Final Project

Week 0: Digital Fabrication Principles and

Practices

Week 1:

Collaborative Technical Development, Documentation and Project

Management

Week 2:

Computer Aided Design

Week 3:

Computer Controlled Cutting

Week 4:

Electronics Production

Week 5:

3D Scanning and Printing

Week 6:

Electronics Design

Week 7:

Moulding and Casting

Week 8:

Embedded Programming

Week 9:

Computer Controlled Machining

Week 10:

Input Devices

Week 11:

Composites

Week 12:

Interface and Application Programming

Week 13:

Output Devices

Week 14:

Networking and Communications

Week 15:

Mechanical Design and Machine Design

Week 16:

Applications and Implications

Week 17:

Invention, Intellectual Property and Income

Week 18:

Project Development

Week 19:

Final Project Presentation

|

Moulding and Casting

The

assignment this week required us to mill some wax to create a positive

mould and then cast around the mould with a silicon to create a

negative mould. From this negative mould you can then remove the

wax by heating and then you are able to cast the desired object with

plaster or equivalent. The ability to create a initial positive

mould is intriguing as it allows the designer to produce the desired

final product and then eventually make exact copies of that initial

design, previously I imagined that you would have to create a negative

initially and then cast from that.

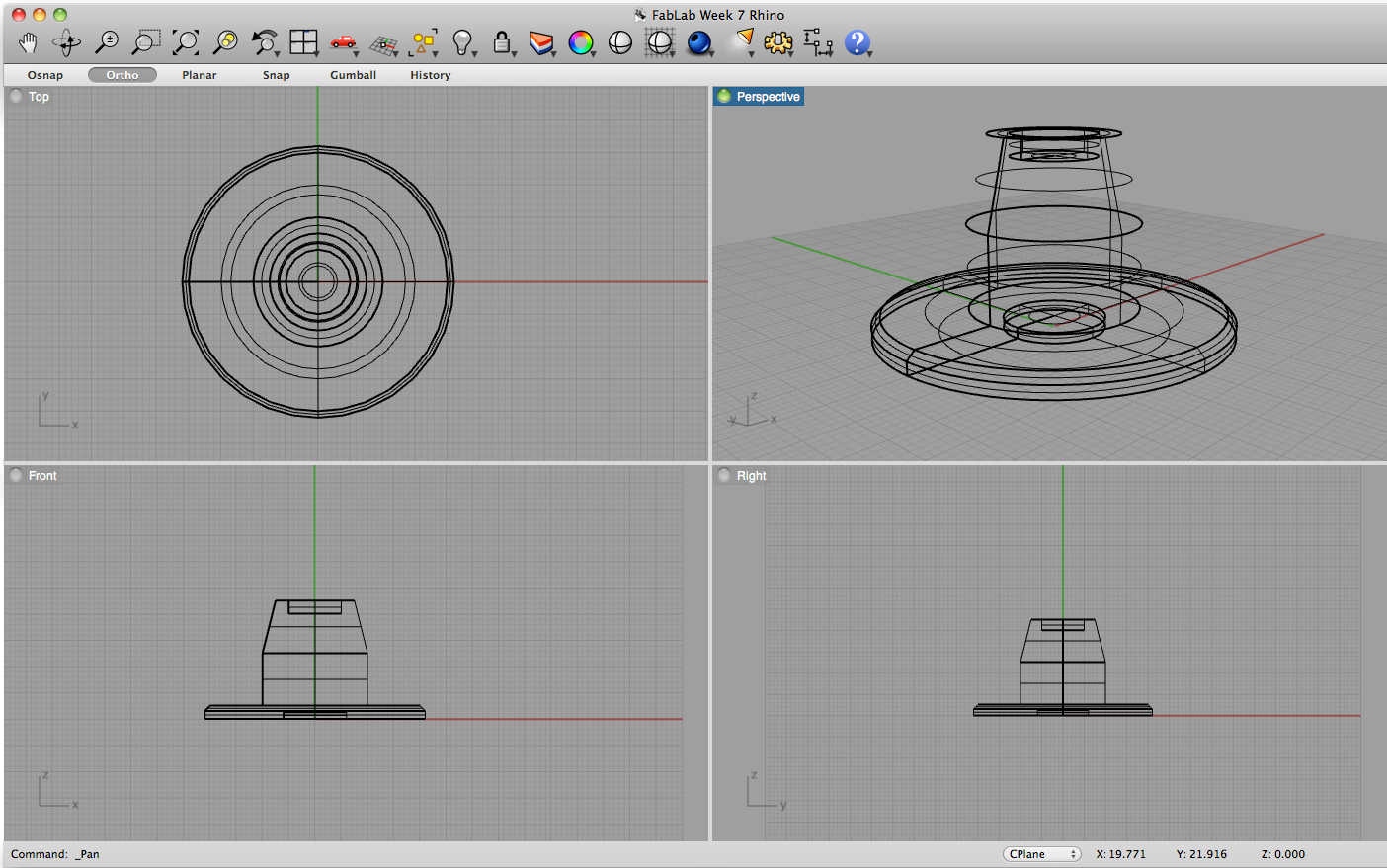

I created a 3D model in Rhino to

mill, the piece shown below is meant to become a part of a bearer

between two different types of construction material; in particular

looking at sole plate junctions at the corners of timber frames.

By exporting the file to an .stl within Rhino a mesh is created, I checked that the mesh created was whole by importing .stl into MeshLab.

Whilst designing this piece I was made acutely aware that the cutting

depth was limited by the flute and the cutting depth on the finishing

tools and was careful to ensure that my design was not greater than

25mm as these were the maximum depth of the tools available.

|

Milling:

