Final Project

Week 0: Digital Fabrication Principles and

Practices

Week 1:

Collaborative Technical Development, Documentation and Project

Management

Week 2:

Computer Aided Design

Week 3:

Computer Controlled Cutting

Week 4:

Electronics Production

Week 5:

3D Scanning and Printing

Week 6:

Electronics Design

Week 7:

Moulding and Casting

Week 8:

Embedded Programming

Week 9:

Computer Controlled Machining

Week 10:

Input Devices

Week 11:

Composites

Week 12:

Interface and Application Programming

Week 13:

Output Devices

Week 14:

Networking and Communications

Week 15:

Mechanical Design and Machine Design

Week 16:

Applications and Implications

Week 17:

Invention, Intellectual Property and Income

Week 18:

Project Development

Week 19:

Final Project Presentation

|

Final Project:

Finally

the projected is completed! This project provided me with a lot of

fustrating experiences, particularly with the internal parts of the

project, but through perserverance I have completed the first iteration

of the project. The project covers skills from various different

topics definied in the Fab Lab syallabus and teaching schedule, these

are: Computer Aided

Design, Manufacturing and Modelling, Electronics Production, 3D

Scanning and Printing, Electronics Design, Embedded Programming, Input

Devices, Interface and Application Programming, Networking and

Communications.

Through, my experiences in the final project, I ended up using a

'spiral development'. Instead of primarily using one large system

(that I had ultitised initially). I broke the development of the

electronics into a series of sequentially manageable sections from

previous sections of the Fab Academy schedule Thereby, I created

smaller boards that performed a single defined role that could be

networked together in sequence.

Electronics rationale/Embedded Programming Part 2:

The internal

operation of the system is driven with attiny44 microcontrollers, with

firmware written in C. The boards are based on the designs shown

within the Fab Academy schedule i.e. Temperature Sensor, Transmit

Receive Sensor and Hello Arduino board. The basic input boards

include an attiny44, ISP header, 10k resistor pulling RST high, power

capacitor. The controller board was driven by atmega 328

microcontroller, with jumpers for all the output pins.

Board Two - Temperature Sensor:

The code for the temperature board is almost entirely lifted from the

temperature sensor code for the input section of the Fab Academy and

included the bit-banging code from the hello.bus.45 example. So this

microcontroller waits for a transmission from the Controller board

before reporting a reader from the board. Using the FTDI 6 pin

jumper breakout board I made in the previous week I debugged the

Temperature Sensor.

Board Three - Moisture Sensor:

So

by this stage I had a working Temperature sensor board working. The

next thing I wanted to do ensure that the moisture sensor board worked

seperately and in conjunction with the temperature board and it was

properly calibrated to sense moisture in a piece of timber. The

connection can only be achieved once the controller board is up and

running.

Sensor Prongs - Moisture Sensor:

I developed the sensor prongs using a combination of bits from a

hardware store, this included nails and picture hangers to locate and

support the prongs - Once this was achieved I soldered wires on to the

prongs and tested with moisture board. Calibration of the values

is achieved through the Python application previously given to us in

the input section of the Fab Lab schedule. It should be noted

that the available copperboard available in the lab was double sided, I

found during the calibration process that the resistance or

transmittance of the copper on the underside of the board effect the

values greatly and would not allow a steady reading to take

place. I had to manually scrape off the copper on the underside

using a scalpel.

Board One - Controller:

The first board

was initally

conceived to connect to the computer wirelessly but due to time

constraints and lack of knowledge I was unable to intergrate this into

the first iteration of the project. Therefore the controller

board

connects directly to the host computer via an FTDI cable, it sends and

receives serial messages from the input boards. Unfortunately the

case I had previously designed didn't accomodate the FTDI connection

and with the larger footprint of the three seperate circuit boards, I

had to modify the case to allow this connection to be secured and

function correctly. This crude arrangement will be improved in further iterations.

Once all the boards were linked using ribbon cables to the ISP jumpers,

I had to develop the controller board code. This proved to be the most

difficult of the whole project as I found it incredibly difficult to

find a basis of the code.

The

code, through a series of loops calls a character and then receives

information back from the serial board. Initially, i wanted to

seperate the values received from the Arduino and plot them on seperate

graphs within in Python but because I couldn't seperate the values

coming through the Arduino I put the live stream from the moisture

content and then when you want to check the temperature to corroborate

the reading, that will be an individual process from the serial monitor. The Arduino code can be found here.

