Bio

I'm Svavar Konráðsson.

I have a Master's degree in mechanical engineering from the University of Iceland.

Here's a video where I tell Neil Gershenfeld a little bit about myself during random review.

Team Spark

I took part in starting Team Spark, the Icelandic Formula Student team, which designs and fabricates electric racing cars and competes against other university teams at Silverstone circuit in England every year.

TS11

We got the help of Rafnar employees to make the composite shell of the TS11, our first racing car. The big protrusions on the sides are battery boxes. Because of time constraints, the steel spaceframe was simply covered with plastic sheets and then we draped fiberglass fabric over them and painted them with resin. And then Snorri offered me a job at Rafnar!

We got the help of Rafnar employees to make the composite shell of the TS11, our first racing car. The big protrusions on the sides are battery boxes. Because of time constraints, the steel spaceframe was simply covered with plastic sheets and then we draped fiberglass fabric over them and painted them with resin. And then Snorri offered me a job at Rafnar!

Our first time at Silverstone Circuit. The car didn't drive, but we learned a lot!

Our first time at Silverstone Circuit. The car didn't drive, but we learned a lot!

TS12

This model worked!

Building the spaceframe of TS12, our second car (and the first one where we had some idea of what we were doing). Lots and lots of tube cutting and positioning. Ívar (in the middle) designed the square tube jig that positions the main members for welding. We got help from Teknís to fabricate it.

Building the spaceframe of TS12, our second car (and the first one where we had some idea of what we were doing). Lots and lots of tube cutting and positioning. Ívar (in the middle) designed the square tube jig that positions the main members for welding. We got help from Teknís to fabricate it.

I'm near the middle, in a teal shirt. We worked with three students from the Icelandic Academy of the Arts, who came up with the name Team Spark, made the logo and chose the team and car colors and designed and made this amazing composite shell which was inspired by the electric eel. This is the unveiling at their graduation exhibition. They even embroidered the logo into the headrest, can you see it?

I'm near the middle, in a teal shirt. We worked with three students from the Icelandic Academy of the Arts, who came up with the name Team Spark, made the logo and chose the team and car colors and designed and made this amazing composite shell which was inspired by the electric eel. This is the unveiling at their graduation exhibition. They even embroidered the logo into the headrest, can you see it?

Team Spark at Silverstone circuit with TS12. I'm in the middle.

Team Spark at Silverstone circuit with TS12. I'm in the middle.

I took TS12 for a spin on a go-kart track. My first time driving an electric car!

I took TS12 for a spin on a go-kart track. My first time driving an electric car!

Rafnar boatyard

Dröfn

My first task at Rafnar was to finish the design of this 6m pleasure boat. Behind it is the RIB that preceded Leiftur. Behind the RIB is the very first full-scale boat that was built with the ÖK hull design.

My first task at Rafnar was to finish the design of this 6m pleasure boat. Behind it is the RIB that preceded Leiftur. Behind the RIB is the very first full-scale boat that was built with the ÖK hull design.

