Project Development

Assignment

- Complete your final project, tracking your progress:

- what tasks have been completed, and what tasks remain?

- what's working? what's not?

- what questions need to be resolved?

- what will happen when?

- what have you learned?

See more info and recording of the lecture here.

Progress on the final project

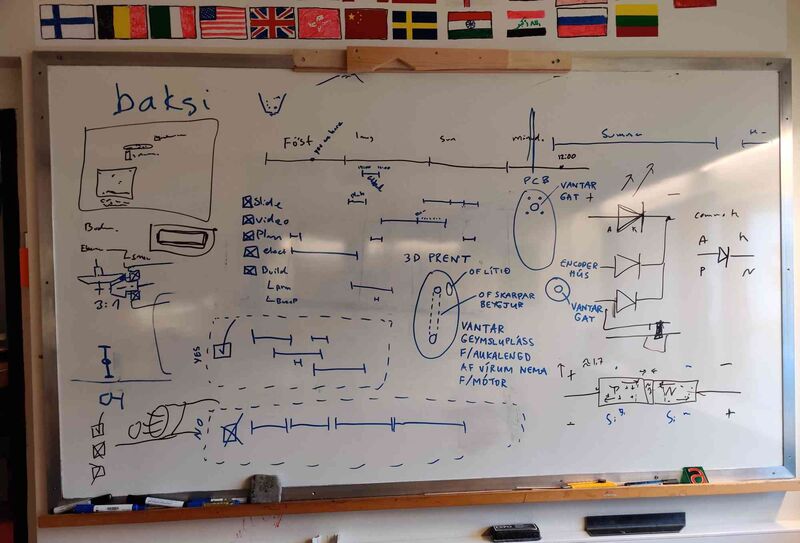

The final project plan.

The final project plan.

What tasks have been completed?

I managed to put together one robot joint and test it successfully. I'm really glad that I got this far.

Because my teaching duties were over for the semester, I was finally able to document as I went along. I found that enjoyable, and the final project documentation is much better for it. I will definitely aim for real-time documentation in my projects from now on.

