Day 3 - Project Work

Okay! Let’s recap:

- We have designed, prototyped, and manufactured most of the components that we will need.

- We have also tested most of the electronics that we are going to use (electronics, motors, drivers, …)

The only things left are:

- Our pump is working, but is not as reliable as we would like it to be.

Sometimes it gets too hot. Sometimes it does not dispense sanitizer

properly…

- We would like to invest some time improving this!

- Our entire system, components and cables are spread across the table, and it

is an eyesore. It is so bad that EMP Recycling is threatening to throw us

all into the bin if we don’t fix it by the end of the day!! (alright.. not

really, but you get the idea…)

- The point is: We need some type of enclosure to contain all our components in a neat little package.

So this is how we will spend most of the day.

- One part of the team will be iterating on pump design and improving the pieces (sizes, proportions, silicone tubes, motor speeds, rolling pins, etc..)

- The other part of the team will be designing the enclosure for our product

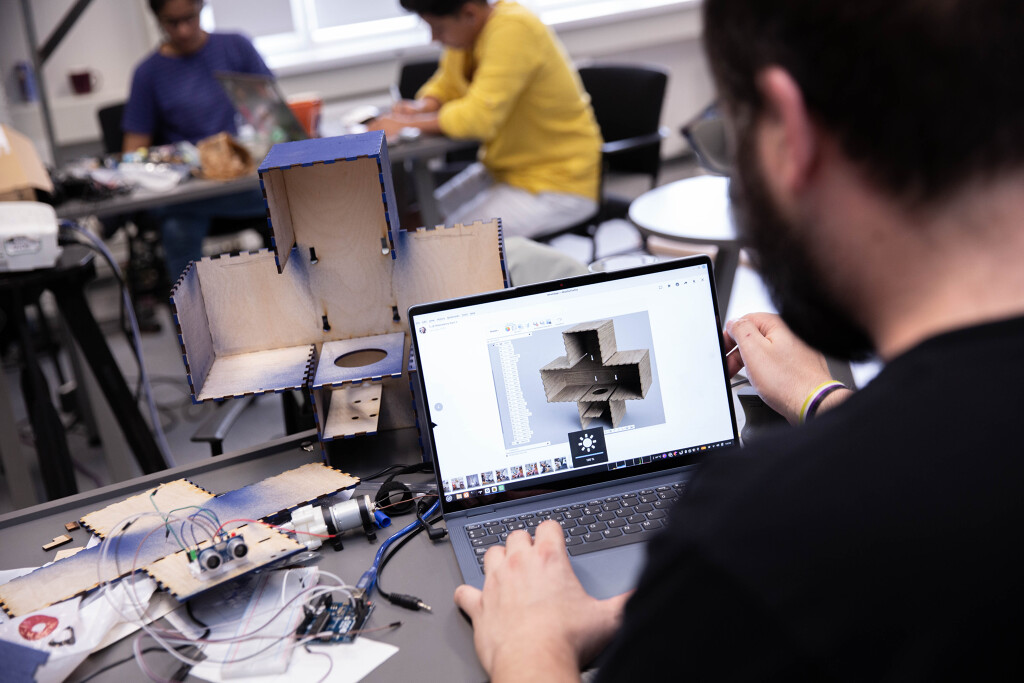

System Integration

In terms of system integration, we would like to have a small-to-medium size enclosure that can fit everything (excluding the power supply that we recycled, due to its weight).

