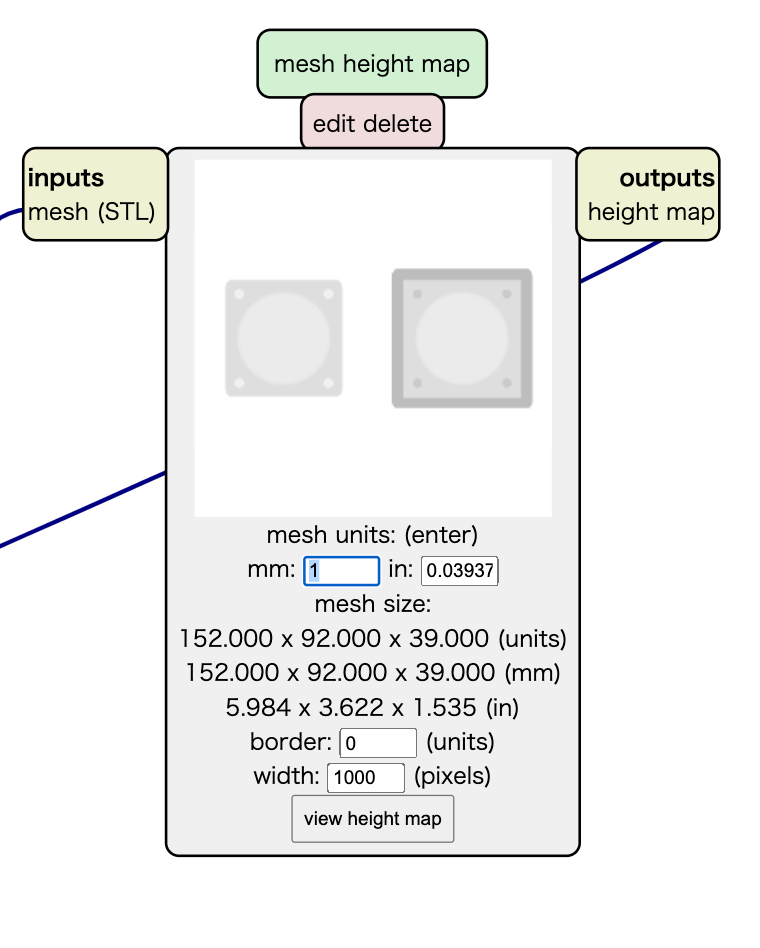

In mesh height map node, Set mesh unit: mm:1

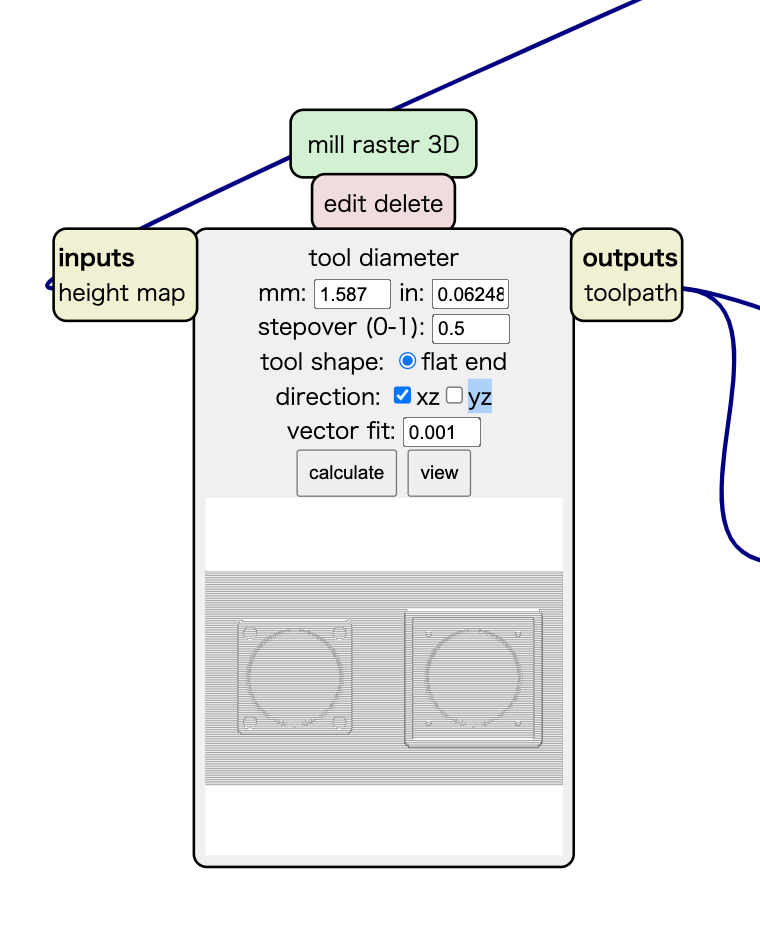

In mill raster 3D node, Uncheck yz