Once this was

completed, I attempted to the mill the was on a Modela MDx-40 using a

6mm roughing tool and a 3mm finishing tool. I used a program

called Cut3D,

that allowed me to create the necessary toolpaths, this program was

very easy to use and included a step by step wizard to allow me to

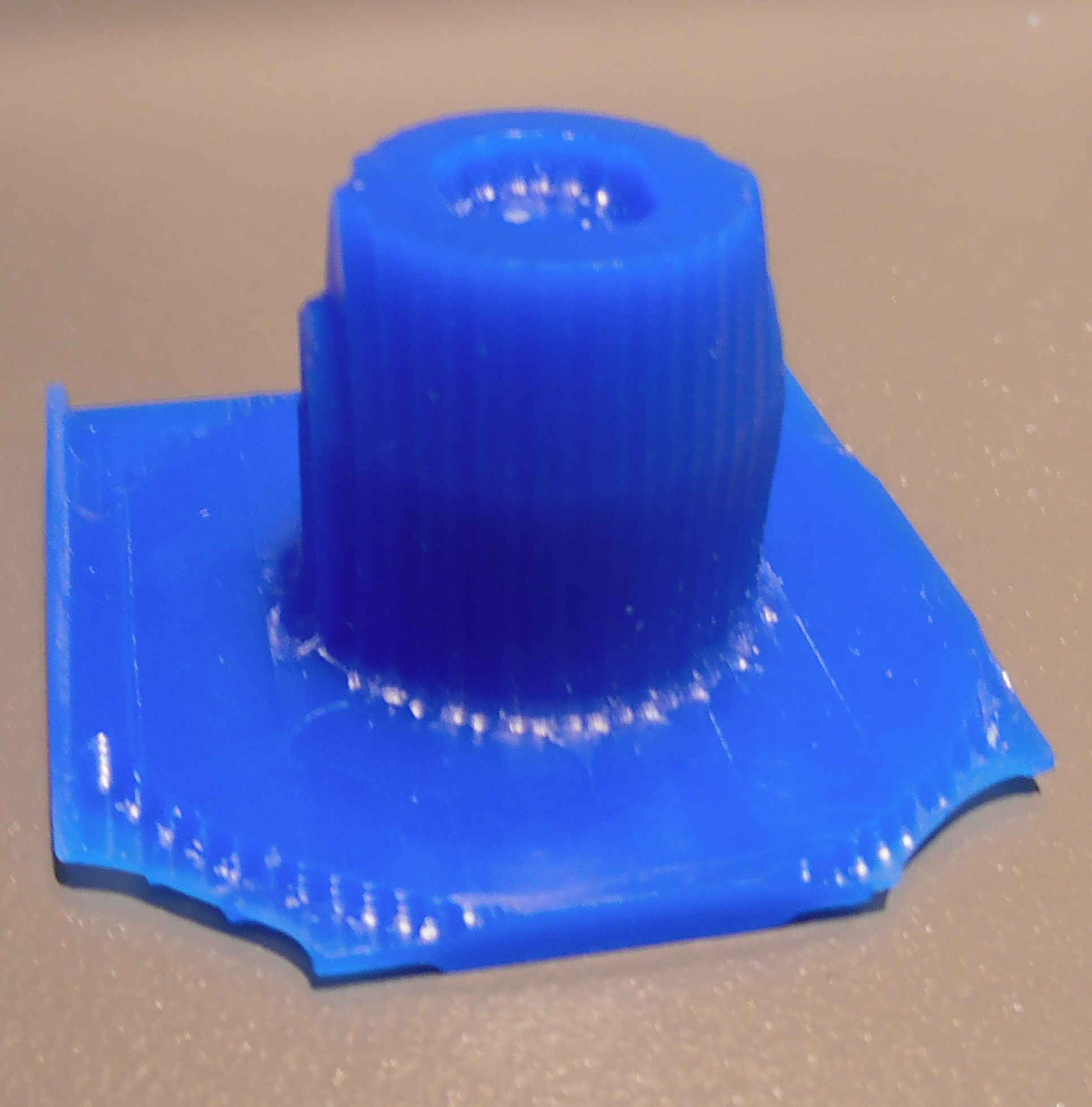

achieve the desired finish. The finished piece did not have the

required finish as the step over on the finishing tool piece was too

small to achieve a smooth finish on the milled wax piece.