Leiftur

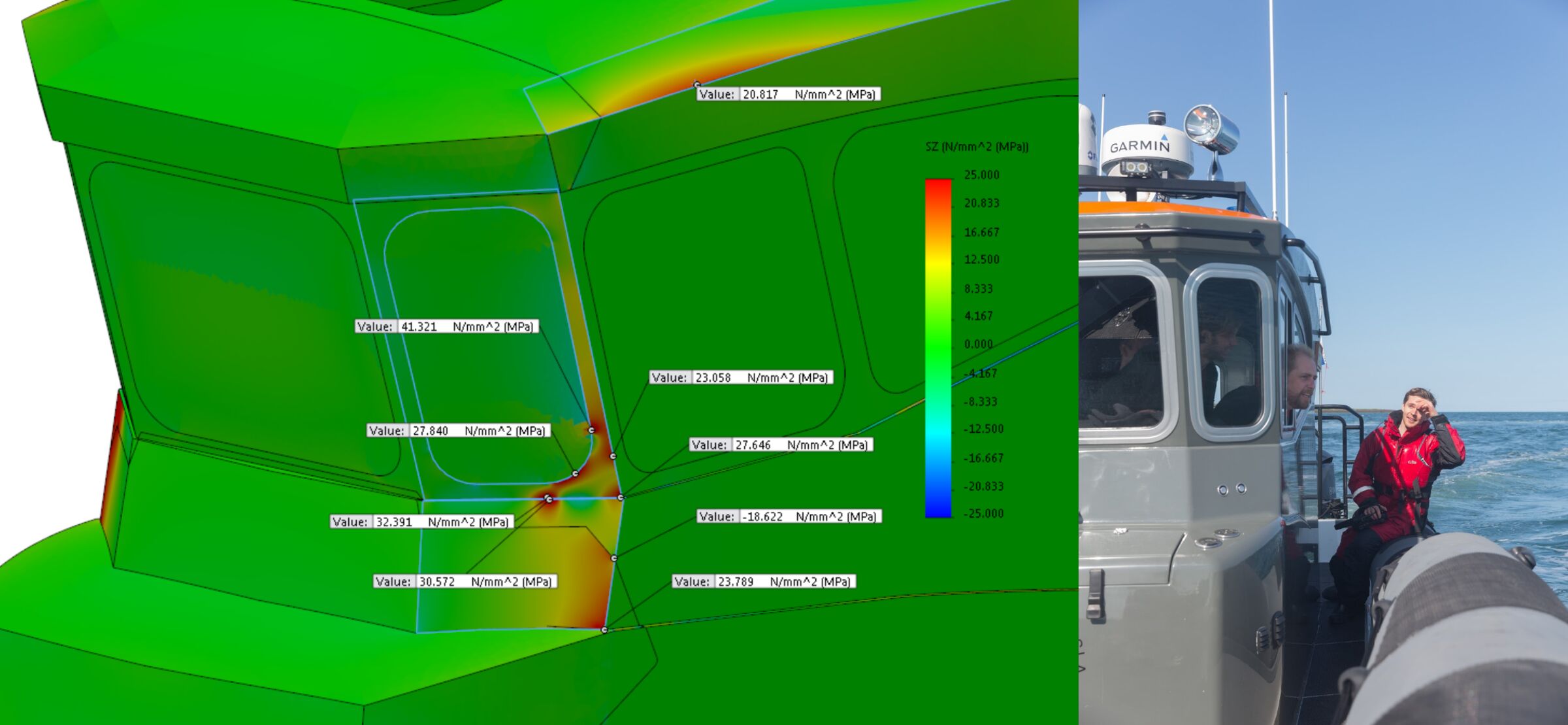

I did the structural design and Lloyd's Register safety certification of an innovative RIB at Rafnar boatyard, a boat that is now manufactured in five countries around the world. This is probably my biggest professional achievement.

Pilot house simulation of Leiftur, the most popular Rafnar boat. The first unit, in grey, went to the Icelandic Coast Guard. You really have to take this thing for a spin to see how unique it is.

Pilot house simulation of Leiftur, the most popular Rafnar boat. The first unit, in grey, went to the Icelandic Coast Guard. You really have to take this thing for a spin to see how unique it is.

My desk at Rafnar boatyard. The first orange Leiftur being delivered to an Icelandic search and rescue team. I put masses on every single component in the SolidWorks assembly and used Archimedes' principle to find its waterline. Its as-built weight distribution was spot on!

My desk at Rafnar boatyard. The first orange Leiftur being delivered to an Icelandic search and rescue team. I put masses on every single component in the SolidWorks assembly and used Archimedes' principle to find its waterline. Its as-built weight distribution was spot on!

