Patuino: PCB production

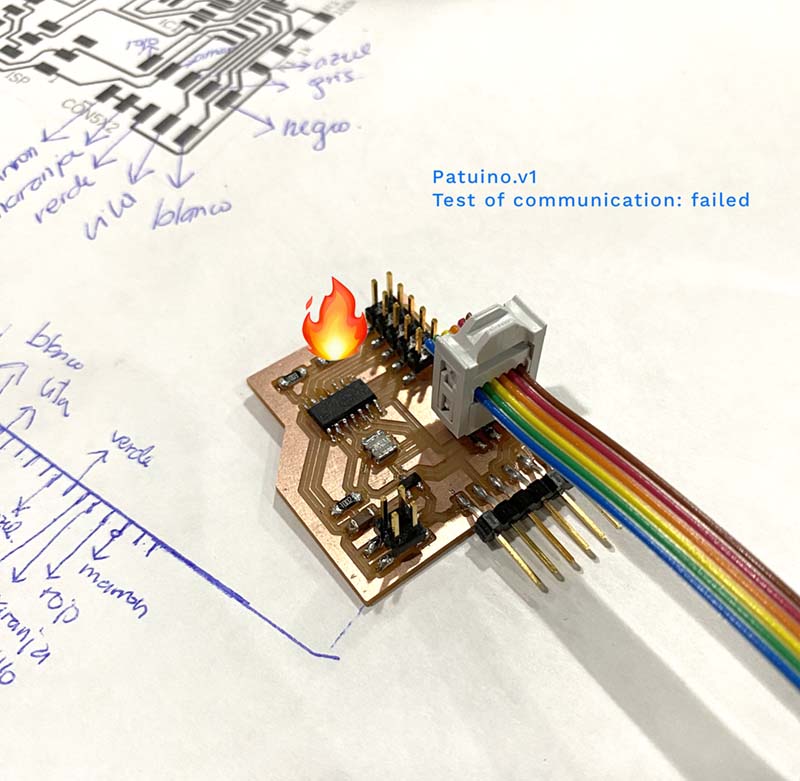

I must say that the production took me more than 2 weeks: the first board burned 🔥 during a functionality test 🫣. Then I made two more boards that didn't produce communication ☹️ due to errors in soldering and connections between components; however, this was an opportunity to continue practicing with the FabLab equipment and soldering technique 😎.