Check the g-code¶

Attention

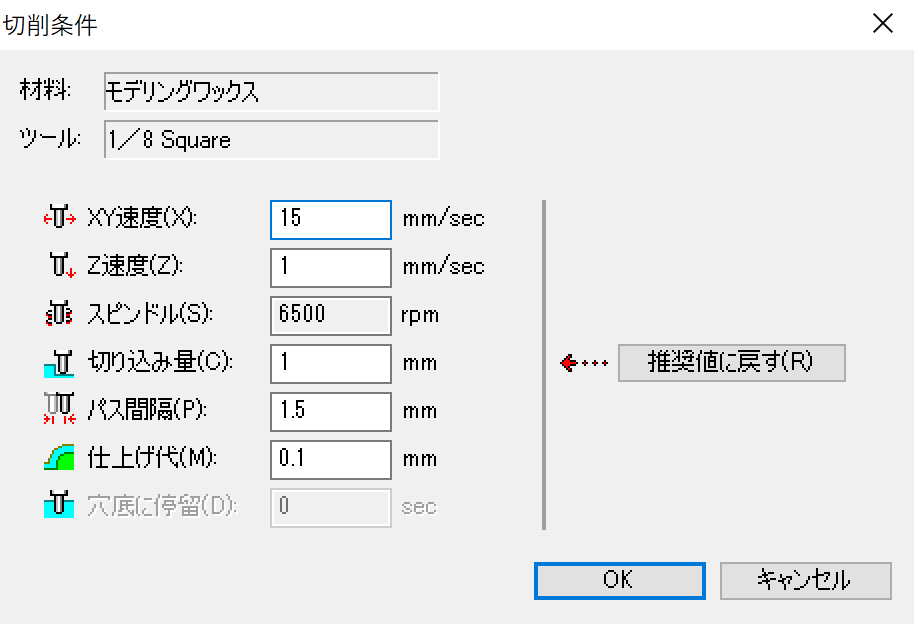

These are default parameter of wax milling in Roland Modela Player 4.