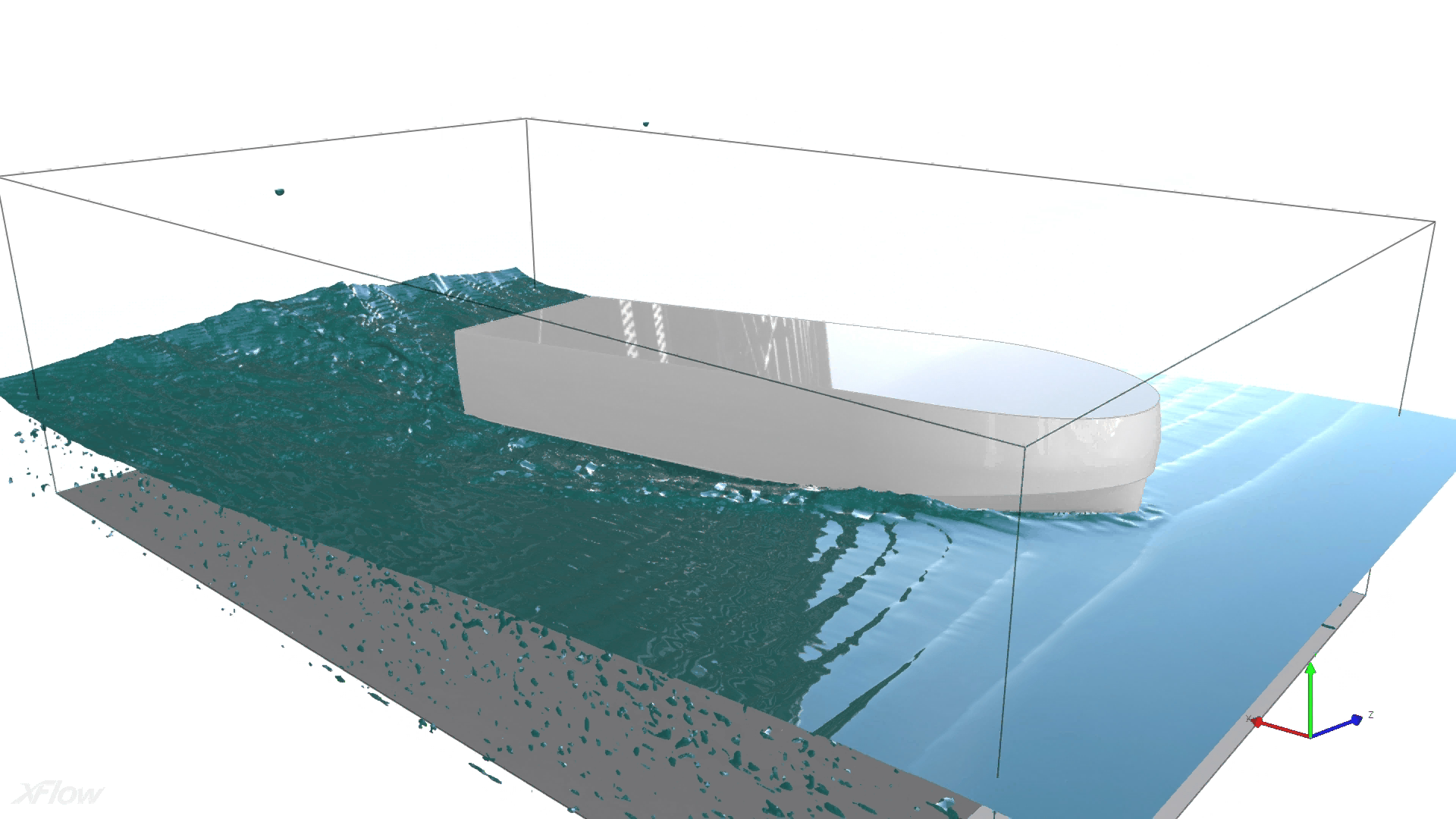

A huge computational fluid dynamics simulation of a Rafnar boat hull.

A huge computational fluid dynamics simulation of a Rafnar boat hull.

Jökla

Jökla the 15m yacht. I'm casually laying my hand on the boat as though it's my baby, but I only designed a couple of air intake grilles at the back.

Jökla the 15m yacht. I'm casually laying my hand on the boat as though it's my baby, but I only designed a couple of air intake grilles at the back.

