Surface Mount Soldering¶

Surface mount soldering is the process of creating circuits using surface mount technology (SMT) components that are mounted directly onto the surface of printed circuit boards (PCBs). Unlike through-hole soldering, which involves putting the legs of electronic components through holes in a PCB, surface mount components are soldered directly to the surface.

They are much easier to de-solder and take up less space than through-hole components. However, through-hole is much easier and not as tedious.

Ne555 Timer¶

Before Fab Academy started, I made a blown up Ne555 timer using surface mount soldering.

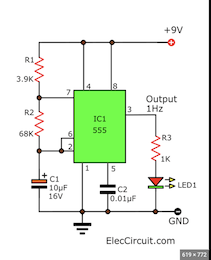

A Ne555 timer is an integrated surface chip that uses delay, timer, and a combination of capacitors to get the desired output. To learn more about the timer, view this video.

Schematic¶

Blown up version¶

This is the larger version that I soldered.

For me, I kept it simple and I didn’t use solder paste or any other extraneous material when I am surface-mount soldering. Essentially, I first applied a bit of solder on one copper pad. Then, I held the small component with a set of tweezers and melted that first blob of solder against one end of the component, sealing the connection. Then, I soldered the other side. To learn more about surface-mount soldering, see this video.