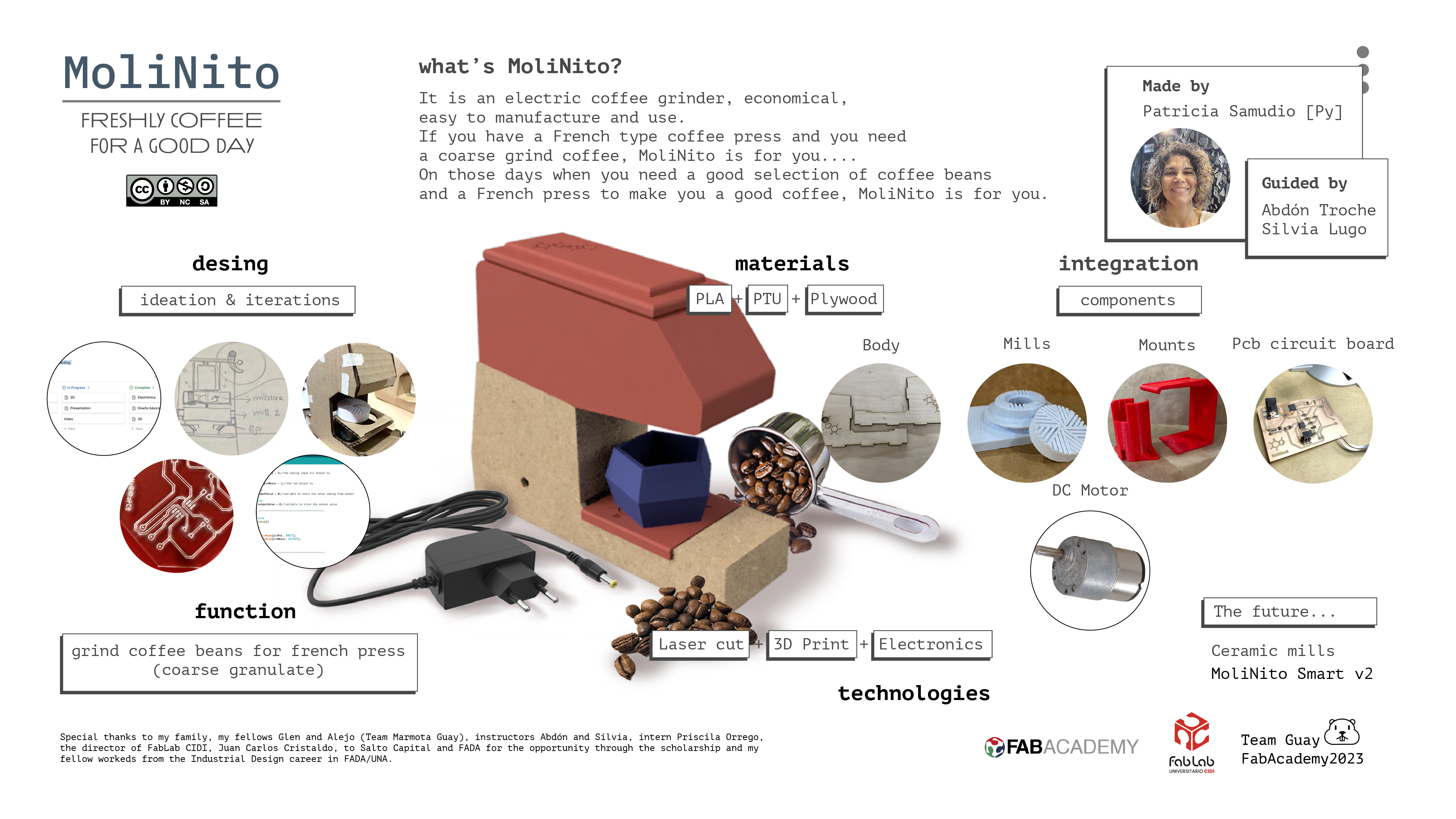

Project development

I have completed a good portion of the final project tasks in a fairly considerable amount of time.

What has worked is the activation of the DC motor through a potentiometer, thus achieving the first development spiral.

As for what did not work is the milling, due to the fact that I did not relic a more precise exploration of the position of the mills in the proposed design (although the design of the stone mills was considered as inspiration -see Notion Page

And I would like to change the design of the grinding wheels, as well as the material and production method: from flat to conical model, to make them in ceramic by the molding and casting method.

To do this, I intend to take the ceramics course offered at the faculty where I teach, which will be given in the next semester of the year, so as to learn a little more about how the product behaves. In this regard, I have already identified some suppliers of ceramic inputs, in addition to the guidance of fellow ceramists.

I learned about the importance and benefit of testing designs from virtual models using the technologies learned throughout the weeks. In addition, I learned a little more about electronic objects and how they work.

It is also pending to incorporate the digital interfaces component to the project, especially to operate it from an app.

☕️ MoliNito is a good start, but it is still under development.

Sumary

What tasks have been completed?

The tasks that were completed, according to the project spiral are:

- Design of the physical structure.

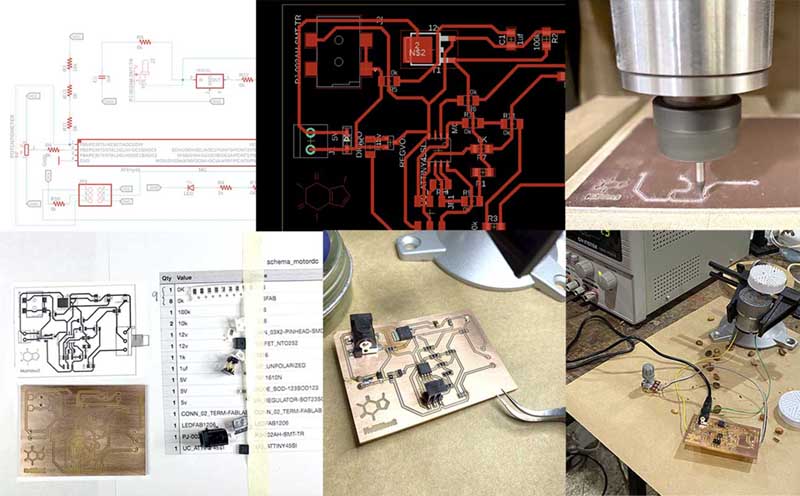

- Electronics design

- MCU programming

- Motor operation