One of the double-curved windows in Jökla broke during construction and the CAD model had also broken, so I got the help of our purchasing manager to measure it very precisely, model it and order a new one. It took ten weeks, cost a million ISK and arrived from Germany perfect, except it was bent the wrong way.

I had accidentally set the document to the American orthographic projection standard instead of the European one! I then changed the setting to First angle projection and ordered another glass pane and they let me keep my job. And the yacht turned out beautiful, but this was most of my contribution to it. Drawing standards are important for getting the build right!

KOL Carbon

A coworker came to me with an idea for a luxury belt and I helped him take it all the way:

I designed this compression molded carbon fiber belt buckle. It's an unnecessarily high-performance material, but I like how the fibers catch the light. This design was a good exercise in double-curved modeling.

I designed this compression molded carbon fiber belt buckle. It's an unnecessarily high-performance material, but I like how the fibers catch the light. This design was a good exercise in double-curved modeling.

Yours truly modeling the belt.

Yours truly modeling the belt.

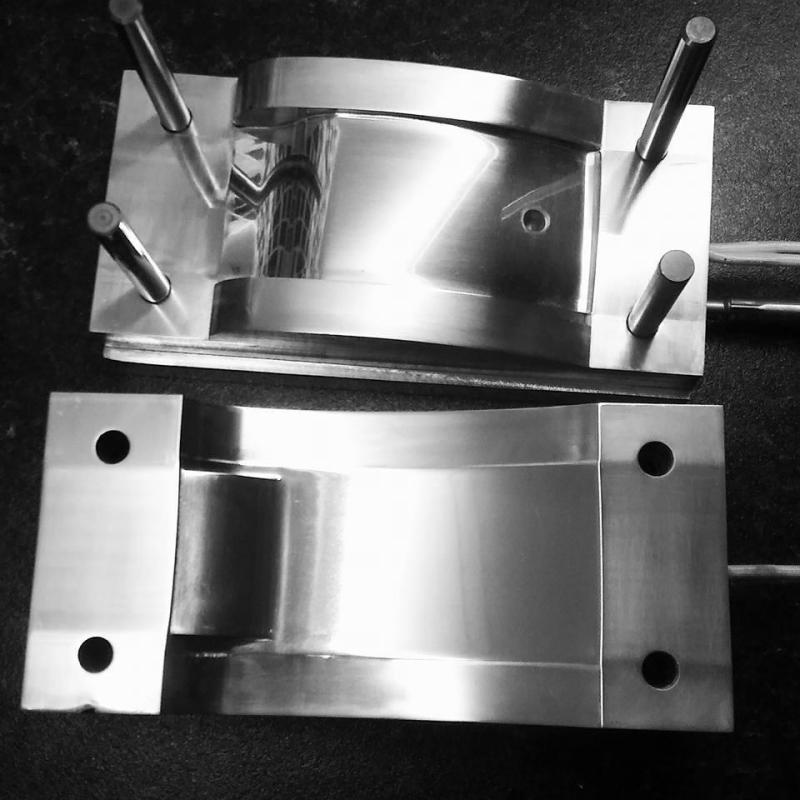

Version 2 of the compression mold, very much simplified and improved. Nice and shiny! The first mold included the hole for the belt, which made the geometry complicated and full of sharp edges which made it tricky to put the SMC material into the mold. With V2 the hole was milled afterwards.

Version 2 of the compression mold, very much simplified and improved. Nice and shiny! The first mold included the hole for the belt, which made the geometry complicated and full of sharp edges which made it tricky to put the SMC material into the mold. With V2 the hole was milled afterwards.

3D Prentun ehf

I started a 3D printing service and ran it for a few years:

I sponsored the Team Spark racing car by donating 3D printed parts.

I sponsored the Team Spark racing car by donating 3D printed parts.

