Horn Kazoo, Zobo¶

Ladies and gentlemen, I present to you the best worst, or worst best 3D printed instrument of all time. The Zobo, AKA, the Horn Kazoo, AKA the bane of civilization

Background¶

If you have read anything on this site, it’s probably obvious that I play in Humpsvakar. a tech student band. As tech students, we are in an constant research effort to unlock the true potential of brass instruments.

Through our R&D efforts, we have arrived at an obvious conclusion: Anything making a noise is objectively better with an added horn.

For instance, it turns out, one can combine an ordinary, boring (and barely functional) megaphone, and a broken baritone horn into a beautiful instrument

Behold the gigatratt: An elegant weapon for a more civilized age.

Then for a more… Extreme example. We took a 53cc chainsaw, removed the muffler and replaced it with a trombone bell

As you can imagine, this most beautiful instrument is at home in any concert hall. Even outdoors, usually a challenging environment for acoustic instruments, is no problem thanks to the… Rich sound and volume.

(do not try this at home. Or if you do, please send me a video!)

Anyway trust me, putting horns on things make them better.

You can thus imagine my exitement when my orchestra colleague shows up in the beginning of August 2022 with a Miniature trombone kazoo!

A Kazoo is a stupid instrument, which sounds weird and requires no skill to play. Perfect for me, that is.

My dissapointment was immeasurable and my day was ruined when I realized that Kazoos make the most noise not from the end, but the membrane, with the bell being almost purely decorative. Clearly this wouldn’t do. As a proud owner of a 3D printer, I set out on a quest to produce the horn Kazoo the world deserved.

Horn Kazoo Mk1.¶

As a starting point, I printed a regular Kazoo. I found this nice model on Thingiverse. As an added bonus, STEP files are included.

The standard model plays alright with a wax paper membrane (even though the paper tends to wear out after a while). But not good enough. The membrane in a kazoo is a very critical part, it turns out.

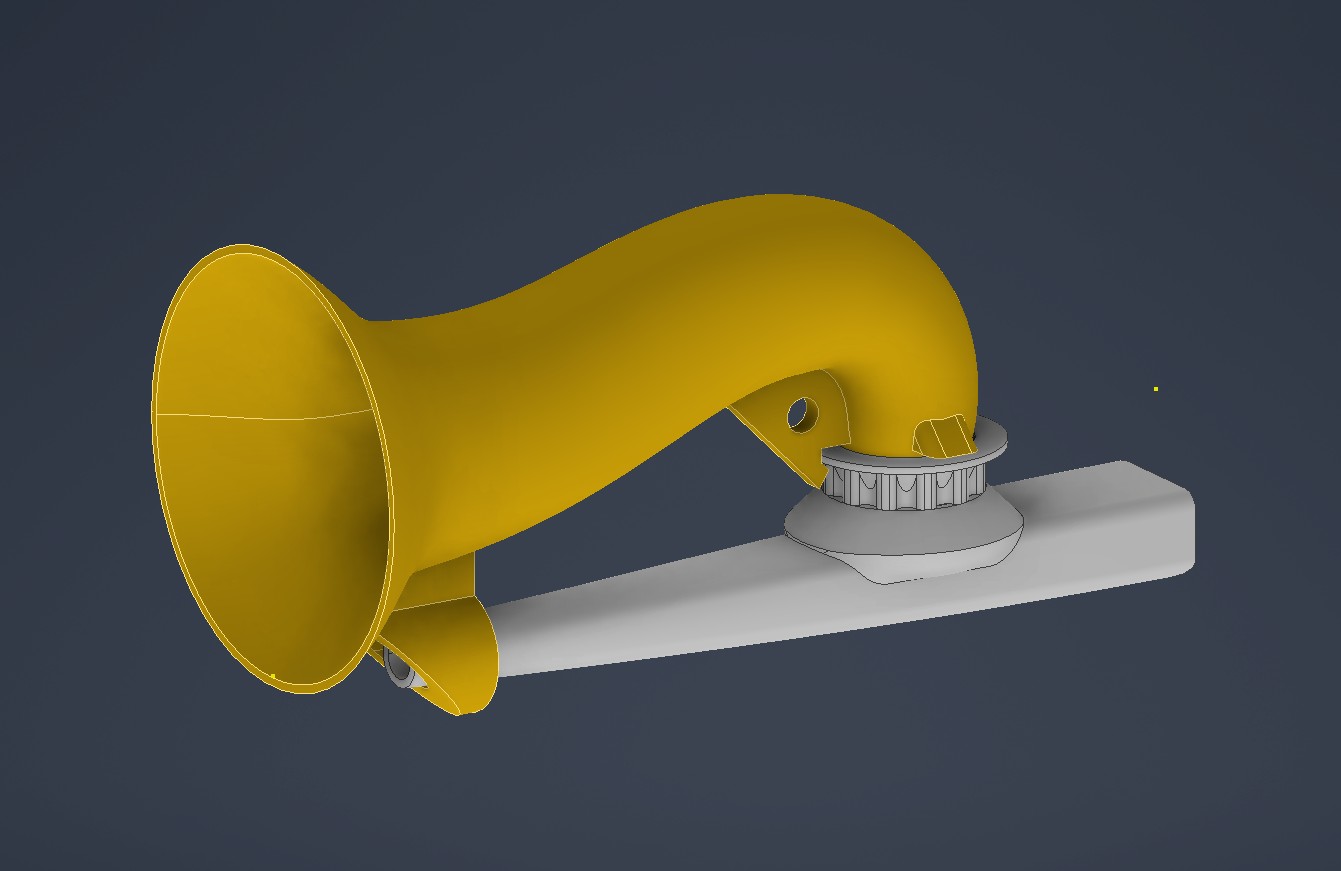

Turns out, someone has already made kazoos with bells. Marketed as “Excessively loud” Sounds good, i thought and booted up Inventor