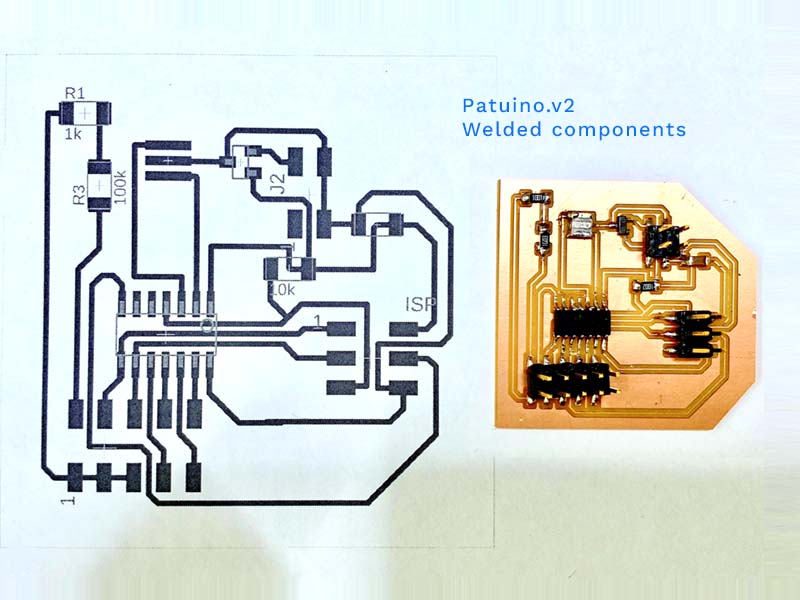

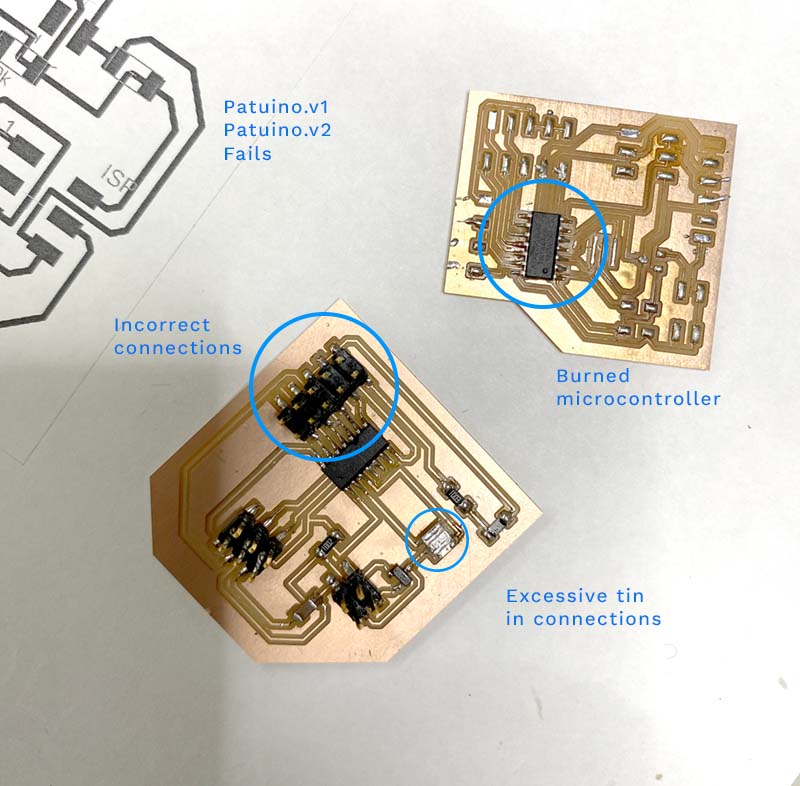

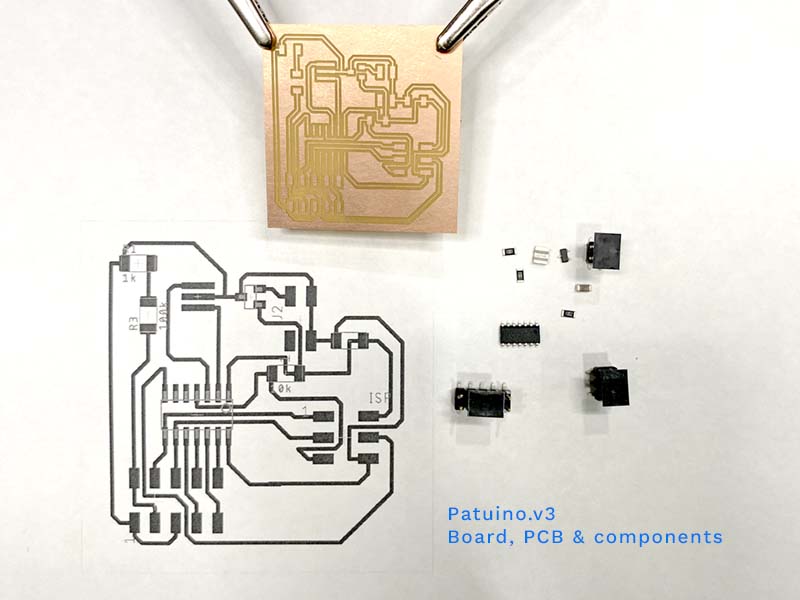