|

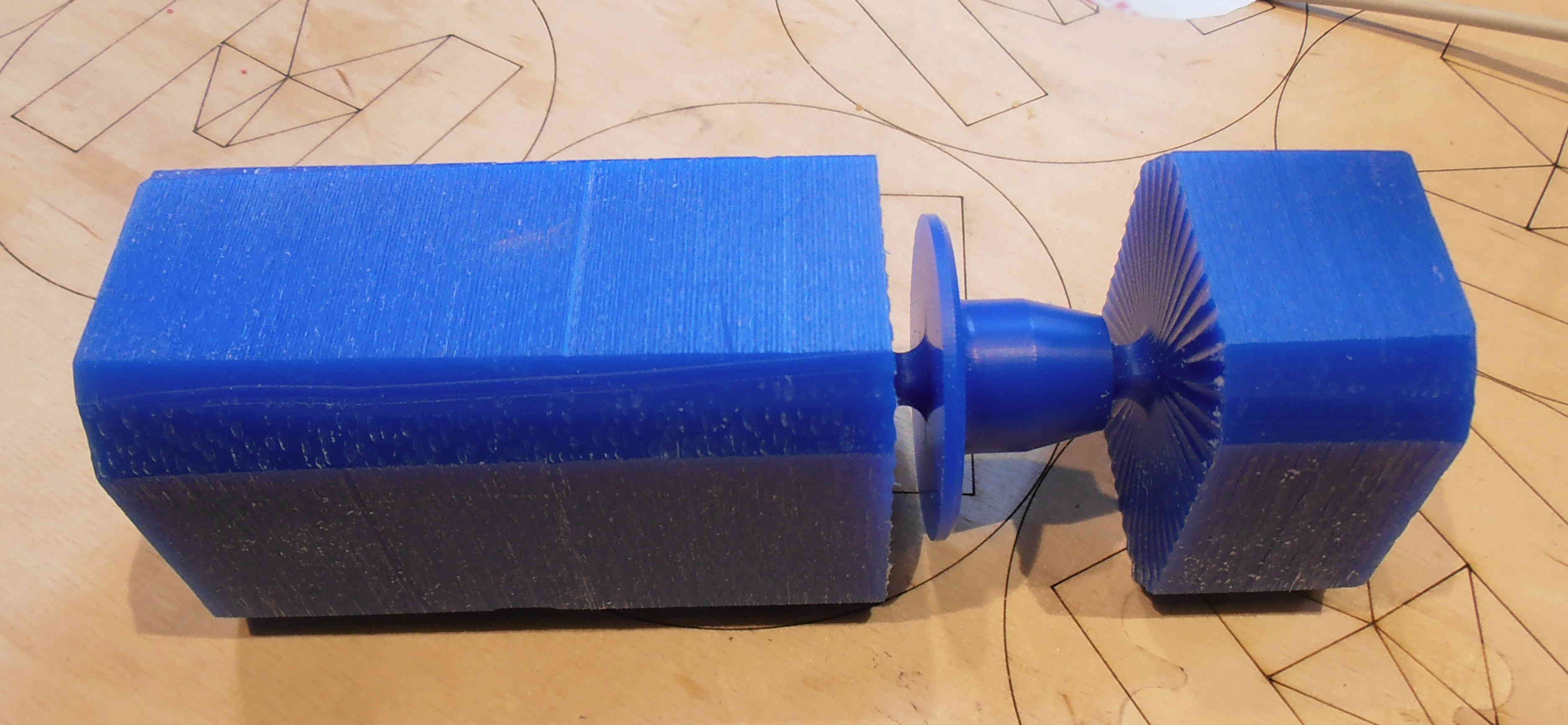

Due to the fact that my finished piece was cyclindrical, I decided for

my second attempt at creating a milled wax object I was going to use

the rotary axis unit (ZCL-40A) that could be fitted into the Roland

Modela (use the accompanying instruction manual to ensure correct

calibration) allowing the object to be turned. Using a different

program Roland SRP Player,

I imported my .stl file and went through the wizard to ensure that my

piece was milled correctly. It was important to note that the

pieces that I milled from, where not cyclindrical but rectangular, to

avoid any problems with the cutting tool I planed the corners of the

wax piece and then used the longest diagonal cross sectional length to

set the diameter of the piece within the program.

Casting Around the Mould:

This

process was fairly time consuming but gave a quality finish around the

circumference of the work piece. Once this was done, I removed

the piece from the original block using a band saw and sanded the

excess remaining part of the milling supports. I required a hole

to be set through the middle of the piece which was not feasible to be

achieved using the milling process and decided to use a pillar drill to

central hole. I started with a smaller than necessary drill bit

to ensure that the alignment was correct but unfortunately I must have

drove the drill bit into the wax too quickly as I caused a slight crack

in the piece to form. I had initally wanted to go through the

hole again with a larger drill bit diameter but decided to cut my

losses and cast the latex around the piece whilst I could.

