Machines, Programs and Tools

Mac computer, screen, IPhone, GitLab, HTML site, patience.

introduction

This is the wings part of the project, the wings panel. The stages in design that I went through and changes that were made to it.

Sketches

The orignal sketch of the wings. Basically the wings my sister competed with in Ragnarok (Comicon Iceland).

Projects

Inkscape

The new version of the wings because the former version got deleted. I had designed them in InkScape but when my computer crashed things got deleted from week 2.

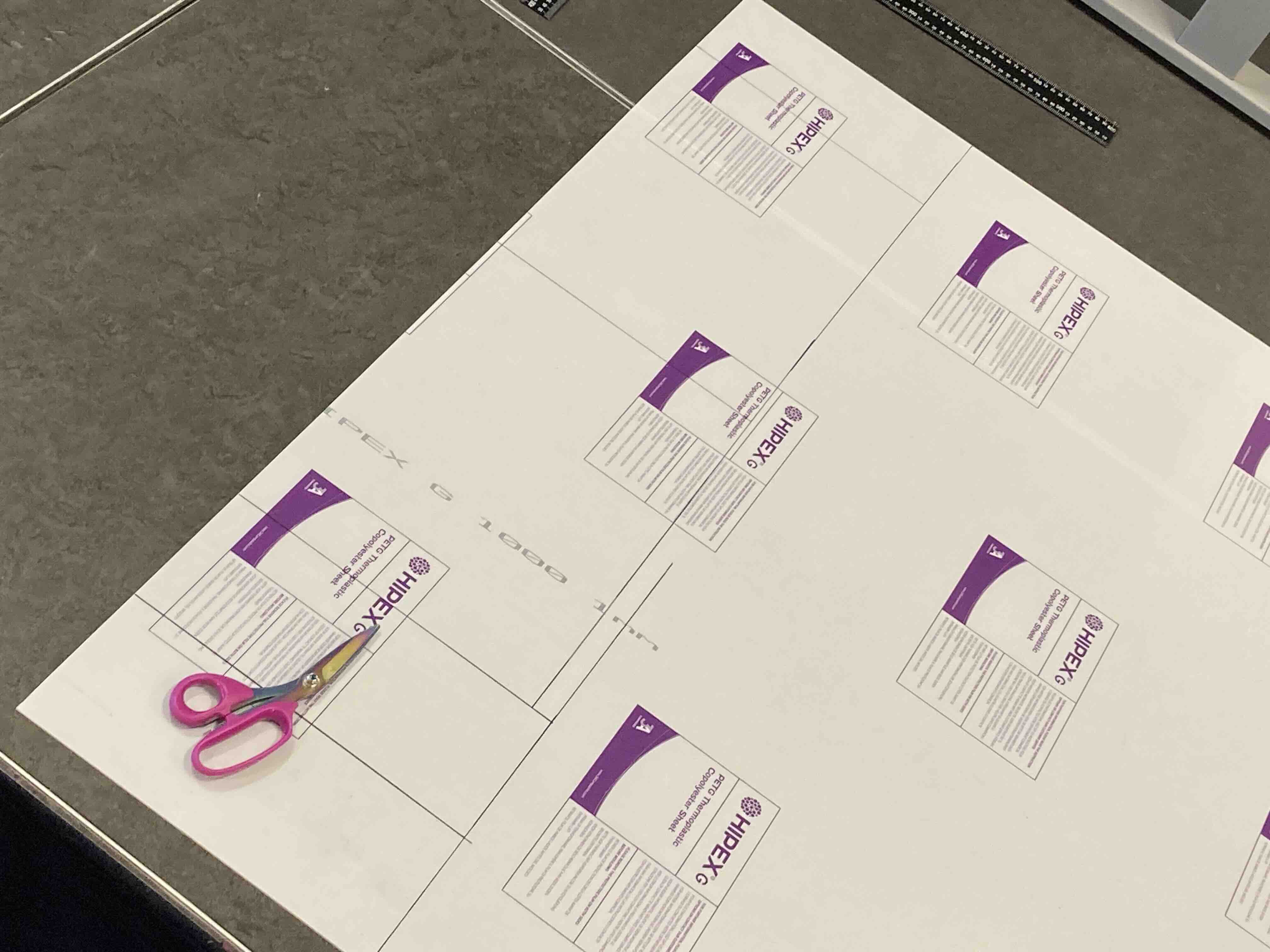

Wing Material

PETG bought at Fást. I ended up with 1mm PETG. Its thin enough to be light but still stable.