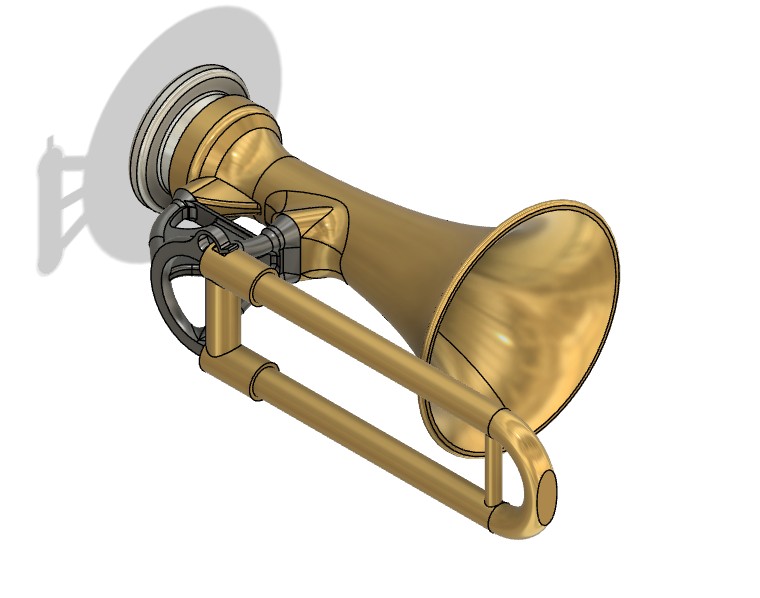

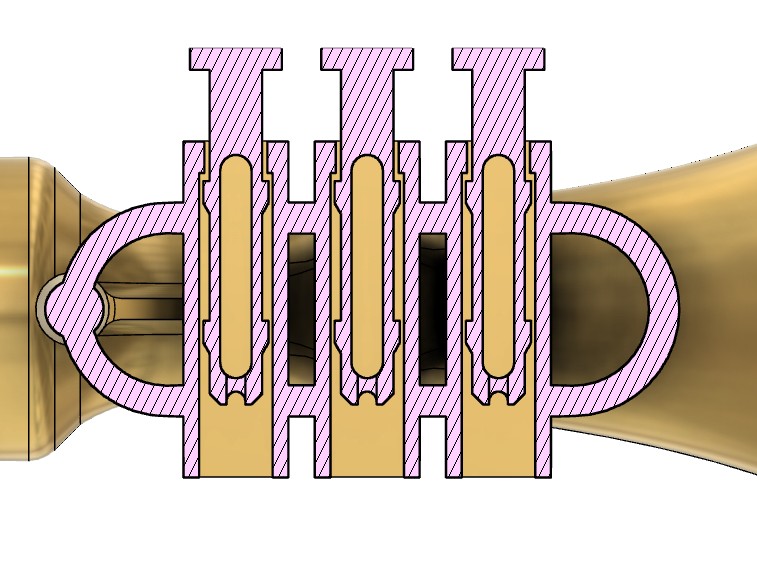

I wanted my bell to resemble a brass instrument more, so I added a recurve for the entire thing to both look nice and be a little more compact. I also added a front support point for the bell to be a little more stable. otherwise the shape is purely eyeballed. The bell is also removable, In case lower volume is desired studio laugh

