Final Project

Week 0: Digital Fabrication Principles and

Practices

Week 1:

Collaborative Technical Development, Documentation and Project

Management

Week 2:

Computer Aided Design

Week 3:

Computer Controlled Cutting

Week 4:

Electronics Production

Week 5:

3D Scanning and Printing

Week 6:

Electronics Design

Week 7:

Moulding and Casting

Week 8:

Embedded Programming

Week 9:

Computer Controlled Machining

Week 10:

Input Devices

Week 11:

Composites

Week 12:

Interface and Application Programming

Week 13:

Output Devices

Week 14:

Networking and Communications

Week 15:

Mechanical Design and Machine Design

Week 16:

Applications and Implications

Week 17:

Invention, Intellectual Property and Income

Week 18:

Project Development

Week 19:

Final Project Presentation

|

Composites

This

week we had to construct a workflow for developing composite

casting. Due to the fact that we are a new lab with no local

guru, me and Roy decided to team up to create the workflow, as we

thought that we could help each other out to develop the scheme of

work. This meant, acquiring the parts for all the composites and

creating the moulds and developing the workflows through trial and

error.

Design:

To enable a more simplistic workflow, the design was to be a

large 6mm thick bowl constructed within Rhino/Solidworks, with us both experimenting

with different composite materials and trying to define the necessary

workflows.

