Assignment Requirements

- Model a possible final project using different CAD approaches (raster, vector, 2D, 3D, rendering, animation, or simulation).

- Compress images and videos used for documentation.

- Publish a clear description of the design process together with the original design files on your class page.

Learning Outcomes

- Evaluate and select appropriate 2D and 3D design software.

- Demonstrate and describe modelling processes using 2D and 3D tools.

- Demonstrate image and video compression techniques.

Progress Status

Summary of completed tasks for Week 02.

Comparison between free software Tinkercad and professional software SolidWorks for 3D modeling.

2D sketches created in SolidWorks, using fully constrained sketches with proper dimensions.

Rendering performed using a SolidWorks assembly, applying different materials and textures to individual parts.

Animated exploded view and motion simulation of an automatic door using SolidWorks.

Software Comparison: Tinkercad vs SolidWorks

For the development of this project, I decided to compare Tinkercad and SolidWorks in order to identify their main differences and evaluate their suitability for digital fabrication workflows.

Due to my professional experience, I have extensive knowledge of SolidWorks for parametric mechanical design based on fully constrained 2D sketches. However, I have limited experience with constructive design software based on predefined geometric primitives, which motivated me to explore Tinkercad.

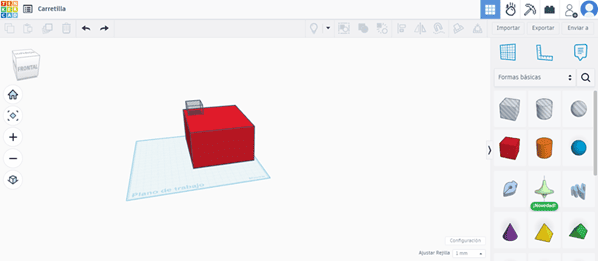

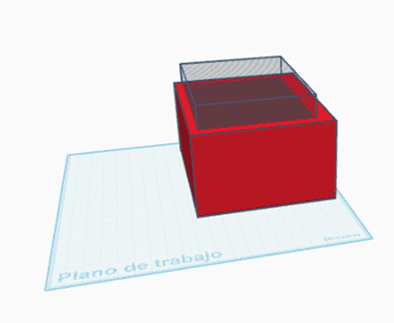

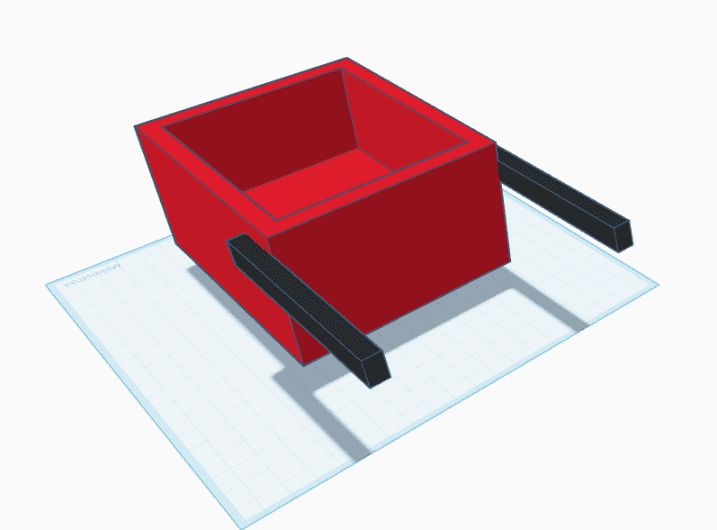

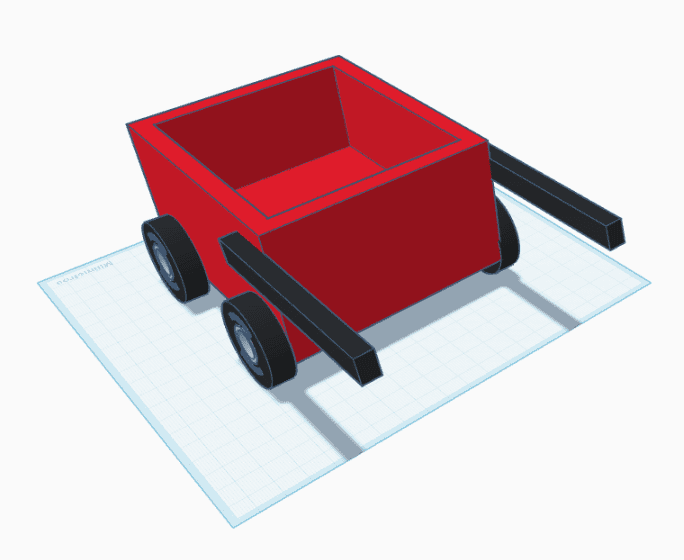

Tinkercad – Constructive Modeling

Tinkercad was used to explore constructive modeling through direct manipulation of geometric primitives, boolean operations, and alignment tools.