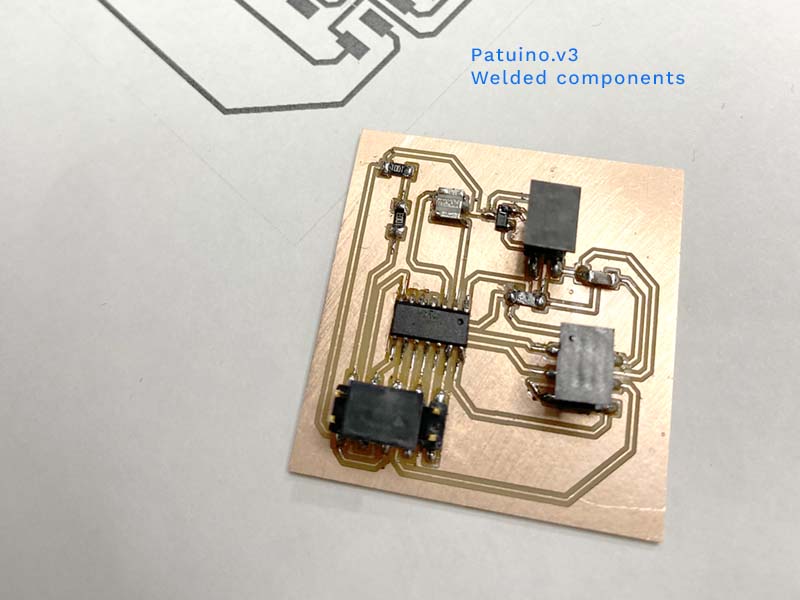

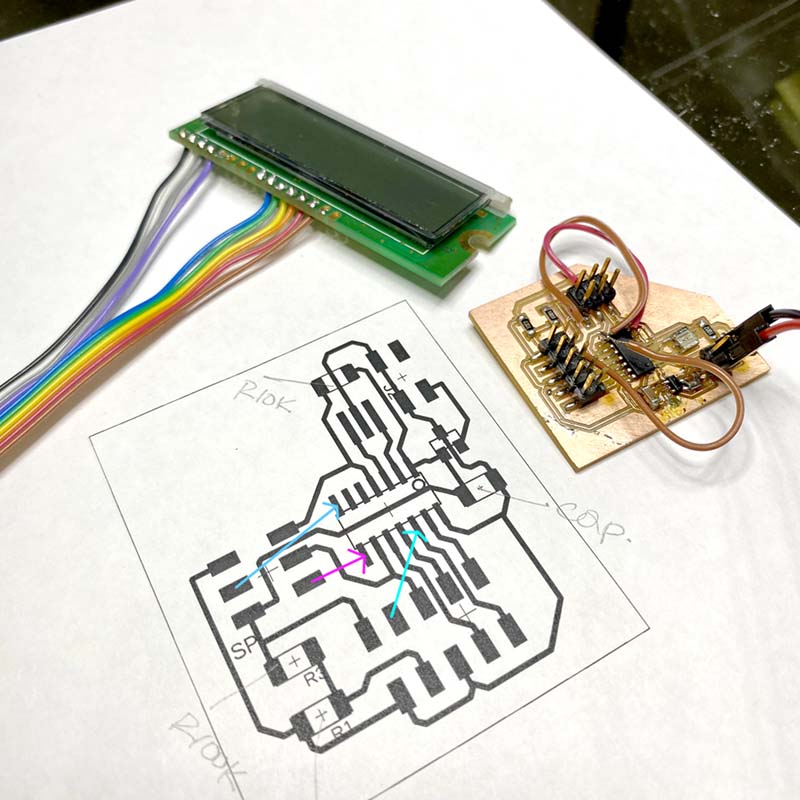

Next, I share images of this part of the process.

