Final Project

Week 0: Digital Fabrication Principles and

Practices

Week 1:

Collaborative Technical Development, Documentation and Project

Management

Week 2:

Computer Aided Design

Week 3:

Computer Controlled Cutting

Week 4:

Electronics Production

Week 5:

3D Scanning and Printing

Week 6:

Electronics Design

Week 7:

Moulding and Casting

Week 8:

Embedded Programming

Week 9:

Computer Controlled Machining

Week 10:

Input Devices

Week 11:

Composites

Week 12:

Interface and Application Programming

Week 13:

Output Devices

Week 14:

Networking and Communications

Week 15:

Mechanical Design and Machine Design

Week 16:

Applications and Implications

Week 17:

Invention, Intellectual Property and Income

Week 18:

Project Development

Week 19:

Final Project Presentation

|

Electronics Production

For

this

week the assignment is centered on the production of a circuit board

and the soldering of electronic components onto the circuit board to

create a FabISP in-circuit programmer. The design of the layout

of the circuit board was not necessary, merely the fabrication and the

installation of the firmware onto the in-circuit programmer was

necessary but these still posed many problems during the week.

Milling the board:

To

create the circuit board it was necessary to mill out a copper faced

rigid epoxy glass (FR4) or phenolic paper (FR1) board. It was

suggested to use FR1 board as it was kinder on the milling tools but

the immediately available board in the laboratory was the expoxy glass

board. Using the .png file supplied through the class links I

imported the file into the router software on the linked computer,

because the router being used was the Roland Modela MDX-40 and not the

specifically specified router in the Fab Lab inventory I thought it was

best to use the properitary drivers and associated software instead of

trying to implement the Fab Modules into the system. Once I had

imported the .png into the software VCarve, I ensured that it was

correct size (22.99mm x 45.21mm confirmed by the guru), and then used

the function in the program to trace the cutting vectors from the

graphical file. Afterwards, I then referenced the traces to the

graphical file provided and close any gaps in the traces using the

vector creation tools in the software, this was needed for the square

pads at the head of the circuit board.

Once the cutting vectors are imported into the program, the tool and

its path needed to be decided. It was suggested that using a 1/64

inch end mill was to be used, the parameters of the tool were uploaded

into the software and a suggested cutting depth of 0.3mm was decided to

scrape off the outer layer of copper to reveal the imported

traces. The circuit board was then, stuck down to a sacrifical

ply board underneath using double sided sticky tape and set in the bed

of the milling machine. the x,y and z axis where centered over the

centre of the PCB.

The first attempt at machining the board was conducted just to mill the outside the outline of the traces.

|

The outline of the traces were far too deep and caused burring of the

copper, so I decided to change the bit type to an equivalent size

engraving type piece (i.e. 0.3mm) and lower the depth of the cut to

0.1mm.

|

Here the cut was a lot neater but far to shallow, here I increased the

depth of the cut to 0.15mm and decided upon looking on the size of the

circuit to mill out all the unecessary copper to ensure no short

circuiting would occur when I soldered the components onto the

board. To mill out all the excess copper the pocket function in

the VCarve program was used to isolate the traces, using this process I

milled out the board.