I found that I had to install additional connectors to ensure that the

analogue inputs came into the correct ports of the Arduino (i.e. A1

& A0)

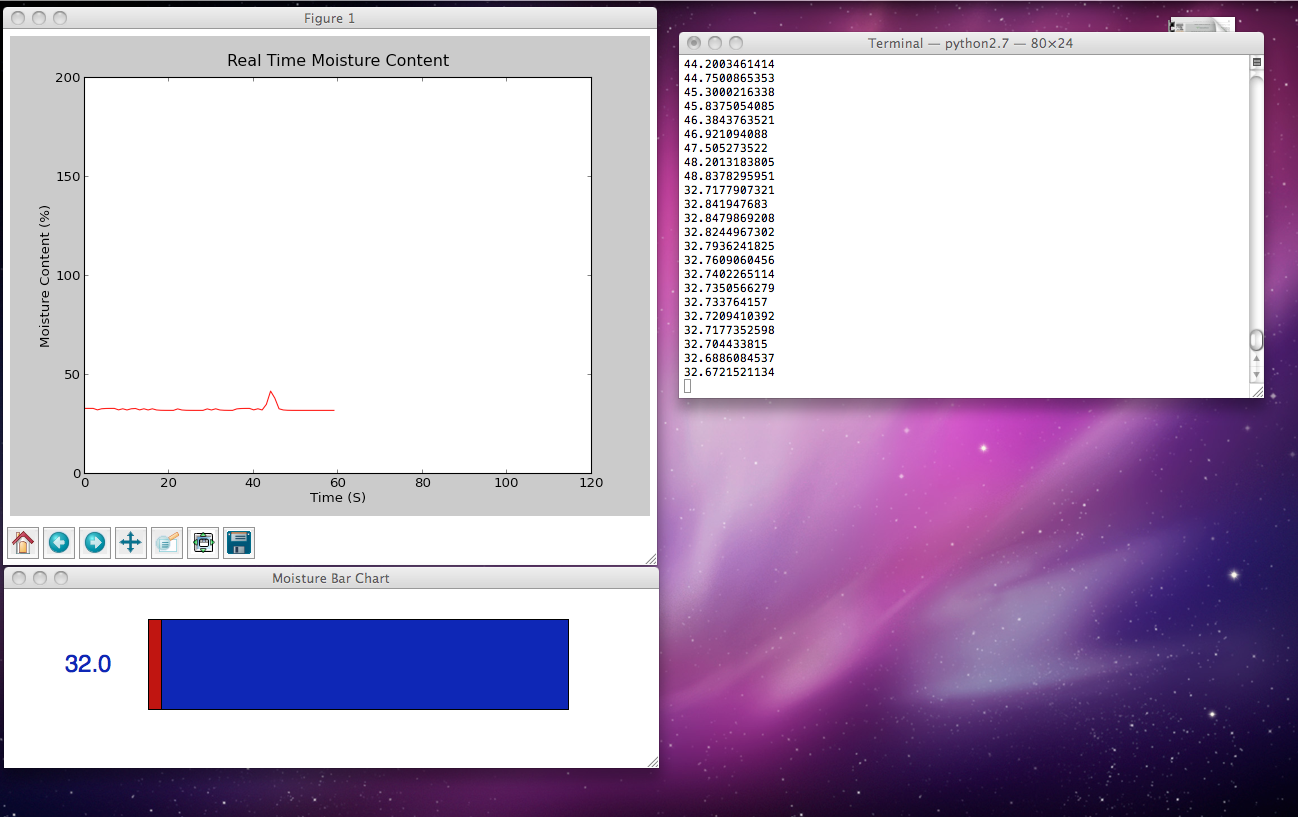

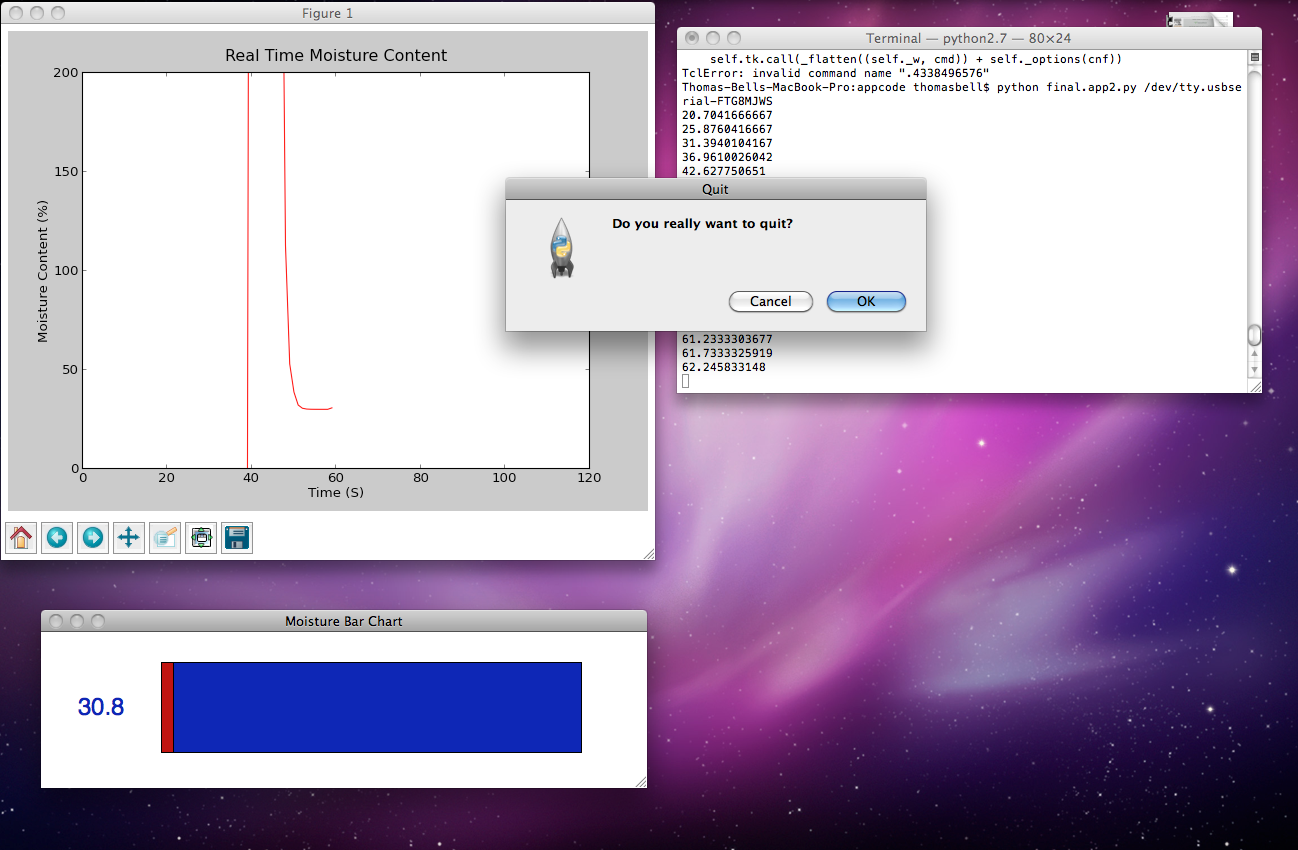

Application and Interface Programming:

The

Python Application that the project uses is based on the Python codes

given to us in the input sections of the Fab Academy schedule.

Looking at the code for hello.temp.45.py and hello.txrx.45.py in

conjunction with there C codes. I found that the Python code is

waiting for the correct pattern of numbers from which it will read two

numbers that it combines into one number.

For instance in the hello.txrx.45.py code, the ord() function computes

the numbers sent from the input mircocontrollers into a numbered

format. The ser.read() function is the operation to read the

information being sent through the serial connection by the

mircocontroller, where 'ser' location and operation is defined within

the program as:

ser = serial.Serial(port,9600)

ser.setDTR()

Once an argument is created through the serial port at the correct baud

rate, a graphic can be produced. For my final project I wanted to

integrate a live plotting graph as an output from moisture

inputs. To enable this it is necessary to package MatPlotLib into

Python to provide a mathmatical graphical interface. To create

the array I used a deque function and set the x and y axis, with a

small amount of values to decrease the dataset and set up the graph

arrangement.

One of the main problems with the live data stream is that it was too

fast for the graph to update and needed to be slowed, using a count

sequence that slows the data feed by a significant factor so the graph

can update correctly. Additionally the code also required

to produce an output file that could be read an analysed with a

statistical package environment and a provide a reading for the

