7. Electronics Design¶

Week Assignment

- Test the operation of a circuit board (group).

- Design a hello-world board with additional buttons and LEDs (individually).

Design a Hello-World Board with Additional Buttons and LEDs¶

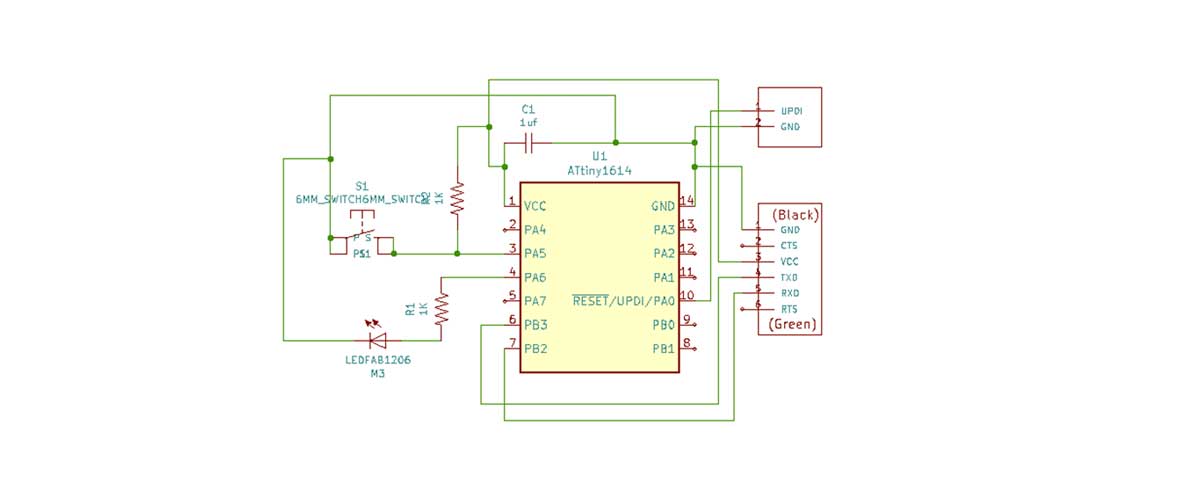

I designed a hello-world board using an ATtiny1614 with an additional LED and button. The design process involves three main steps:

- Defining the schematic

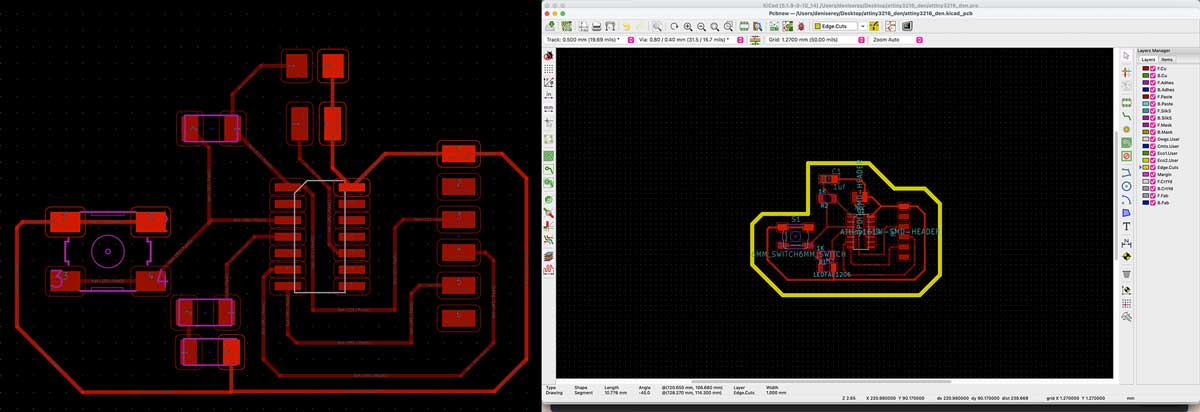

- Designing the PCB with the traces

- Building the PCB

As we were introduced to KiCad during the class, I used the ATtiny1614 datasheet as a base for my design.