|

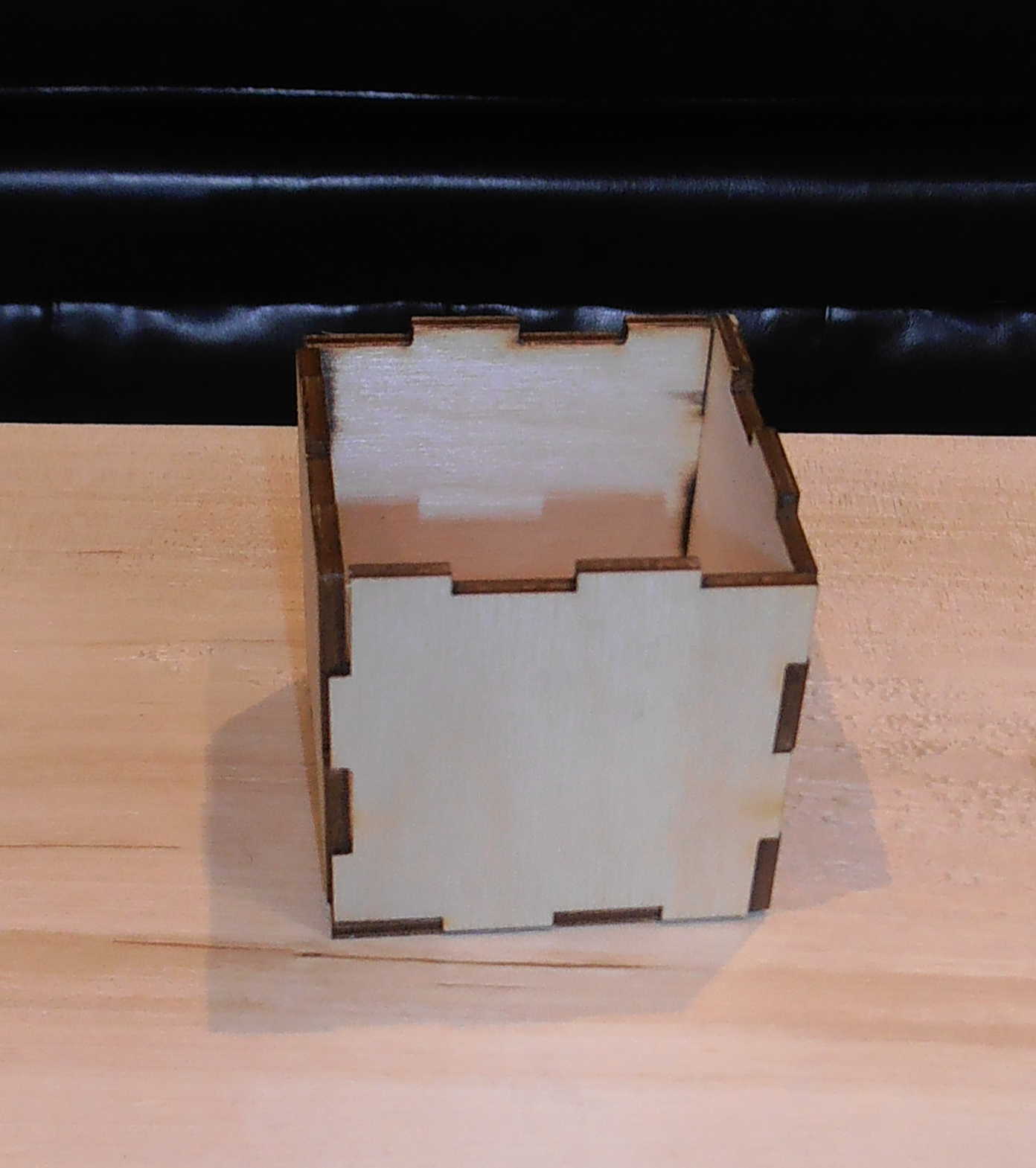

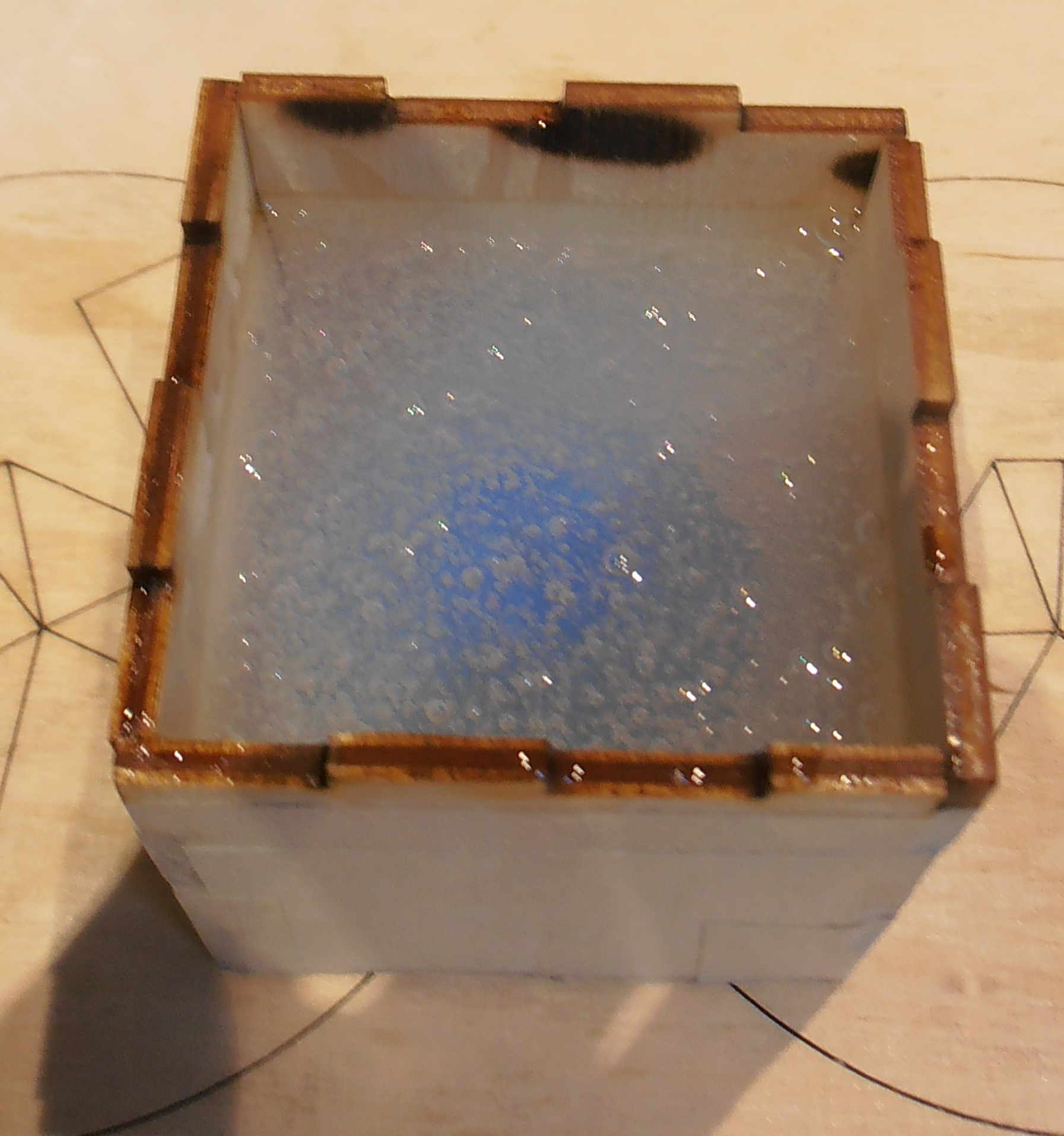

To enable this

to casting process to be successful I needed a demountable container to

pour the silicon, in around the machineable wax piece. In order

to do this I used a snap fixed ply box, created by Roy for the snap fit

construction week assignment and taped the joints to ensure that it was

fully watertight. In then placed piece base down in the box, so

the base of the box gave access to the base of the mould for ingress

and egress of the cast and the was respectively.

|

|

I then, create the silicon moulding gel by using the instructions on

the box for the portions for the silicon and the activation

liquid. The ratio here was 1:10 activator to silicon, and I

decided to measure this roughly by using spoonfuls. My advice is

to not do this as I ended up putting loads of air into my mixture which

should be limited at all costs to allow for a smooth finish to form. To

ensure that the amount of air entrapment in the silicon is limited,

when you mix the silicon material together you should try and shear the

material and consciously try not to fold in any air into the mixture

that could potentially cause bubbles to form within the silicon.