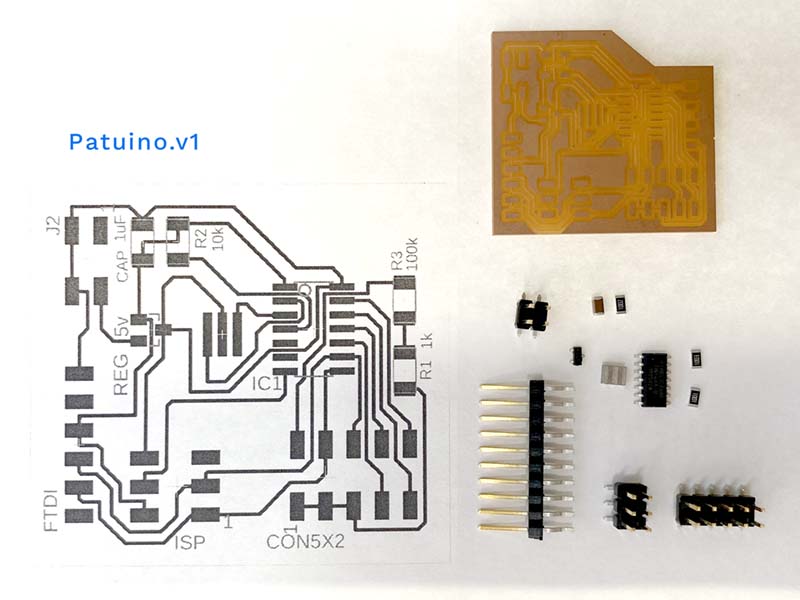

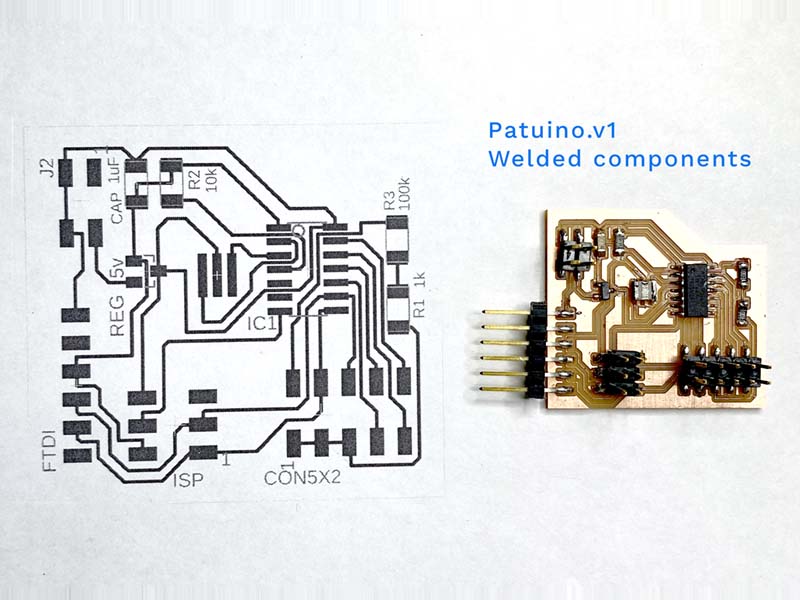

Patuino version 1: components, welding and fails.

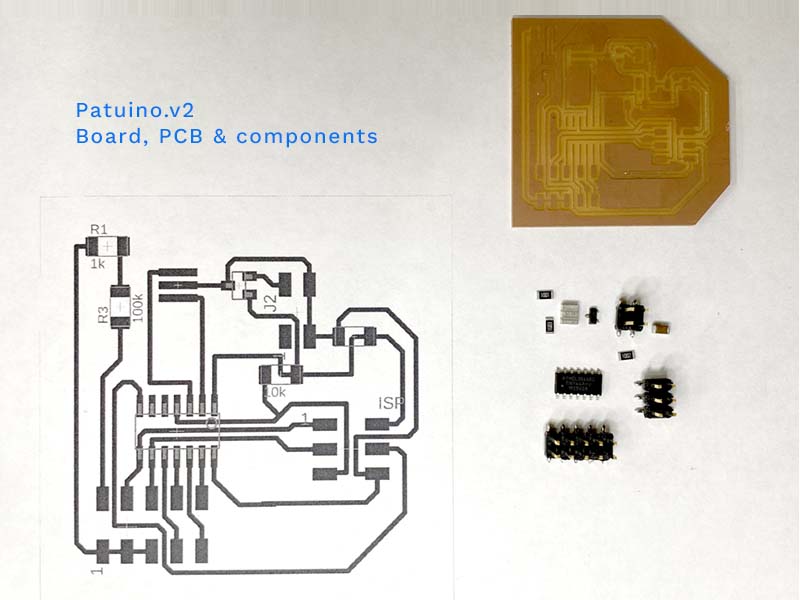

Patuino version 2: components, welding and fails.

Patuino version 3: components, welding and fails.

📍 From the burnt circuit board I learned: Verify the voltage of each component: if there is a component that operates at a higher voltage than the processor logic, attention should be paid to the connections between the voltage component and the regulator (when different voltage components are on the same PCB).