Example ATtiny1614 Board¶

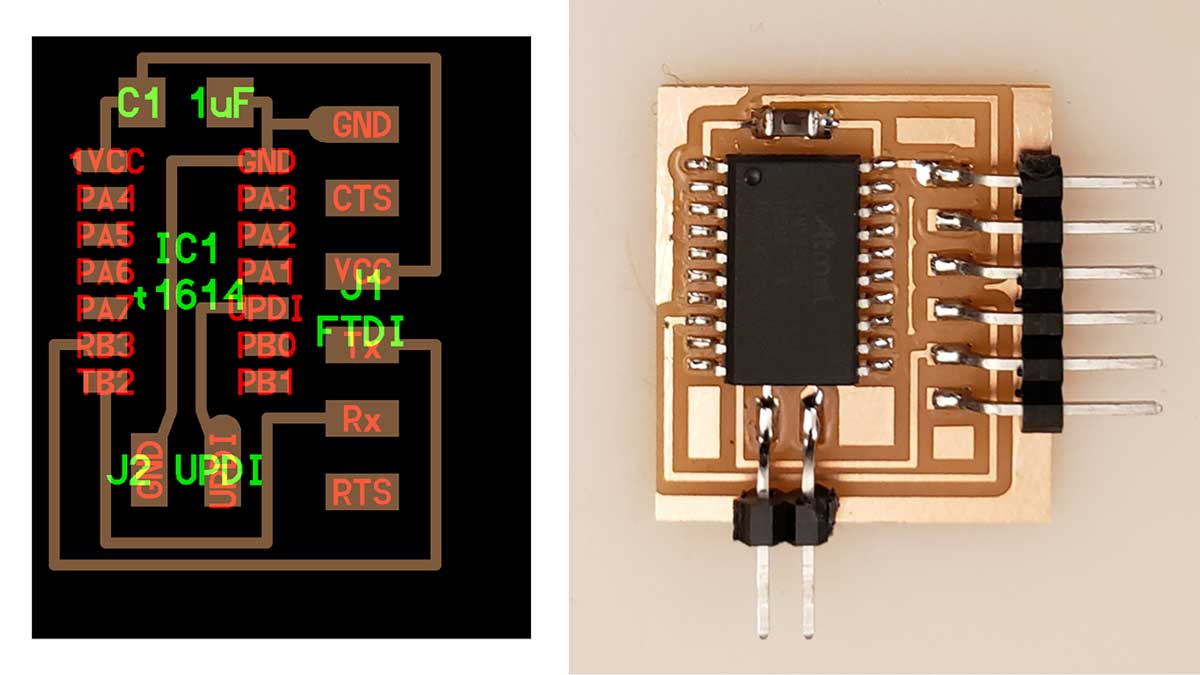

I opened KiCad and created a new project. Using the FAB library that we added during the class, I redrew the hello-world board example with an ATtiny1614, a UPDI connector, a capacitor, and an FTDI connector. I also added an LED, a resistor, and a switch.

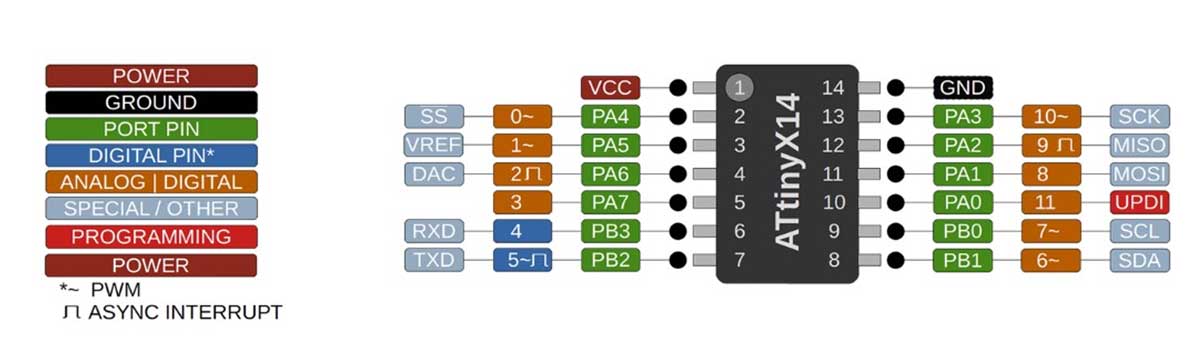

To determine which pin to use for the LED and the button, I referred to the following diagram:

Initially, I used pin number 8, but later I realized that all pins except Ground, VCC, UPDI, and TX/RX were available options.

