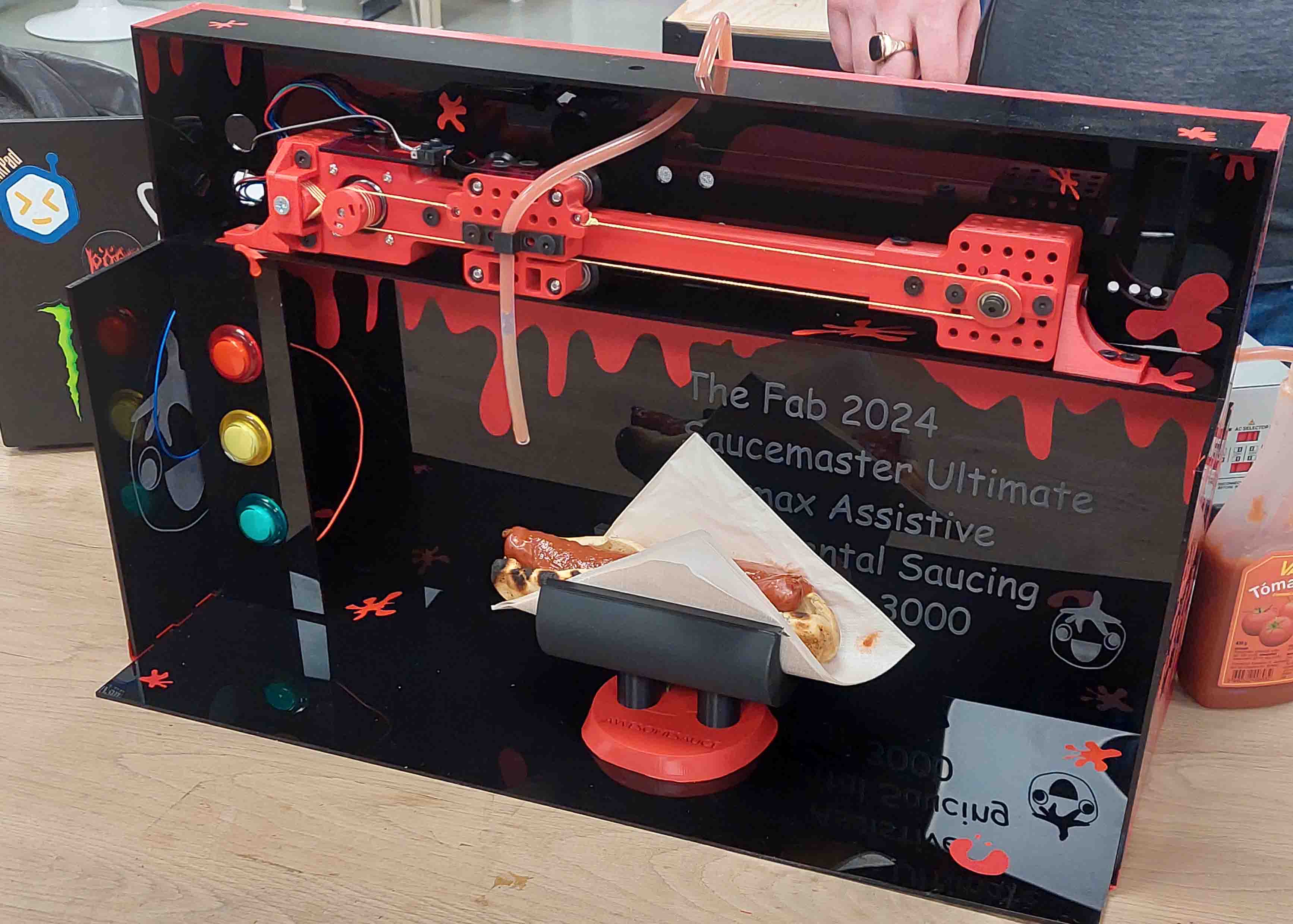

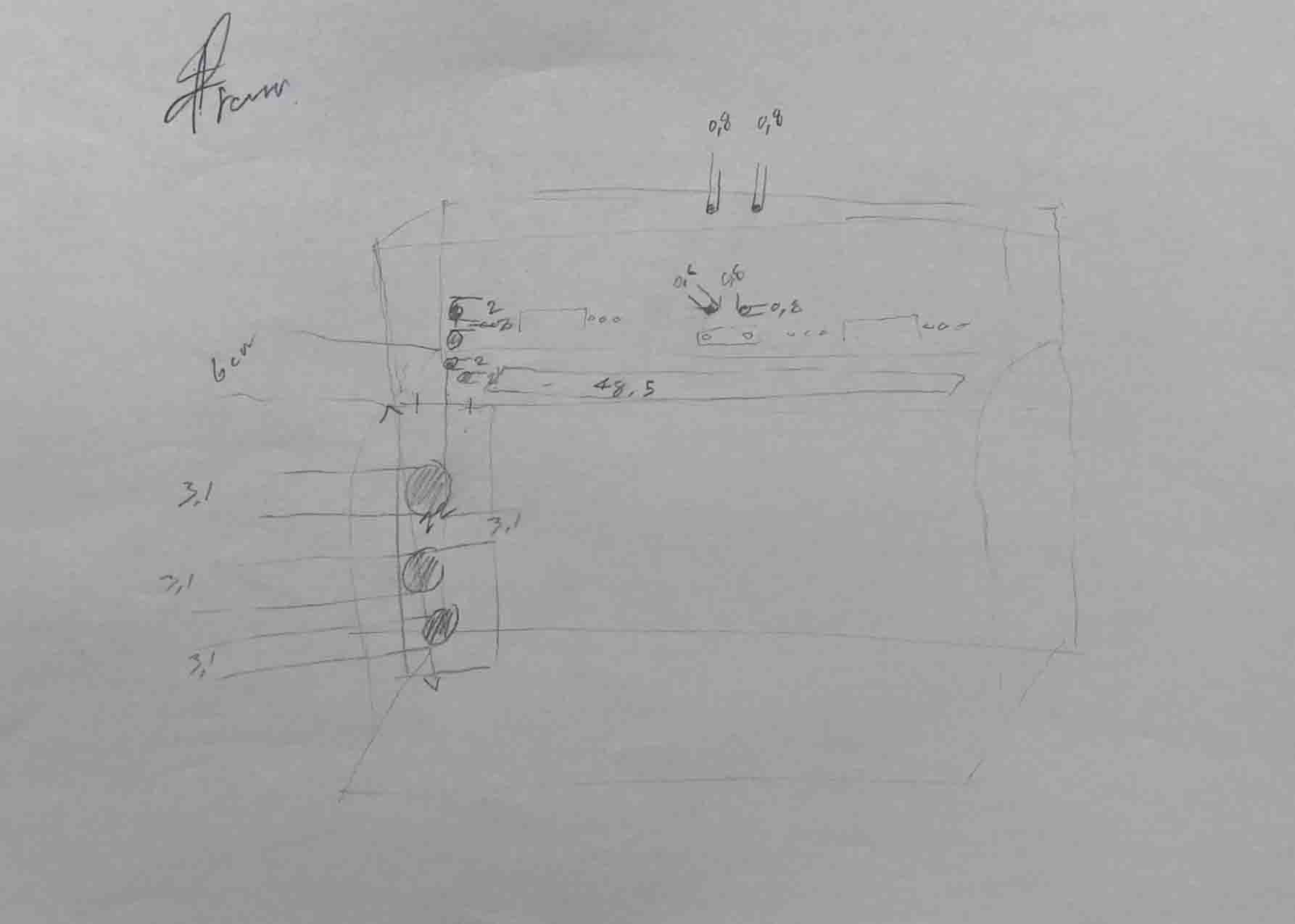

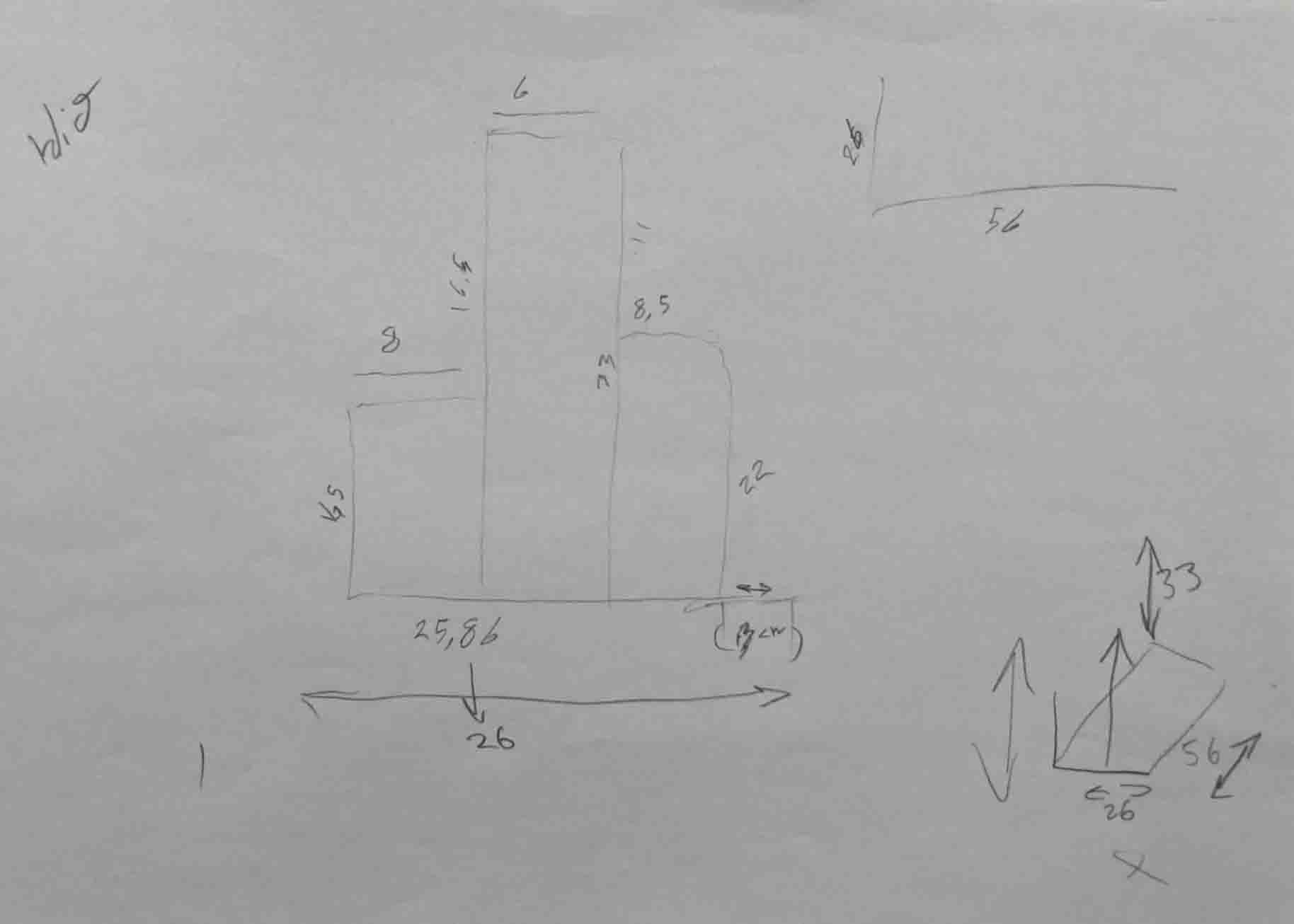