Image files: tinkercad_01.png – tinkercad_05.png

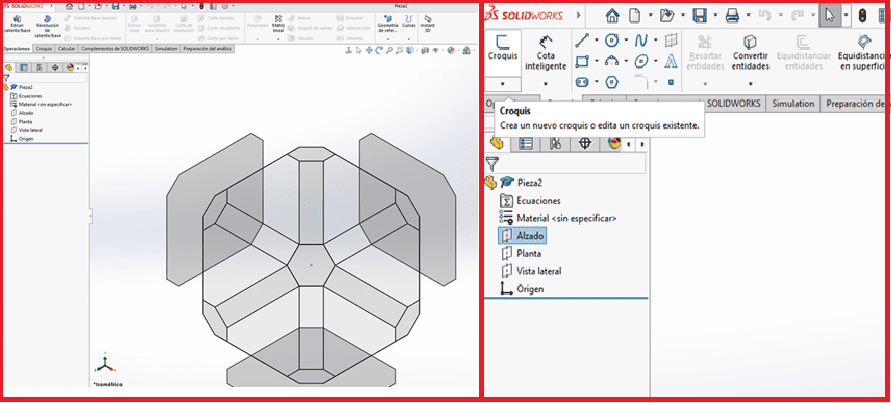

SolidWorks – Parametric Modeling

SolidWorks was used to develop a fully parametric, fabrication-oriented design based on constrained sketches and multi-part assemblies.