Initial Attempt¶

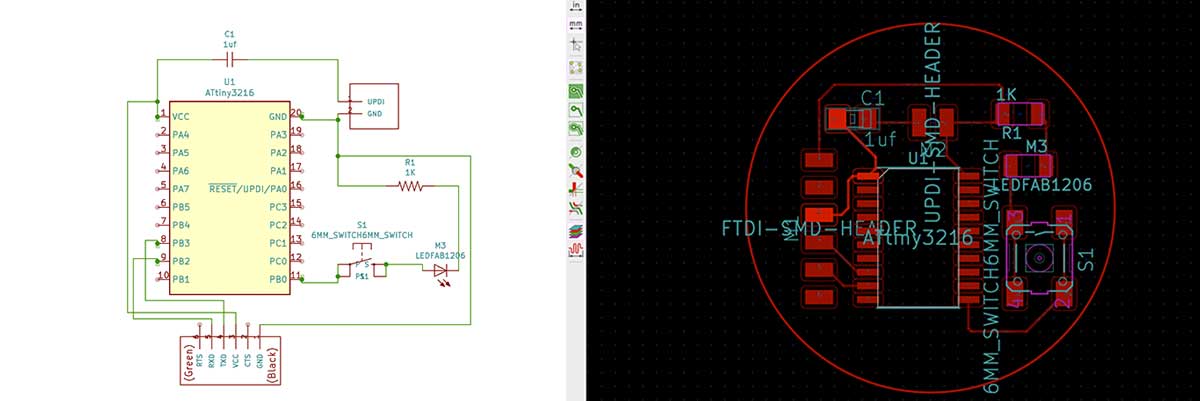

I first created a schematic with the 3216 microcontroller but later corrected it to use the 1614. I kept the file name as 3216, as advised by Oscar, to avoid potential bugs. However, I found that the microcontroller was not utilized effectively in this design.