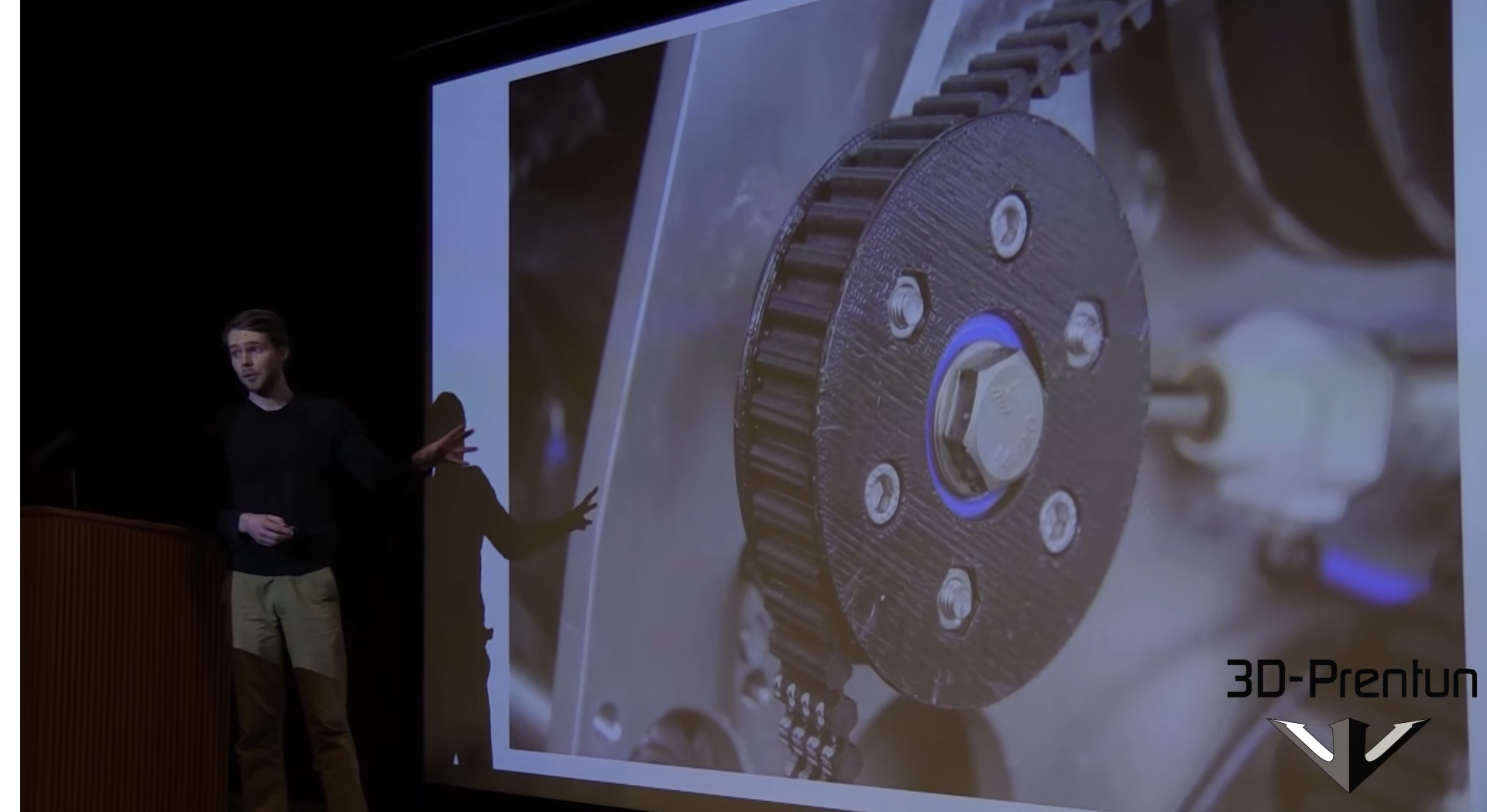

A presentation of the potential of industrial 3D printing for engineers on the Day of Engineering 2016. The video is in Icelandic.

A presentation of the potential of industrial 3D printing for engineers on the Day of Engineering 2016. The video is in Icelandic.

The first ad I bought to introduce the new 3D printing service.

Having fun with the Form 1.

Having fun with the Form 1.

SLA prototypes for Genki Instruments.

SLA prototypes for Genki Instruments.

Cooling slush splitter for a food factory.