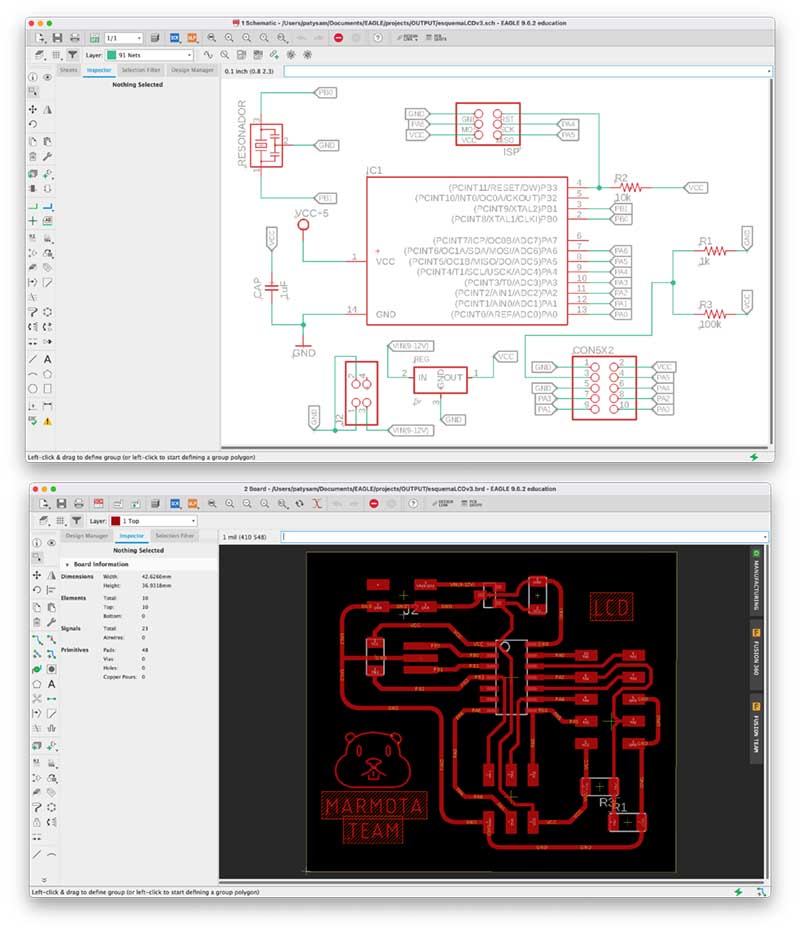

📍 From all the non-functional boards, I learned: If the process involves generating the schematic from a board, it is good to first trace the schematic on paper to interpret the connections; then use EDA software for the schematic and design before moving on to the CAM process.