Image files: solidworks_01.png – solidworks_07.png

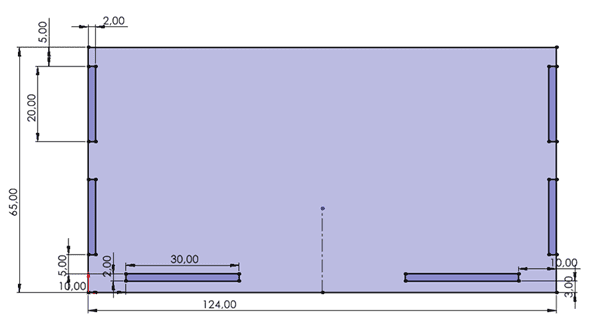

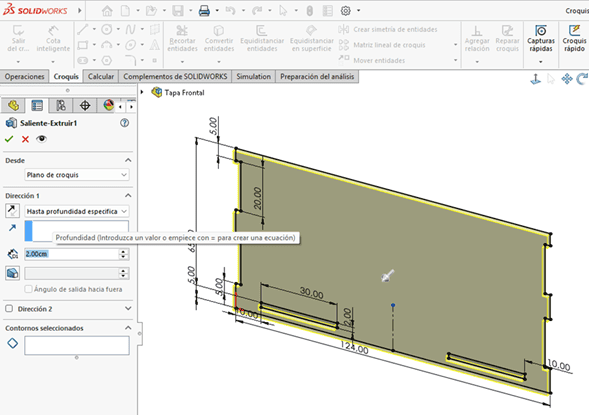

2D Modeling with SolidWorks

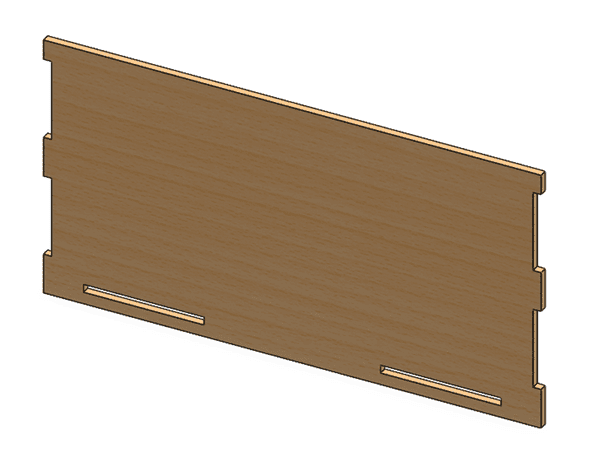

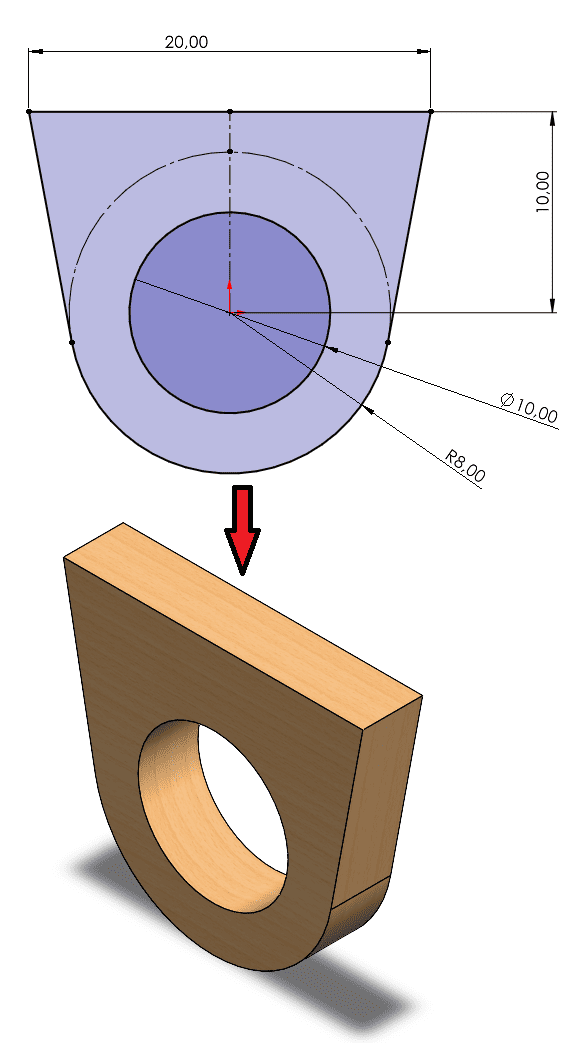

2D modeling in SolidWorks provides a strong foundation for accurate and parametric 3D design. By working with fully constrained sketches, it is possible to precisely define geometry using dimensions, relations, and reference entities, ensuring design intent and dimensional consistency.

As shown in the sketch, defining a complete 2D profile allows full control over critical features such as widths, radii, hole diameters, and symmetry. Once the sketch is fully constrained, it can be directly transformed into a 3D part through extrusion or revolution, maintaining full parametric control and enabling an efficient transition from design to digital fabrication.