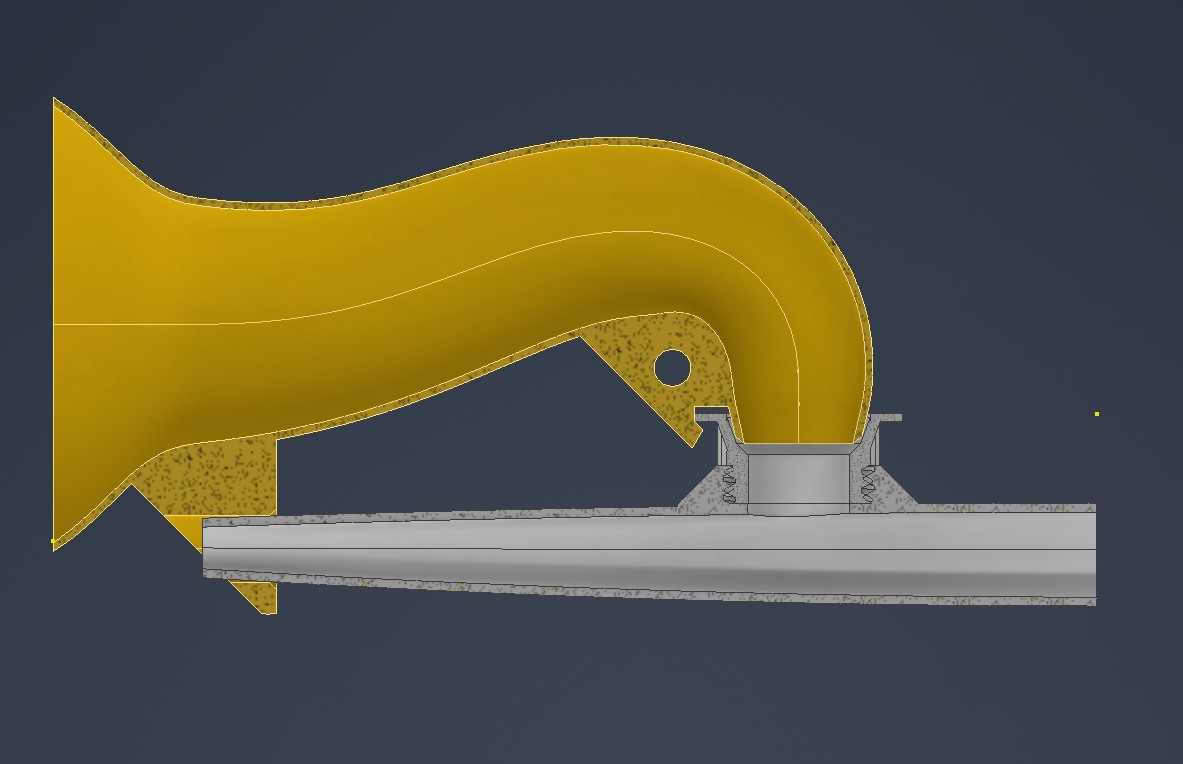

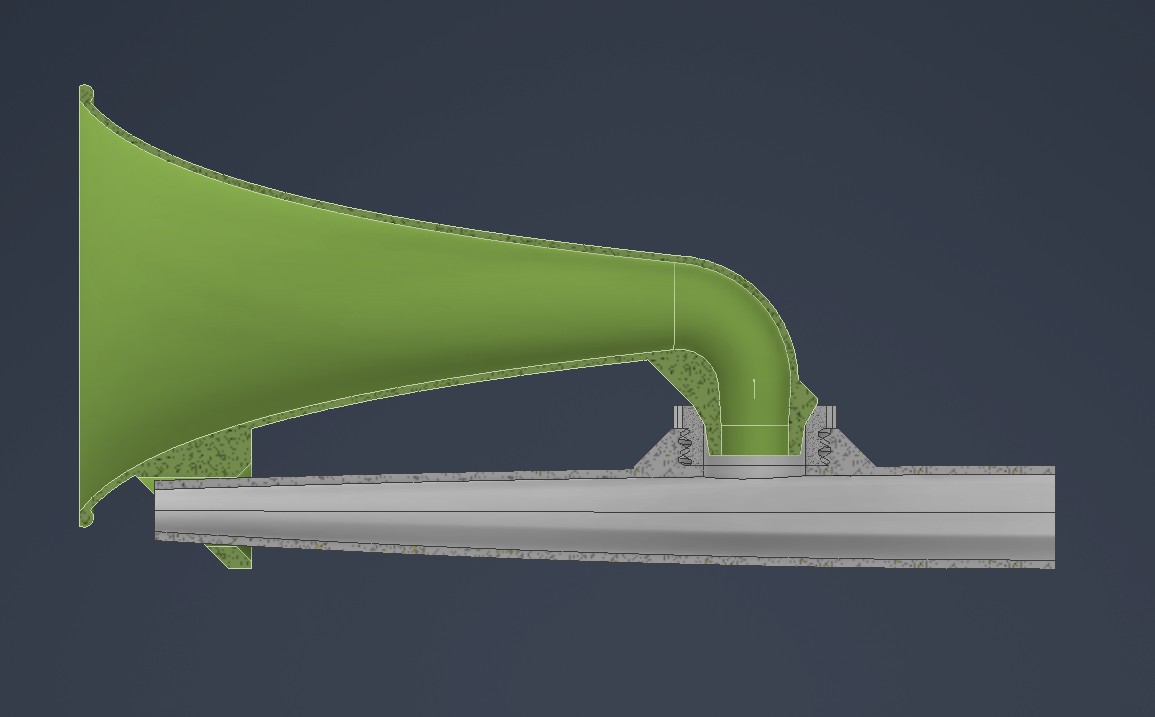

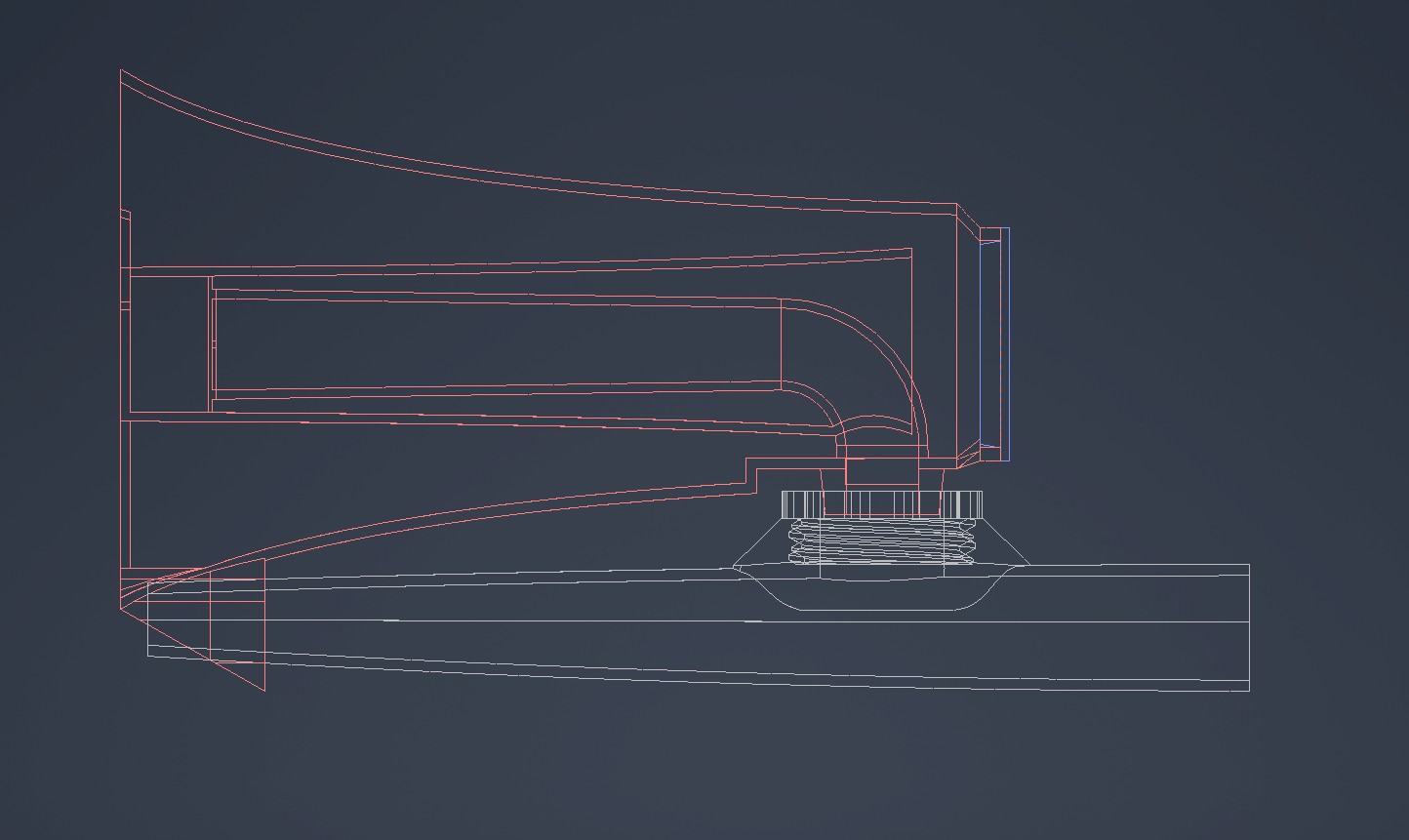

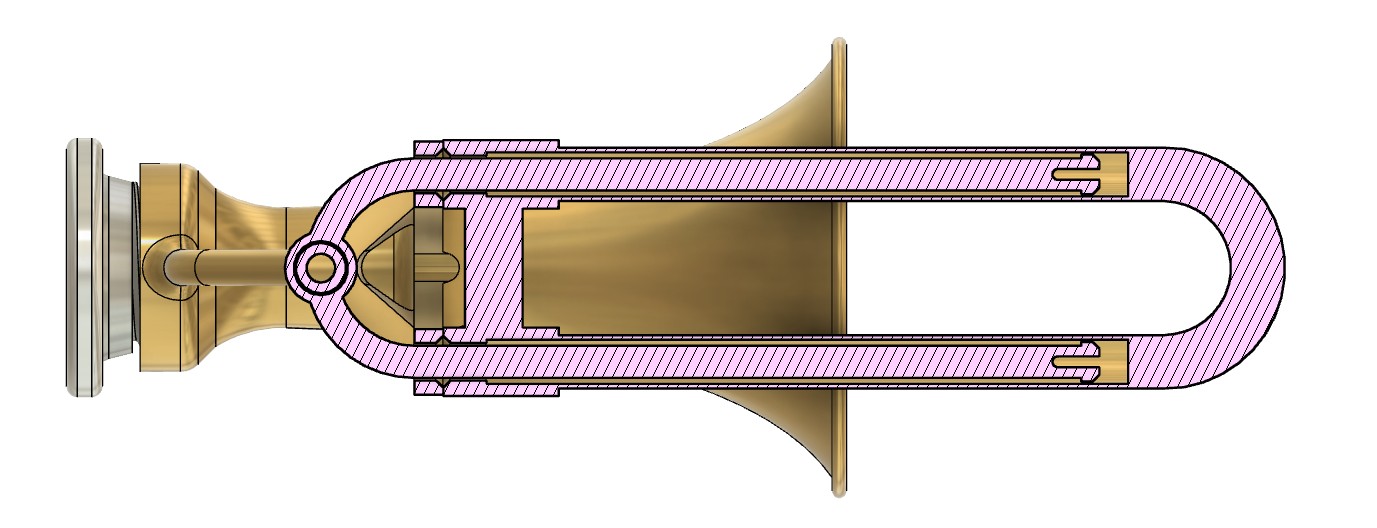

Cross section showing bell shape.

by September the design has been improved with a better locking system. This model provides way more volume than a regular kazoo, at least judging from the reactions from the remaining orchestra. But as it turns out, this is far from the final evolution of the Horn Kazoo

Dead ends¶

At first, I wanted to optimize the shape of the horn to produce maximal sound. I found this highly interesting Wikipedia article on horn loudspeaker theory. As it turns out, loudspeakers and megaphones use an exponentially widening horn , compared to brass instruments, where the horn is not only used for amplification, but for creating a resonance. thus, the length relation is different.

