Printer Maintenance

Mr. Budzichowski taught us how to clean the extruder pully gears. He referenced this workflow from Prusa that details the process, and added a few tips. For this assignment I worked with Griffin Orsinger.

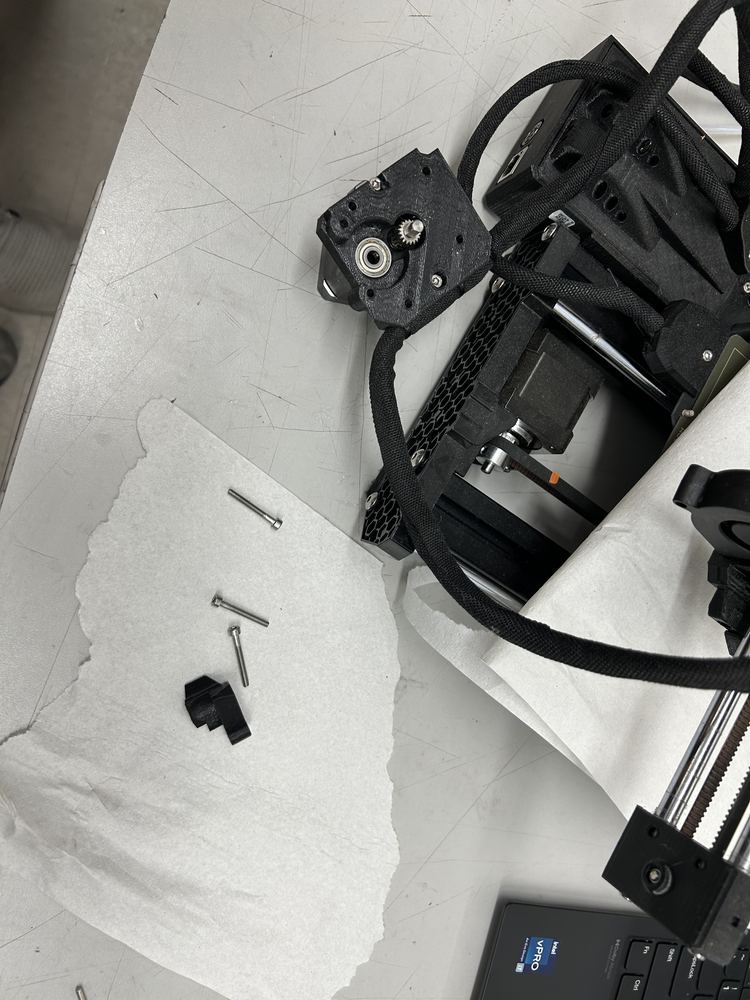

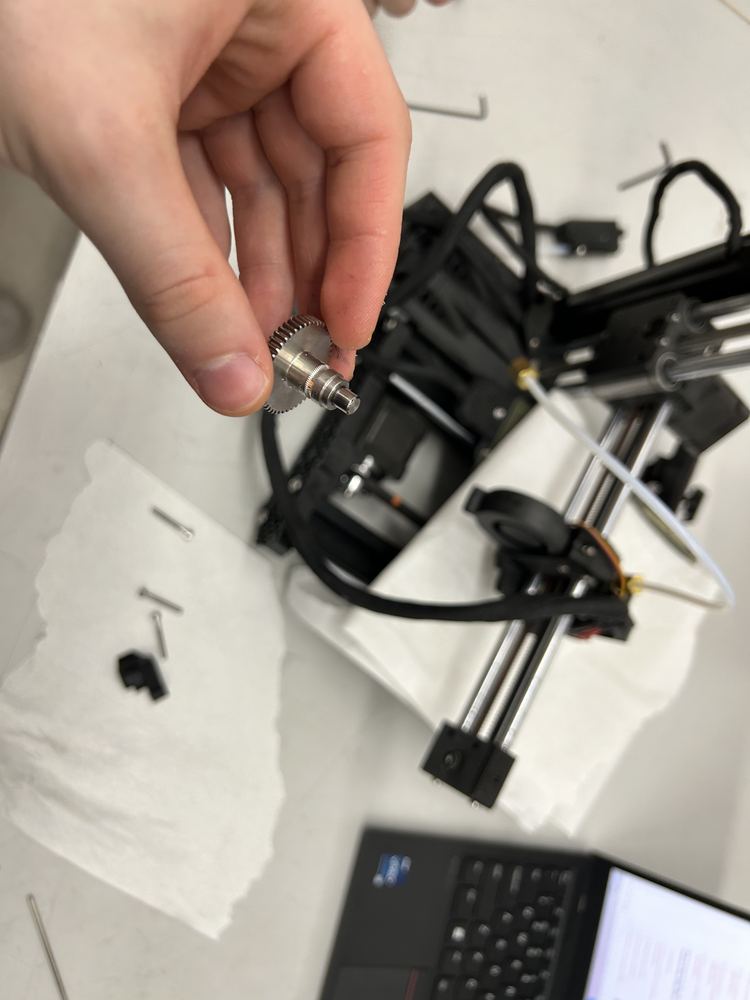

We followed the instruction in the workflow to take out the gear, and we used a microscope and a pick to remove the filament from the teeth of the gear.

