Final Project

Week 0: Digital Fabrication Principles and

Practices

Week 1:

Collaborative Technical Development, Documentation and Project

Management

Week 2:

Computer Aided Design

Week 3:

Computer Controlled Cutting

Week 4:

Electronics Production

Week 5:

3D Scanning and Printing

Week 6:

Electronics Design

Week 7:

Moulding and Casting

Week 8:

Embedded Programming

Week 9:

Computer Controlled Machining

Week 10:

Input Devices

Week 11:

Composites

Week 12:

Interface and Application Programming

Week 13:

Output Devices

Week 14:

Networking and Communications

Week 15:

Mechanical Design and Machine Design

Week 16:

Applications and Implications

Week 17:

Invention, Intellectual Property and Income

Week 18:

Project Development

Week 19:

Final Project Presentation

|

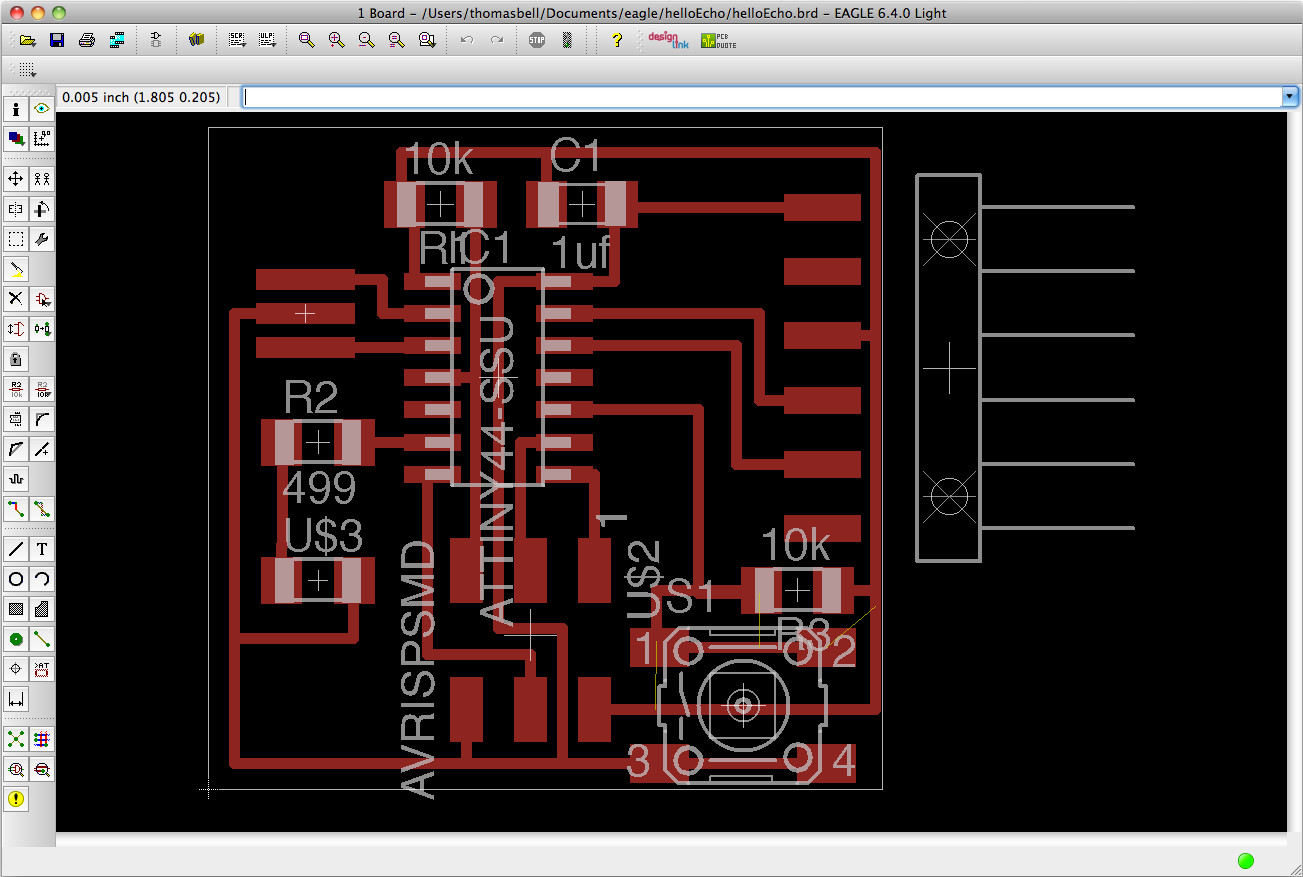

Electronics Design

For

this

week the assignment focussed on the design and the production of the

hello world circuit board. The most appropriate method of doing

this was by designing the schematic and then the board layout in Eagle and then creating a

.png file from the traces and then using the

necessary milling software to create the board as we have done in a previous week. Following Anna's tutorial

it was simple enough to import the required fab and component

libraries, and put together a schematic that included the basic

hello-world board plus the additional switch and LED necessary.

Using Eagle:

By making nets (links)

between components you connect elements on the schematic without a

physical connection as long as they are labelled the same within the

schematic, this can create a less cluttered schematic workspace, but

you should remember to keep track of which parts are connected,

otherwise the schematic can become slightly convoluted and choatic.

To create the board layout, I followed Anna's layout and manually

routed all the traces, using the tolerances in the program (i.e 16mm)

to ensure that the traces weren't too close together. Once I had

iteratively developed the traces to the most compact area I could, I

ran the design rule check within Eagle to ensure that the circuit ran

correctly. I received several warnings, as certain components

didn't have a value (i.e. the switch) but this was ok, because they

didn't impact on the functioning of the circuit.

|

I

exported the traces as a .png image at 500dpi from Eagle and then

imported them into the milling software VCarve, which this lab has

already preinstalled as the router is not set up to use with the Fab

Modules. Once I Imported the .png image, I created vectors

from the image and then milled the board. Unfortunately, my first

attempt the board was not completely flat on the bed and was not milled

correctly.

The

second attempt of milling worked out perfectly, and I began stuffing

the board. Be aware that the LED is still a diode and will only

accept current in one direction, I had to remove the LED after

forgetting this! Also, ensure that for the FTDI header solder the

single pad last, as it had a tendency to remove the pad completely if

you solder that pad first. For the AVRISPSMD, I had to create the

header pins from separate header pieces and solder them on

individually, this can be done but it is not recommended!

After, I had finished stuffing the board. I ran a program on the

board that was provided by our Guru, this was a simple program to

ensure that the board worked. I installed this using the AVR programmer

we used in the previous week to program our FabISP and made sure there

was power to the board using the USB into the FTDI header. The

simple program shone the LED when the button was pressed, the board

worked first time.

|

FAB ACADEMY 2013

FAB ACADEMY 2013