After looking at wikipedia’s nice animations I tried a couple of alternative horn designs. Loudspeaker designs use a throat next to the driver so I incorporated that + a more exponential horn shape

Furthermore, It turns out that thanks to sound reflecting, the horn can be “turned in” on itself. This is how most megaphones are setup. I obviously had to try this design as well.

Unfortunately, both of these designs turned out to be disappointments. The problem lies in pressure. Unlike a compression driver, the Kazoo membrane doesn’t produce a significant pressure difference. In fact, compared to the voice causing the vibration, it loses pressure. A design with a throat or too long of a bell will simply absorb the sound energy, instead of amplifying it. By sheer luck I was actually quite close to a good design on the first try.

Despite these disappointments, I made two crucial discoveries.

New membranes.¶

The wax paper membranes I started with were as mentioned previously not good. So i tried other materials. Quite a few other materials. Such as:

- ESD bag

- Window tinting film

- Plastic bag

- Receipt paper

- regular paper

- Kapton tape

None of these were any good. By reading online I found that industrial Kazoo membranes are made out of mylar, a thin film polymer. In general, the membrane needs to be thin and “crunchy”

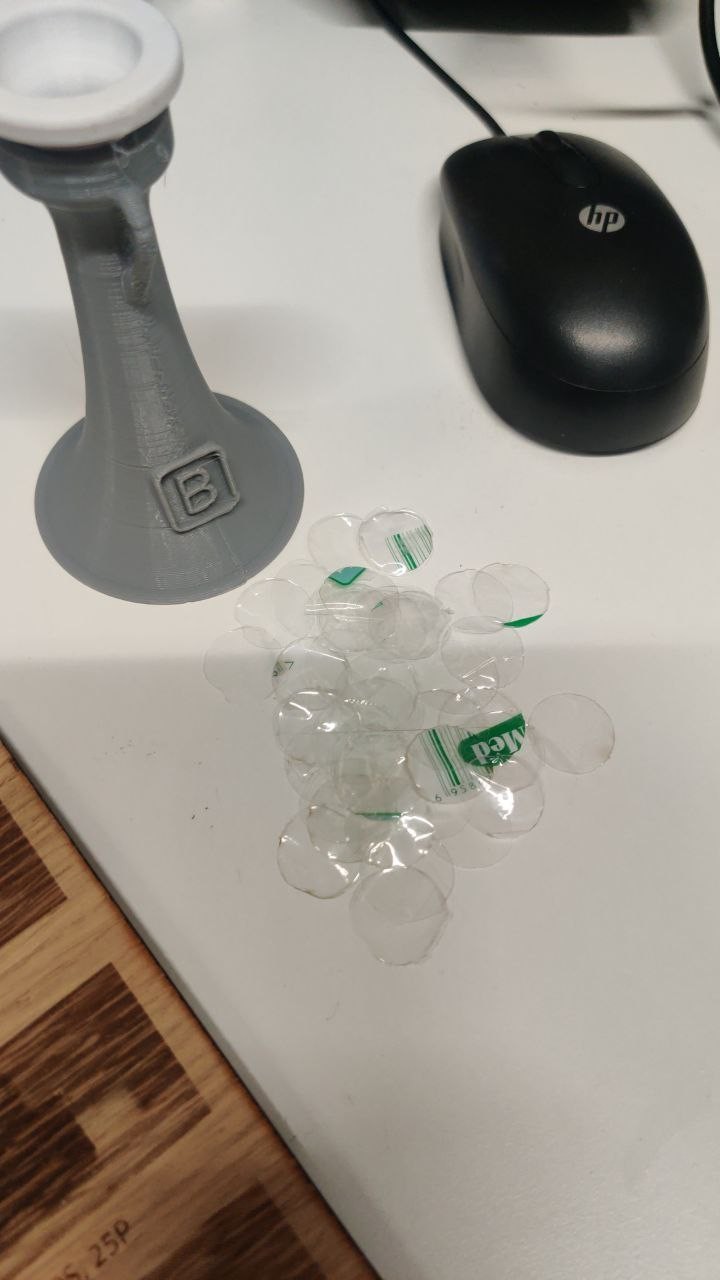

Eventually random experimentation paid off. It turns out the wrapping of single use face masks make excellent Kazoo membranes. As masks are not needed anymore (🤞🤞) This is an excellent source.

The plastic appears to be LD-PE of some kind. Interestingly, membranes made from the printed areas make noticeably less sound than fully clear ones.

With a laser cutter I can in minutes make tens of membranes.