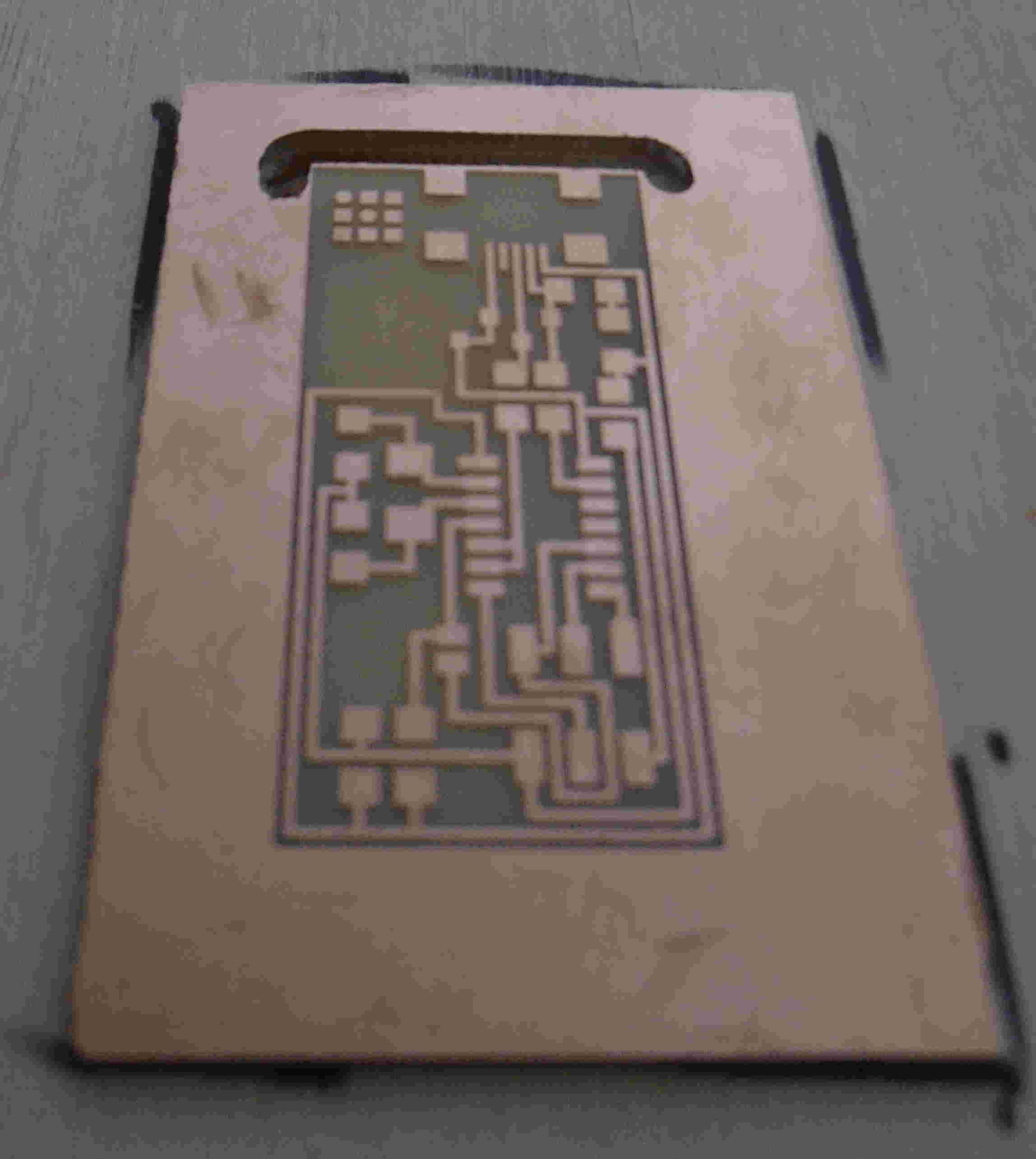

|

Here the finish was much better but far more time consuming to achieve

the milling process. Once the interior of the board was milled

effectively, the outer edge of the board needs to be cut through to

allow soldering. This was achieved by changing the mill piece to

a 0.6mm end mill, drawing an outline of cutting around the board and

setting the depth of cut to the depth of the printed circuit

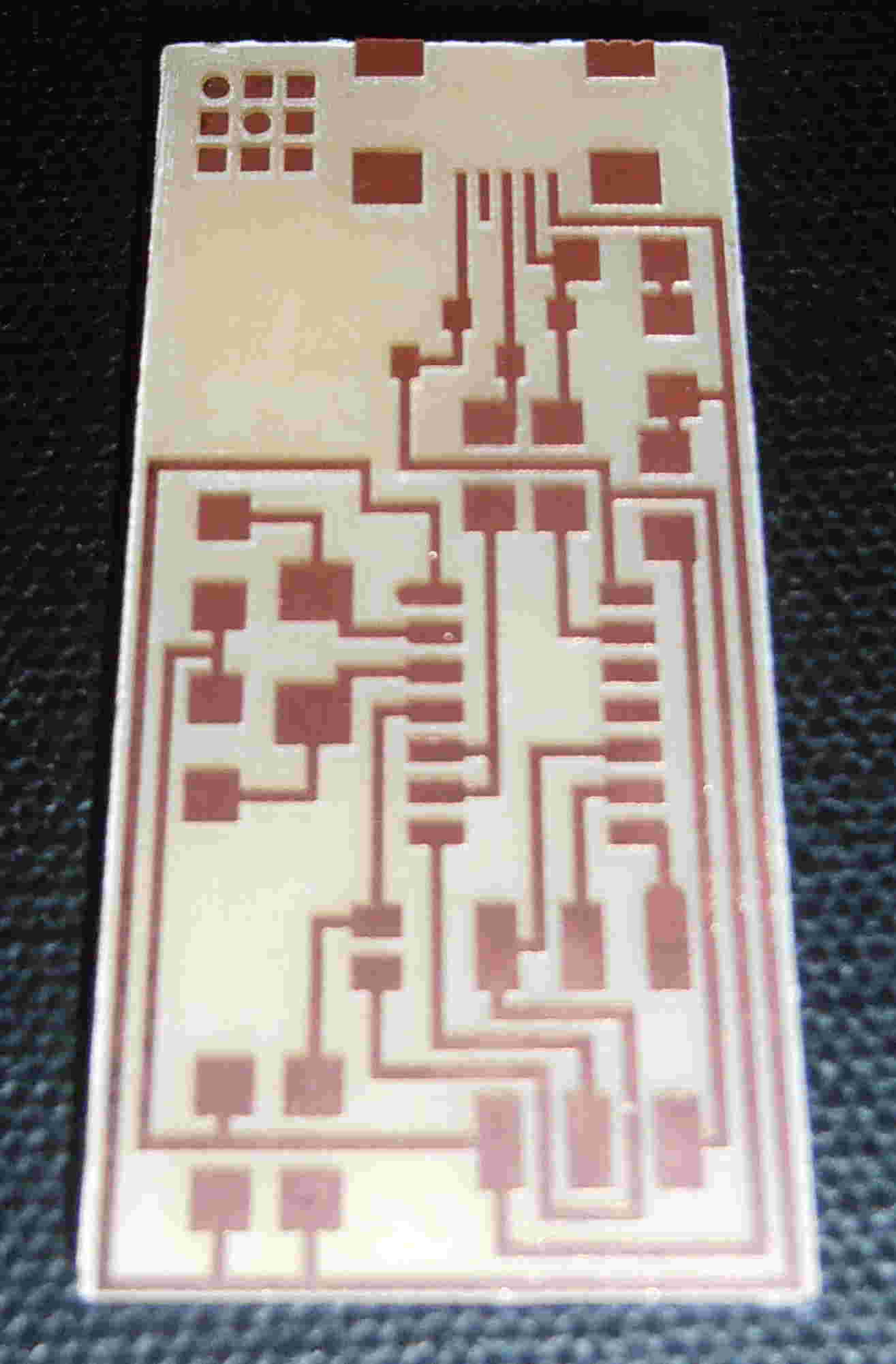

board. The final mill noard ready for soldering is shown below.

|

Soldering the circuit board:

I gathered the required parts shown in the specification

in the class lecture links. Unfortunately, I had access to only

one diode and no headers and I'm waiting on a delivery of the

parts. I then arranged all remaining parts and prepared for

soldering. My preparation included obtaining a helping hand,

debraiding tape, tweezers and a clamp to restrain the circuit

board. Due to the fact that I had spare boards from the milling

procedure I practiced soldering some resistors down to a reject circuit

board and gained confidence in the process before commencing soldering

on the final board. I started soldering the components inside out

to minimise obstruction from components, firstly the chip, then the

resistors following a handy tutorial

from a previous student of the course to order the installation of the

chip. Once I had soldered all the components available, I had to

stop and await the delivery of the necessary to finish the soldering

and programming the ISP.