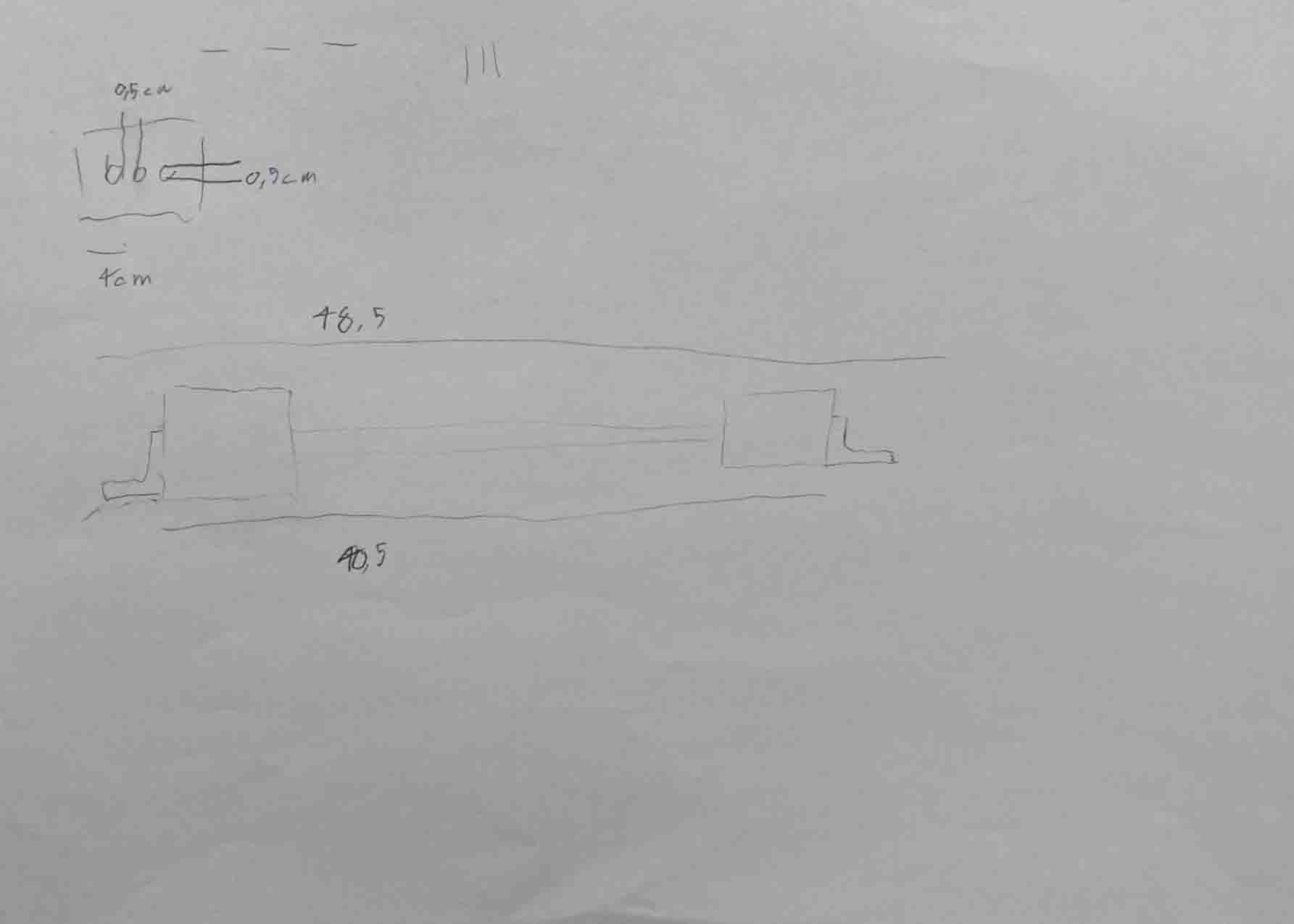

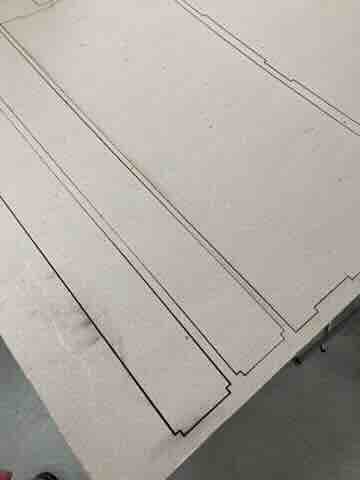

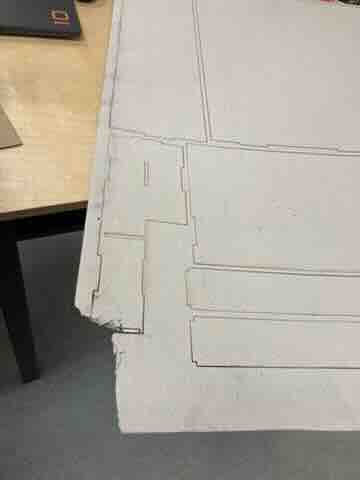