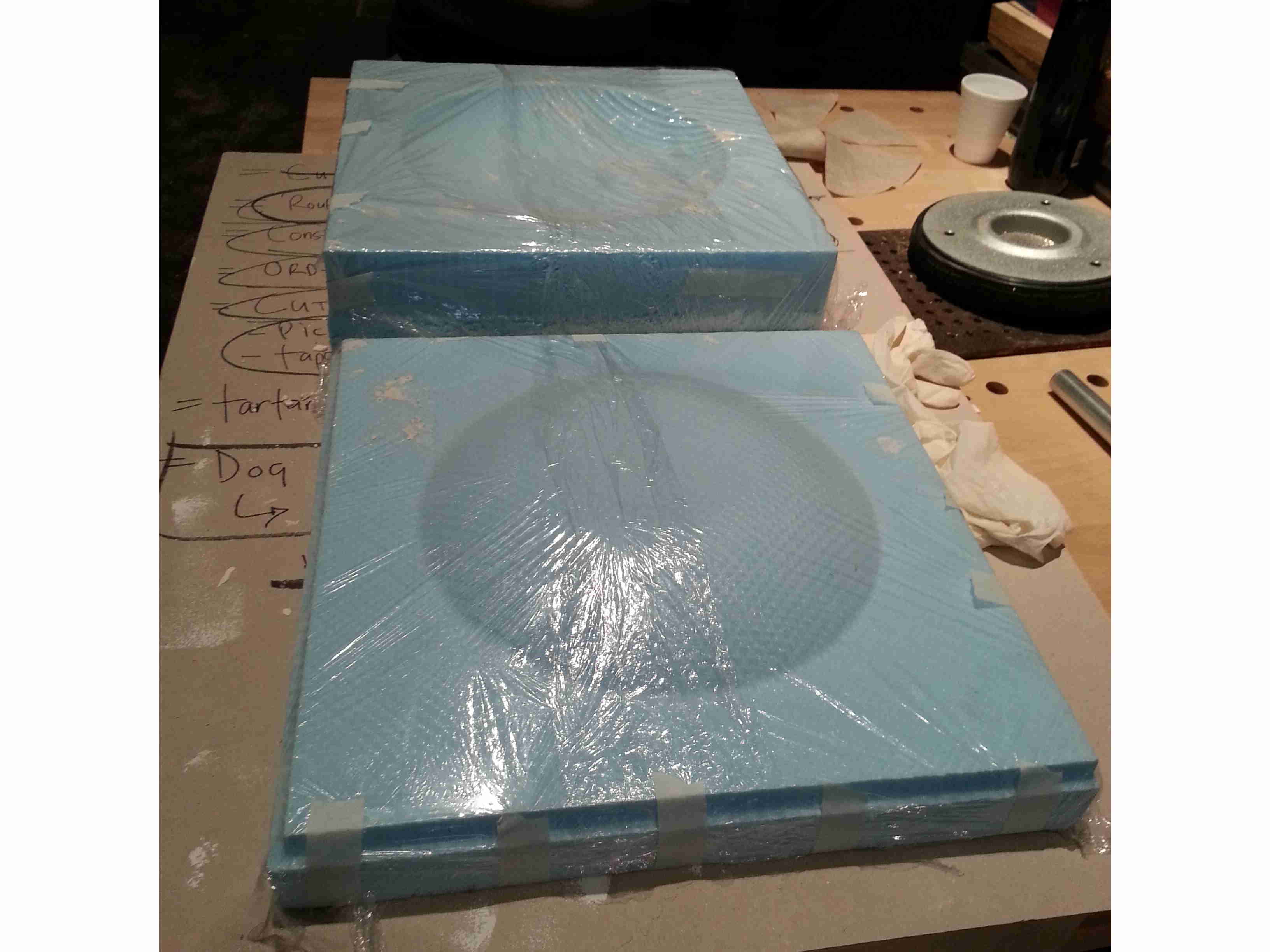

Once the design was finalised, the file was exported and open in the

same program (Cut3D) as was used in the moulding and casting week of

the Fab Academy. We defined all the tools paths for both the

negative and positive parts of the mould seperately and exported them

as a millimetre GCode for use on the large milling machine. It was decided to

use some modelling foam to construct the mould parts, and this was

milled out accordingly.

Milling:

It was noticed that during the milling process the first piece (the

negative) that was milled the finishing pass was only directed in one

angle, so there was a ripple effect on the mould. It was thought

that this texture would be quite a nice contrast to the inside face if

whilst milling the positive mould we made sure that we ran an

additional pass at 45 degrees to the initial pass. Conducting

this second pass didn't create a completely smooth texture because the

mill piece was fairly large and the stepover we set for the GCode was

slightly too large to ensure a smooth finish, in contrast it created a

surface with many little nodules that gave an interesting juxtaposition

to the underside of the bowl.

Casting:

At the lab we didn't have access

to the vacuum bagging techinque so the methodology of casting was to

clamp and weight the mould to create the necessary pressure to bond and

bind the laminations together. During the creation of the mould

we ensure that there was a significant border around the bowl to allow

us extra room to clamp the moulds and place the weight required.