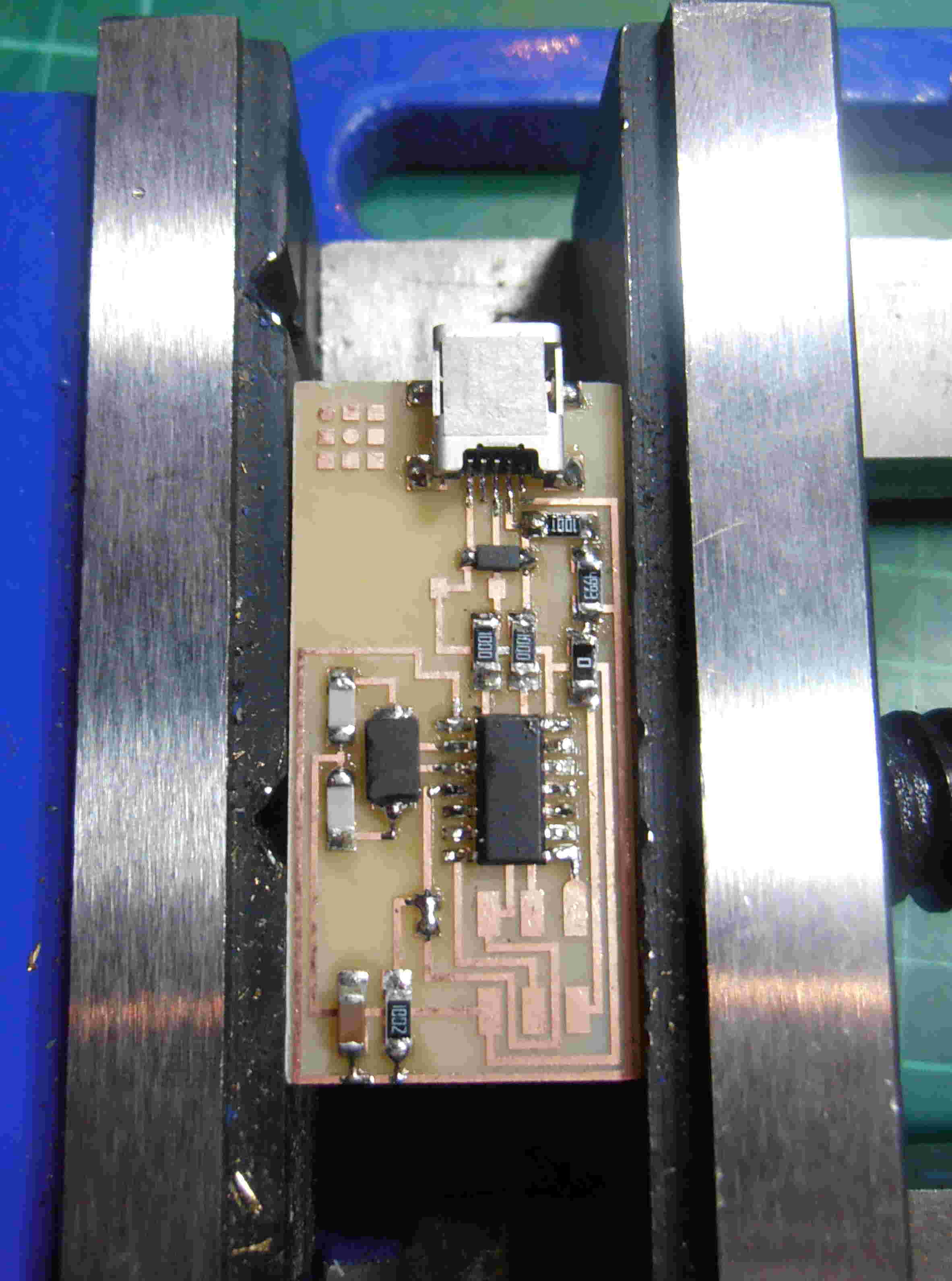

This image shows how far I got to completing the ISP this week and with

a little luck should be updated within the next week when I have

finished off the soldering and the programming.