Refering to this, Set the wax milling parameter in appropriate mods’ nodes

Note

From Assignment of finish cut in 2022

| Spec of PROVerXL4030 | value | Value in finishcut | Result |

|---|---|---|---|

| cut speed(max) | 2000 mm/min = 33.3 mm/s | 20 mm/s | OK |

| spindle speed | 12,000 RPM | 10,000 RPM | OK |

| plunge speed | 2000 mm/min = 33.3 mm/s | 2.5 mm/s(Rolad’ Defaults) | slow |

Milling¶

Ref. Tip Genmitsu PROVerXL 4030

Rough cut path¶

Finish cut path¶

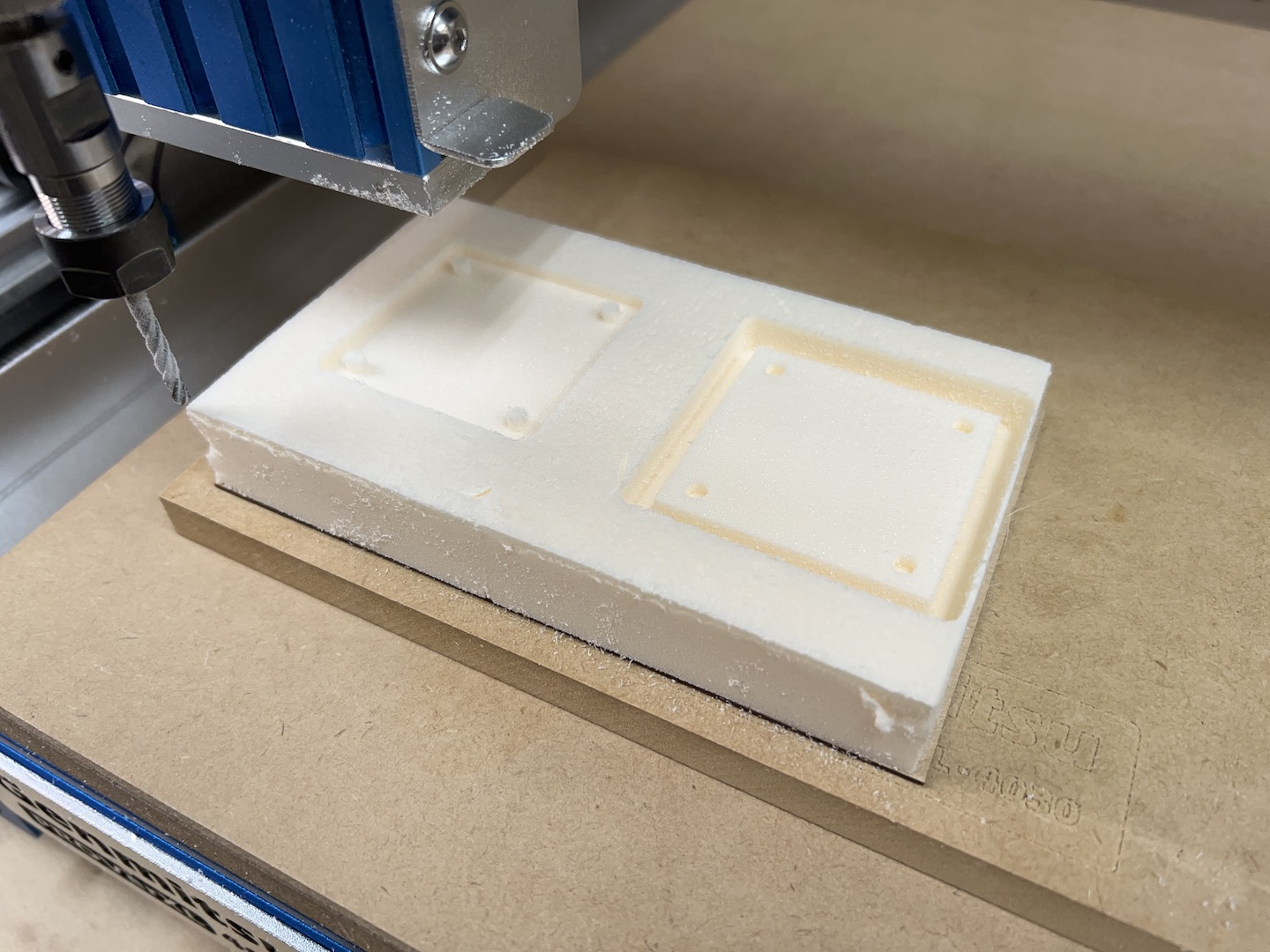