When pouring the silicon over the mould you should ensure that the

mixture is pour in from the highest point possible to try and disperse

any air within the mixture by the yield stretch pour method.

|

|

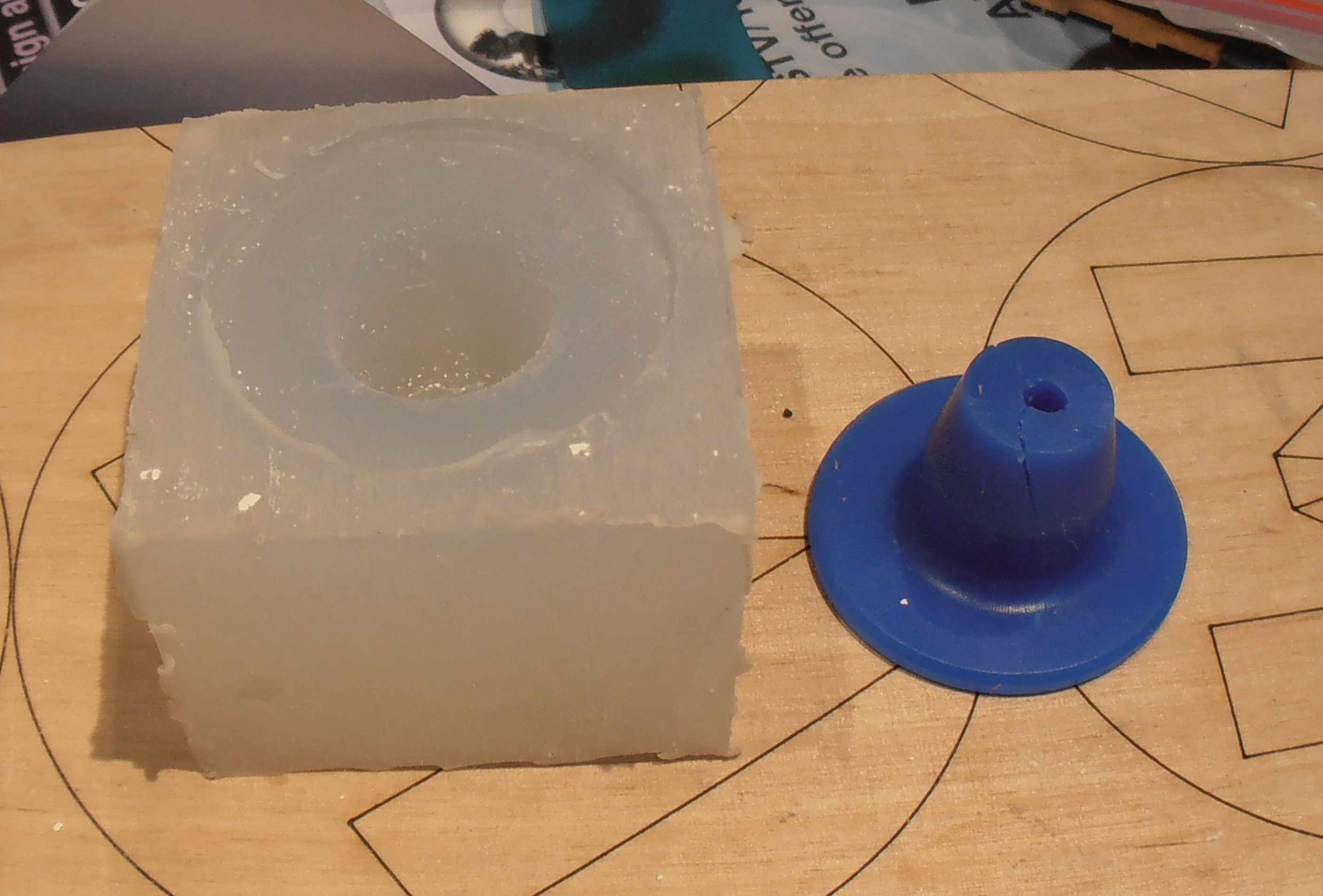

After the silicon has cured the wax can then be melted and

removed. I found that the shape of my mould and the flexibility

of the mould material allowed me to pull out the wax positive without

the need to melt the wax in the oven. The mould was full of

little air bubbles but hopefully these bubbles are within the set

silicon solid and not on the surface, only time will tell!