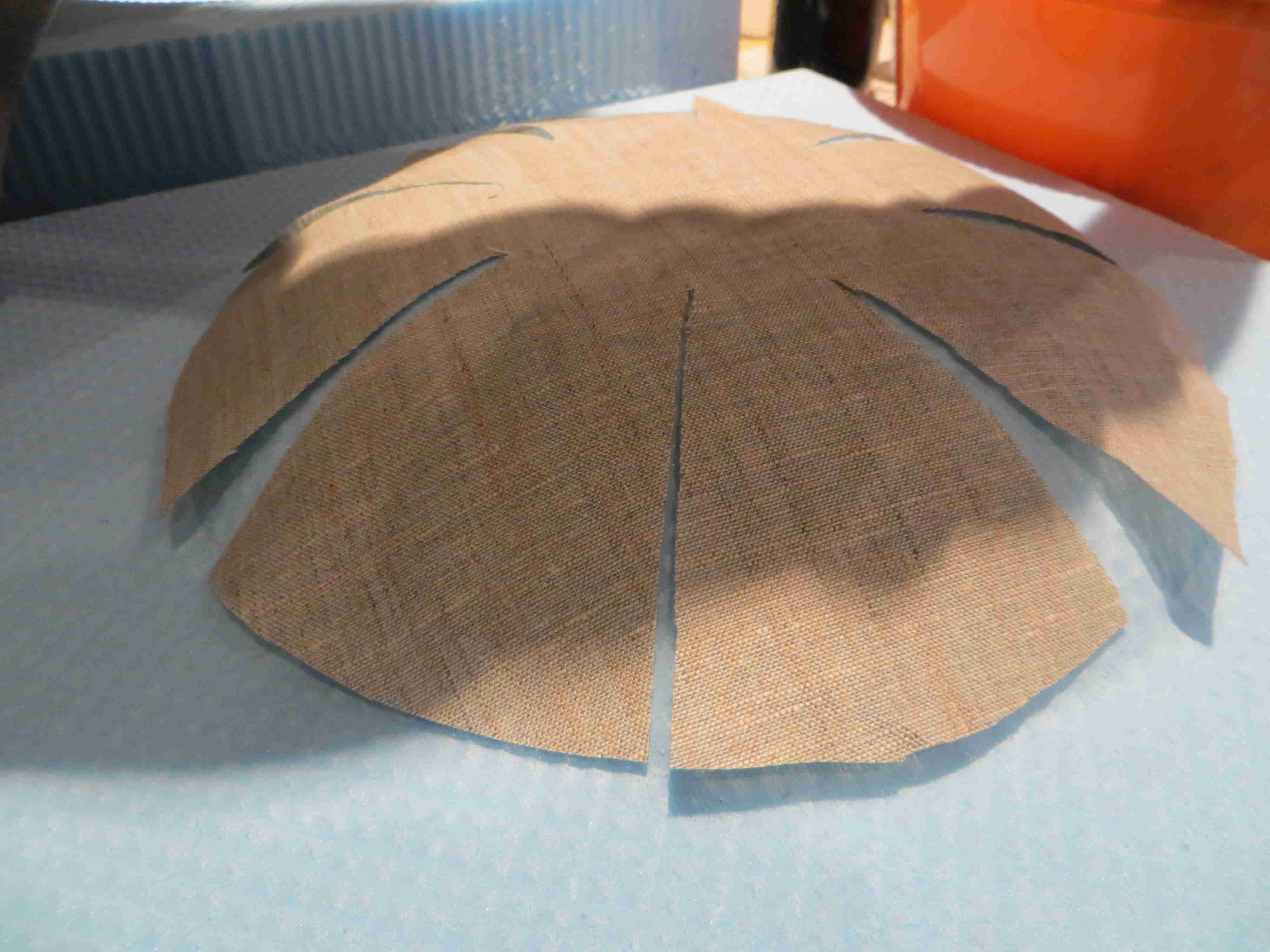

We first attempted using linen and Herculite composite, because the

bowl has a curve profile the template for the linen had to allow for

variation of the profile and not allow the linen to crease. Therefore,

star shaped layers of linen were laser cut to accomodate the profile of the

bowl.

