Week 10

Machine Week

A collaboration between Fablab Reyjkavík & Fablab Vestmannaeyjar

this Project was done in collaboration between Fablab Reykjavík & Fablab Vestmannaeyjar Me Gabríella & María all devided tasks and worked towards a common goal

Link to FLR group page

Link to FLV group page

Pump

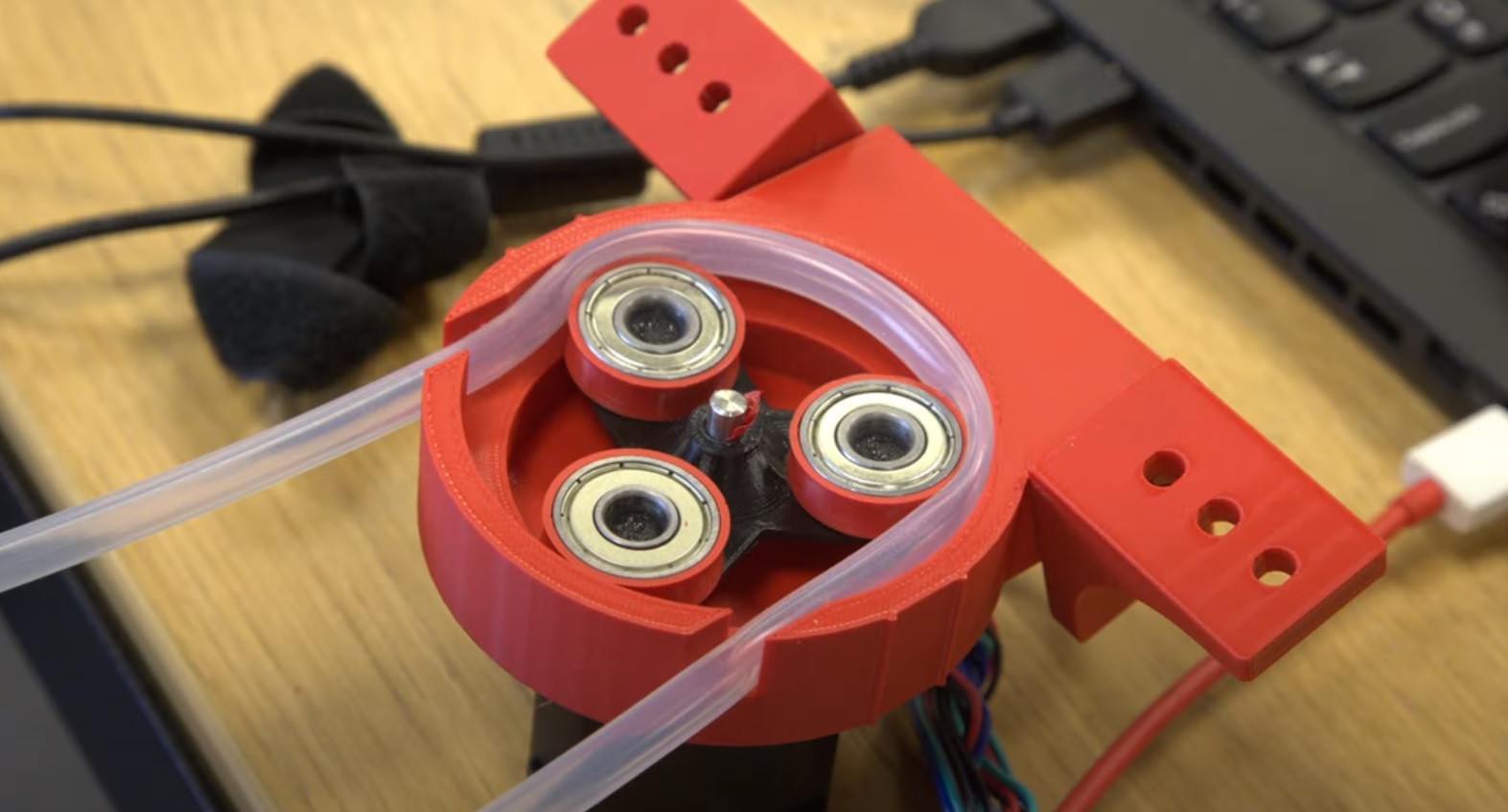

We decided early on that a peristaltic pump would suit our purposes the best. so this became my first responsibility for the Machine. I started by searching through Printables for a suitable model seeing as I knew this had been done a million times in a million ways and rather than reinventing the wheel I just modifies a design made by Shane.