Cooling slush splitter for a food factory.

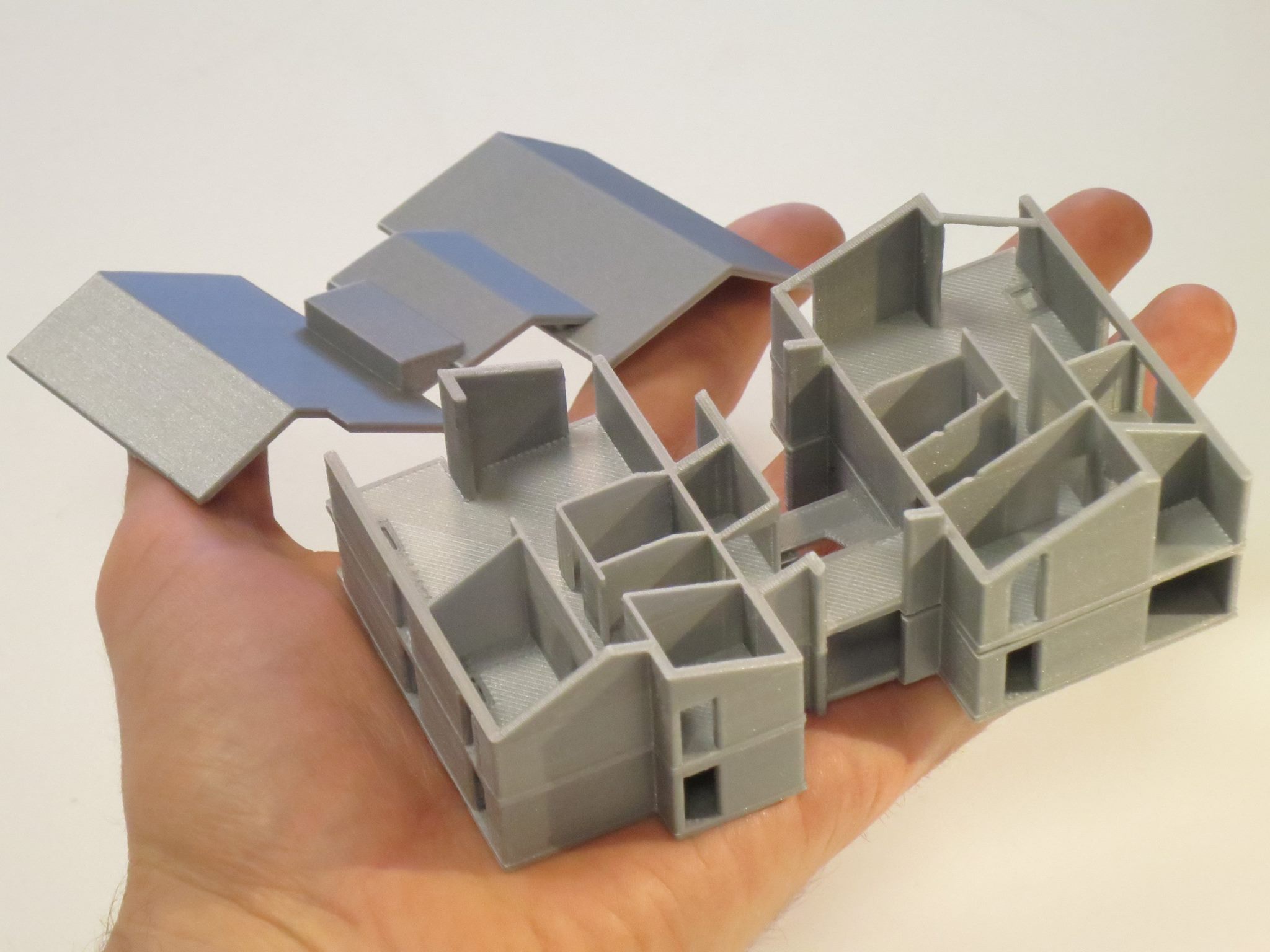

A nice openable architecture model.

A nice openable architecture model.

