Final Project

Week 0: Digital Fabrication Principles and

Practices

Week 1:

Collaborative Technical Development, Documentation and Project

Management

Week 2:

Computer Aided Design

Week 3:

Computer Controlled Cutting

Week 4:

Electronics Production

Week 5:

3D Scanning and Printing

Week 6:

Electronics Design

Week 7:

Moulding and Casting

Week 8:

Embedded Programming

Week 9:

Computer Controlled Machining

Week 10:

Input Devices

Week 11:

Composites

Week 12:

Interface and Application Programming

Week 13:

Output Devices

Week 14:

Networking and Communications

Week 15:

Mechanical Design and Machine Design

Week 16:

Applications and Implications

Week 17:

Invention, Intellectual Property and Income

Week 18:

Project Development

Week 19:

Final Project Presentation

|

3D Scanning and Printing

This

weeks lecture provided an introduction to 3D scanning and printing and

the necessary programs used to enable you to do these process.

3D Scanning:

Initially

I started with the 3D scanning part of the assignmment. Here at

the MakLab the available 3D scanning machine was the Next Engine, for

observing other people scanning objects I decided to go for an object

that had a matte finish in order to get good clarity for my

object. Looking I found a scallop shell, that I thought would be

interesting as it had a highly textured finish and a myriad of colours

on the underside.

Due to the fact that the

rubber fixings that were to fix the object were in white, I removed

them and placed corresponding black rubber pads so that there was

enough contrast between the predominately white shell and the object

scanning mounting to enable me to correctly identify each and remove

the necessary parts after the scan had finished. The properitary

programming supplied for scanning was very easy to use to enable the

scanning. It is very wise to conduct a trial scan on just one

face/orientation before commencing the full 3D scan to ensure the

necessary clarity, detail is achieved and whether or not the object

needs dusting to allow for the object to be scanned properly.

Another element that should be checked is the distance of the object

from the scanner to ensure that the object is within the optimal range

for the scanning type, a handy diagram within the program will show you

the correct depth, also it is wise to check that when the object

rotates 360 degrees it stay within the area you selected for scanning.

Use the test has been undertaken, you can conduct the full scan (the

length of which will vary with the scan density and quality).

During the scanning process, the program takes .jpg pictures at the

varying orientations, I have imported a few below to get an idea of the

object that is being scanned.

Once

the scan had completed the program showed a 3D model of the shell,

unfortunately it seemed to be formed of two faces that were set

independent from each other. Using the scanning package, trimed

off the restrainted pads (that were attached to the turntable) and I

tried the smooth command, but this didn't join the two faces of the

shell, it just smoothed the surface of the connected wireframed

segments.

Failing

this I tried the 'fuse' command but this process didn't work

either. I believe it is because the edge of the shell was too

thin for the scan settings and the scanner did not pick up the edge of

the shell and thereby failed to connected the two seemingly seperate

entities.

Thereby

the only option was to try and repair the wireframe manually, I saved

the model as a .stl and opened it with the program MeshLab to see

whether this was feasible and then I could attempt to 3D print a scaled

down version of the shell. Unfortunately, the holes in the wire

frame were too many to do manually in the time allocated, so I decided

to move onto the 3D printing section of the assignment.

3D Printing:

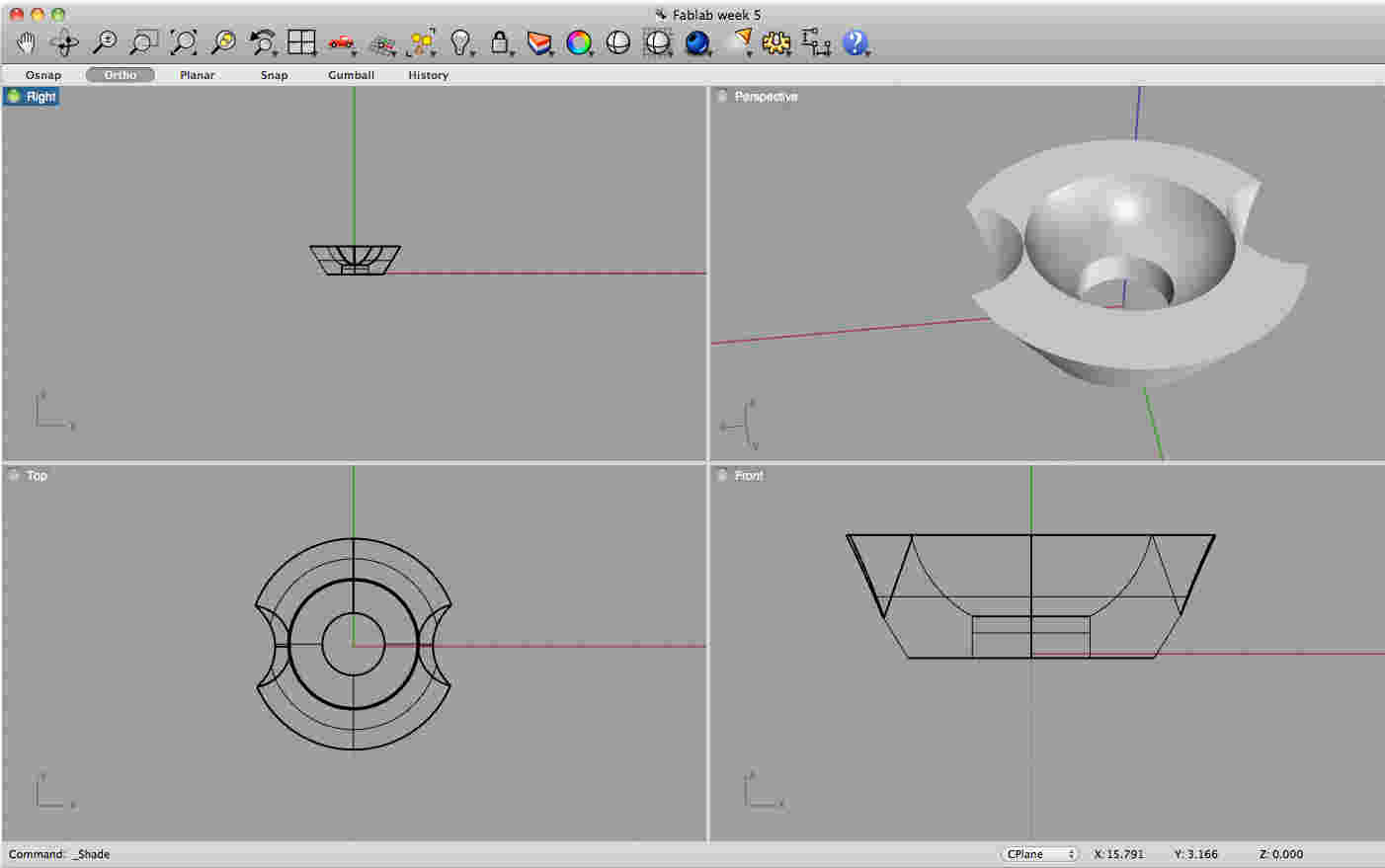

For

the 3D printing section of the assignment, made a simple model with

solids in Rhino, to form a shape to print. I used several solids

with some boolean functions to create a interesting shape, that are

still small enough to print within a reasonable timescale.

|

I then

exported the file as a .stl model that created a 3D file, I then opened

the file in MeshLab to check whether there were any holes in the

wireframe that will cause issues with the 3D print. Luckily there

were no holes in the wireframe, so I imported the file into Cura (the

program here that is used for creating printable 3D files). Cura

gives a representation of the base of the 3D printer, from which you

can scale the project easily using the embedded scaling tool.

Once you are happy with the size and the density (i.e the amount of

internal fill) of the print you then you can export it to a

G-code. The G-code, is a horizontal by horizontal slice guide for

the laser printer to follow and the program will give you an estimated

time to completion - my project took in the region of 20-25mins.

After the G-code is created it is then placed on a SD card and inserted

into the machine for printing. The whole process was effortless

and yielded fairly good results, although at the beginning, you should

keep an eye on the noozle to ensure that the initial outline does not

foul the 3D print.

|

FAB ACADEMY 2013

FAB ACADEMY 2013