Mechanical Design / Machine Design

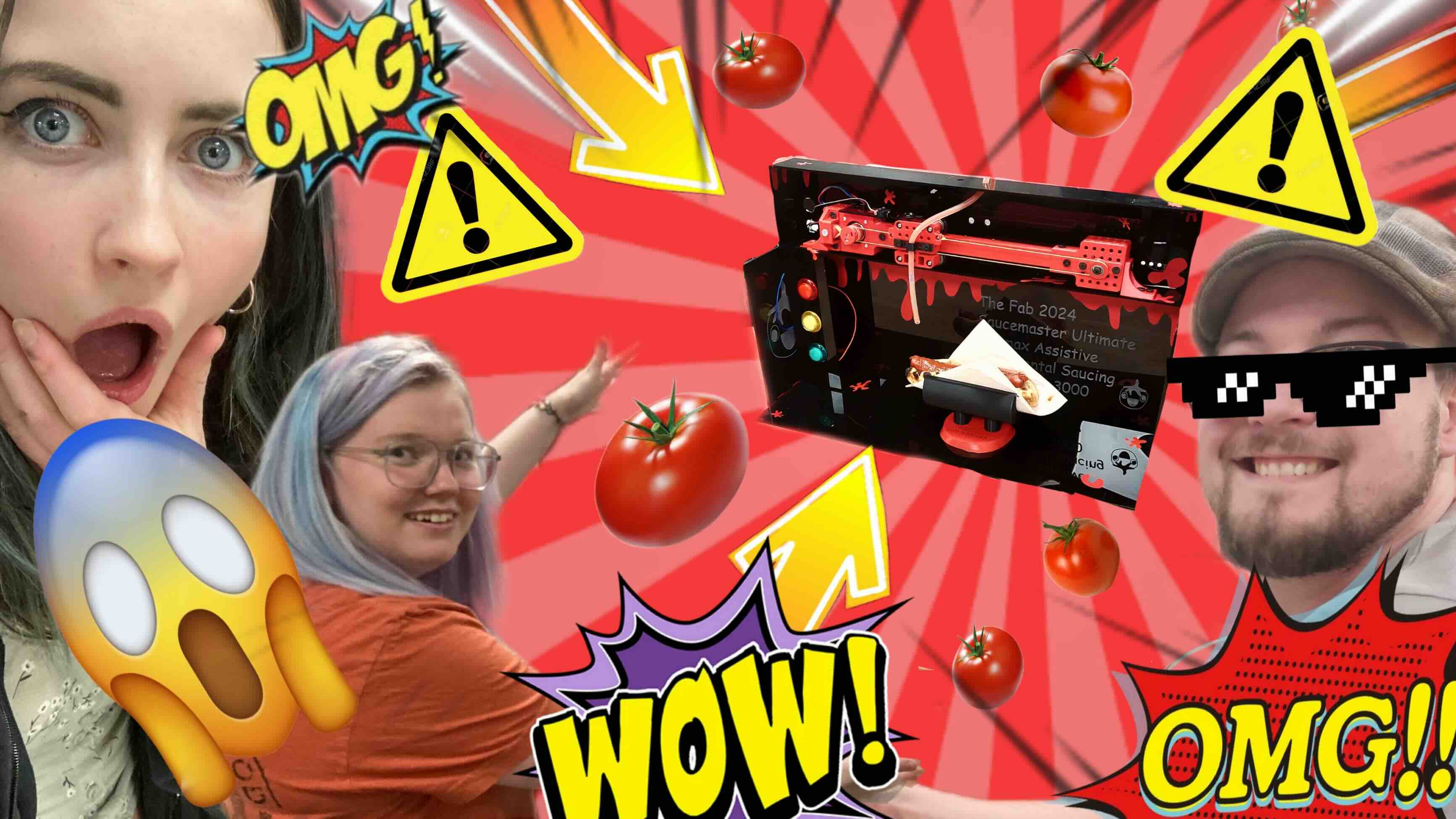

Project description

Group Assignment

actuate and automate your machine - document the group project and your individual contribution.

Group Assignment

design a machine that includes mechanism+actuation+automation+application - build the mechanical parts and operate it manually - document the group project and your individual contribution.