|

|

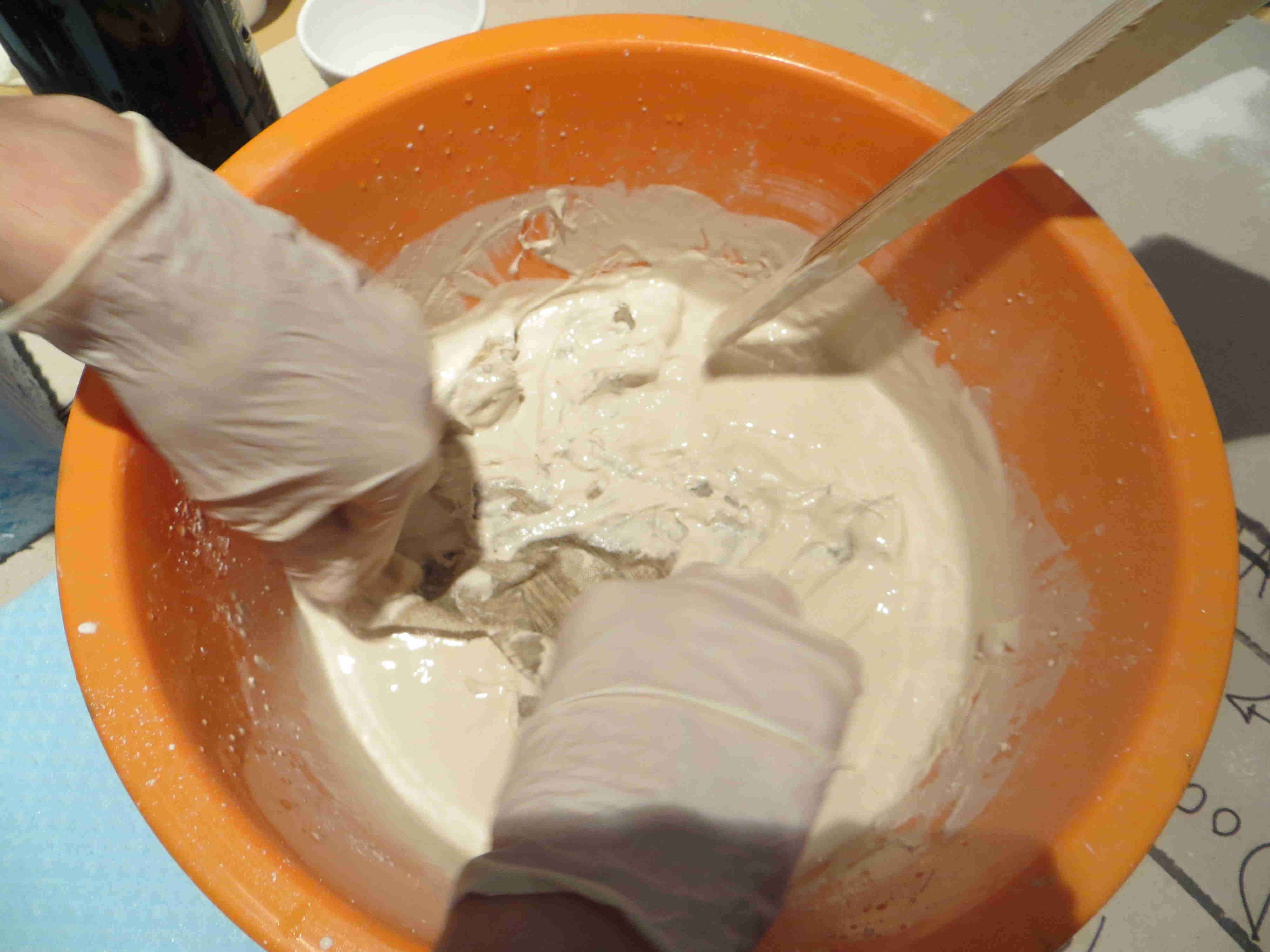

Firstly, we used a layer of clingfilm to line the negative part of the

mould prior to mixing to ensure a easy release from the mould. The

Herculite was then mixed in accordance with the recommendations given

by the manufacturer once the mix was ready we dipped two layers of

linen into the Herculite and placed them in the mould and poured in

the remainder of the Herculite. Once the linen was saturated with

the Herculite it was very difficult to flatten and orientate into the

necessary position in the mould.