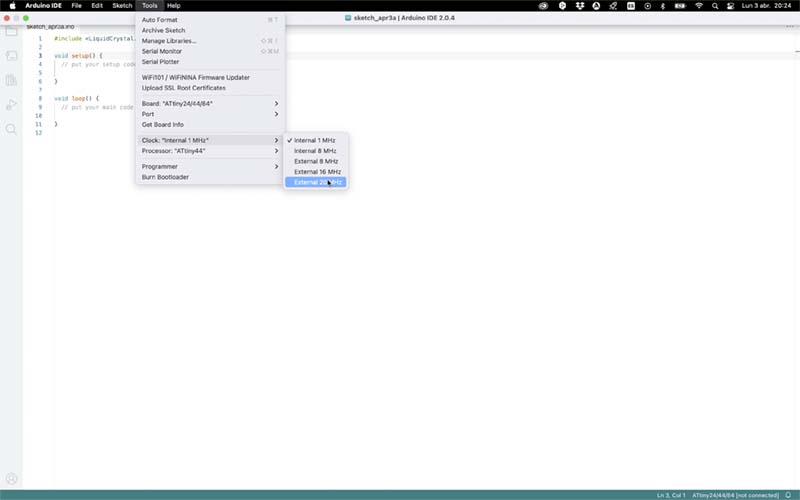

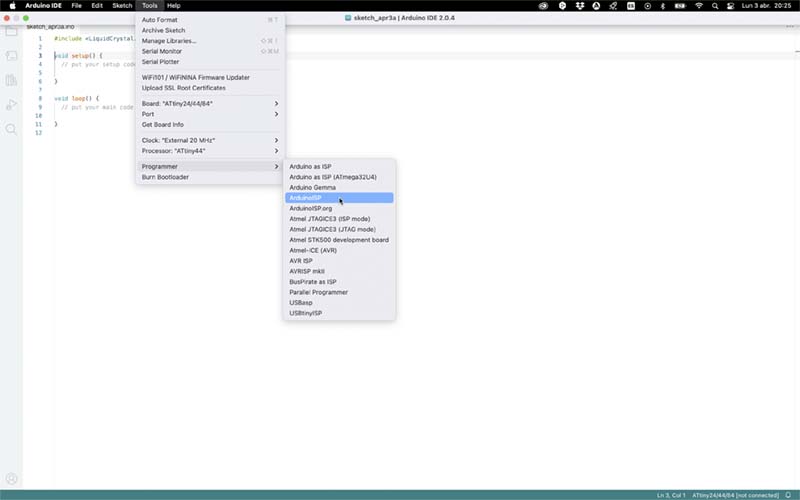

Patuino v4: the final

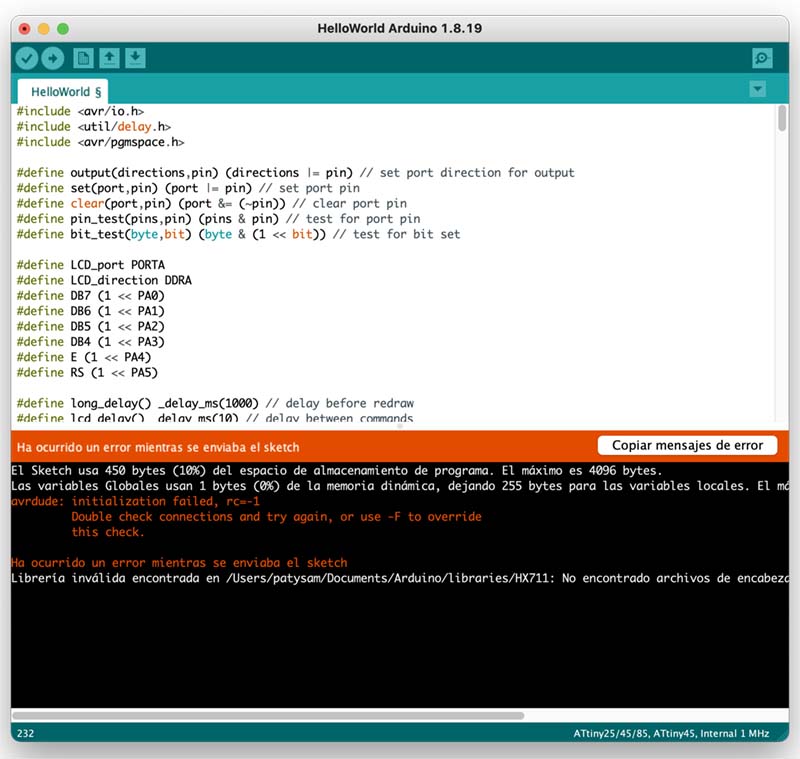

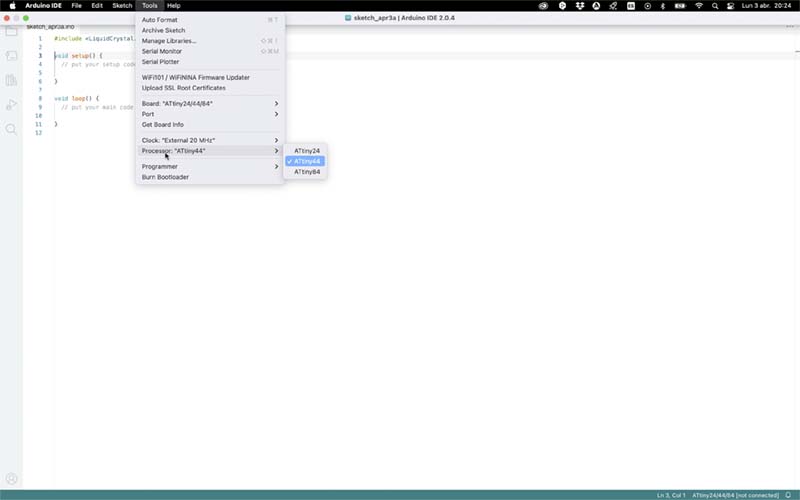

So, I went back. Together with Abdón, we checked the initial scheme and through that I was able to recognize several mistakes made: some connections were missing and others were wrong 😱. No problem! Let's start again: new scheme, new board 😎. But...

The almost final 🫠

Well, the end didn't turn out to be the end.

I ran a fifth plate: machined, ok - soldered, ok - initial test run, mmm, not so good.