The Zobo¶

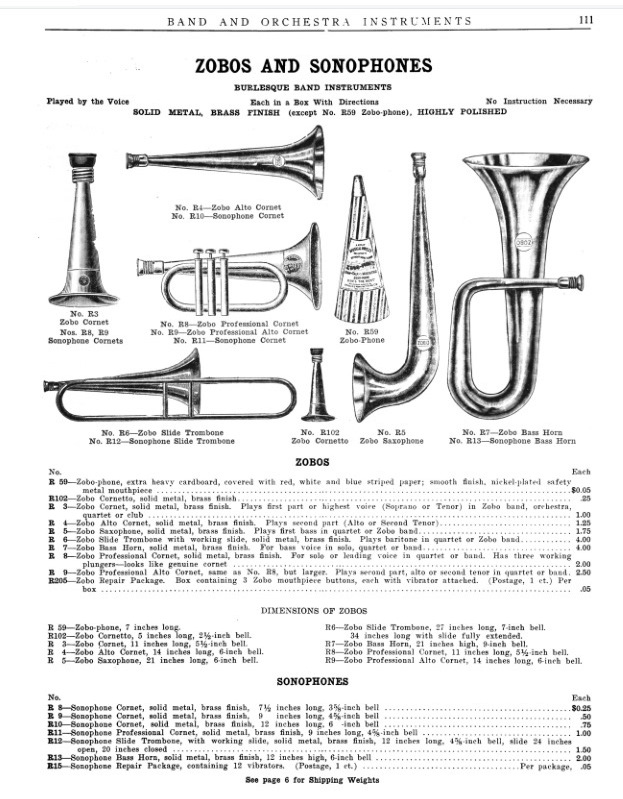

When googling random instruments I stumbled across something remarkable. An extremely random website called brasspedia Has an article on an instrument called a Zobo horn. Or Kazoo. Or Songophone. Depends I guess.

Evidently, the early 1900s were something of a golden age for novelty instruments. Unclear if there is any correlation with drug laws not being invented yet…

This was in any case just what I was looking for. The original Zobos were actually made of brass. and resemble different instruments, Including a trombone! Full circle! I even found Patent drawings, from 1896. So I won’t get sued at least (the modern Kazoo patent is from 1902, but earlier versions existed decades before).