|

|

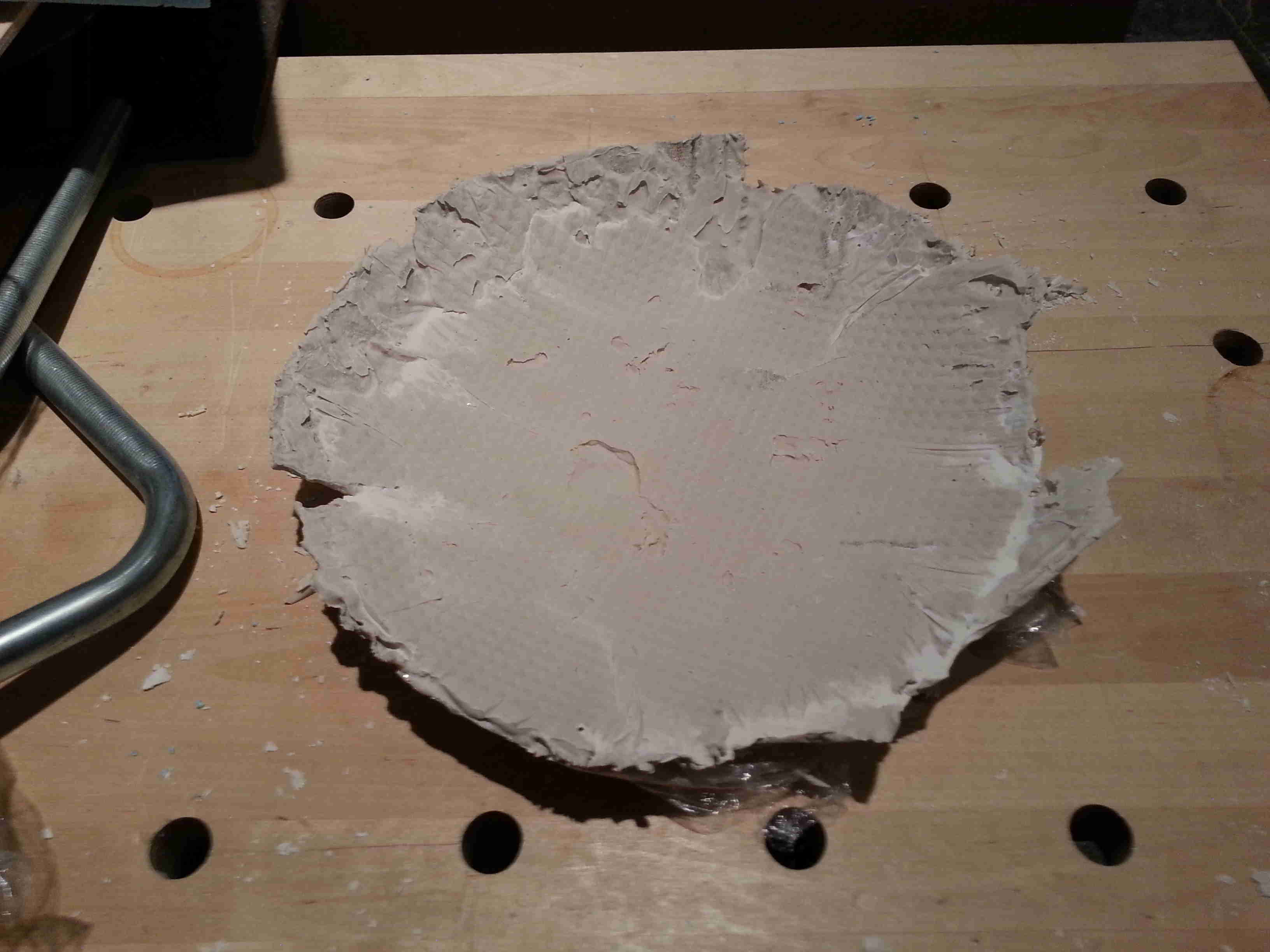

The first cast, didn't turn out as intented; the cling film was just

laid in the mould and was not fixed properly down to the negative and

postive mould. This allowed the cling film to fold up

into to material although it did allow for an easily release of the

finished product - it was noted when the composite material was

splashed onto the bare foam it was difficult to remove so a release

mechanism should always be used. Additionally, we found out that

we did not put

enough of the casting material to fill the mould entirely so the

pressure we placed upon the mould still caused air pockets to form and

a non complete cohesion between all the laminations.