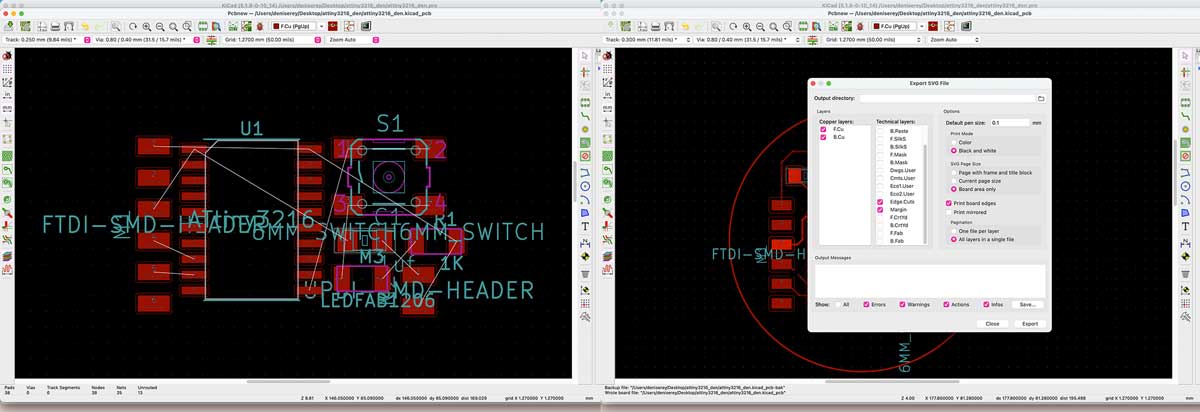

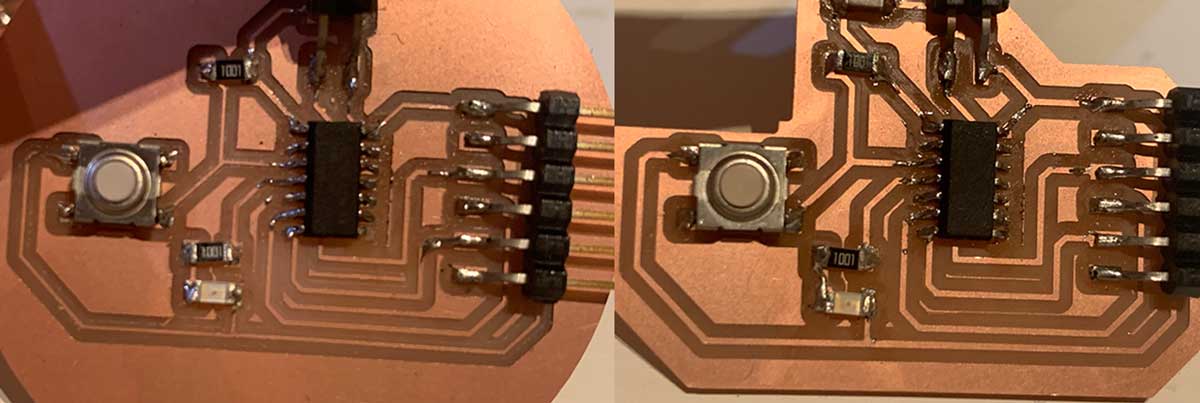

During the lab session, I started exporting the .svg file to open it in Inkscape and convert it to a suitable .png. An instructor pointed out that I should move the LED to another pin to make the design functional. I revised the schematic, adjusted the connections, and added a new resistor.

Options to Check When Exporting to .svg:

- Copper layers: F.CU

- Technical layers: Edge cuts

- Print mode: Black and white

- SVG page size: Board area only

- Print board edges

- Pagination: All layers in a single file

Preparing the .png in Inkscape¶

After organizing the components, I created the outline and exported the design to .svg. I opened the file in Inkscape and created three layers:

- Background

- Traces

- Interior

- Background Layer: Added a large black rectangle.

- Interior Layer: Moved the outline into this layer and filled the figure with white using the bucket tool.

- Traces Layer: Moved the traces into this layer and turned them white.

I exported the interior and traces separately. For the image definition, I used 1000 dpi.

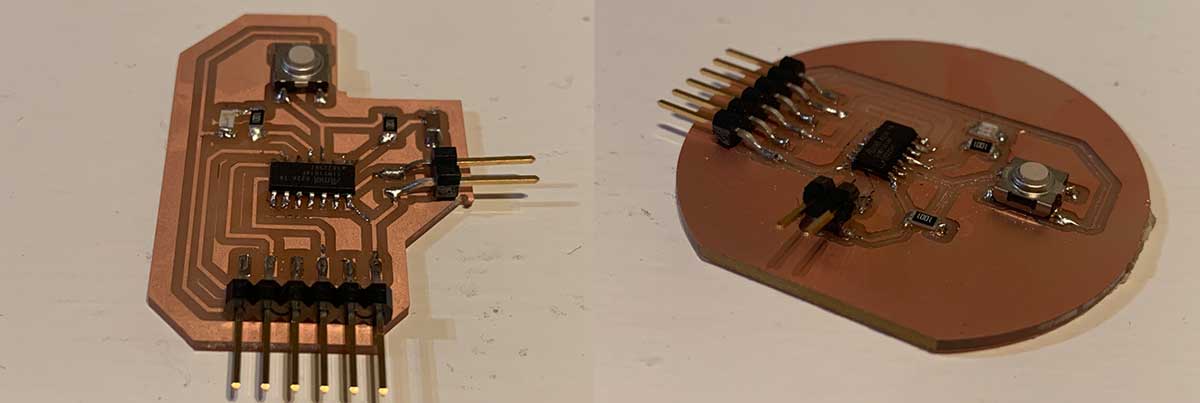

After exporting, I used Mods to mill the PCB.