|

Finally

managed to get the board soldered. The ordered diodes proved to

be the wrong type of diode (one with 3 securing pins), fortunately

there was several 4.7v Zener diodes on hand. Using the same

orientation (i.e. the line indicates the cathode), I soldered on the

final component onto the board. I was able to do this as the

diodes provide a voltage regulator for the USB connector but is rather

archaic as the USB drivers are fairly stable and therefore a 3.3V regulator is not really necessary.

Programming the circuit board:

Before

I could commence programming my FabISP I had to configure my computer

to allow me to do this. Firstly, I had to redirect direct the

path directories within my computer so that when I installed the

required CrossPack program the computer would look for it in the

correct directory. Using Mac OS 10.6.8 I opened terminal and had

to navigate to the root directory, this is achieved by using the

command cd.. comannd to go back to the root directory and then

following the tutorial linked here.

Following the tutorial in

the content section of the Fab Academy website, i downloaded the

firmware and followed the steps but got the below error message when I

inputted the 'make hex' command.

Thomas-Bells-MacBook-Pro:firmware thomasbell$ make hex

avr-gcc -Wall -Os

-DF_CPU=20000000 -Iusbdrv -I. -DDEBUG_LEVEL=0

-mmcu=attiny44 -c usbdrv/usbdrv.c -o usbdrv/usbdrv.o

In file included from usbdrv/usbdrv.c:12:0:

usbdrv/usbdrv.h:455:6:

error: variable 'usbDescriptorDevice' must be const in order to be put

into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.h:461:6:

error: variable 'usbDescriptorConfiguration' must be const in order to

be put into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.h:467:6:

error: variable 'usbDescriptorHidReport' must be const in order to be

put into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.h:473:6:

error: variable 'usbDescriptorString0' must be const in order to be put

into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.h:479:5:

error: variable 'usbDescriptorStringVendor' must be const in order to

be put into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.h:485:5:

error: variable 'usbDescriptorStringDevice' must be const in order to

be put into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.h:491:5:

error: variable 'usbDescriptorStringSerialNumber' must be const in

order to be put into read-only section by means of

'__attribute__((progmem))'

usbdrv/usbdrv.c:70:14:

error: variable 'usbDescriptorString0' must be const in order to be put

into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.c:89:14:

error: variable 'usbDescriptorStringDevice' must be const in order to

be put into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.c:111:14:

error: variable 'usbDescriptorDevice' must be const in order to be put

into read-only section by means of '__attribute__((progmem))'

usbdrv/usbdrv.c:142:14:

error: variable 'usbDescriptorConfiguration' must be const in order to

be put into read-only section by means of '__attribute__((progmem))'

make: *** [usbdrv/usbdrv.o] Error 1

Thomas-Bells-MacBook-Pro:firmware thomasbell$

After discussion with the guru, it was discovered that this was a

probably with the firmware that we downloaded and some elements of the

CrossPack AVR code had been altered causing the original firmware to be

non-compliant. Using this new firmware, the hex command and all

the other necessary commands worked first time, note you should be in

the firmware folder within terminal to ensure that the commands

work! The programming of my FabISP worked first time (once I had

put the header cable on the right way) and I decided just to remove the

solder bridge and not the 0 ohm resistor as it will allow me to program

subsequent boards without any additional power to the other ISP's when

they are being programmed.

|

FAB ACADEMY 2013

FAB ACADEMY 2013