Computer-Controlled Cutting

Hey there! Can you believe we're already in the third week? We've had the chance to interact with some of the machines in the fab lab, which is pretty exciting! 😅 Now, it's time to get down to business and start making some cuts with the cutting plotter and laser. Let's get to it! ✂️

So, this week we started working as a team and one of the tasks was to check out the tech available at the Fab Lab CIDI Universitario in San Lorenzo, Paraguay.

For this that task, we’ve been hitting up the instructors and checking 👀 out the fabers 2022 documentation, since there were no changes or new additions made. The equipment remains the same 😎.

We tested the laser cutter and cutting plotter with different materials, and also learned about their models and features.

Vinyl cutting

In our lab, the vinyl Cutter machine that we have is a GCC Puma IV 60 LX. Some this features are:

- Max width: 600 mm

- Max length: 500 mm (roll type)

- Max thickness: 0.8 mm

- Max cutting force: 500 g

- Max cutting speed: 1020 mm/s

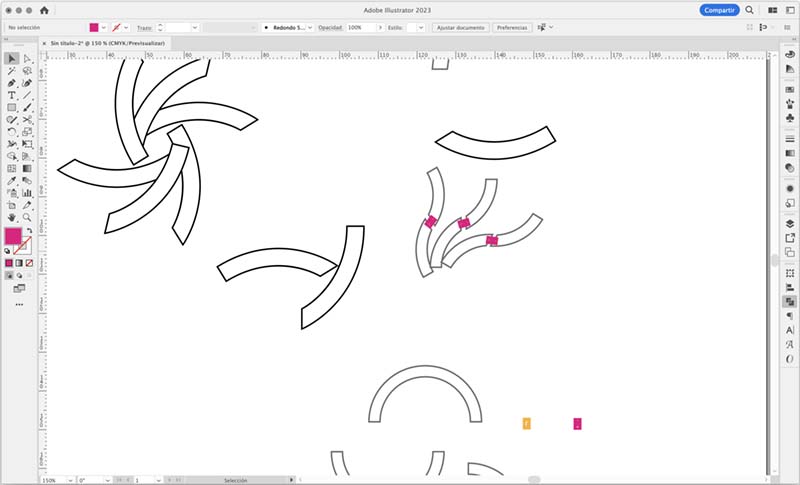

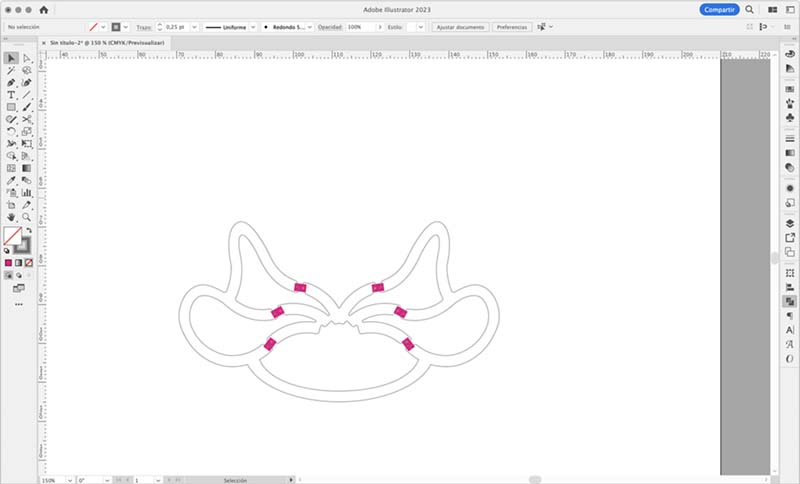

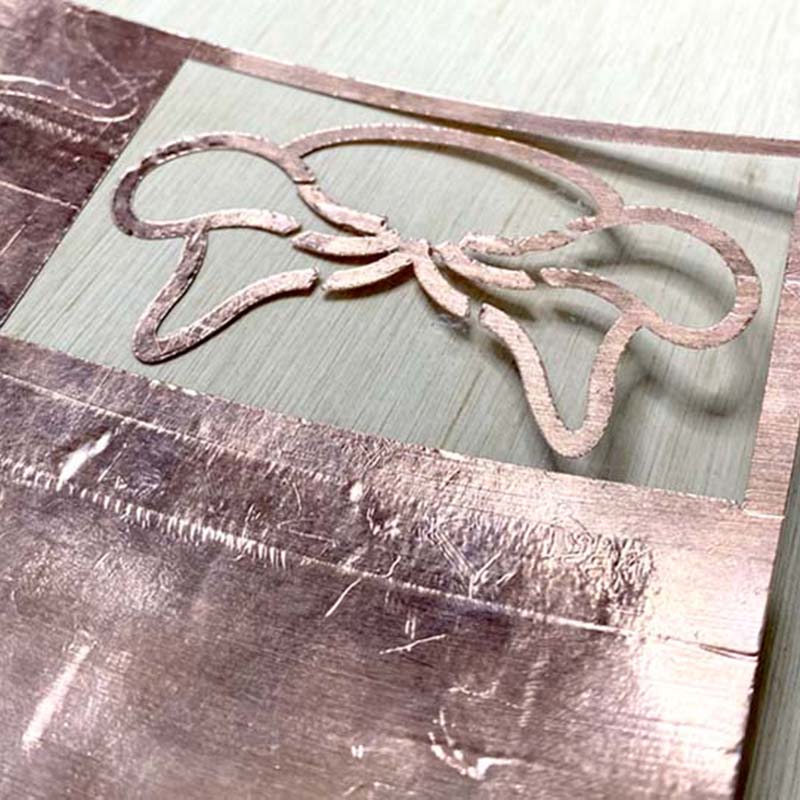

For preprocessing the images that I wanted to cut, I used Adobe Illustrator. I drew a circuit using a rectangular shape, smoothing out the lines and then applying a reflection to the shape to obtain the final design. The document was prepared with the .dxf extension 😎.

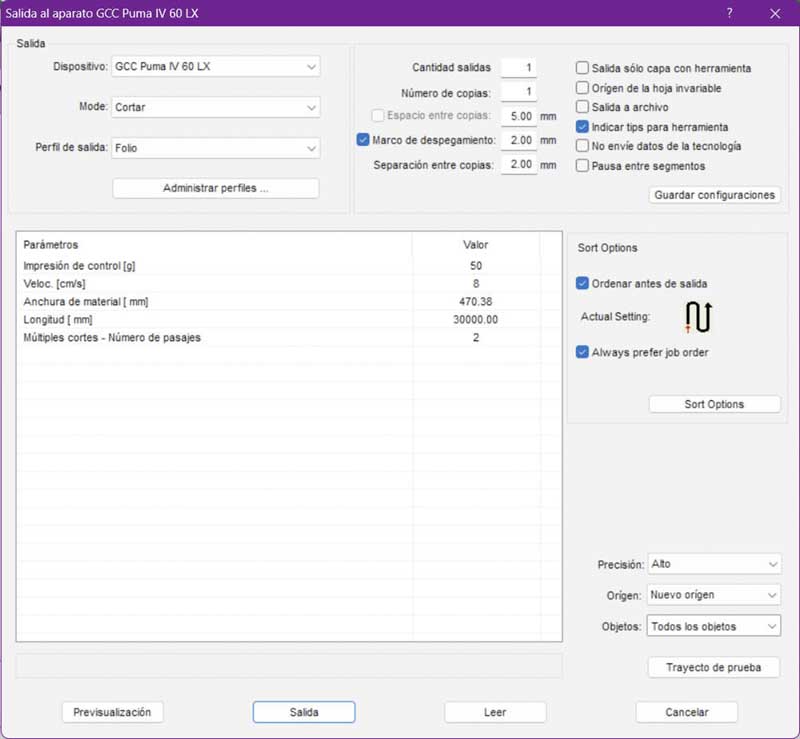

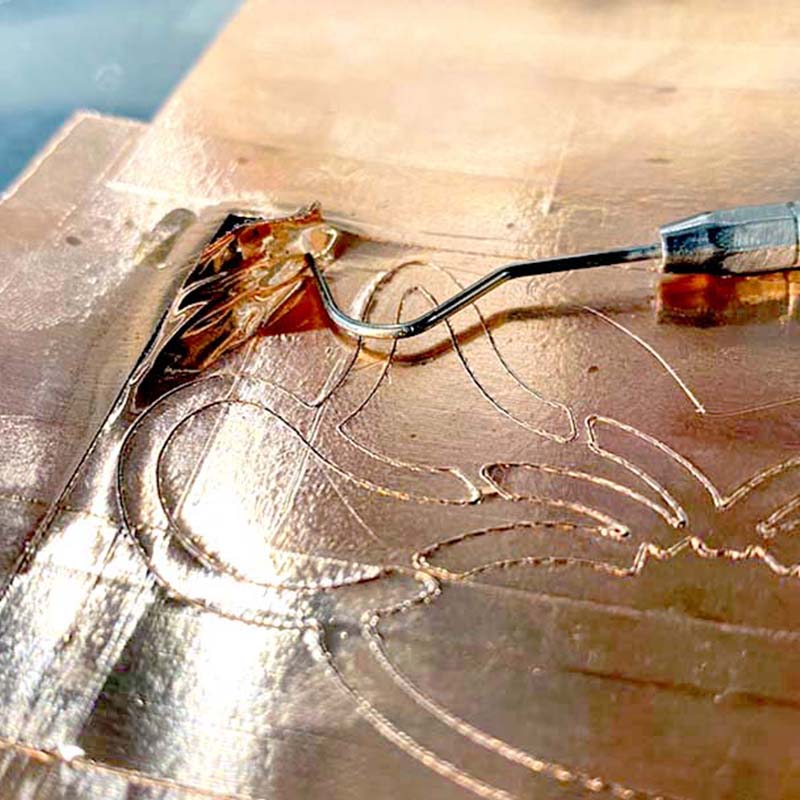

In the Vinyl Cutting Software (GreatCut 4), I imported the .dxf file; we used adhesive copper tape, attached to an acetate board to take it to cut.