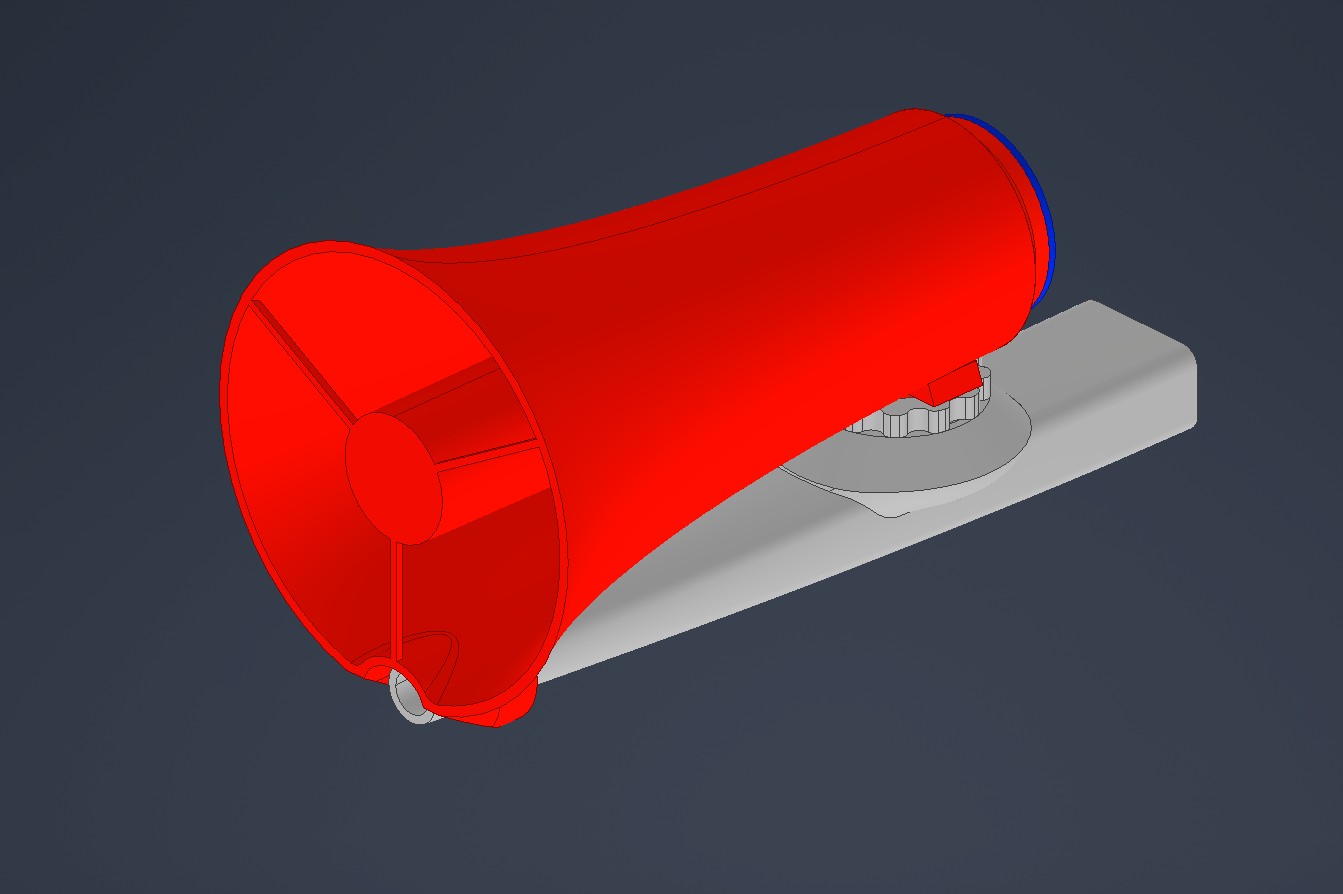

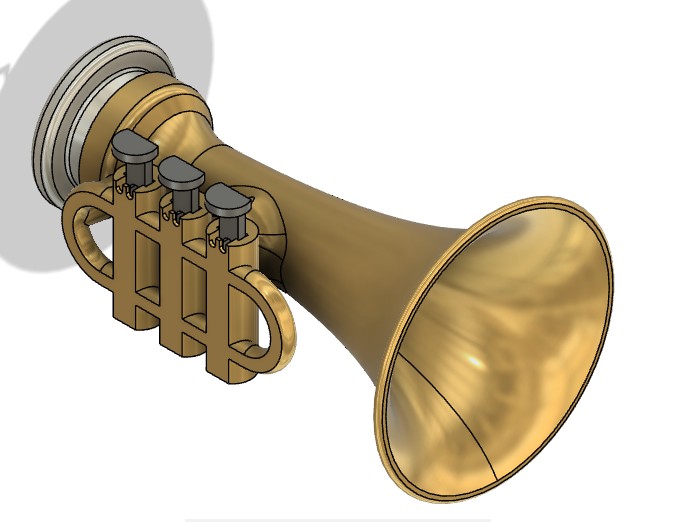

Anyway, I was completely sold, so I CADded and 3D printed my own version.

Two things quickly became clear. First, the Zobo plays differently than a Kazoo. There is no path for the air to escape, so the user has to open their lips slightly for the air to have a path out.

Secondly, it’s better than a Kazoo. The sound is way louder even than my horn Kazoo, and surprisingly it has a wider register, as the user can slightly increase the back pressure on the membrane to resonate at lower notes than usual. In my opinion the sound is also nicer, kind of like a saxophone in the high range.

Best of all, It has less parts and is faster to print than the old horn Kazoo. We clearly have a hit product on our hands.

I have played around with different sizes and lengths of horn, but have settled on a smallish one that seems ideal (again, very close to the original guesstimated size). After some feedback from my (mostly unwilling) test audience I have made some further improvements. Namely, A lanyard ring. This has proved to significantly reduce stolen, stepped on or otherwise tragically lost horns. Making a fake trombone is also still on the bucket list, in order to close the circle.

Anyway, other orchestras seem much more open to the concept (perhaps not being a part of the R&D cycle has something to do with it). And the horns can certainly be printed with a logo in orchestra colors.

Zombone & Zumpet¶

Yeah, it happened.

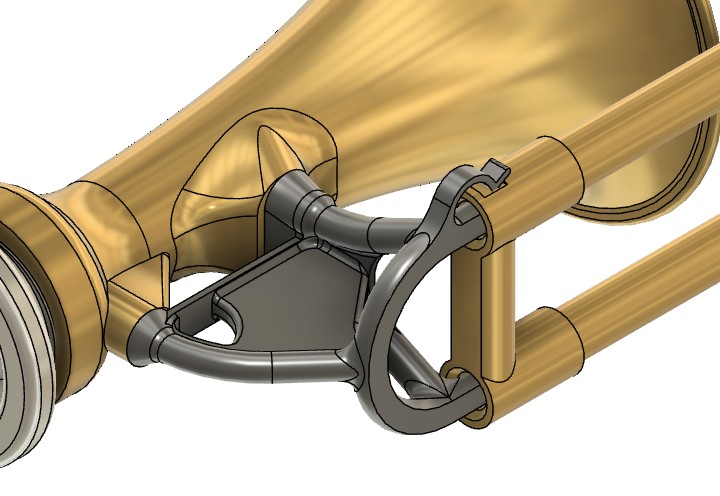

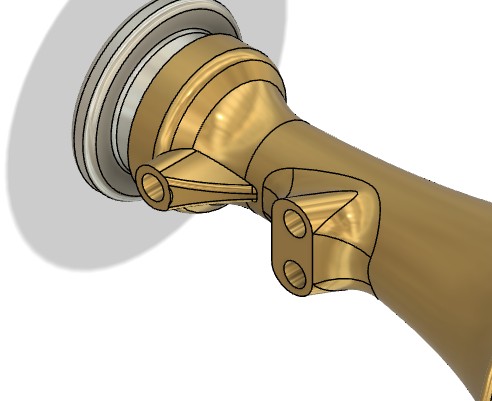

To begin with, I essentially CADded a slide, and then built out a support structure out of the Kazoo body. The slide is held by two rings and a screw. The support structure also doubles as a lanyard ring.

With the slide being completely for decoration (Just like a real trombone) I was able to design a split pin type end on the inner slide. This allows for the slide to be assembled, but prevents it from falling off (this very much is not a feature of a real trombone.) Anyway, off to the printer.

After some retries to get the slide tolerances right, it actually works! and quite well. I even printed a couple in black with little hot rod flames to match my actual, also plastic trombone.

(Don’t talk to me, or my son, ever again)

Anyway, I quickly found stuff to improve from v1:

- The slide support structure on the horn currently requires a lot of support material. This could be revised.

- The screw is annoying to source, a fully 3D printed design would be better.