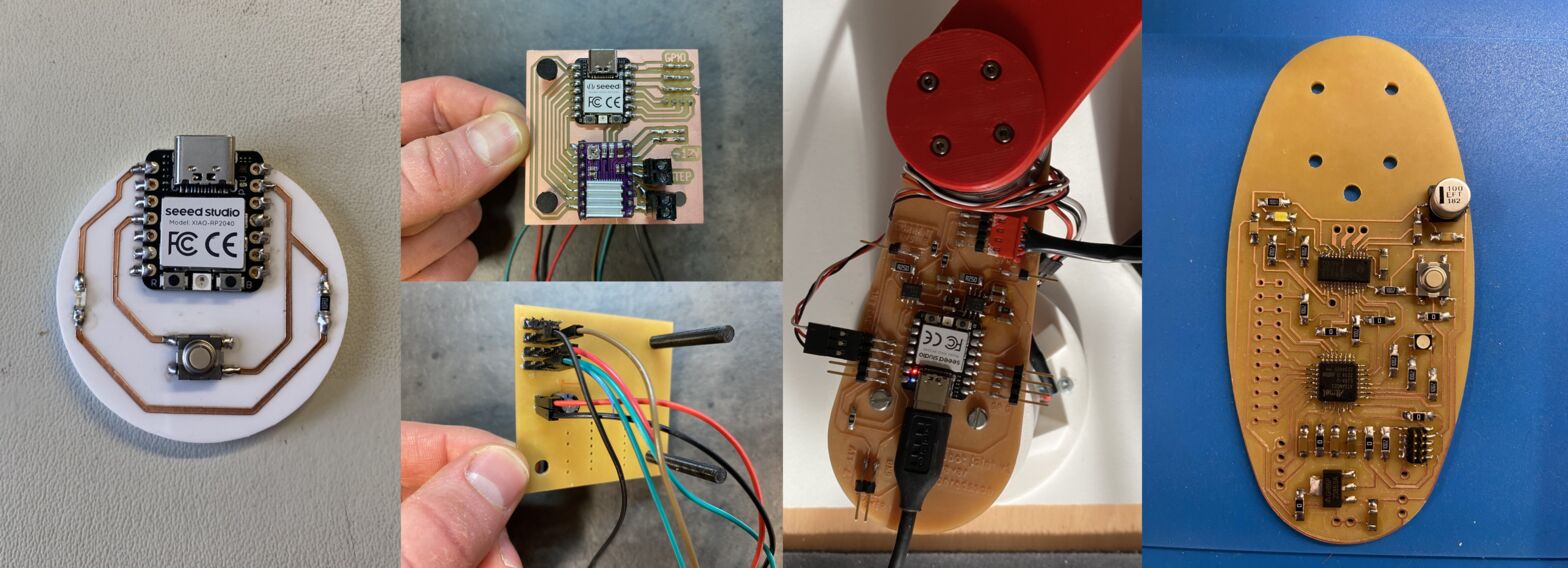

I approached the project in spirals, just trying to make one robot joint work. In the first spiral I took the Stepper RP2040 Modular Thing, changed its shape and added a few things. I did a lot of testing and debugging and found that the Toshiba TB67H451FNG motor drivers are not a good fit for brushless motors. That was quite a big blow, because I had spent a lot of time designing that board. But Rico Kanthatham urged us to make the major mistakes in our final project early, and I had done that. I did spiral 1 of my final project in Output Devices week (and two more weeks after that). So I still had time to find another motor driver and start the electronics design again from scratch.

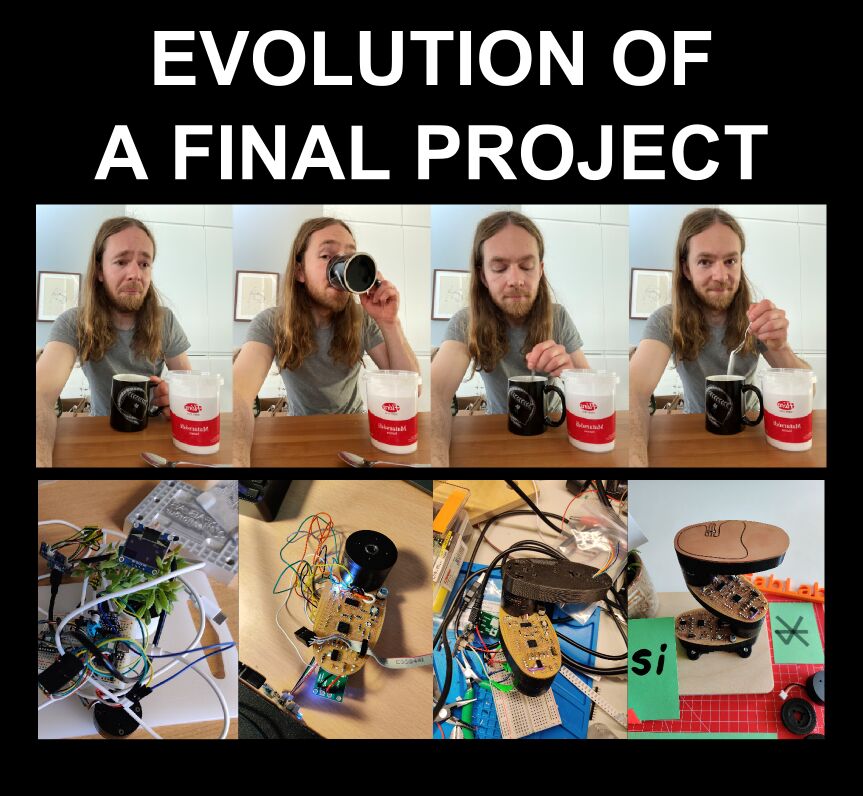

The evolution of my PCB design skills can be seen in these four boards:

My PCB design journey. Right-click the image and select "Open image in new tab" to see the boards better.