Afterwards, I decided to use a plaster based cast, to see if any of the air bubbles are on the surface of the mould.

|

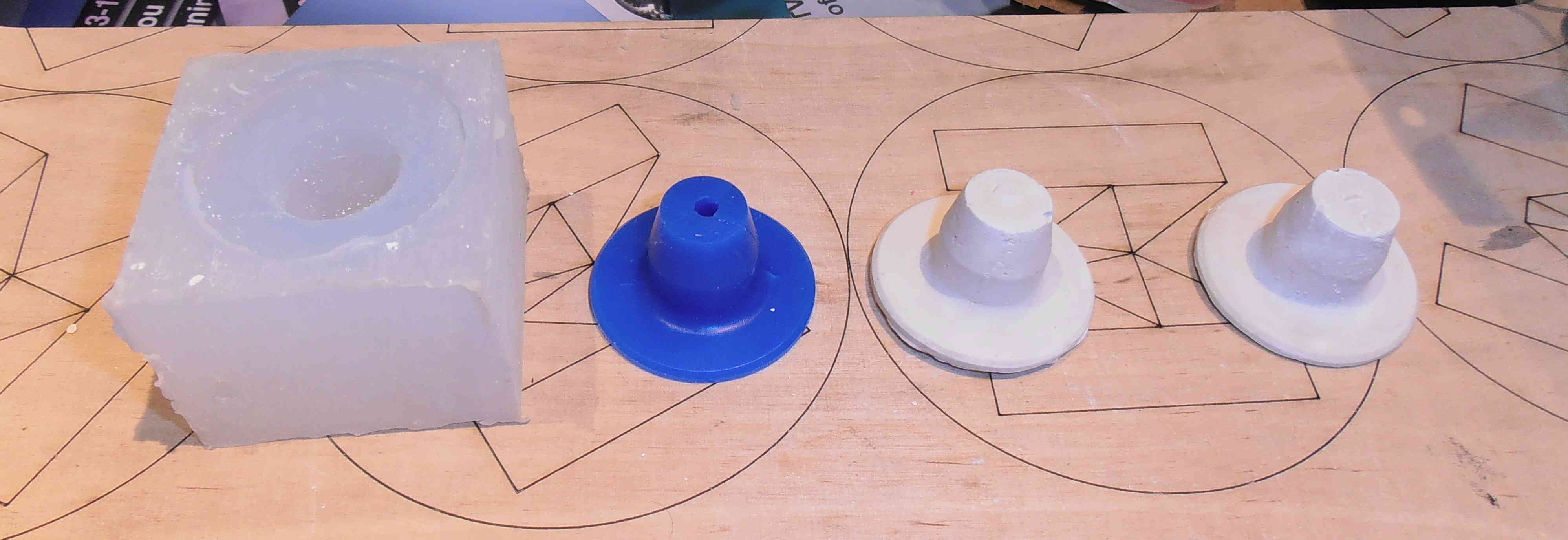

Using

the Hydrastone was very complicated and found this tutorial for the

setup of the process very useful except I used a 4:10 water to plaster

mix as it was stated on the outside of the packet that the Hydrastone

came in. After about 30 minutes I was able to demould the cast

easily from my flexible silicon mould, the plaster finish picked up all

the details of my primary wax mould (including the crack I caused)

there were a few air pockets/bubbles in the finished mould although I

was surprised there wasn't any more! Next time, I would

definitely, ensure that the silicon was made without as many air

bubbles as possible and make sure you trim the Hydrastone almost

immediately after it has initially cured otherwise it the material is

extremely hard and not easy to trim accurately.

|

FAB ACADEMY 2013

FAB ACADEMY 2013