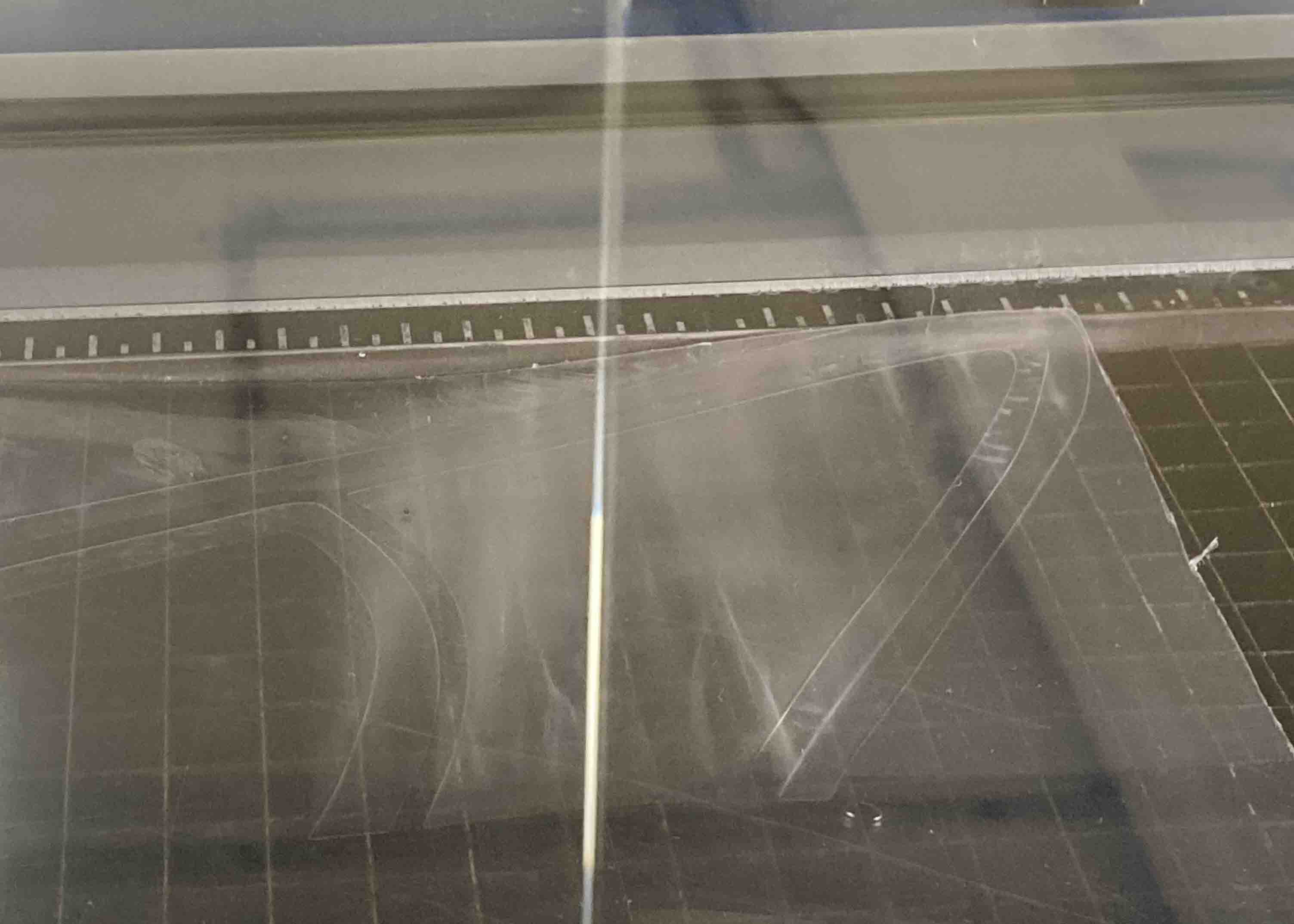

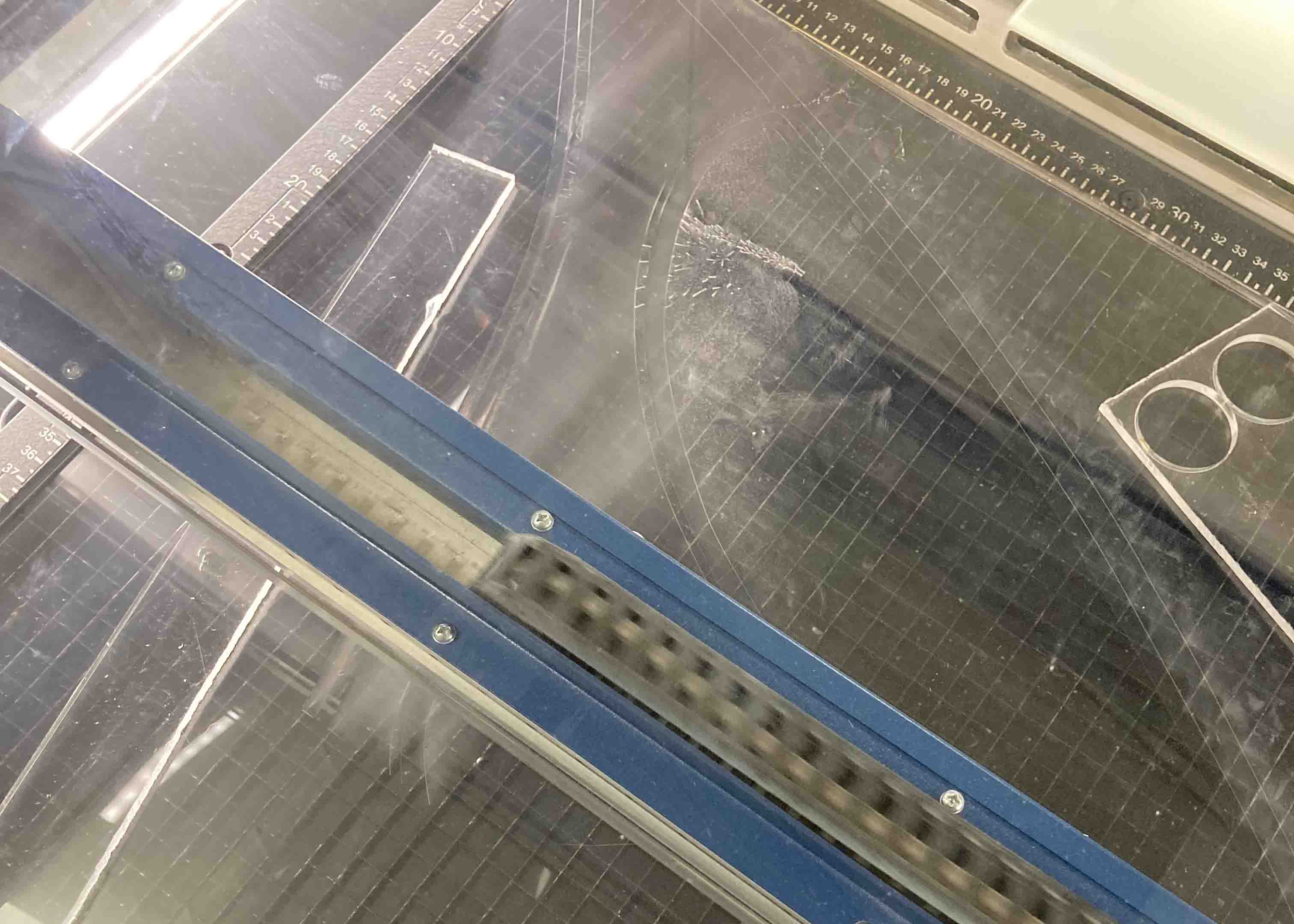

Lasercutting

while lasercutting the material I figured out that it needs to be weight down or it warps. The heat from the lazer can also melt it instead of cutting. Took me a while to figure out the right settings for the Laser.

Job type: combined. Raster settings, Speed:40% Power:20%. Vector setting, Speed:100% Power:100% Freq:50 Hz

