8. Computer controlled machining¶

Our group assignment for the week was to do our lab’s safety training about with test for runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for the CNC machine

Zack Budzichowski: Designed and ran the CNC cut of the test patterns, analysis Dan Stone: Measured the cuts and compared to design, documentation Adam Durrett: Documentation and analysis

Safety Training¶

Tom Dubick gave a presentation on Aspire software and the workflow and safety for our ShopBot.

Dr Taylor gave his Foundation of CNC presentation to our lab.

We learned about the bits (flutes, upcut/downcut, shank diameters, length of cut, etc.) along with the feeds and speeds for the bits we have in our lab.

Testing the ShopBot¶

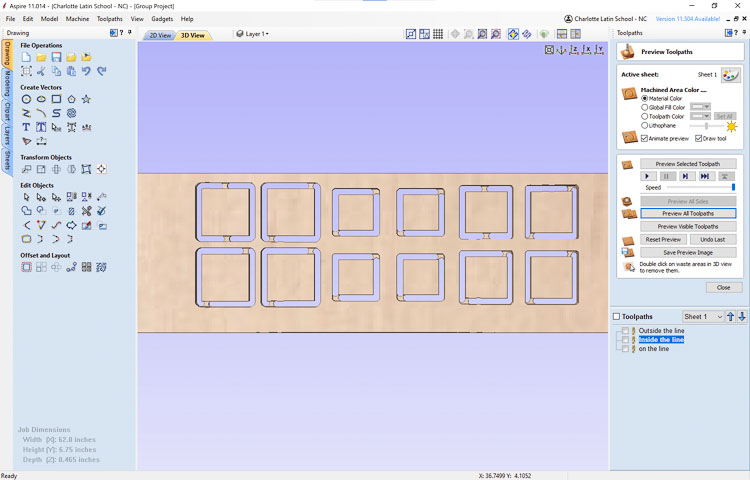

- We created an Aspire file to demonstrate the difference of the various toolpaths (inside, outside and on the line)

Cutting test¶

The following files show our test cut set up

The file had a number of shapes with planned sizes

Getting it into Aspire to create the tool path

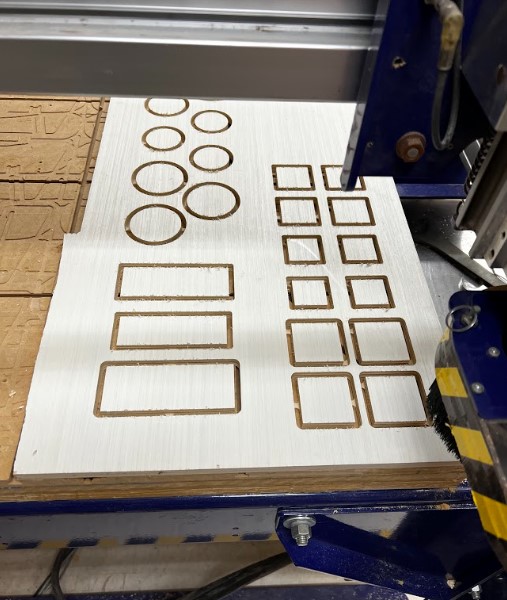

Once tool path is read we can cut

And we have the cut ready to measure

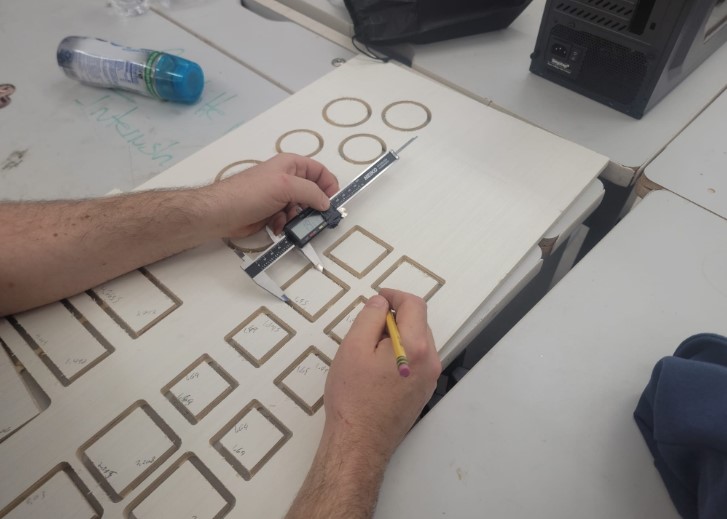

Here we start to measure so we can compare

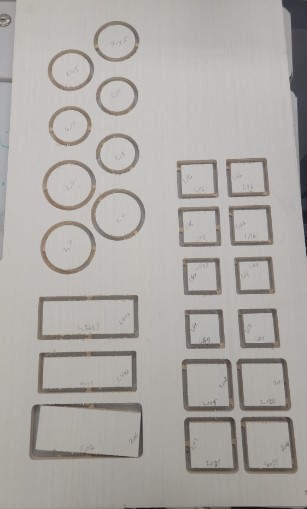

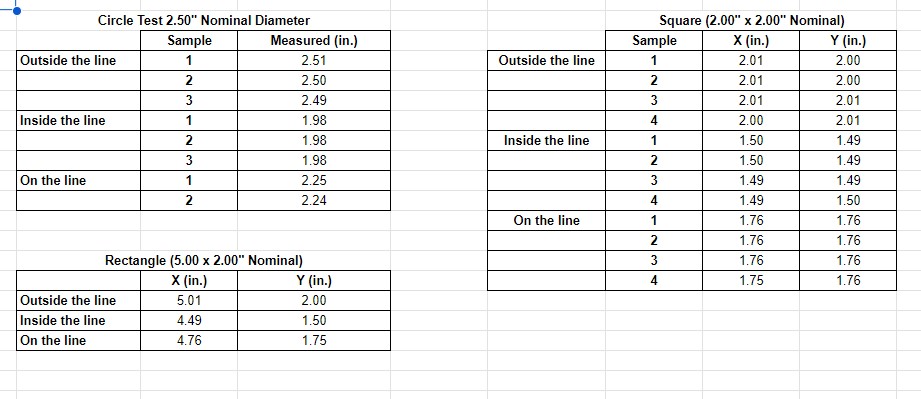

Here is the overall results

We had a hard time measuring as it was hard to be consistent with the caliper placement

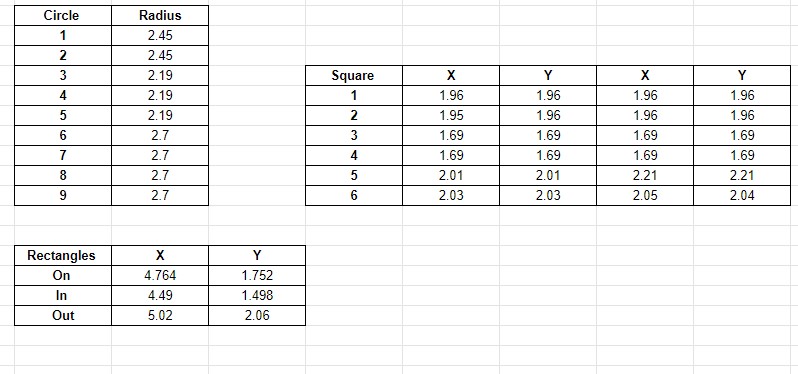

After further review it looks like the calipers got rezeroed halfway through and so a more careful measurement yielded the following

As we can see the outside the line cut are right on the mark and on the line / inside the line are smaller by the size the of the bit…looks like our CNC is calibrated well