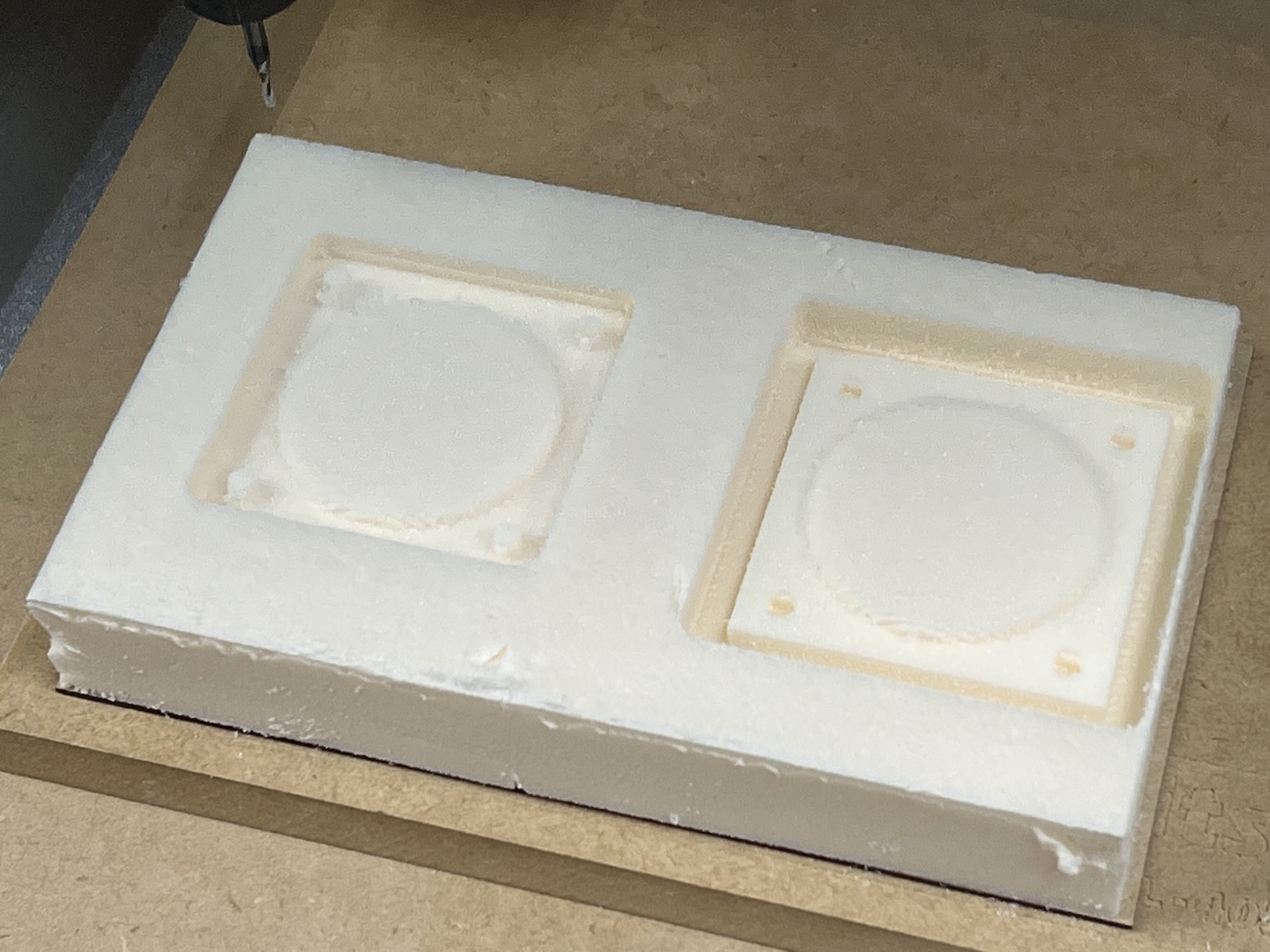

Test Milling foam¶

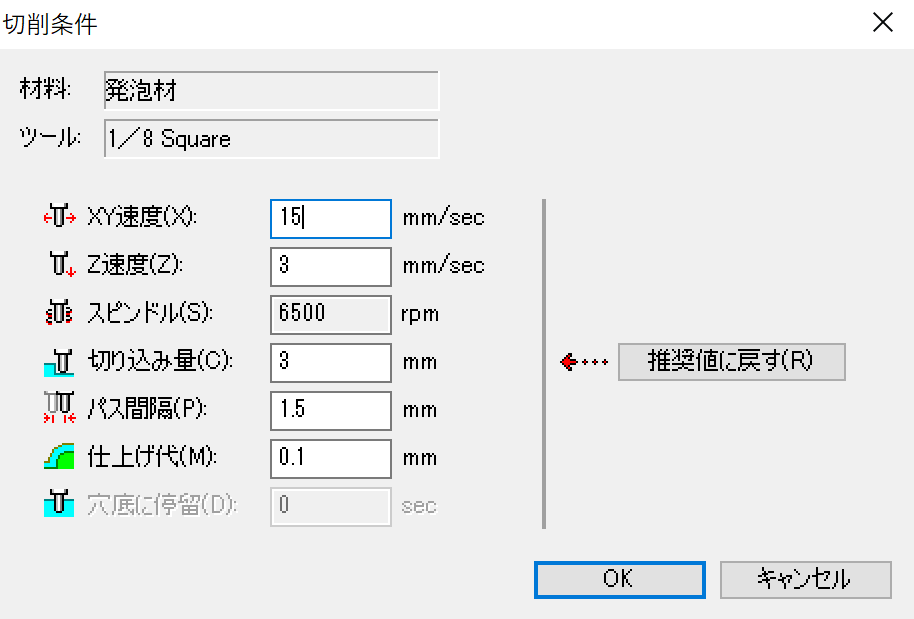

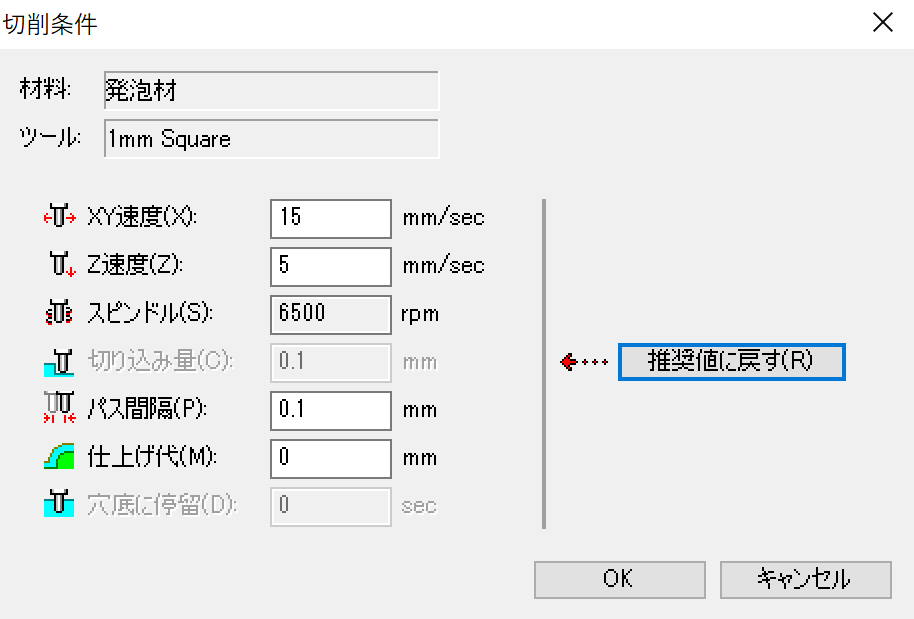

Note

For foam milling, this is the reference setting from Modla player4

Rough cut¶

Finish cut¶

Attention

Endmill¶