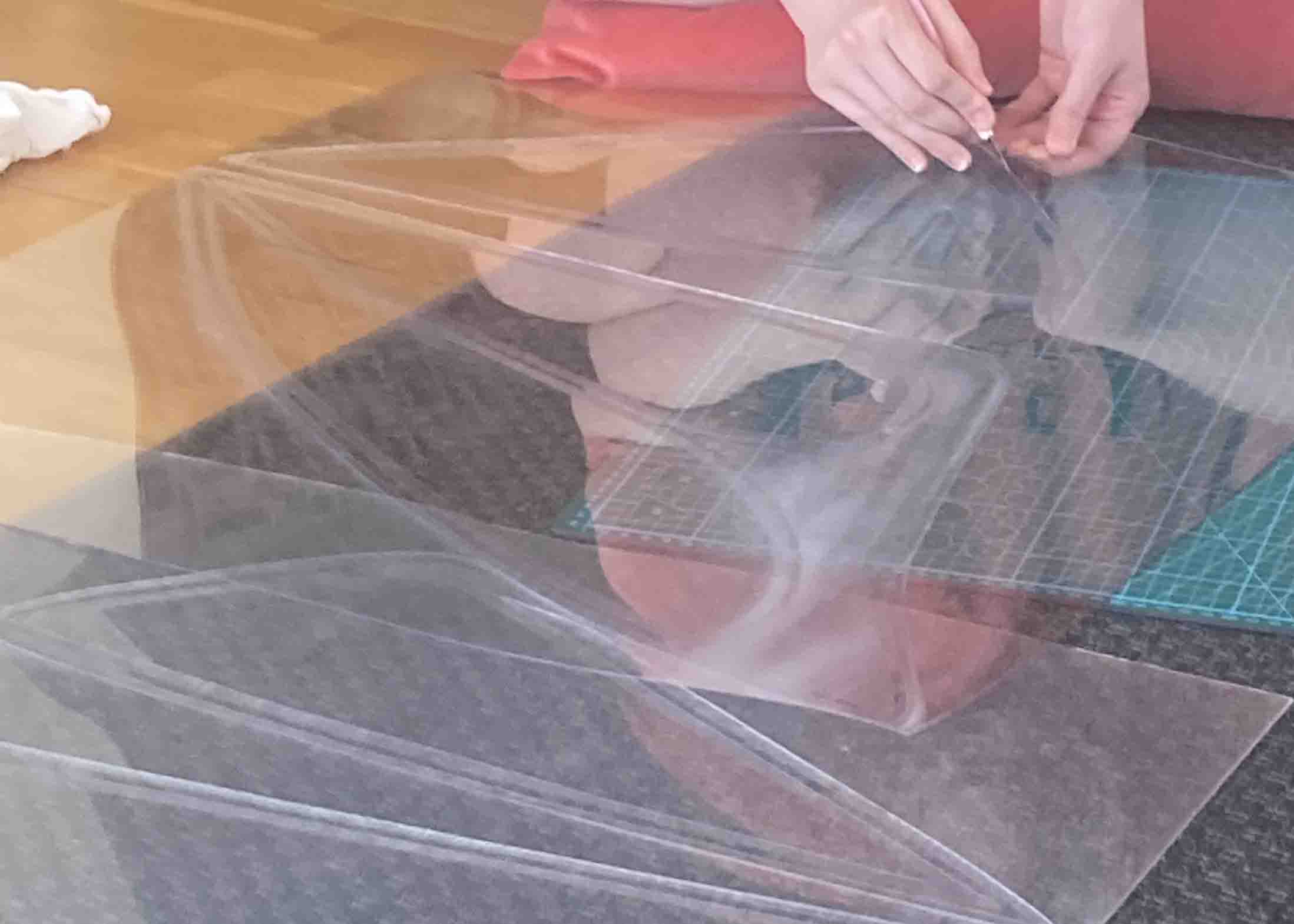

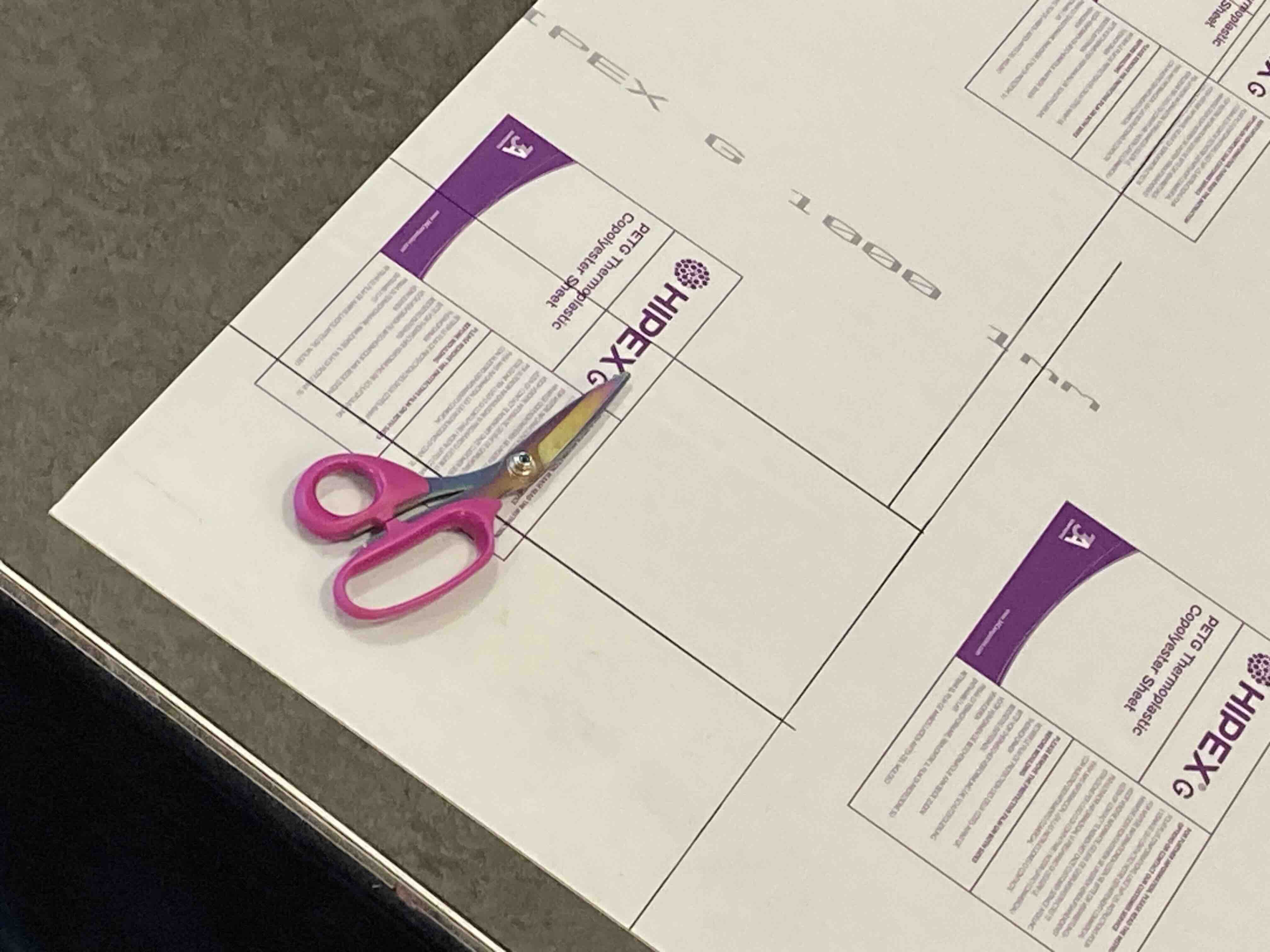

Cleaning and cutting

I needed to finish cutting the materal by hand because I didnt find the right setting at first. The material had warped so I could not use the file again to cut through making a second pass.