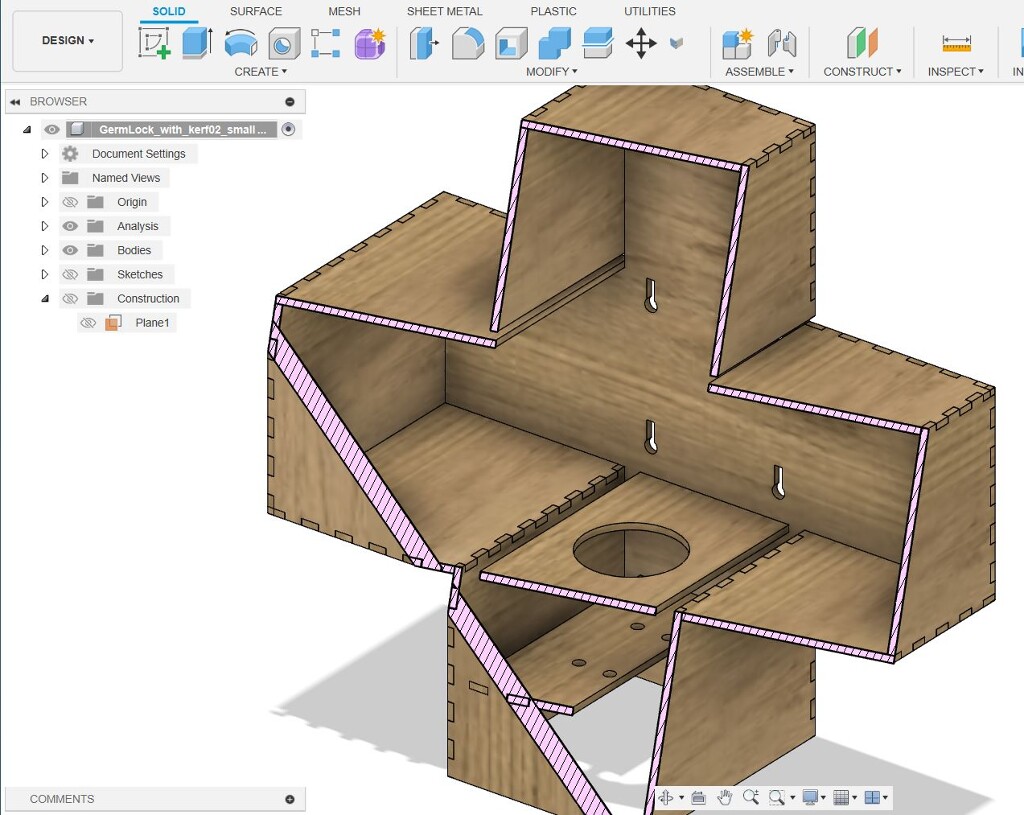

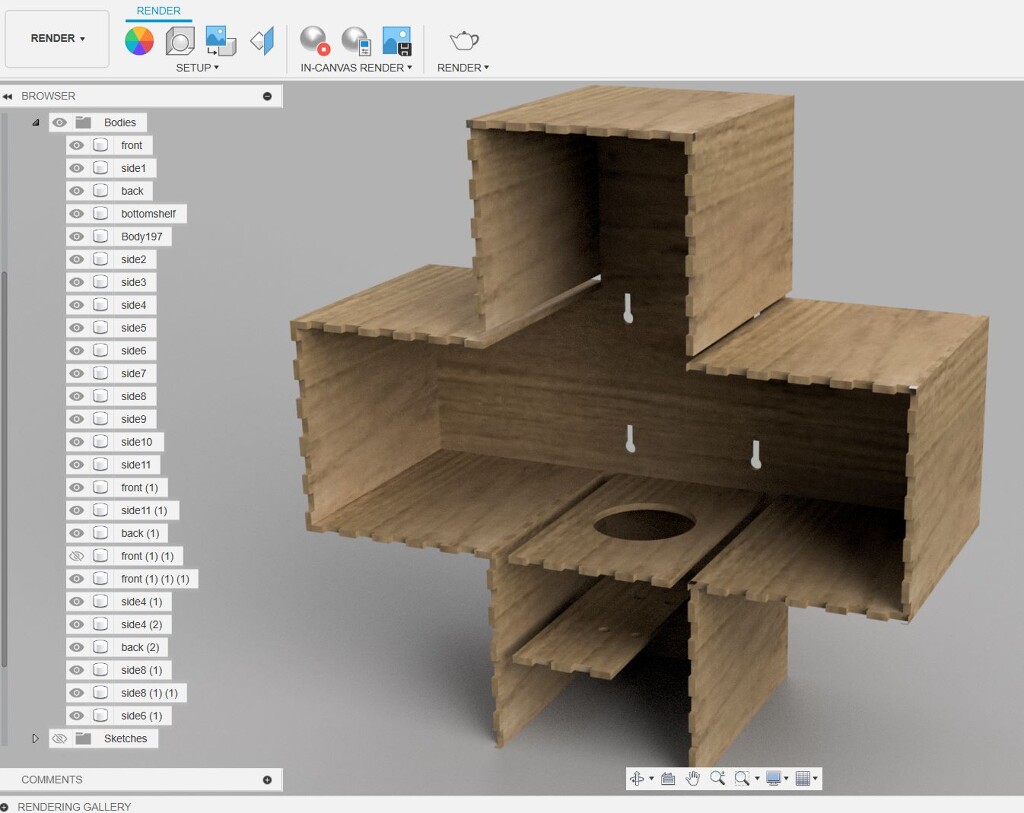

Since our product will be used in hospitals and places that require hygiene and sanitary conditions, we opted for a red-cross/hospital-friendly design.

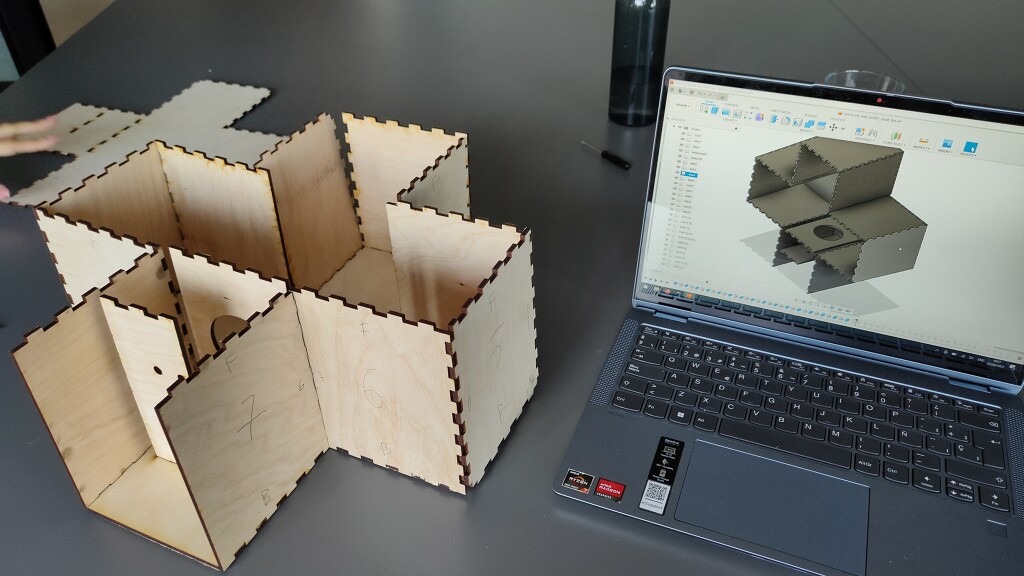

Manufacturing

We parameterized our model so that we can adjust most of the dimensions, as needed.

Two of the ones we needed to adjust were:

- material/stock thickness: as this could change if another team decided to use all the available plywood