My PCB design journey. Right-click the image and select "Open image in new tab" to see the boards better.

- My first board was very simple; it had just a Xiao module, an LED with a current-limiting resistor and a button. It was a good first design project and I was so happy when I got the LED blinking!

- My first major design was the machine controller for the Teamanator, the Terminator-inspired tea machine that Andri, Hafey and myself finished successfully during an intense weekend in Fab Lab Reykjavík.

- My second major design was spiral 1 of my robot joint, which embeds a Xiao module onto the board.

- In spiral 2 I wanted to go further, so I embedded the SAMD21 chip directly onto the board, which I think is much cooler. I had the confidence to do that because I had played around with the RGBB Modular Thing and managed to program it with the Atmel-ICE. I think I've come a long way, because I had not designed an electronic circuit before starting the Fab Academy.

What tasks remain?

I need to connect the second robot joint and try operating them together. The robot is also missing a Z-axis (up and down). While I've been finishing up the documentation of the weekly assignments, I've been thinking about ways to make a clean-looking Z-axis. I think I have a good solution, but it requires a hack (see "What questions need to be resolved?").

I also need to make some kind of an end-effector. My instructor Þórarinn helped me make an electromagnet, but in the final push, I had to do triage and decide which parts of the project needed to be abandoned and which ones I might finish. I put all my energy into getting the motor control board made and assembled with all the wires hidden.

What has worked? What hasn't?

Everything I've tested in the final project works. I made sure of that before I assembled it. It was a bit of a risk to wait so long before actually fabricating anything. In the last Global Open Time meeting on the Saturday before I presented, I was milling the first board for my final project, and my final project still looked like this:

Meme from Þórarinn. The actual image is the first one in Þórarinn's meme at the bottom of this page.

Meme from Þórarinn. The actual image is the first one in Þórarinn's meme at the bottom of this page.

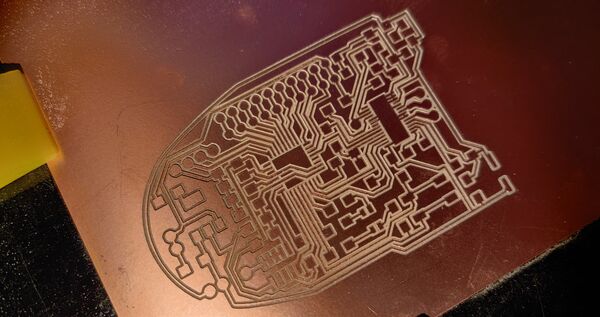

This was my second major attempt at milling this board. The first time I used a 0.01" milling bit, which broke after an hour of milling, in the middle of the night. You can see my reaction to that in my presentation video. Then I tried a V-bit, which is much stronger and more durable, but if you don't get the Z-height exactly right, the track that it mills will either be too thin or to thick. This may result in traces disappearing. While Global Open Time was still in session, the Modela MDX-20 finished milling with the V-bit:

The moment I realized that I could finish my final project.

The moment I realized that I could finish my final project.

I went to the video conferencing screen in the lab with my hands up in victory, and they guys celebrated with me.

Look at those beautiful traces.

Look at those beautiful traces.

As for the outcome of the final project: I love how you can see all the electronic components and yet the robot has a clean look and all the wires are hidden. All of them! That took a LOT of system integration work. The robot actually looks pretty much exactly like I envisioned it.

However, assembling the robot was hell. Wires kept breaking and it was difficult to get them into the 3D printed part. I wouldn't want to do it like this again. This was spiral 2. In spiral 3, I want to design a multilayer PCB that contains all the wires that are currently hidden inside the 3D printed part. Then I can realize my original vision of a robot that is made of motors and PCB and nothing else! And it will still have a clean look! The prospect is exciting, but my goodness, this project is so much work. I really need a good summer holiday.

Also, pretty much all the software interface work remains. I did receive a grant for my engineering buddy Guðjón Bergmann to do some work on that.