-

Rough cut

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

- Tool_dia: 1/8” =3.175mm

-

Finish cut

- 0.0625” DIA 2FL SE AlTiN 1/16

- Tool_dia: 1/16” =1.5875mm

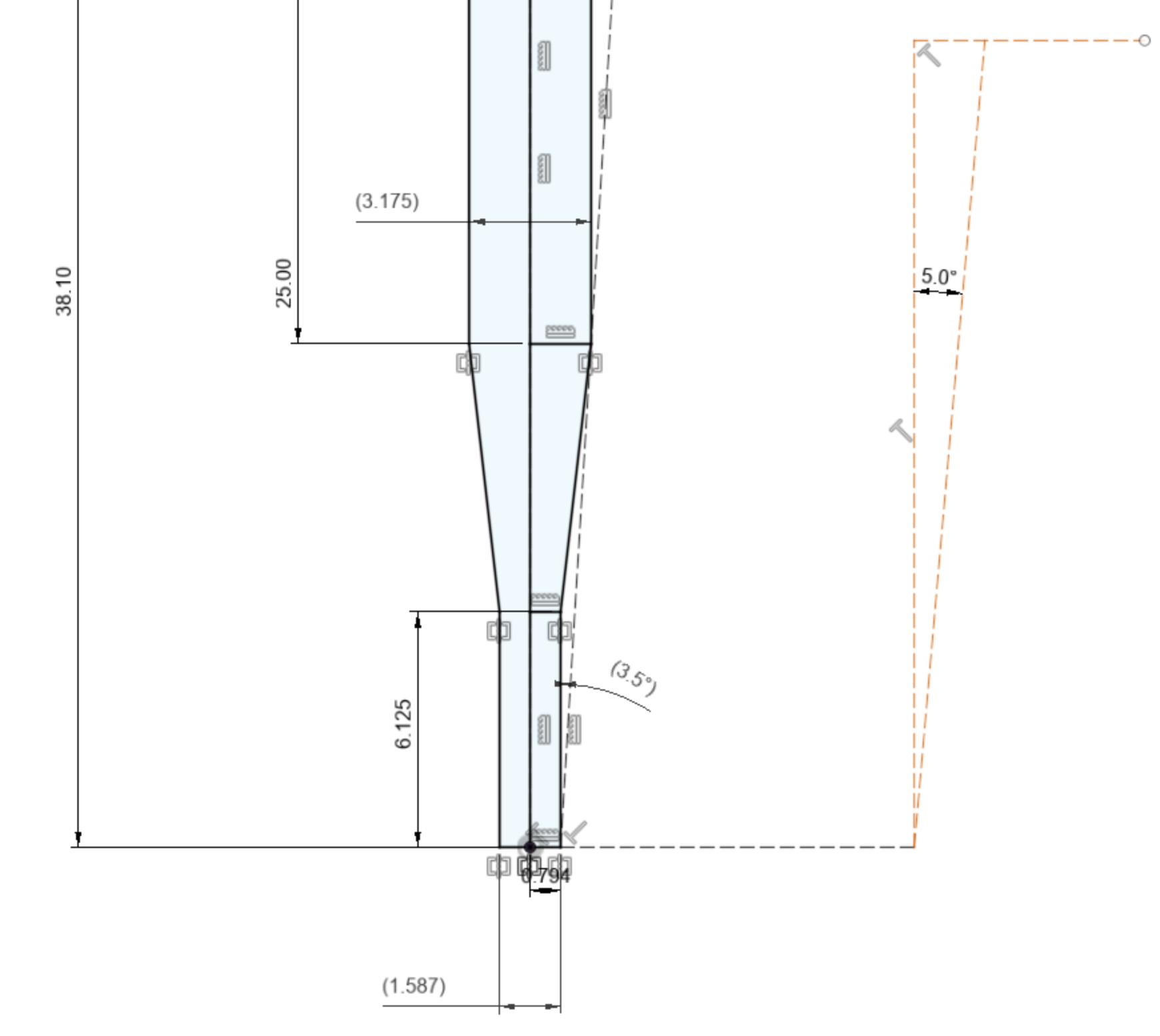

Design to prevent of hitting by tilt¶

- 1/16