temperature once the moisture content is read, unfortunately I didn't get around to creating this output. The file can be

found here.

|

|

Final Comments:

The project, was an interesting undertaking as I had never having

undertaken any programming prior to this course and it provided a

stumbling block to the completion of the final product from the

outset. Further iterations will be needed if this were to be

developed into a comercial product, this process is more of a

conceptual starting point than a fully finalised product.

The spiral development technique that allowed the constituent parts to

be built seperately also increased the size of the product.

Through further development all parts could be pulled together to

provide a much smaller footprint for the circuit and the product

itself. Two elements of the product had to be clipped from the

production of the product due to my lack of knowledge and time, the RF

wireless component and a standalone power source any further

development should implement these processes as they will be

fundamental to the successful operation of the product in practice.

There are theortical shortcomings to the project as well, because the

natural electrical conductivity of timber varies from species to

species further calibrations are needed for the most common types of

timber species rather than the one that the product is presently set up

for. This should be incorporated in the application interface and

the python program as well as a time lapse option to increase the

reading of the sample.

Conclusions:

Overall I am

fairly disappointed with how the project turned out, I had to remove

elements of the product that I originally wanted to incorporate.

Barring this, I found the development of a entire project very helpful,

it helped gain an appreciation of how to break the project down into

small increments and gain a more holistic approach to electronic

product design.

|

FAB ACADEMY 2013

FAB ACADEMY 2013