Then we took out the pulley bearing (not in the workflow - Mr. Budzichowski recommended this step) and used a can of compressed air to remove excess material. Here is the before-and-after of this step.

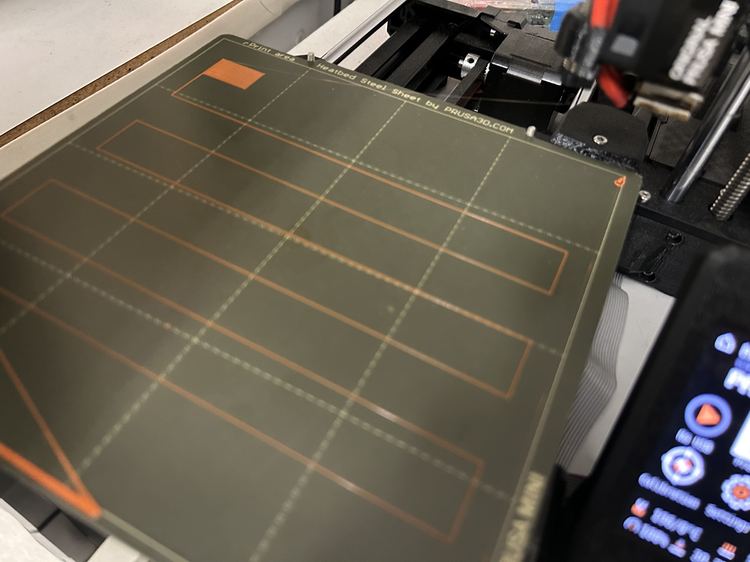

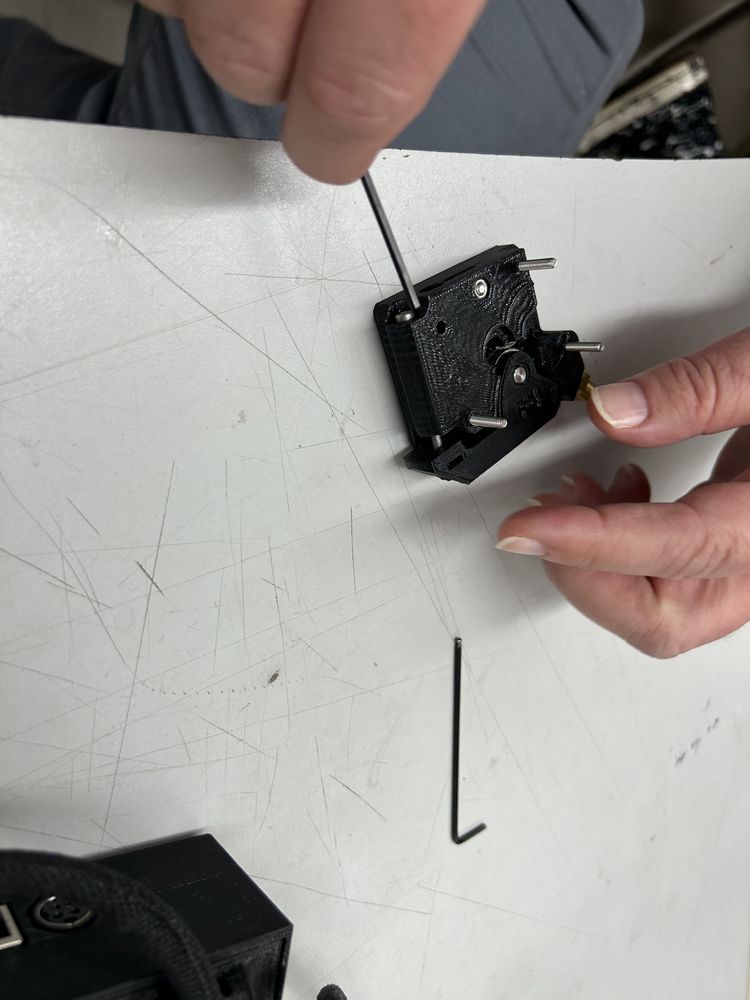

We then reassembled the printer, and Mr. Budzichowski warned that it is very important to make sure the spring piece is parallel and the screw isn't too tight when reassembling the bearing. After screwing that in, the filament sensor fell out! We simply stuck it back in tight, cut the filament at a 45 degree angle, and reloaded the filament. This worked! We ran the First Layer Calibration and slightly increased the z-value for the extruder offset.