During the milling process, the instructor noticed that my traces were too thin and the UPDI connector was placed behind the capacitor. I corrected these issues in KiCad, adjusting the trace thickness and repositioning components to make better use of space.

Final Design¶

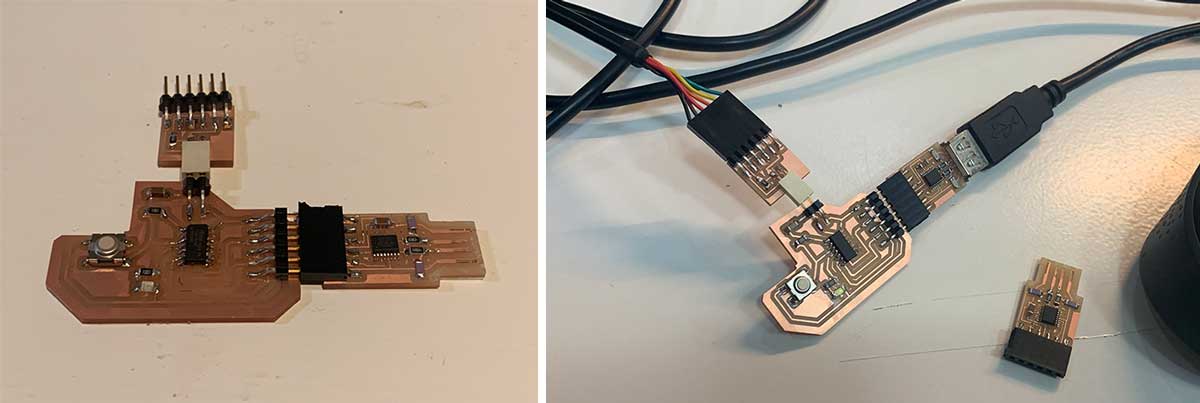

For the final board, I selected different pins for the LED and switch to facilitate programming. I also added two 1k resistors, one for the LED and one for the switch.

Components Used:

- ATtiny1614

- Capacitor 1µF

- UPDI connection

- FTDI connection

- 2 resistors (1kΩ)

- LED

- Switch

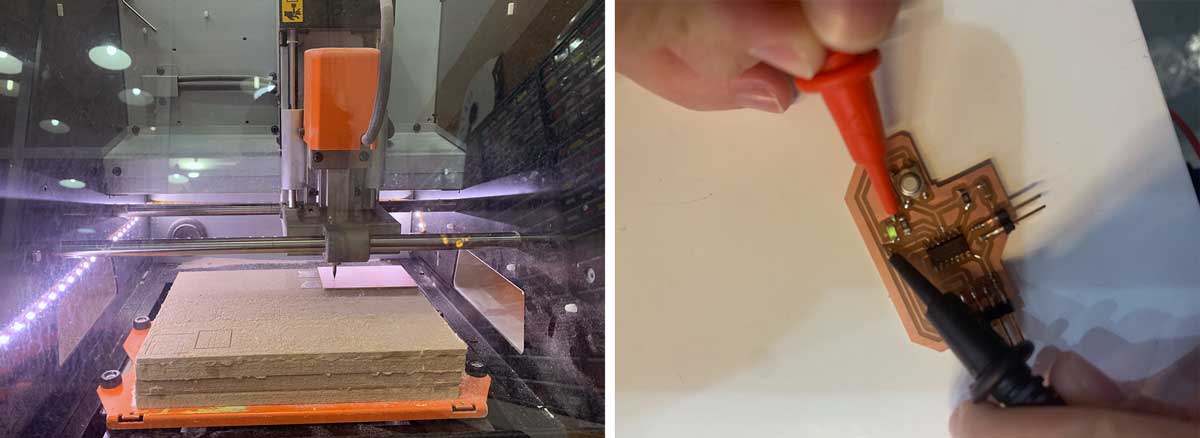

I used the alternative corner for milling as the left-bottom corner was not well leveled. I set the Z-axis to -0.5mm for a proper cut.