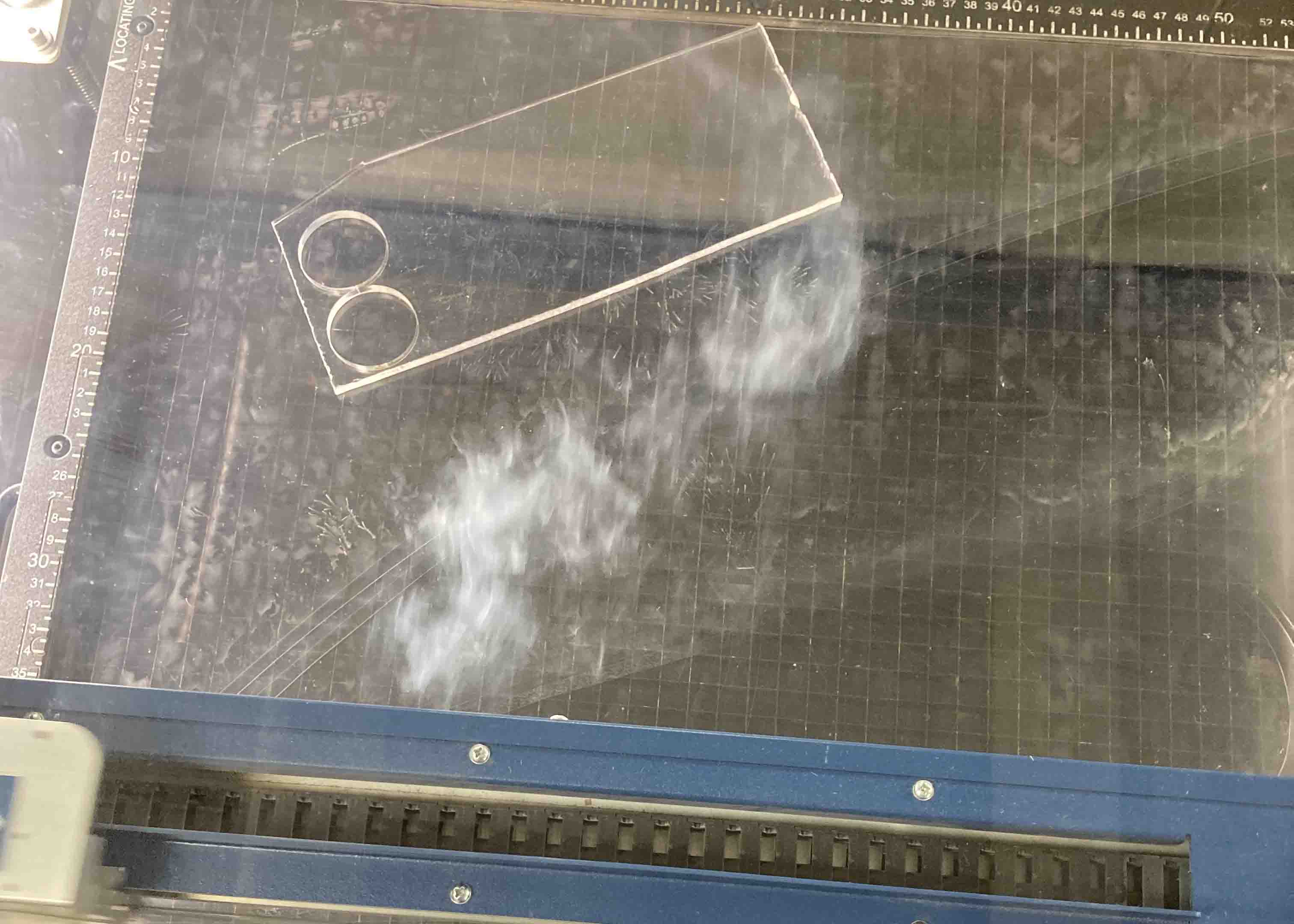

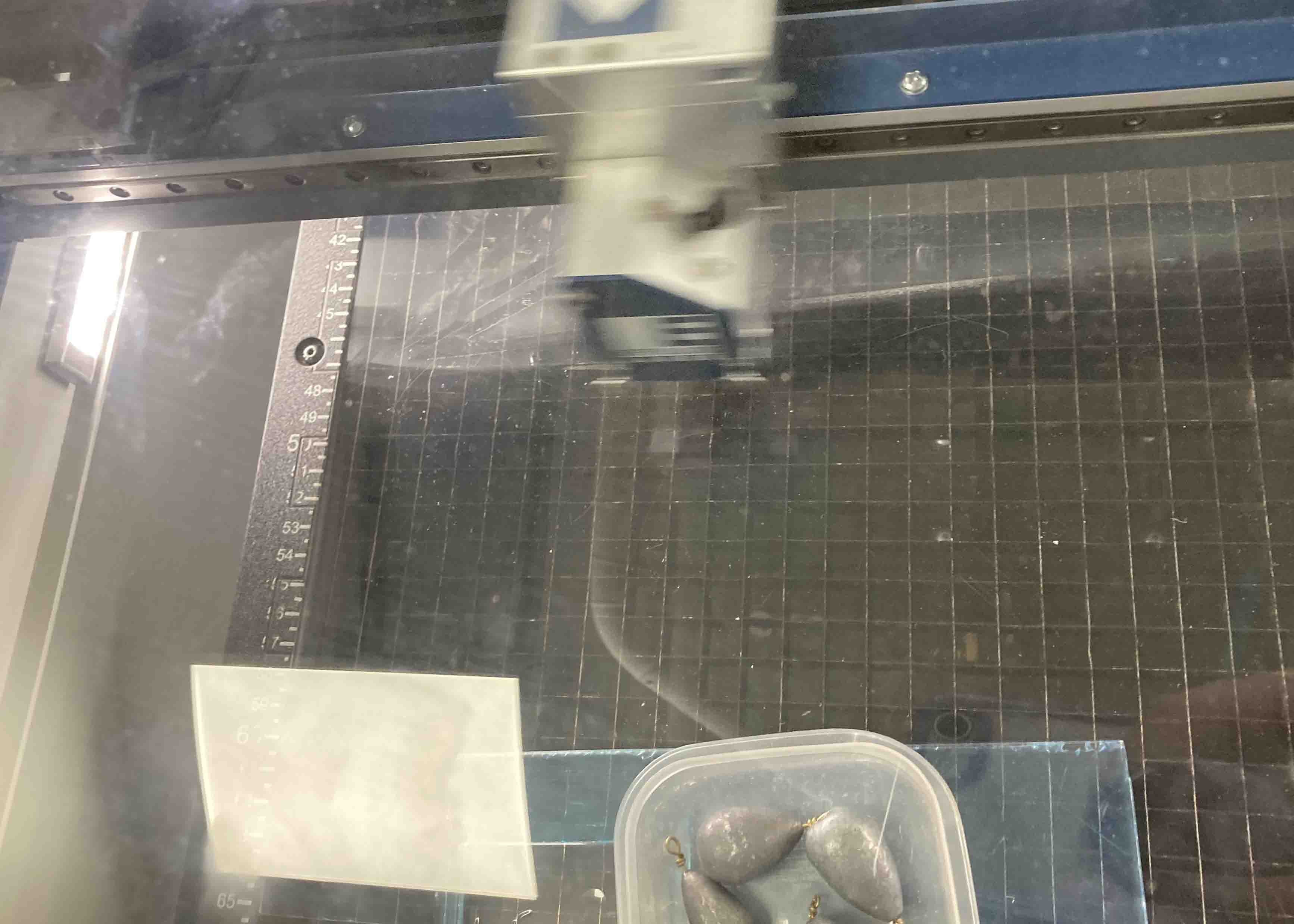

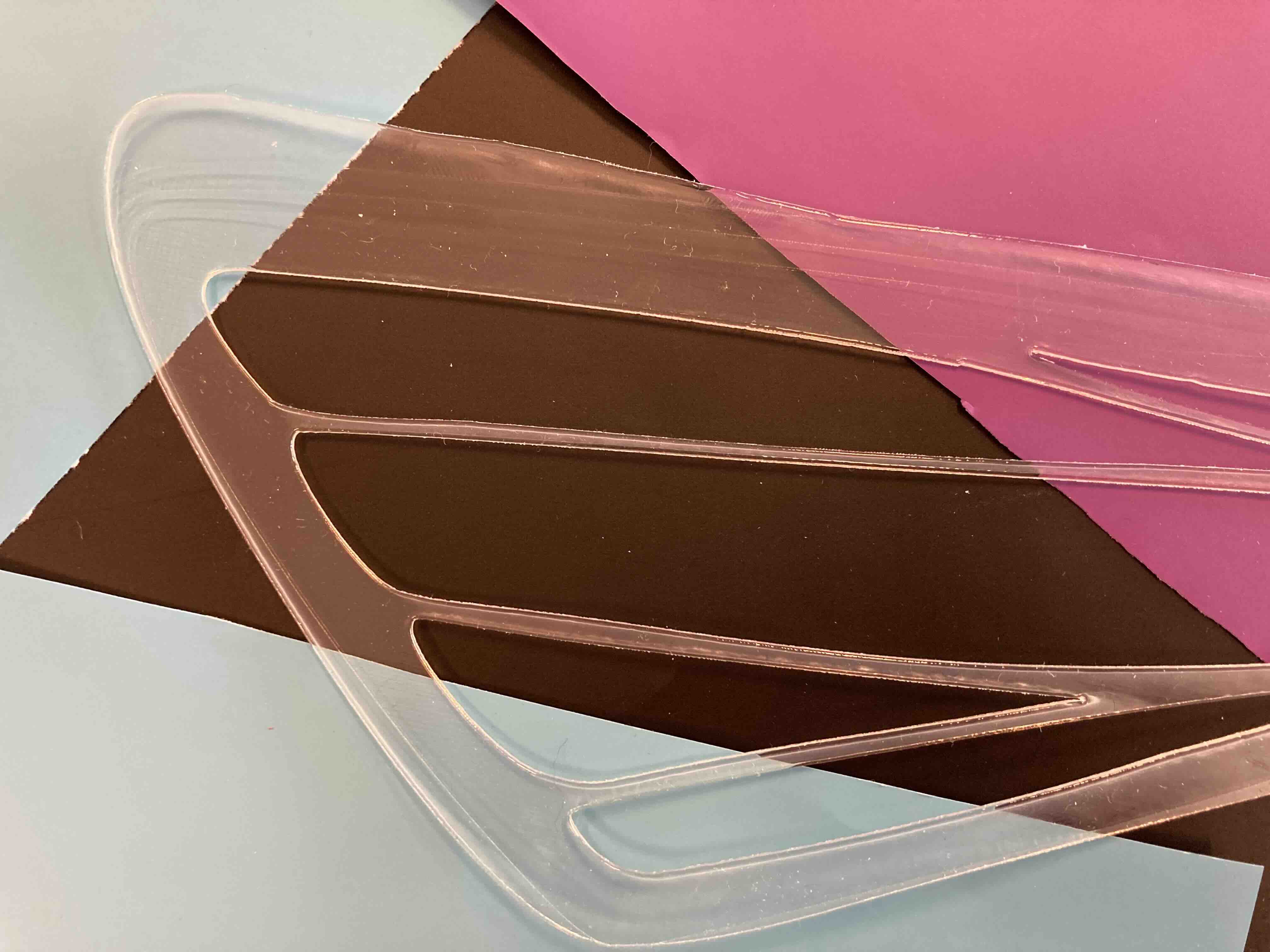

Lasercutting with cutout

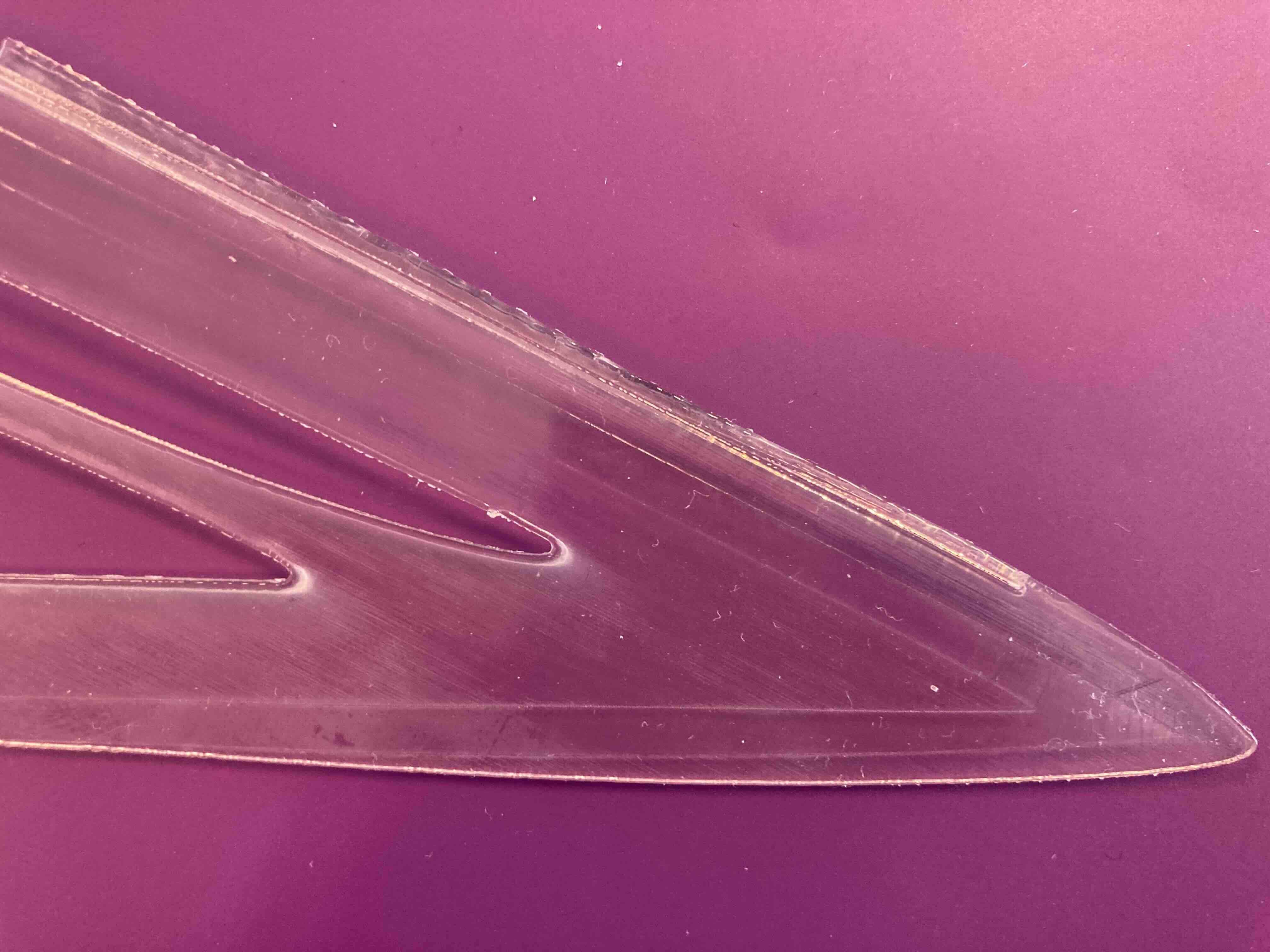

Second set of wings, I put a cut out in the wings because even though they are only 1mm they were too heavy for the servos. I also changed the settings on the laser

Job type: combined. Raster settings, Speed:100% Power:20%. Vector setting, Speed:60% Power:20% Freq:50 Hz

3rd set of Wings

I found a better setting for the program so it cut through this time. Added a little structure to them. The second set were too flimsy.

Job type: combined. Raster settings, Speed:100% Power:50%. Vector setting, Speed:11% Power:100% Freq:500 Hz