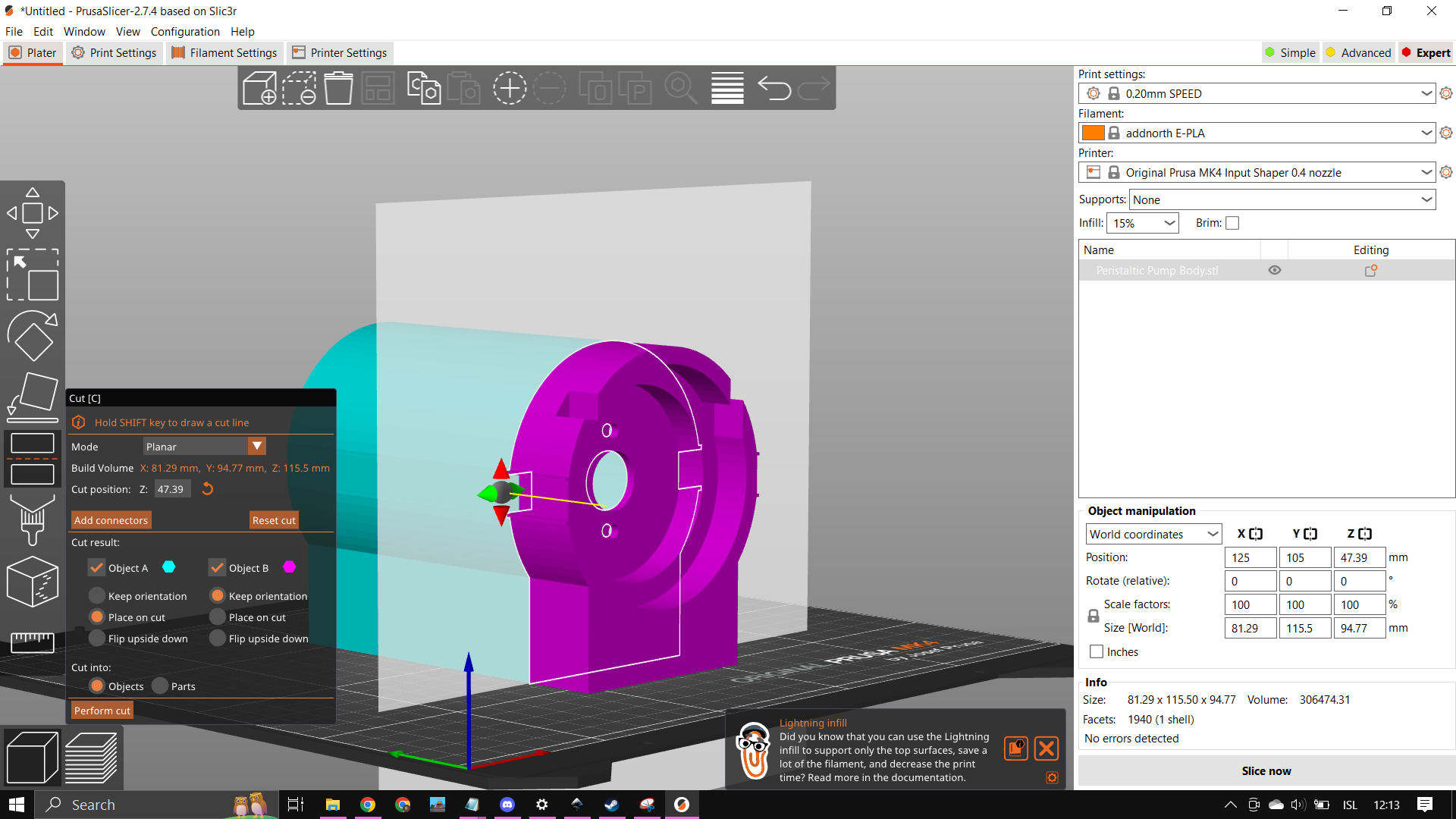

The first and most crucial modification I did to Shanes model was to cut the motor housing completely off on the Prusa slices so I could then mount a stepper motor on the mack rather than the brushless motor shane made the pump for

then with all the parts of the pump together I found out that it could not compress the hose enough so I quickly printed up some gaskets around the bearings to fix the issue, and that worked Like a treat

There was now one other problem beacause of these gaskets and that problem was that the bearings now clashed woith the lid for the pump so I resorted to the caveman solution of just grinding the lip away with a rotary tool and all was fixed.

with the pump out of the way I was free to go focus on the electronics, and this turned out to be more of a chore than I anticipated.