I tested the boards for shorts and connection issues. The LED worked as expected!

To program the board, I used the FTDI and UPDI connections from week 4 and followed the instructions on this page.

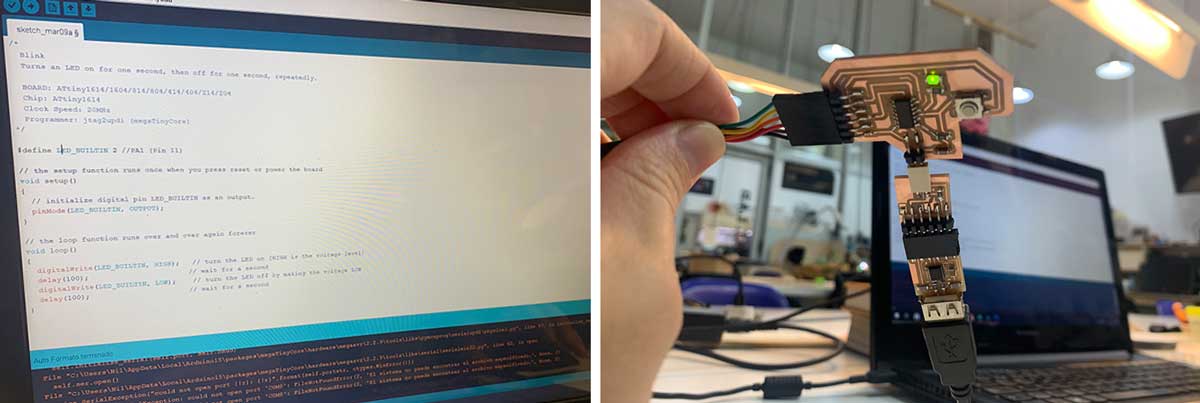

I used Arduino IDE to install megaTinyCore, selected the ATtiny1614 microcontroller, and configured the proper port. I encountered issues on my Mac, which seemed related to the USB connector type.

/*

Blink

Turns an LED on for one second, then off for one second, repeatedly.

BOARD: ATtiny1614/1604/814/804/414/404/214/204

Chip: ATtiny1614

Programmer: jtag2updi (megaTinyCore)

*/

#define LED_BUILTIN 2 //PA6 (Pin 2)

// the setup function runs once when you press reset or power the board

void setup()

{

// initialize digital pin LED_BUILTIN as an output.

pinMode(LED_BUILTIN, OUTPUT);

}

// the loop function runs over and over again forever

void loop()

{

digitalWrite(LED_BUILTIN, HIGH); // turn the LED on (HIGH is the voltage level)

delay(1000); // wait for a second

digitalWrite(LED_BUILTIN, LOW); // turn the LED off by making the voltage LOW

delay(1000); // wait for a second

}

Files¶

Find all the files here:

Design Rule Check¶

To properly use KiCad, I followed the beginner guide to KiCad. I also consulted this tutorial on running the Design Rule Check. Initially, I used the default settings for trace width and spacing but found them too thin. I adjusted the settings as follows:

- Min Track Width: Changed from 0.2mm to 0.3mm

- Min Via Size: Changed from 0.4mm to 0.8mm

The Design Rule Check button displays a modal where these parameters can be defined. Errors are indicated with a white arrow and detailed in the modal.

- Clearance: By Netclass

- Min Track Width: 0.3mm

- Min Via Size: 0.8mm

Testing the Board with the Multimeter¶

Since I was unable to join the group for Raspberry Pi testing, I fulfilled the assignment by testing my new board with a multimeter. I watched this video on how to use a multimeter to guide me through the process.

I compared the board against my blueprint and checked the schematic for correct polarities. Before connecting the board to power, I verified the following:

- Checked for shorts between VCC and GND

- Ensured the microcontroller was soldered in the correct position

Measurements taken included:

- Voltage

- Resistance: To verify resistor values

- Continuity: To test for open or shorted conductors, switch operation, and clear circuit paths