Models of the North Tower in Kópavogur were given to the companies that rent each floor. The man who commissioned the job later became our investor.

Models of the North Tower in Kópavogur were given to the companies that rent each floor. The man who commissioned the job later became our investor.

Architecture exhibit at the town hall in Reykjavík. You know, architects were my best customers.

Architecture exhibit at the town hall in Reykjavík. You know, architects were my best customers.

Assembling the architecture model for the Black Mirror episode that was shot in Iceland.

Assembling the architecture model for the Black Mirror episode that was shot in Iceland.

The set of Black Mirror with the model that we made.

The set of Black Mirror with the model that we made.

Our biggest project was a scale model of the international airport in Keflavík. The Revit models were not printable, so we modeled all the buildings in SolidWorks. We printed the current airport buildings in white, and the future building projects in grey.

Our biggest project was a scale model of the international airport in Keflavík. The Revit models were not printable, so we modeled all the buildings in SolidWorks. We printed the current airport buildings in white, and the future building projects in grey.

The model was a huge hit in construction planning meetings. It's so much easier for all stakeholders to understand than 2D plan drawings. And you can rearrange things and play with variants of the buildings.

The model was a huge hit in construction planning meetings. It's so much easier for all stakeholders to understand than 2D plan drawings. And you can rearrange things and play with variants of the buildings.

We worked our way up to Stratasys FDM machines.

We worked our way up to Stratasys FDM machines.

With the Stratasys machines you can print 100% solid ABS parts like this temporary damper bracket in a design office, instead of milling them out of engineering plastics with all the noise and mess that comes with that.

With the Stratasys machines you can print 100% solid ABS parts like this temporary damper bracket in a design office, instead of milling them out of engineering plastics with all the noise and mess that comes with that.

Smári, the designer and CEO of Ekkó Trawl Doors with a detailed 3D printed model that he takes with him to trade shows.

Smári, the designer and CEO of Ekkó Trawl Doors with a detailed 3D printed model that he takes with him to trade shows.

SAFE Seat ehf

The design team at Rafnar was annoyed at the high price of suspension seats for speedboats, and we thought we could do better. So when we left Rafnar, we started a small company and designed a novel suspension seat.

Pitching at the Startup Reykjavík accelerator.

Pitching at the Startup Reykjavík accelerator.

Speaking at Investor Day. The video is in English.

Speaking at Investor Day. The video is in English.

We won the Golden Egg; Iceland's main business plan competition. Páll Einarsson, product designer, is on the left and Birgir Fannar Birgisson, industrial designer, is on the right.

We won the Golden Egg; Iceland's main business plan competition. Páll Einarsson, product designer, is on the left and Birgir Fannar Birgisson, industrial designer, is on the right.

We got second place at the University of Iceland's Practical Innovation awards. Páll seemed surprised!

We got second place at the University of Iceland's Practical Innovation awards. Páll seemed surprised!

Skenkir

This is my favorite university class project:

Getting a sip from Skenkir (video).

Getting a sip from Skenkir (video).

Fab Lab Ísafjörður

Now I work at Fab Lab Ísafjörður and I'm interested in ways to introduce students to computer-controlled machines.

Myself on the left and Þórarinn Bjartur Breiðfjörð Gunnarsson, my Fab Academy instructor and the director of Fab Lab Ísafjörður, on the right.

Myself on the left and Þórarinn Bjartur Breiðfjörð Gunnarsson, my Fab Academy instructor and the director of Fab Lab Ísafjörður, on the right.

I like to think of myself as an inventor. I realize that in many people's minds the word "inventor" is almost synonymous with "crackpot", but as a child I thought Gyro Gearloose was the coolest character and I always wanted a shed full of tools and inventions like he has. Now I work in a Fab Lab! I've even referred to myself as an inventor in public:

Interview in Icelandic about my work and studies

I agree with mixtela's thoughts on being an inventor. For me it's like being a writer. You don't have to be a successful published writer to call yourself a writer. You just sit down and write.

You can decide to be an inventor. You don't need to have invented a world-changing device, all you need is to make things that you haven't seen before.