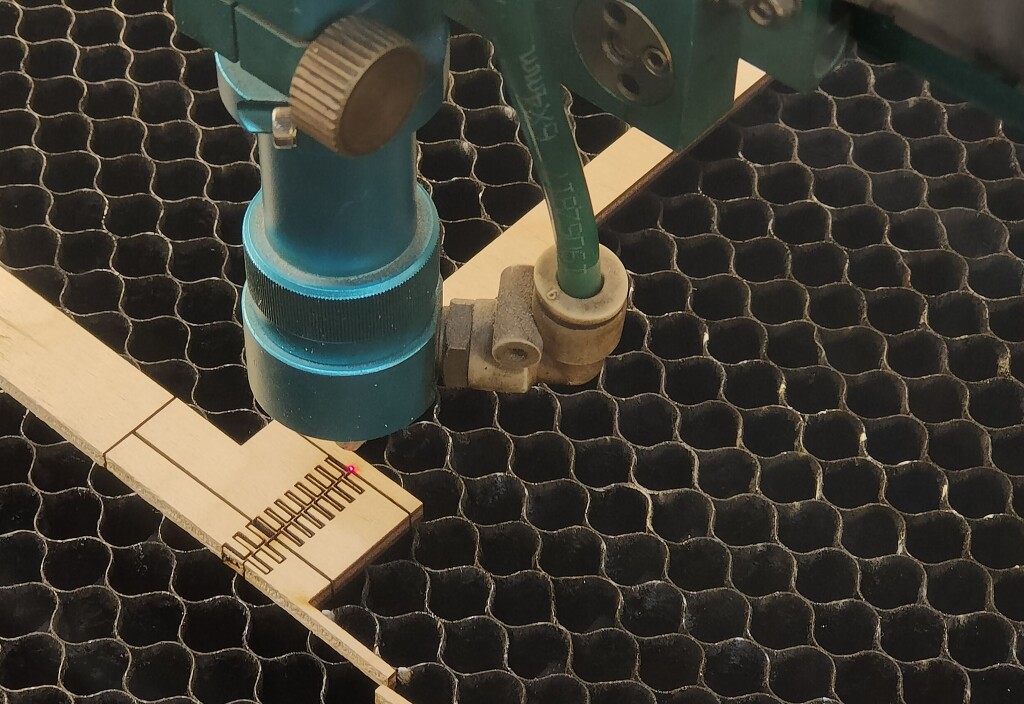

- laser kerf: as this changes from one machine configuration to the next, and it is highly recommended to do a small scale test before cutting all the pieces.

This picture below shows how we tested various kerf sizes using leftover scrap material we found in the workshop. Since this can be tested in a few cm^2 of material, we decided to use this tiny piece.

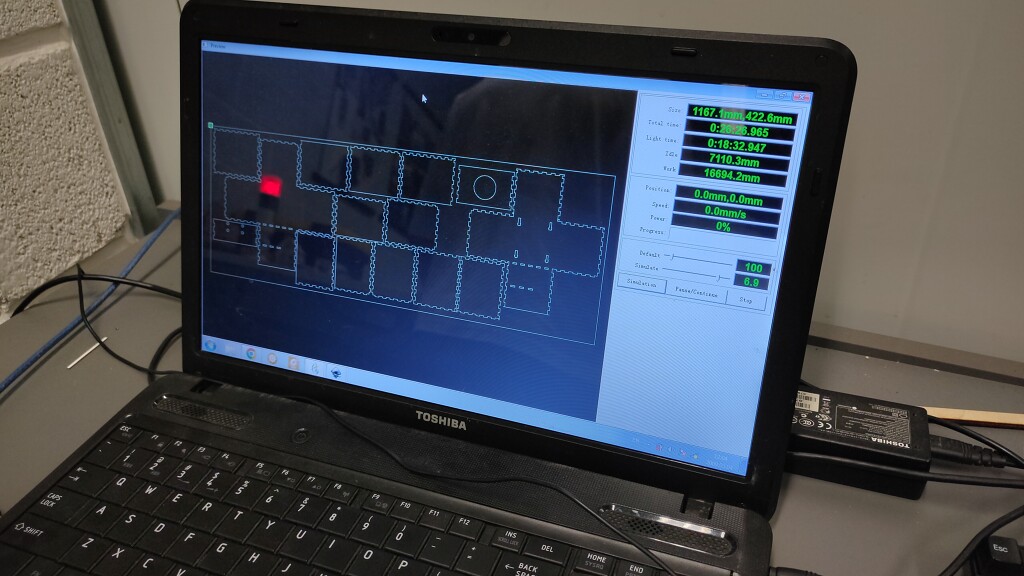

Once we got our parameters (stock=4mm, kerf=0.22mm for our laser machine), we updated our designs and nested all the pieces so we minimize the wasted material.

Final assembly

A few design decisions that we incorporated:

- Make it small/medium in order to reduce material usage.

- Make it easy to assemble without requiring extra components (no nails/screws)

- We ended up using glue in some parts just to improve longevity, but the fitted parts were so well-adjusted that it didn’t really need it.

- Provide a hanging mechanism, so it can be attached to a wall/door during future VilniusTech showcases

- Create removable parts (top of the left/right arms) so that the bottle of sanitized could be exchanged/refilled easily without having to disassemble the entire box.

Jump to day 4

This is the end of Day 3!

Jump to day 4 to see the final touches and the completed device.