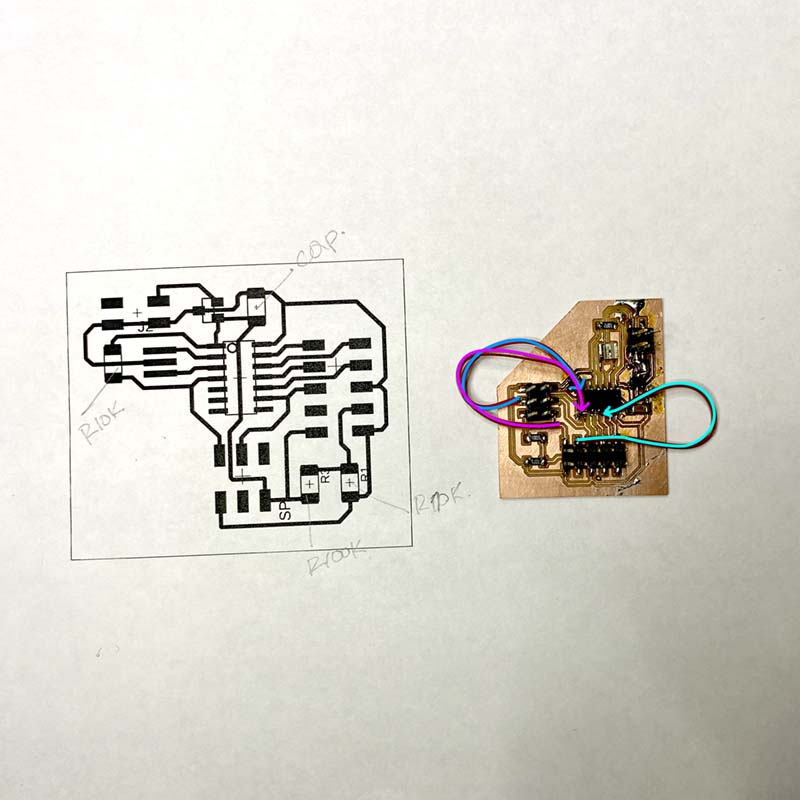

Reviewing board, schematic and layout again, the debugging process on the board begins: again, with guidance from Abdon, 'some physical adjustments' are made on the board.

And the board was left with 'three suspension bridges', which finally gave a communication result!

There remains the task of machining and soldering the last, last board.

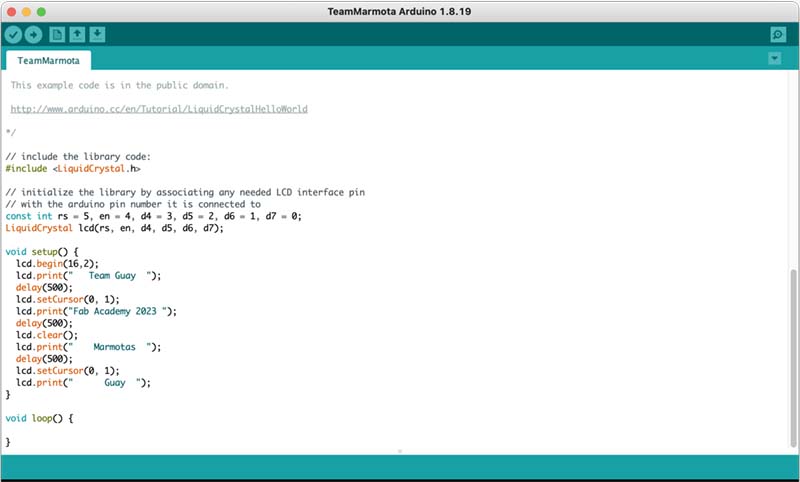

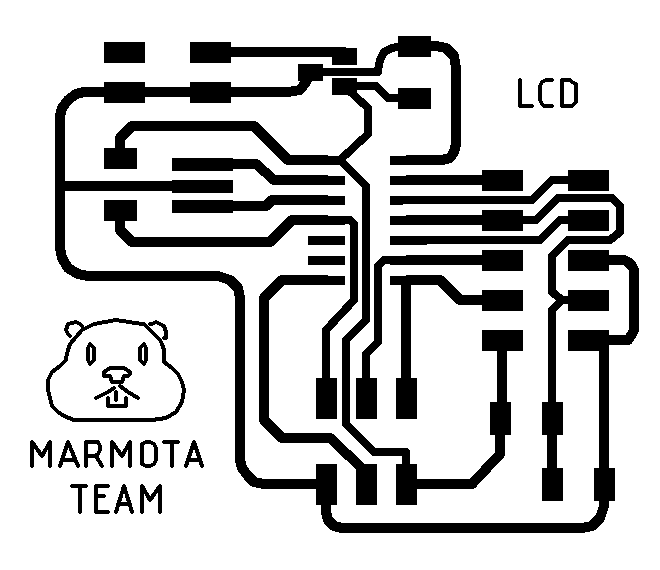

Patuino version 4: welding, debugging and LCD Display on.