3D scanning and printing

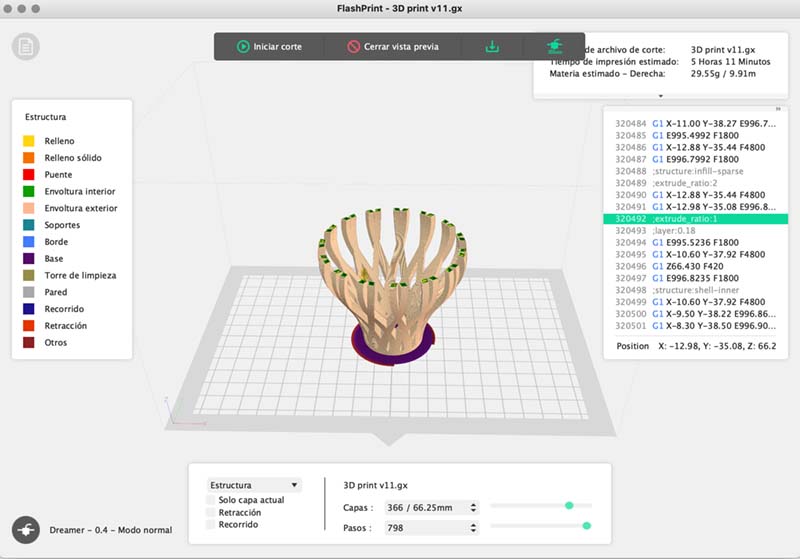

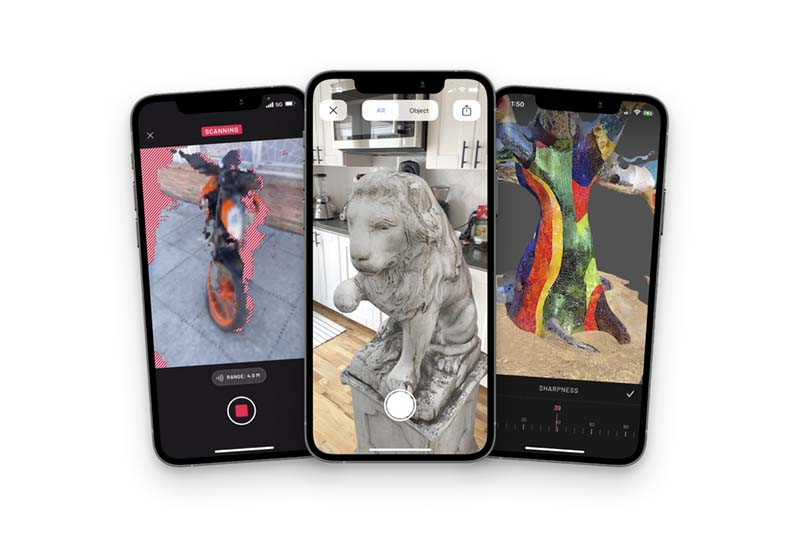

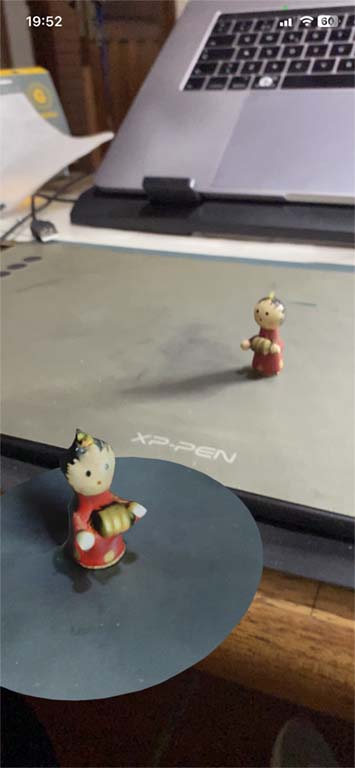

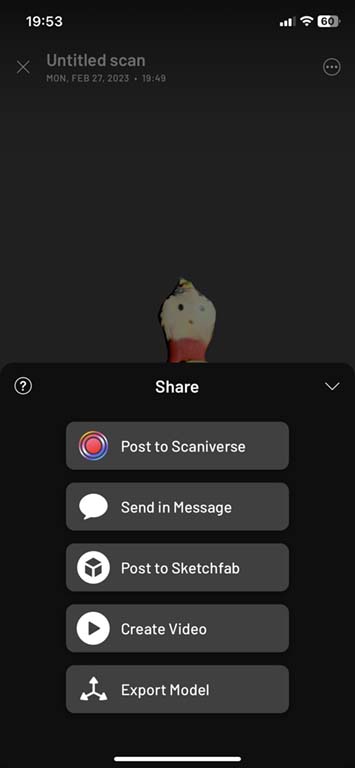

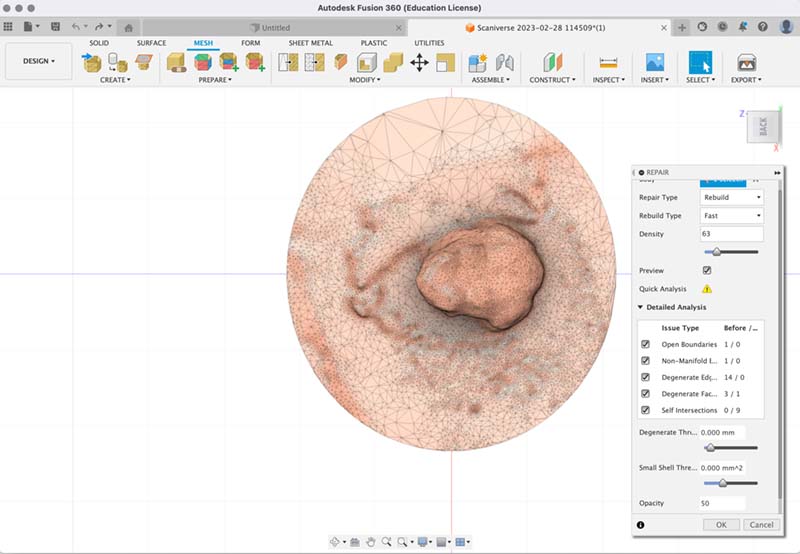

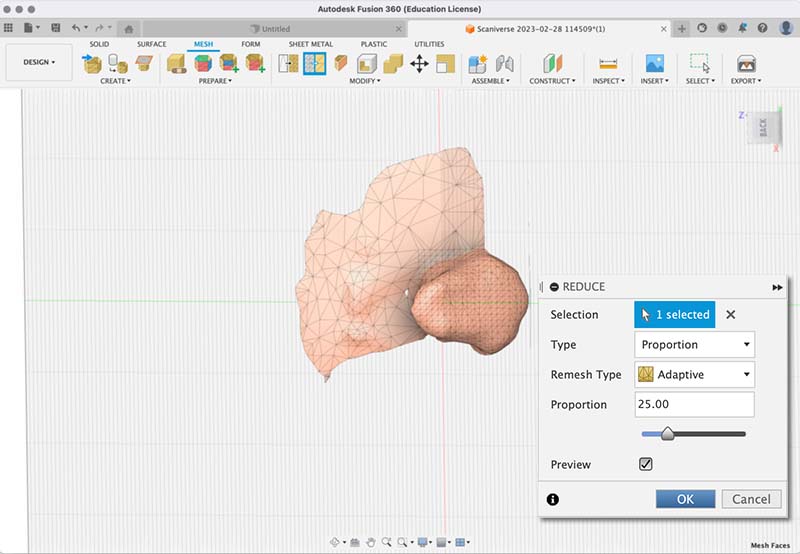

In the 5th week of the FA 😰, we began to explore additive manufacturing technologies with 3D printers; in addition to the process of scanning objects for the purpose of modeling and printing them.

To learn more about additive manufacturing, I refer to what I read on the site Hubs.com about 3d printing 🤩. Below, I highlight a few paragraphs that helped me better understand what it is, the materials and the difference with other manufacturing systems.

3D printing

3D printing is an additive technology that is used to manufacture parts, even of more complex geometries than "traditional" technologies, and in a usually fast way.

"Additive" because it does not require a block of material or a mold to manufacture objects, it simply stacks and fuses layers of materials increasingly wide (plastic, powder, cement, chocolate, sugar, resin ...).

In general, it is low cost and can create. It is widely used in the engineering industry, especially to create prototypes and light geometries.

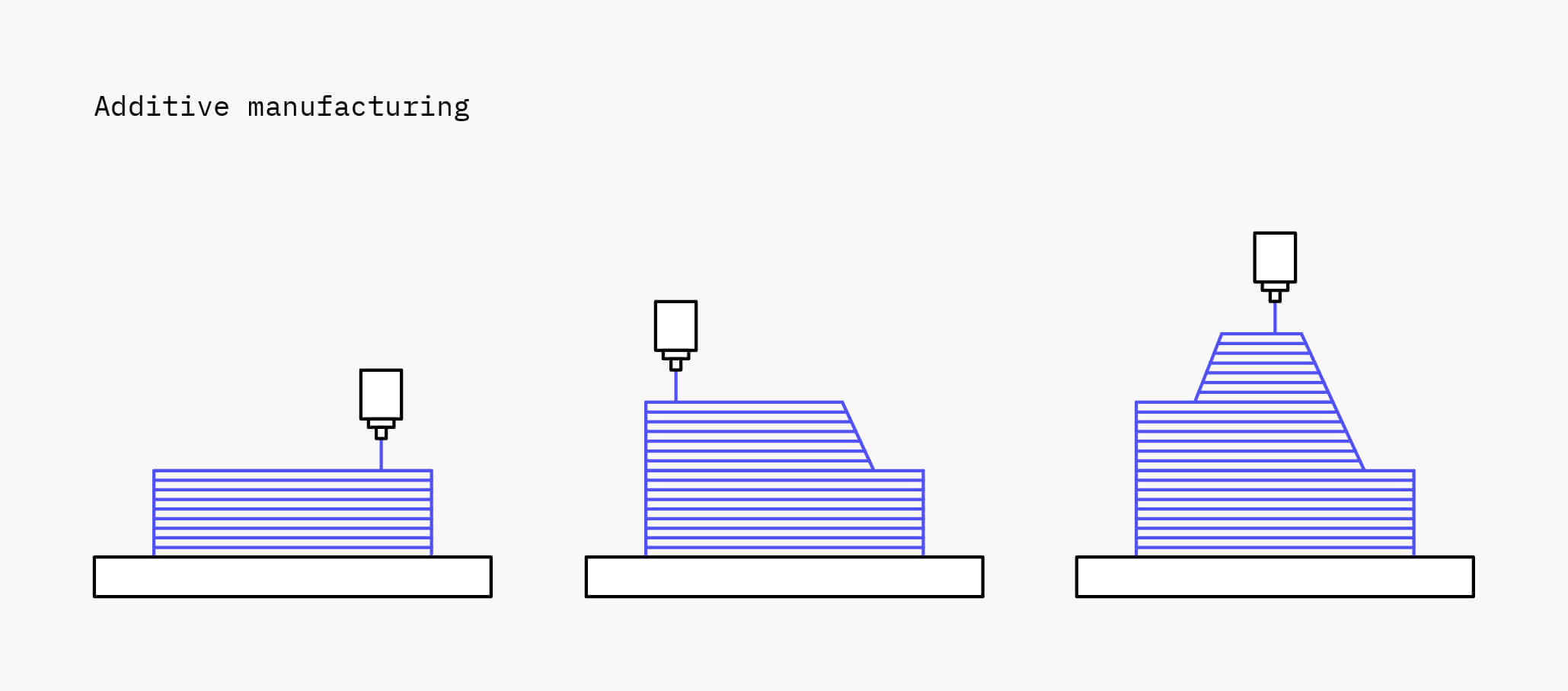

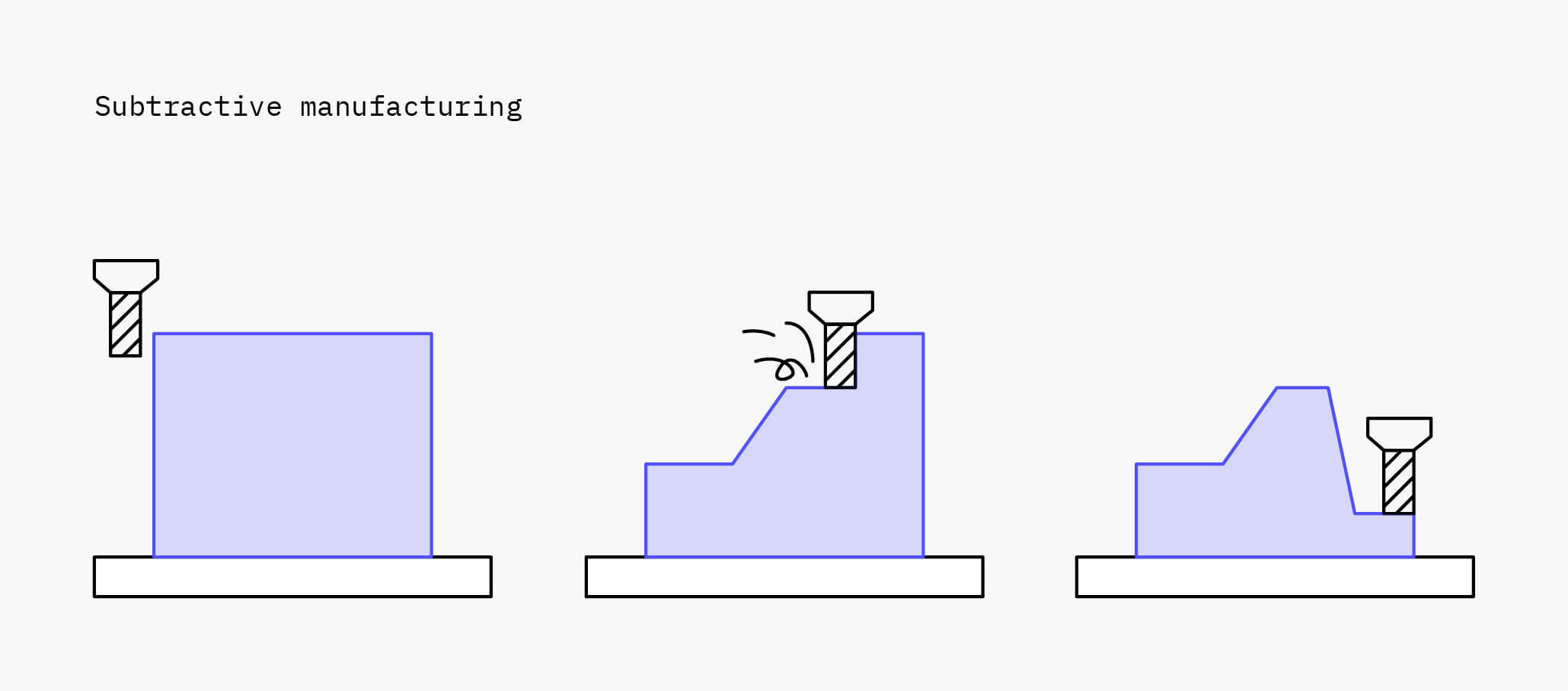

Types of manufacturing

Additive manufacturing: Additive manufacturing builds up 3D objects by depositing and fusing 2D layers of material.

Subtractive manufacturing: Subtractive manufacturing, such as milling and turning, creates objects by removing (machining) material from a block of solid material that's also often referred to as a 'blank'.

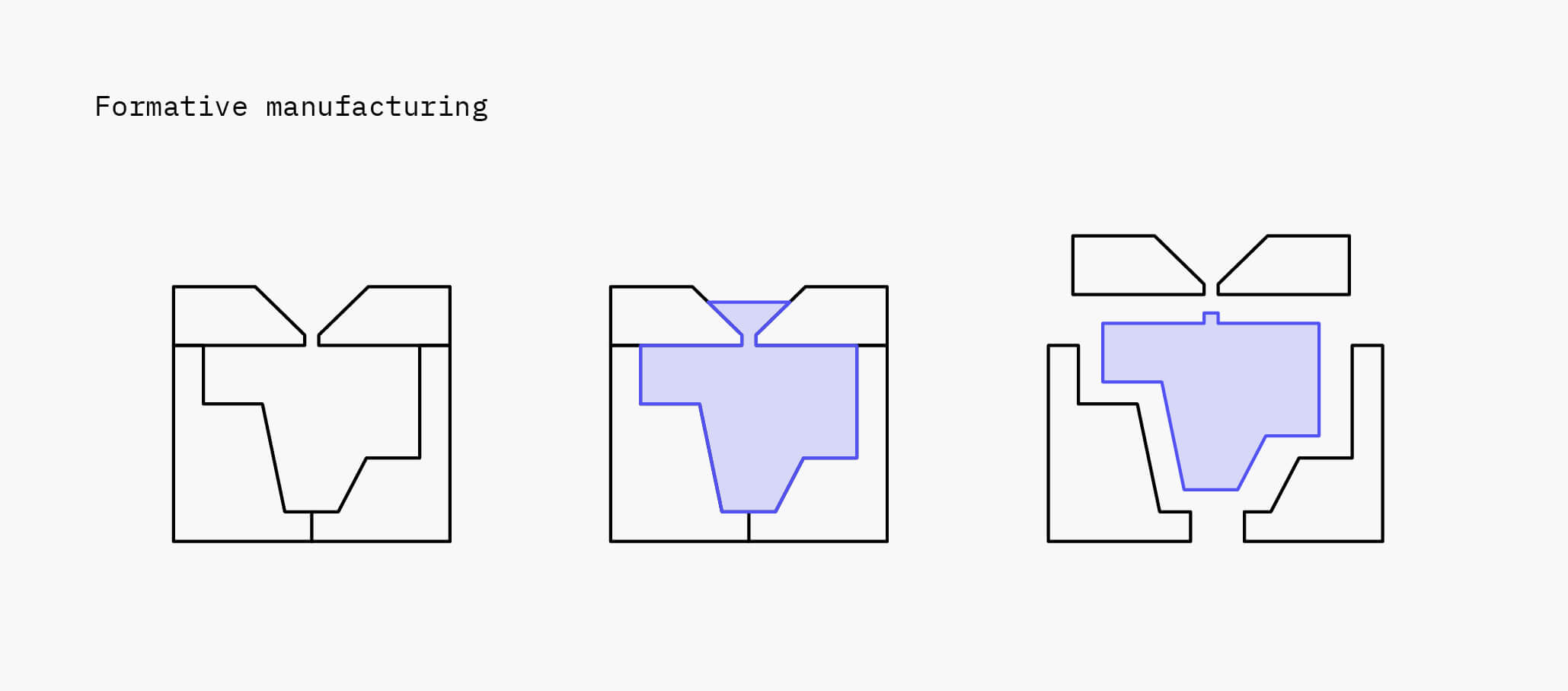

Formative manufacturing: Formative manufacturing, such as injection molding and stamping, creates objects by forming or molding materials into shape with heat and/or pressure.

📍 Definitely, the Hubs site is added to my favorites for learning 🤩.

For the choice of a manufacturing technology, we consider:

- Additive manufacturing: best for low volumes, complex designs, and when speed is essential.

- Subtractive manufacturing: best for medium volumes, simple geometries, tight tolerances, and hard materials.

- Formative manufacturing: best for the high-volume production of identical parts.

Types of 3D printing

This week allowed me to learn about the types of 3D printing, of which I knew only three from observing the printers of Fab Lab Cidi and other fablabs (PTI Cerro, in Uruguay).

So, following the reading on the Hubs.com site, 3D printers are categorized according to the type of process:

- Vat Polymerization: liquid photopolymer is cured by light.

- Material Extrusion: molten thermoplastic is deposited through a heated nozzle

- Powder Bed Fusion: powder particles are fused by a high-energy source

- Material Jetting: droplets of liquid photosensitive fusing agent are deposited on a powder bed and cured by light

- Binder Jetting: droplets of liquid binding agent are deposited on a bed of granulated materials, which are later sintered together

- Direct Energy Deposition: molten metal simultaneously deposited and fused

- Sheet Lamination: individual sheets of material are cut to shape and laminated together

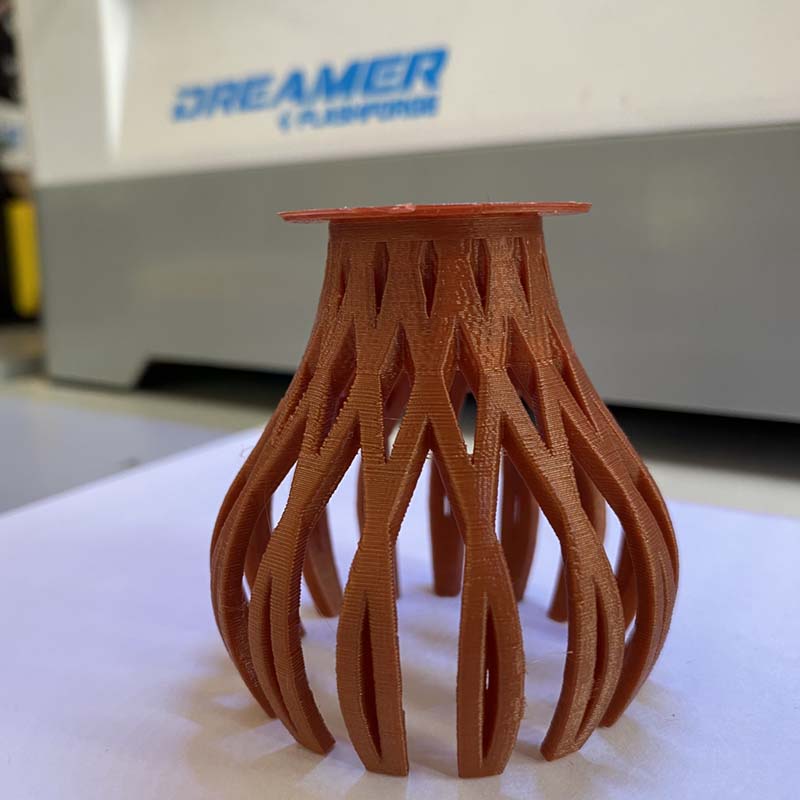

📍 In our Fab Lab, the 3d printers are the type of Material Extrusion.