'Let the Elephant fell the trees, let the bushpig dig the holes, let the mason wasp fill in the walls, let the giraffe put up the roof, then we'll have a house.'

African Proverbs

Mechanical and Machine Design

What is Machine Design?

Machine design is defined as the use of imagination, scientific principles and engineering techniques to create a machine or structure economically, in order to satisfy your requirements or those of the requirements of a customer. Machine design is the first step involved in creation of a machine. It gives the basic idea of how a machine will look and function. To read more: Click Here.

Steps in Machine Design

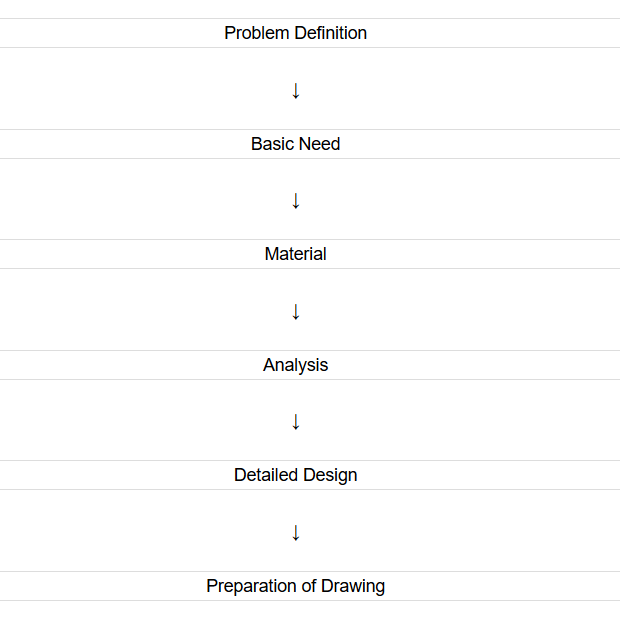

The picture below shows the steps to be taken when designing a machine

Note: Material involves cost analysis. Analysis involves feasibility, optimization and tests

Factors Influencing Machine Design

The following is a list of factors that influence the machine design process:

Types of Machine Design

As manufacturing technology evolves, we’ve seen impressive leaps when it comes to the creativity and complexity of machine design and mechanical engineering. Machine elements that once seemed impossible are now commonplace in today’s manufacturing world, and while we all want to strive to be at the forefront of innovation, we can also make use of existing technology to get us moving in the right direction. This is where the fundamentals of machine design come in, and they can be broken down into three categories, Adaptive Design, Developmental Design and New Design.

Adaptive DesignOne of the most basic, but widely used types of machine design is Adaptive Design. Think of the saying “don’t reinvent the wheel”. Often times, there is a machine component or design element that already exists and has been widely embraced that could be adopted to suit your purposes. Adaptive Design utilizes basic features and tweaks them slightly to better fit a particular application. Modifying technology that has already been proven effective can save engineers time and businesses money, and is often far more effective than trying to design a part from scratch.

Developmental DesignSimilar to Adaptive Design, Developmental Design uses existing concepts and technology but adds or combines new machine elements and components to create something unique. An example often referred to in Developmental Design is the motorcycle, which is essentially the marriage between a bicycle and a combustion engine. The motorcycle was certainly a massive development in manufacturing technology and machine design, but it relies on preexisting mechanical elements to serve as the building blocks for something new.

New DesignThe vast majority of machine design will fall into the previous two categories, but there are still new and unique parts and technology being created all the time. These one of a kind innovations would be considered New Design, where engineers and designers come up with something entirely original. This is far less common, and often requires a great deal of time, money and research. Because we live in a world of shared knowledge and technology, it is usually more productive and efficient to modify that which already exists, but with the right idea and the proper experience, elements in the New Design space can be extremely lucrative and beneficial to the manufacturing world as a whole.

What is Mechanical Design?

According to excerpts from Shigley's Mechanical Engineering Design, Mechanical design means the design of components and systems of a mechanical nature—machines, products, structures, devices and instruments. For the most part mechanical design uses mathematics, materials, and the engineering-mechanics sciences. Additionally, it uses engineering graphics and the ability to communicate verbally to clearly express your ideas.

Basics of Mechanical Design

Whether you’re creating a components from scratch, or modifying widely used technology, it is important to understand the basics of mechanical design. To design and produce an effective part, engineers must take into account all aspects of form and function to ensure that their product will not only operate as expected, but be able to be manufactured in the first place.

Understanding Stress/ForceIn what kind of environment will your part live? Under what stresses will it routinely be placed? There are many factors that can help or hinder a parts performance (temperature, moisture, dust/debris, impact, range of motion, etc.) When it comes to mechanical design, the more research an engineer can do up front the better. A machine element that works great in the snow could fail in the desert, and these varying conditions will need to be accounted for.

Know your MaterialsWith a keen understanding of the stresses at play in a particular environment, the next decision in the machine design process is what material to use in manufacturing a part. Certain metals are more resistant to corrosion and warping. Different plastics hold up better to heat and friction. If weight is a factor, there a number of high-strength light-weight materials available, but they come at a cost. These are all factors to keep in mind throughout the machine design process.

Understand the TechnologyBefore a part is completely designed, it is important to have a firm understanding of the manufacturing technology at one’s disposal to ensure that a part can be produced effectively and affordably. Mechanical engineers will often work closely with their machine shop to discuss challenges or limitations in their design elements, and to brainstorm potential areas of improvement (machine availability, required tolerances, bend geometry, etc.) The most mind-blowing design in the world could look great in a CAD model, but if it doesn’t do a lot of good if it can’t actually be machined.

To read more, you can also visit HERE.

You can go to the assignment from here Assignment.

You can follow the progress of the Final project HERE.