'If you want to know the end, look at the beginning.'

African Proverbs

This week I worked on defining my final project idea and started getting used to the documentation process. I came up with two project ideas, out of which as the couse progresses, would select one to develop. The first is an automated fabric screen printing machine called 'Fab Mode'. The second is an open source Vinyl cutter called 'Open Vinyl'. Detailed explanation and illustrations of the project ideas are presented below.

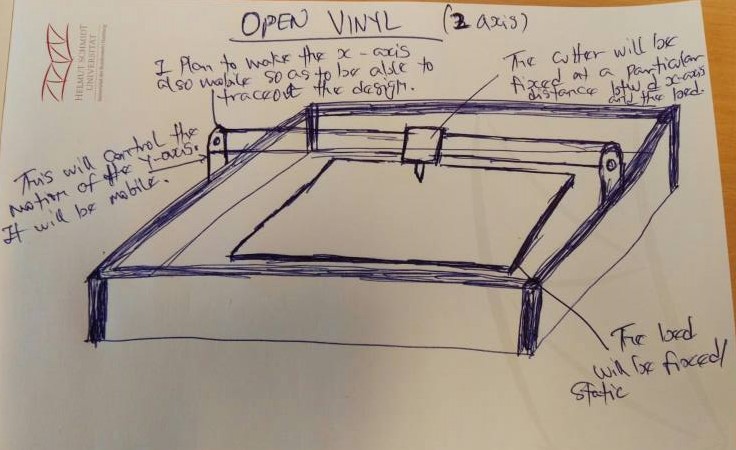

Open Vinyl'

Open Vinyl is a low-cost open source vinyl cutting machine mostly used for the production of T-Shirt designs. For more information on what a Vinyl cutter is Click here. The development of Open Vinyl be based on experimentation with different low-cost materials so as to develop a very affordable machine that can be implemented in any settings. More information about the project will be documented weekly as the Fab Academy progresses.

How It will work

The following are the steps with which Open Vinyl could work:

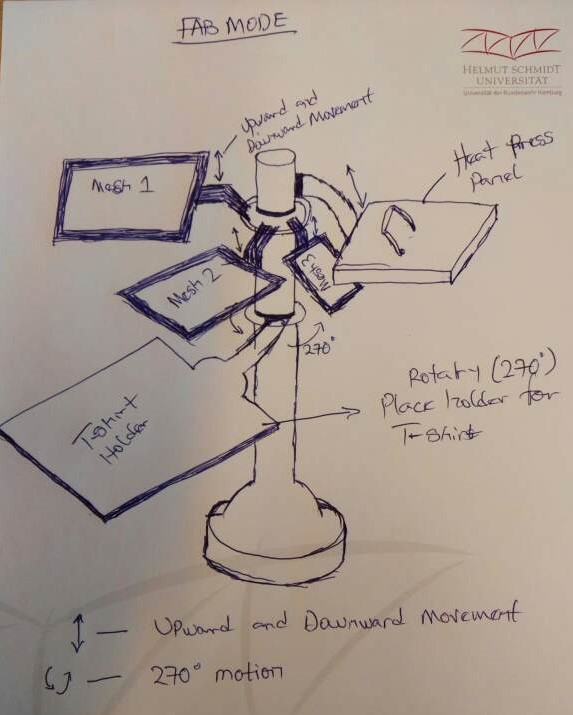

Fab Mode'

Fab Mode is a 3-colour automated screen printing mechanism embedded with its own heat press machine. To know more about how screen printing works, please Click here, and for the information on how heat press works please Click here. As depicted in the illustration above, Fab Mode will have 3 meshes slots which can handle three colours, one placeholder for blank T-shirt, and one fixed heat press machine. These meshes will be designed to be based on upward and downward pressure mechanisms, while the placeholder for the T-Shirt will be rotary, automatic. This T-Shirt placeholder will be moved from one mesh to another depending on the numbers of colours worked on, and then finally to the embedded heat press component to heat treat the design. In addition, the squeegee blade for applying the ink on the blank T-Shirt will also be automated. Another conceptual design of Fab Mode could also have placeholder for paint tubes, but time will tell which part of the concepts would be implemented.

How It will work

The following steps explains how Fab Mode would work:

Benefits of these projects

I believe any of these projects will contribute to the Open Source Hardware platform, and could also be used to boost entrepreneurial purposes in different areas, because there is an increase in the number of creative youths generating income from the production and manufacturing of unique T-Shirt designs.

New Projects

In the recent development and propagation of Corona virus, I started pondering on the idea of developing an InfraRed Thermometer (Non-Contact). This sensor will also include a camera module and a screen display that shows the body heat (thermal) of the material been measured. I finally concluded to work on this idea on 25-03-2020. So in the coming day, I will start working on the full project such as thorough study of the project, designing of the CAD, circuits, and exterior components, as well as other components that might be needed.

Incremental Innovation

Open source projects similar to this has already been done by guys that are almost close to Einstein. The links appended here are the projects that I find very similar to this project. Open Source Project1 and Open Source Project2 . With this projects, I could easily get some visual supports for the development part of this project.

Of what use is my Fab Academy commitment if I cannot design my own PCB board for this project! So I pledge to do everything within my human capability, as well as with the support of my Fab Gurus (Daniele Ingrassia and Jorge Montalvo Navarette) to create a flexible, easy-to-use, as well as easy-to-fabricate project. So, in case you are wondering what I will be doing different in this project, there goes your answer.

So help me God!

Thank you for your attention! You can follow the weekly progress of the final project, please click Main Final Project.