Rendering and Assembly in SolidWorks

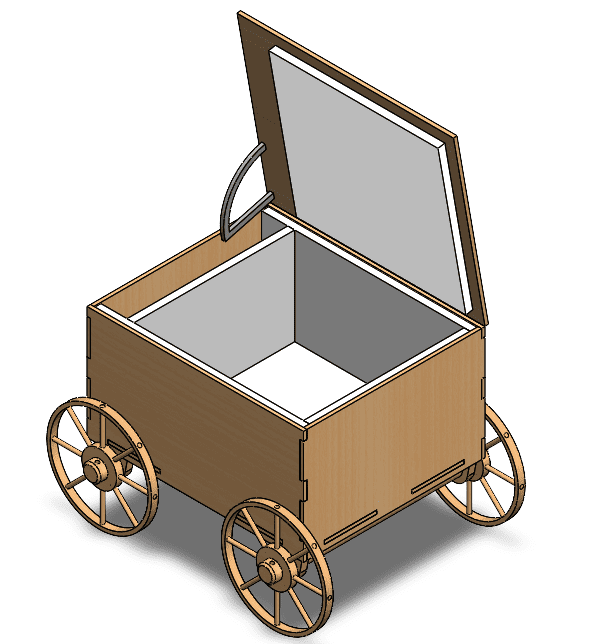

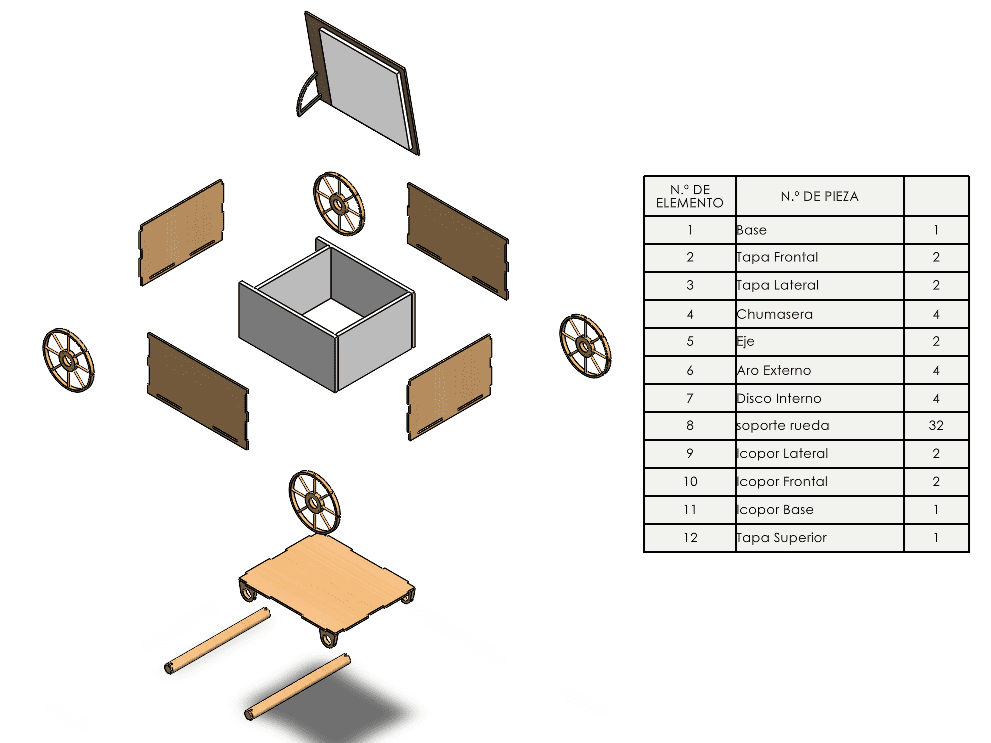

Assembly modeling in SolidWorks allows the integration of multiple components into a single functional system using defined positional and geometric relationships. This approach makes it possible to verify fit, alignment, and mechanical coherence before manufacturing.

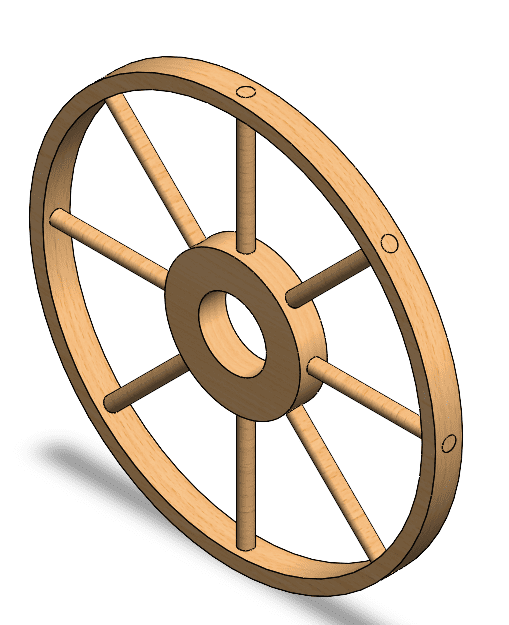

For this project, individual parts were assembled and organized into subassemblies to simplify design management and future modifications. The wheel was modeled as a dedicated subassembly, improving clarity and reusability within the main assembly.

Rendering was performed directly in SolidWorks by applying different materials and textures to each component. This process enhances visual understanding of the design and helps communicate material selection, surface finish, and overall structure.

As shown in the exploded view, the final assembly includes a clear representation of how all parts interact, along with a bill of materials (BOM) that supports documentation, fabrication planning, and assembly sequencing.

Animation in SolidWorks

SolidWorks animation tools were used to visually communicate the behavior, structure, and assembly logic of the project. Motion studies and exploded animations provide a clear understanding of how components interact and how the product is assembled.

Functional Animation

This animation shows the fully assembled model in motion, allowing a quick evaluation of proportions, component relationships, and overall design coherence. Animated visualization helps validate the concept before physical fabrication.

Exploded View Animation

The exploded animation illustrates the assembly sequence and spatial relationship between parts. This visualization is especially useful for documentation, fabrication planning, and understanding how individual components are organized within the final product.