- The slide has an annoying habit of extending by itself and getting in the way. Real trombones solve this with a slide lock, so something similar would be nice.

- The slide is also challenging to print, with an approx 50% failure rate. What’s worse, the failures usually occur almost at the end of print.

After a couple of rounds of iteration I implemented the following changes.

The support structure for the slide is now moved to the slide itself. This allows the complete structure to be printed without supports. Furthermore, the assembly is now attached with glue, eliminating the screw. The slide also now incorporates a very simple slide lock, to hold it retracted.

The outer slide is also redesigned with two parts. This drastically improves print reliability. The components are now assembled with glue.

I’m still doing small changes to wall thicknesses and shapes to strengthen the structure, but in general I am really happy with the concept of the trombone version. As an added bonus, the fake slide gives a little bit of satisfaction every time I hum a note, and my brain actually thinks i picked the correct slide position!

I realized that I could mount all kinds of stuff to the same mounting interface as the trombone slide.

Behold, the Zumpet!

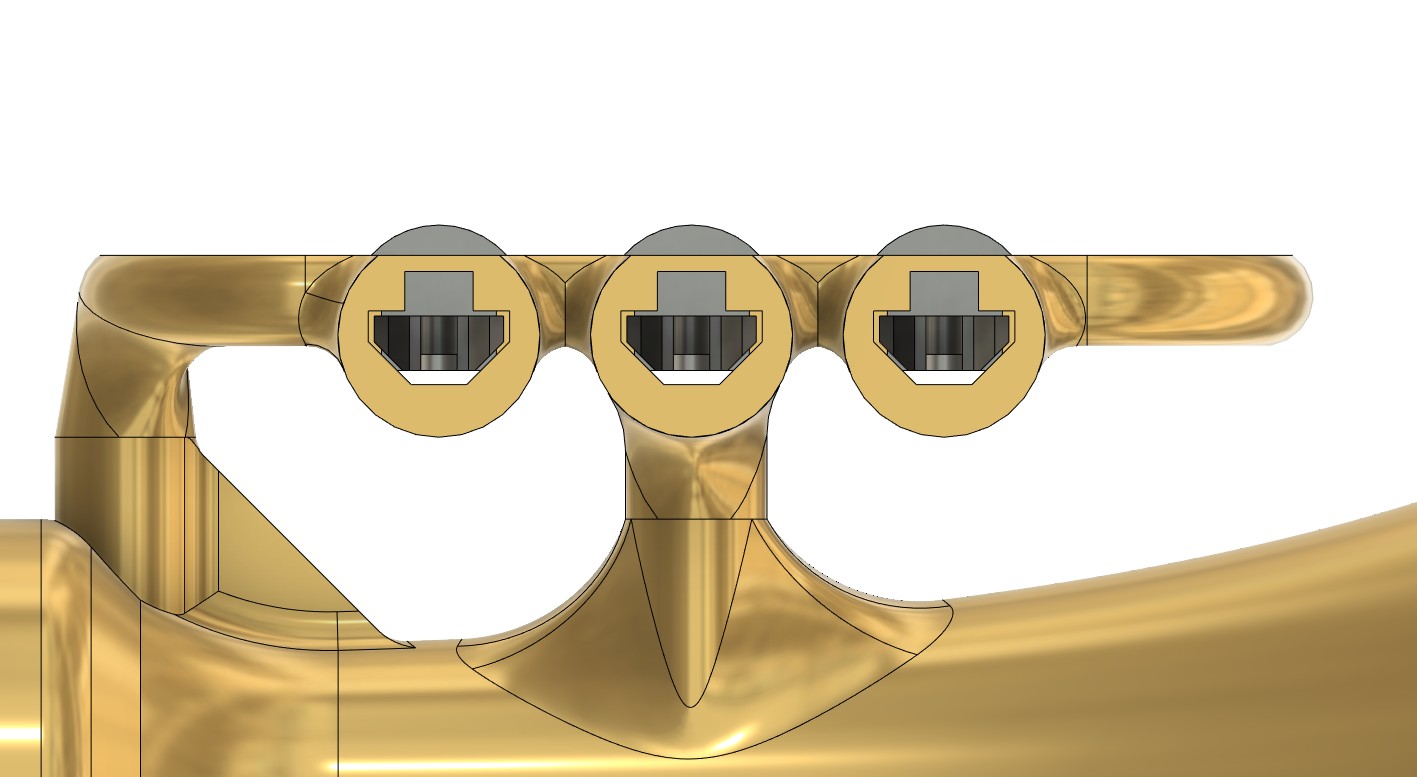

As the Zombone has a functioning slide, I naturally set out to make the valves function as well.

The valves have a plunger, with a similaar split pin as the zombone slide, meaning they can be inserted and then hold position. Return is achieved via a small rubber band.

The valves work, but print quality is still varied, resulting in quite varying levels of friction. Furthermore, the rubber bands tend to break fairly often. Some development seems to be necessary,

The top bridge surface was for some reason printing badly, furthermore, the slicing software insisted on making the bridges lengthwise instead of crosswise…

The solution was having the top contact surface be angled instead. This also took a number of development versions to get right, but in the end, the valves now seem to have a consistent fit!

If you have read this far, first of all congrats. And apologies. Oh and HMU if you want your own best worst instrument beer, money and/or barter can buy.

You can click the rocket to get to the top now. You’ve deserved it. –>¨