What questions need to be resolved?

Magnetic angle sensor placed off-axis. The PID loop still worked. If I move it a tiny bit further away from the middle, the motor goes haywire.

Magnetic angle sensor placed off-axis. The PID loop still worked. If I move it a tiny bit further away from the middle, the motor goes haywire.

Can I place the magnetic angle sensor far enough from the axis so that I can put a Z-axis leadscrew through the hole in the middle of the brushless motor? I've done a preliminary test with me holding the sensor off-axis, and it may work.

What will happen when?

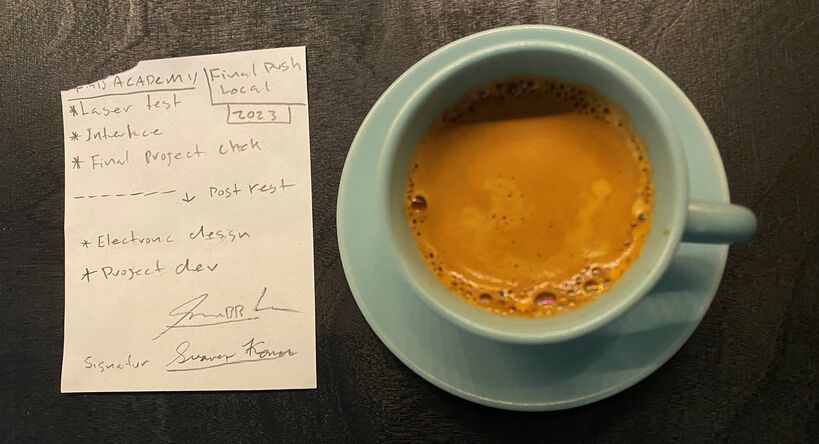

Note about the final push from Þórarinn. We signed it and everything. It's sitting on the espresso corner table that I made in Machining week. The espresso was quite well extracted (here's another reference image).

Note about the final push from Þórarinn. We signed it and everything. It's sitting on the espresso corner table that I made in Machining week. The espresso was quite well extracted (here's another reference image).

Guðjón Bergmann, who is studying Aerospace Engineering at TU Delft, will make a mockup of the software interface, and possibly do some real-world testing this summer. His work will finish in the beginning of August. I don't know when I will have time to do more work on this project myself, but I really want to get my "only motors and PCBs" robot made at a PCB house. That would be so cool. But right now I'm on my last chance to write a Master's thesis in Mechanical Engineering this winter. So I'll probably focus on that in the fall of 2023.

Guðjón Bergmann.

Guðjón Bergmann.

What have you learned?

Demand-side time management is a really important part of the Fab Academy, because if you just think about what you would like to accomplish and line those tasks up linearly, you will run out of time. The project must be designed with the time and energy you have in mind. Spiral development is also very useful to me. My instinct is to try to get all the way to a finished product in one giant leap, but spiral development, where you complete a rough and simple version first and then see if you have time for another complete spiral with more features, has much better results. As Þórarinn said after I presented my final project, Fab Academy is really one big lesson in project management. However, I've never used Gantt charts or other detailed project management methods, because I like working in research and development, and there you never know where the road leads you or how long it's going to take.

It's often possible to mock up a technical idea in a day or a weekend that you've been thinking about for years, and finally see if it's good or not. I've tried many things during the Fab Academy that I've been thinking about for a long time. And they're not as intimidating as they seemed. I've discovered the joy of distributed work on an open source community project (the Frankenstein MCU). Look! I figured out a way to add Zoom video conferencing to the FMCU and made nice instructions on how to run that version locally, for the other developers. This is my first time doing this sort of thing and I really like it. I've discovered a world of collaborators in the Fab Lab network.

My instructor Þórarinn has been very supportive throughout this journey and taught me many things, especially relating to electronincs. He is the resident meme master in the Fab Academy chat on Mattermost. Seriously, I think half of the memes on the meme channel came from him. He even made a meme just for me by rearranging the image series on my ideas page: