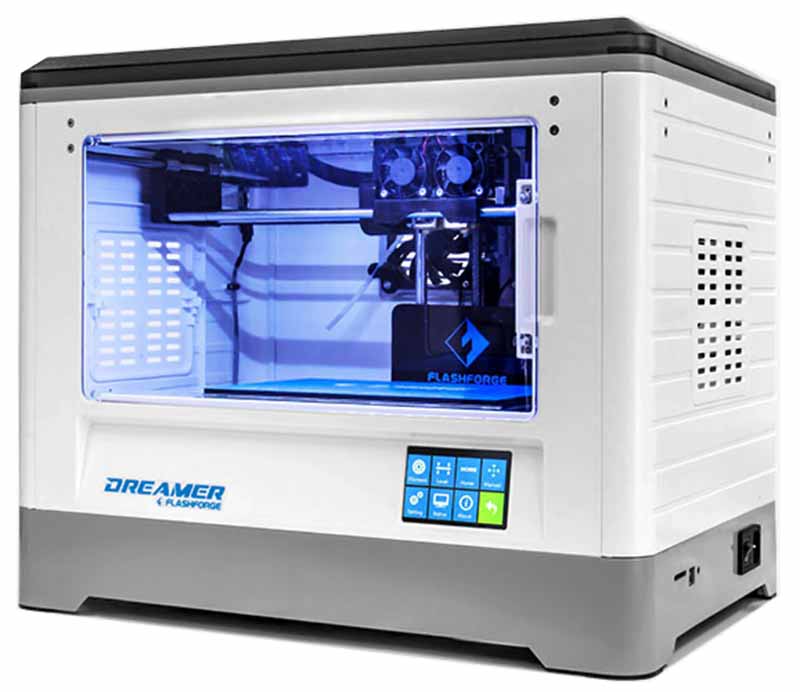

3D printer: Flashforge Dreamer

Specifications:

Here in the lab we have the 3 FlashForge dreamer. This machine has an enclosed case, this improves printing because the outside conditions don't affect the environment inside the machine.

The machine has 2 extruders, that can achieve a temperature of 240 ºC (464 ºF) and a heated bed of 120 ºC (248 ºF).

We can print with different plastics filaments that came in spools and have 1.75 mm in diameter.

Those materials have different specs to be printed:

- Range from 200 ºC to 240 ºC in the extruder can melt from PLA to Nylon and ASA.

- The bed can be off or setup to heat up to improve the adhesion of the parts to be printed.

- The printing volume is 230 x 150 x 140 mm.

Testing 3D printing rules

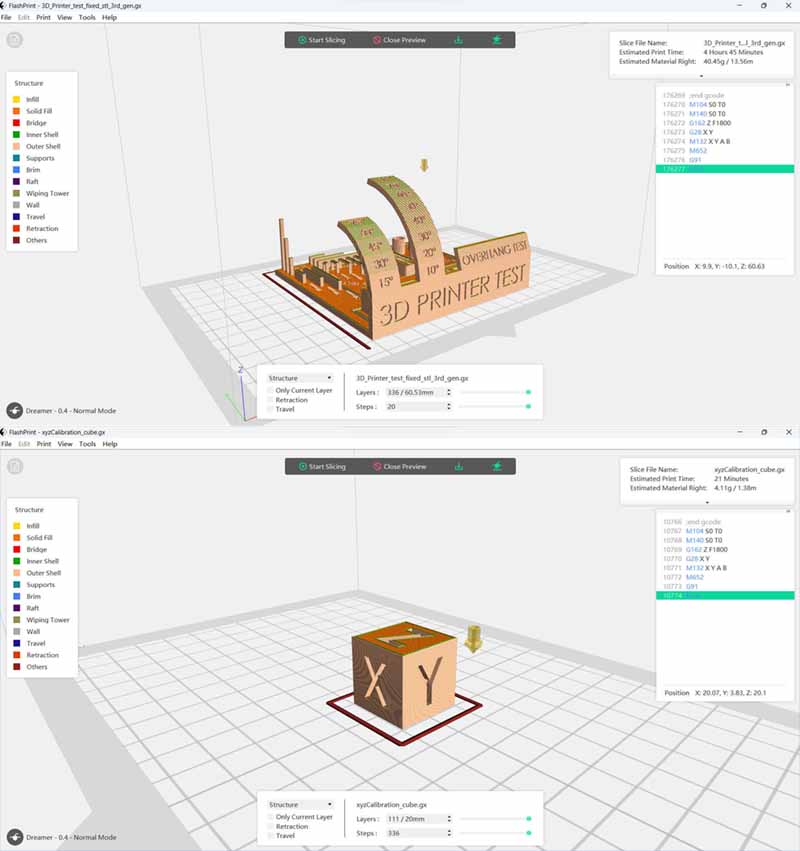

We download from Thingiverse a multiple test model to print.

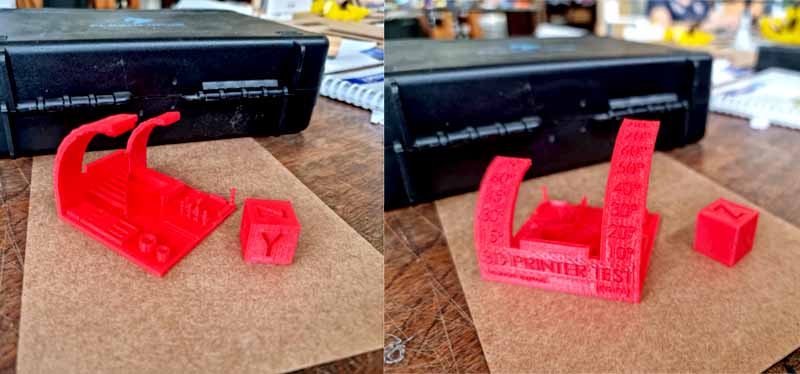

- All In One 3D printer test

- XYZ 20mm Calibration Cube

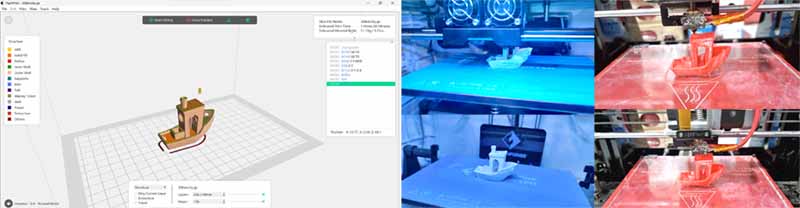

- 3D Benchy

Results

We use PLA for this prints, the settings were almost the same, between 200-215 ºC for the extruder, 50 ºC for the bed, 50 to 60mm/s speed of printing.

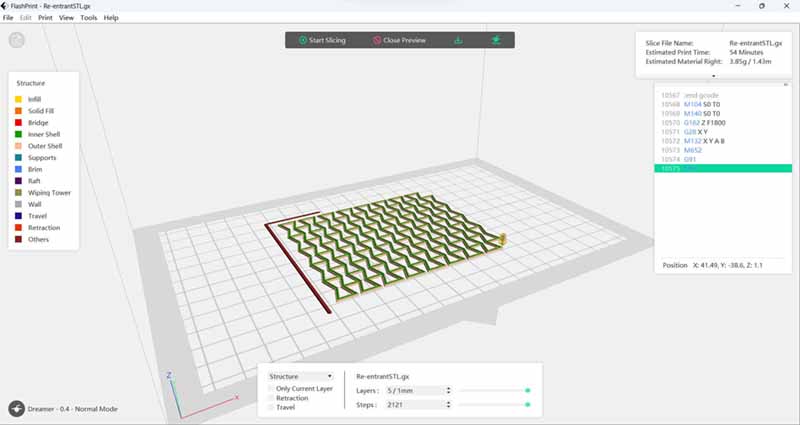

We also tried to 3d print over fabric. For this printings we used TPU 95, with the settings 220 ºC for the extruder, 70 ºC for the bed and a printing speed of 20 mm/s. For this kind of 3d print, you have to 3d print a couple of layers and then add the fabric, tighten it, and keed printing the rest of the layers over the fabric surface. The heat of the filament fuses the materials and generate a strong bond between them.