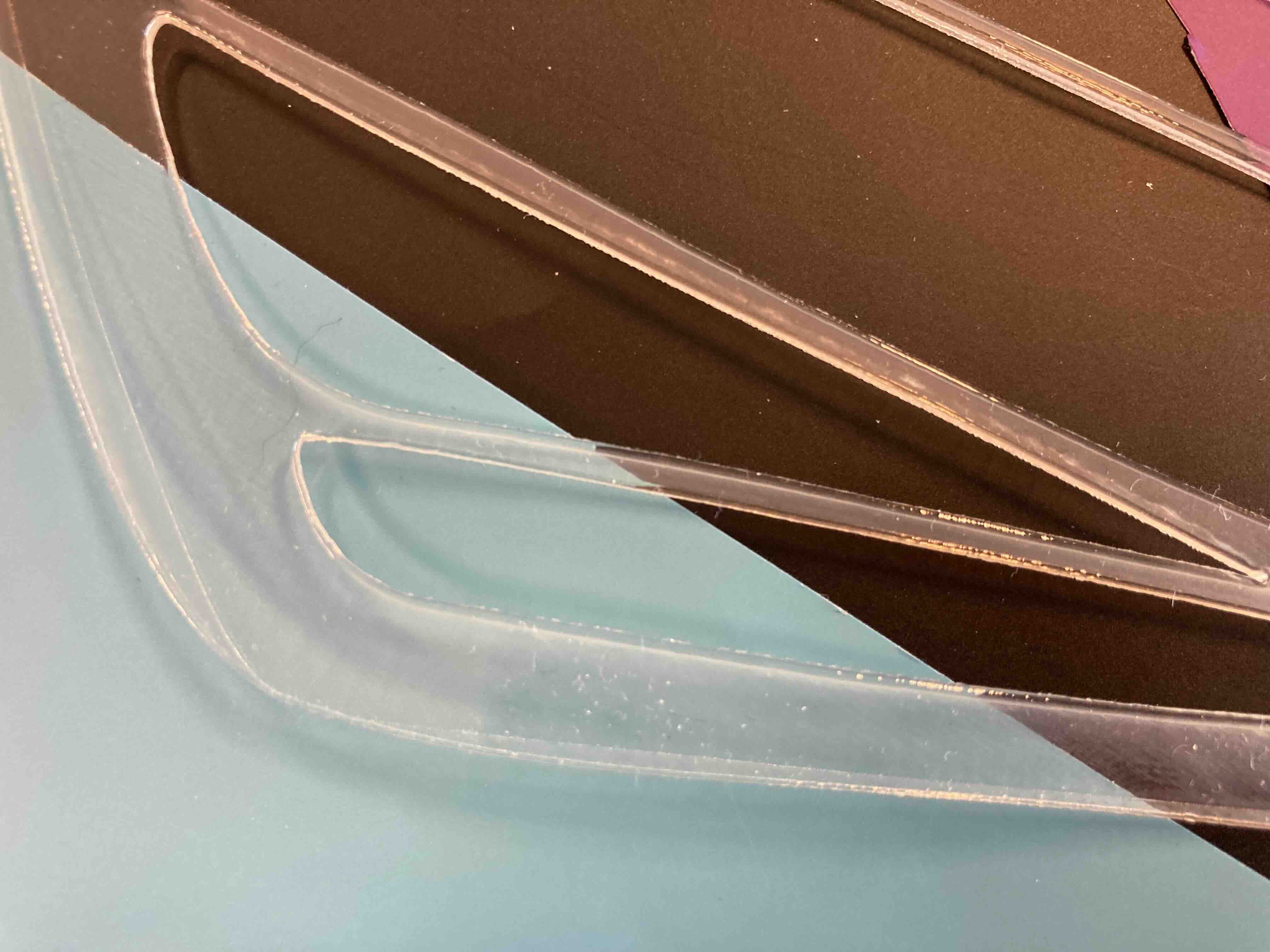

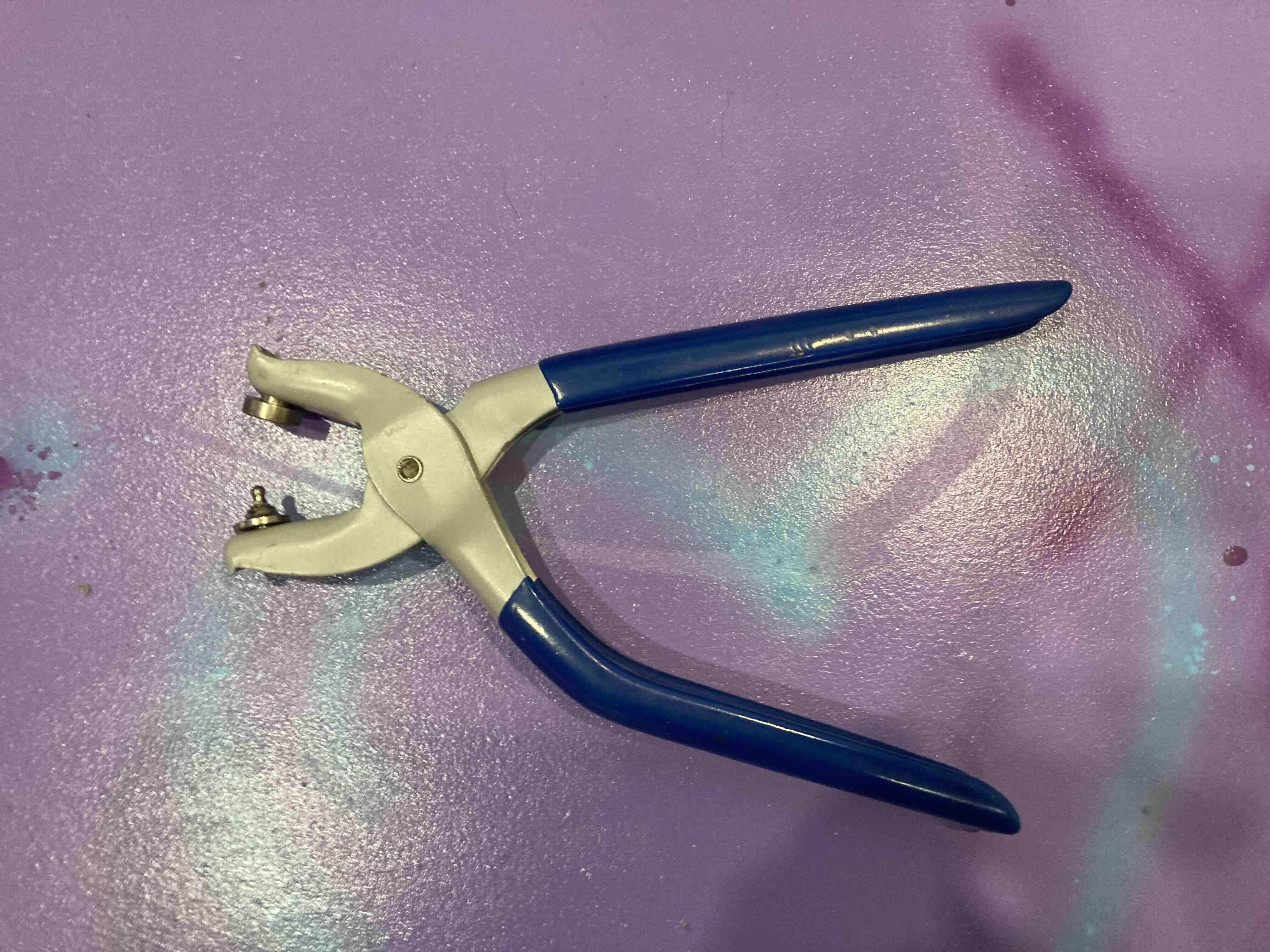

Making the holes

How I marked the holes to fit them to the wing clip. I put them in the wingclip and marked the hole placement then punched through with a hole puncher.

Fully assembled

The wings fully assembeld and attached to the backplate. the wings locked together when they moved. The wings were always supposed to have cover on them but now the cover was needed to make the flapping smooth and realistic.

Adding more structure to the wings

Added AeroKote to the wings and wrapped them in it. Used the heat press to attach it. Found out that I need a different AeroKote that has a melting temp below 220°F or 104°C. That was not available in Iceland and needs to be specially ordered. Going to use that for the next version of the wings. Heat pressed it with PETG and it still shrunk. I have ordered a different material to cover them in that will hopefully work better. But they were sturdier and the movement was smooth.

Wings and Cosplay dress

Wings fully assembled with the wings wrapped and functional. They work well like this but I didnt want to waste material to cover them in vinyl, since it would not look good with them not smooth. But future wings will be cover in vinyl with lights.

Summary

The wing panel journey was not fun. Each new set of wings showed new problems. I thought in the beginning I would burn down the lab since the sparks from the laser were crazy. I will not cut out a new pair of wings until they figure out a better venting situtation for the lab. The whole lab smelled like burned plastic. But now I have them pretty much the way I like them and have figured out the ratio of cut out vs. stability. The main problem will always be the weight the servos can carry. I have also ordered sturdier servos that can carry more weight. The competition wings will be cover in vinyl and have LED lights. The PETG will act as boneing for the wings.