Electronics

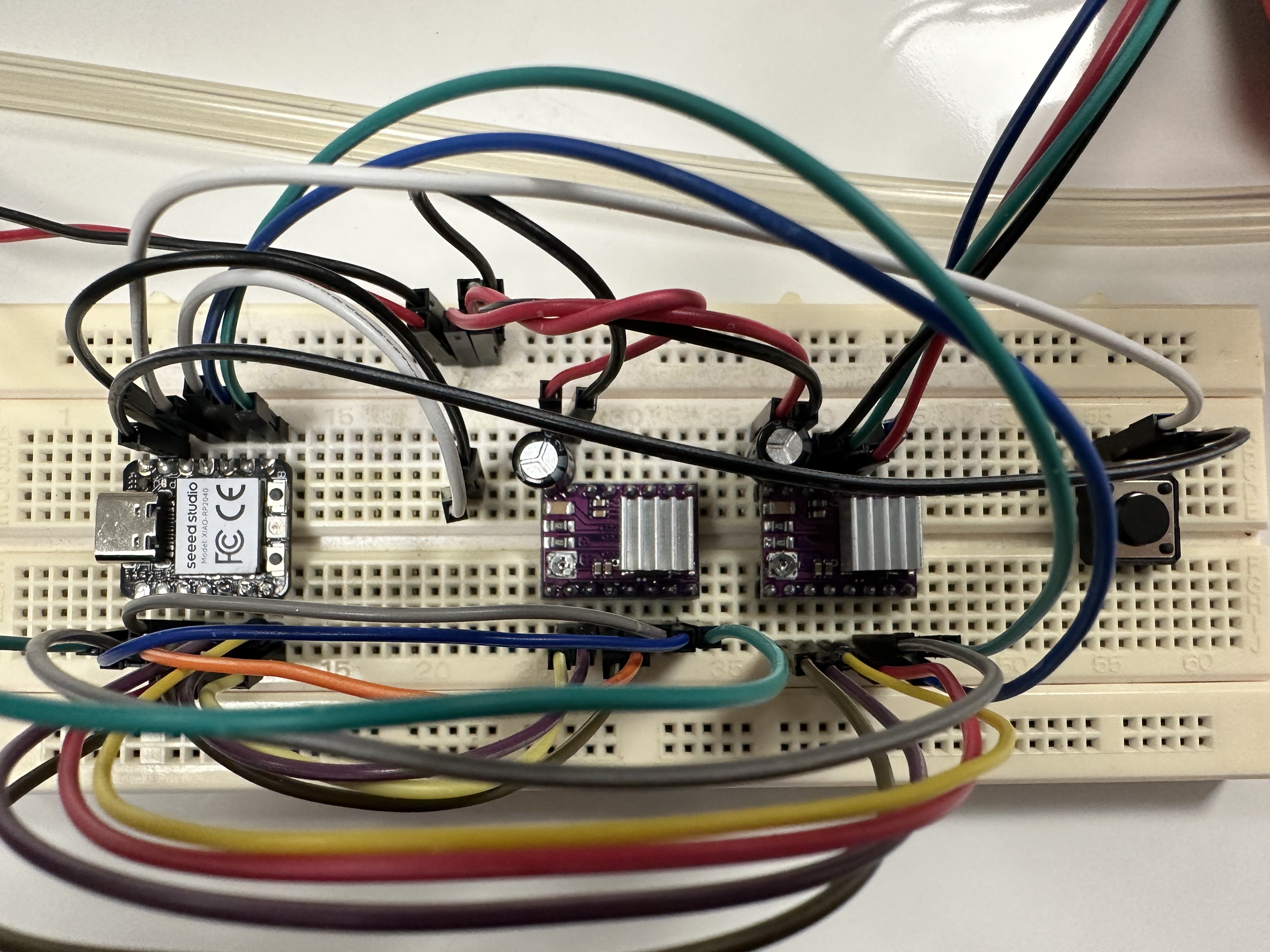

Knowing that Frosti and María had spent some time working on a modular things core X/Y Board that I knew we were having some issues with Me and Andri sat down and focused on trying to get the board he and his group had done the preavious year.

But this board seamed to be more trouble than it was worth since every code we tried to ruin on it seamed to not want to work, so after an entire dsay of trying to get this board to work we almost gave up but decided to reverce engineer the board and put everything on a bread board.

this was the goose that layed the golden egg in our case, suddenly and seamingly like magic everything was working. the pump, the code, the electronics, everything!

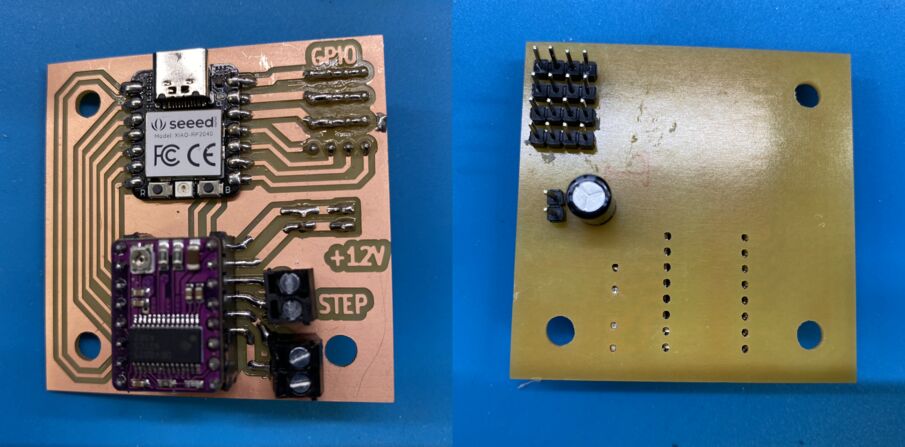

now I made the pcb using easy eda and am hoping to convince the mill at the lab to cooperate with me So I can finalise the electronics.

final machine

scrambing for time we could now finally assemble the machine and get it up and running, and to our immence surprice it worked perfect on the first try

and with that icelanders never have to worie about theyre ketchup ever again.

Link to youtube VideoFiles

Pump HousingPump Lid

Pump Rotor

Bearing Gaskets

Code for the electronics

PCB PDF