|

|

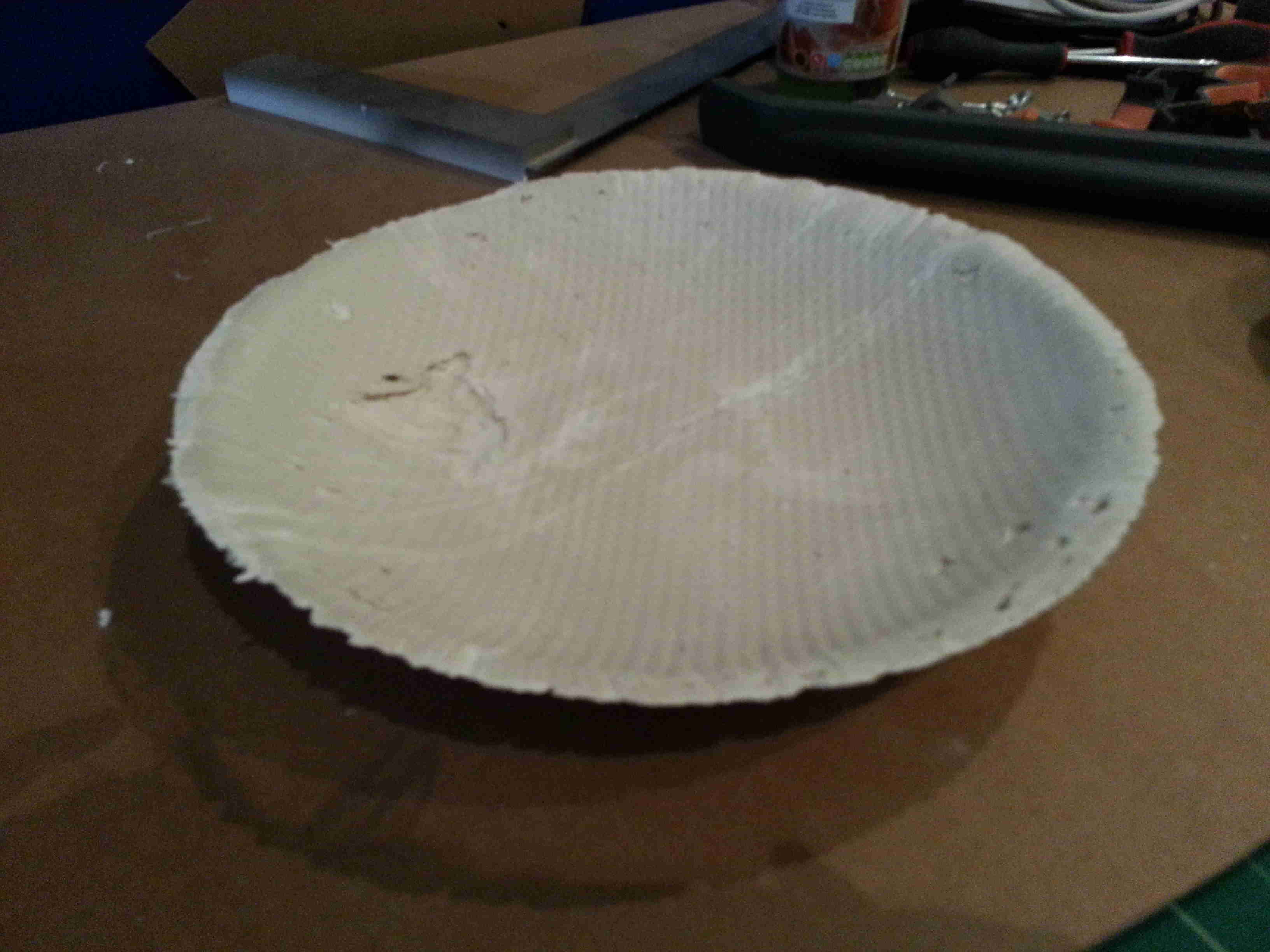

For

the second attempt, we ensured that the cling film was sufficient

anchored using masking type and ensured that the cling film could

stretch to form a tight alignment with the mould. Secondly, the

amount of material we used was increased to ensure that the mould was

sufficiently filled. The methodology this time was to pour a base

layer of Hermculite before setting the dry linen on top and then pouring

a second coat of Herculite on top and then applied the pressure with

clamps and weights as before.

|

|

The outcome was significantly better than the previous attempt,

although the amount of mix was still slightly short - next time the

volume of the bowl wil be measured and the amount necessary will be

determined. It become slightly more difficult to find the exact

amount necessary as linen/fibre is being added, the volume of which

will also have to be determinded to achieve the perfect amount.

The final below picked up the contours of the mould very well but there

was areas where there was cling film trapped in the cast and where the

pressure within the mould did not allow for an even covering of the

matric to permeate through all parts, so there were areas where the

linen was visible. The linen which was visible was very strong

and showed that when the two materials are bonded they do form a strong

and stiff material.

|

|

For the second methodology the idea was to use Polyurethane as the matrix and

spaghetti as the matrix for the material. It was thought that

aligning the spaghetti and ensure that they were held firmly in place

along the curved elements of the bowl would prove tricky. The

idea was to place the spaghetti first and then pour the Polyurethane on top

of spaghetti to allow for a strong bond to develop and allowing the Ployurethane to be orientated and secured in the right locations.

|

Afterwards, we mixed the two parts to form the Polyurethane,

the mixture was still fairly liquid so we began the preparation of the

casts but before we realised it the mixture started to cure rapidly and

we lost the first batch of the casting material. The 2nd attempt

we prepare the cast properly prior to mixing, because of the problem we

had with the final plaster cast, extra material was used. This

was a mistake, because the Polyurethane

maintained liquid state for approximately 5 minutes after mixing,

therefore there was a large amount of overflow when pressure was

applied onto the mould causing quite a mess.

The cast was successful, but there were elements of cling film that we

used fo the release mechanism embedded in the material. Next time

this procedure is used. it is recommended not to use the cling film as

a real mechanism as the chemical reaction was extremely exothermic and

caused the cling film to deform into the cast. Once the edges

were sanded the bowl looked good, but you could add an additional

colour pigment to the Polyurethane

to make the bowl more attractive. Overall, I was fairly pleased

with the result, given a through more attempts the workflow could be

quick and efficient but we finished there because we didn't want to use

all the material as other academy students will need it.

|

FAB ACADEMY 2013

FAB ACADEMY 2013