Final Project

Week 0: Digital Fabrication Principles and

Practices

Week 1:

Collaborative Technical Development, Documentation and Project

Management

Week 2:

Computer Aided Design

Week 3:

Computer Controlled Cutting

Week 4:

Electronics Production

Week 5:

3D Scanning and Printing

Week 6:

Electronics Design

Week 7:

Moulding and Casting

Week 8:

Embedded Programming

Week 9:

Computer Controlled Machining

Week 10:

Input Devices

Week 11:

Composites

Week 12:

Interface and Application Programming

Week 13:

Output Devices

Week 14:

Networking and Communications

Week 15:

Mechanical Design and Machine Design

Week 16:

Applications and Implications

Week 17:

Invention, Intellectual Property and Income

Week 18:

Project Development

Week 19:

Final Project Presentation

|

Mechanical and Machine Design

From

now until the end of the Fab Academy course the class is required to

fabricate and develop a machine. We can either modify a machine

from the project archive, or develop an entirely new machine from

scratch using Fab Inventory components. After much deliberation

we decided to build a 3D scanner as the lab we are starting within the

University did not have any specific 3D scanning facilities.

There are several different iterations of 3D scanner projects published

online, after chatting through the options we decided to try mimicking

and altering the FabScan

project developed by Francis Engelmann as there was continuing support

on this project and a Google Group for a discussion forum.

To begin with as a group we decided which elements of the machine we

could modify to meet the requirements of the assignment. We

decided that we could create a snap fit case to reduce the amount of

screws necessary to reduce components in the case manufacture,

additionally we decided to try and add a light to provide constant

lighting to improve scanning quality.

We then broke the project into sections which we could analyse and

break down into manageable components. These were the structure,

mechanical and electronic components.

Developing the electronics:

I was tasked with creating the electronic elements, I immediately began developing an Arduino out of Fab Lab Inventory components to provide the processing for the FabScan

- this was due to the fact that we should develop the machine from

scratch and buying an Arduino like the one shown in the project files

would not have been allowed. Therefore I decided to try and use

the Hello Arduino detailed in the embedded programming class notes in Week 8.

This posed several problems as we were additionally developing the

breakout broad for the stepper motor so we needed to ensure that we

could connect all the boards correctly. Therefore, as I was

unaware how the breakout board would be manufactured I decided to use

the modified the Hello World Arduino that had headers for every pin on

the chip so compatability and alignment was assured.

Additionally, I need to realign the pins within the Arduino software when I upload the sketch to match up with the pin outs for the ATTiny mega chip.

|

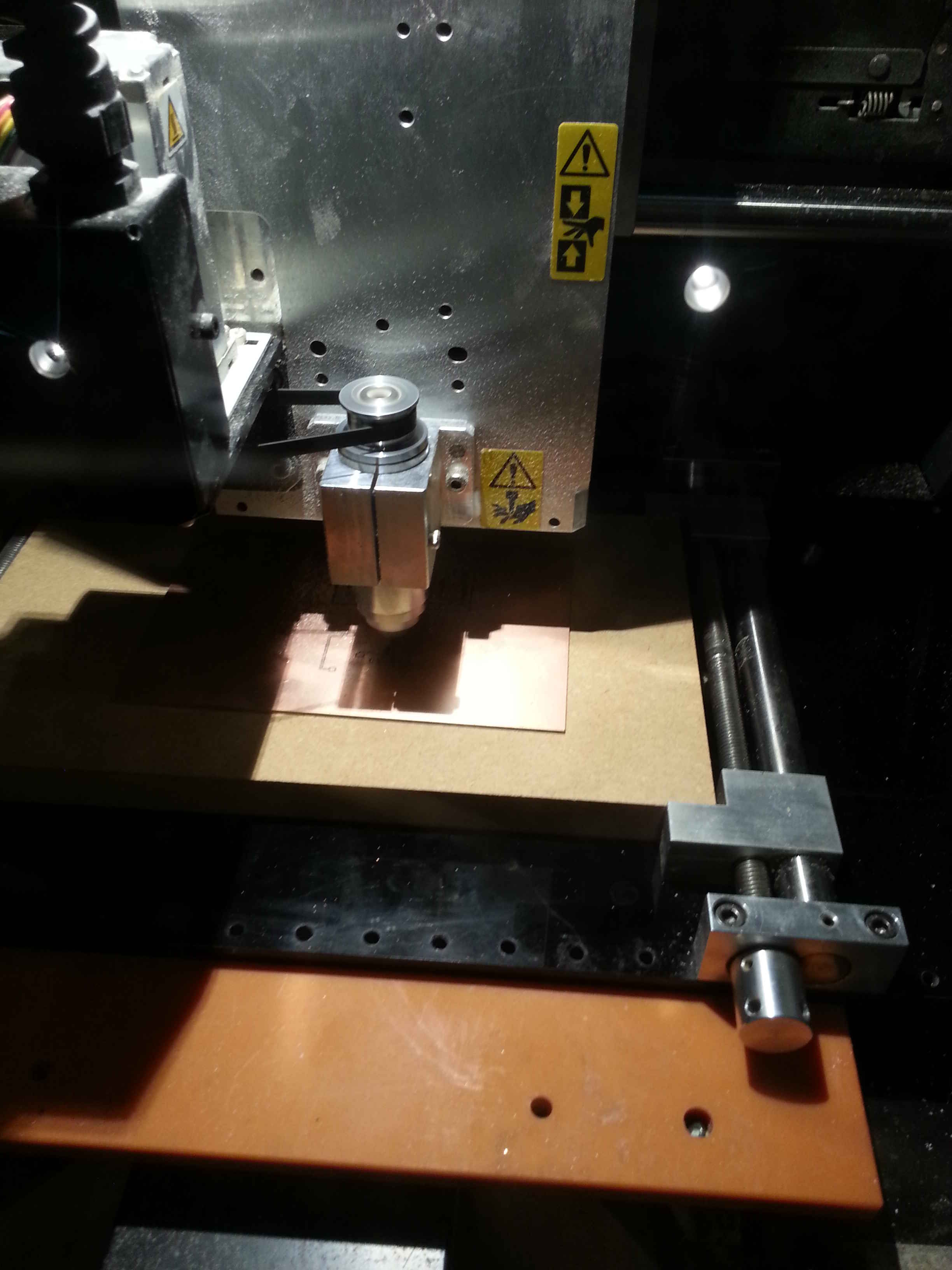

I began milling the board, this

proved troublesome as the bed of the lathe/milling machine wasn't

completely flat so some areas of the board was milled too deep and in

others not milled at all. After milling 7 different boards none were

perfect to solder on so I decided to press ahead by using a scalpel to

scrape out the areas of the board that weren't milled and attempt to

solder the component.

After

several attempts at soldering the board, the traces kept lifting

because they were too small to continue being adhered to the board. I finally managed to get the board soldered.

Before commencing with the programming for the Hello Arduino, I tried

to upload the sketch example given to us in the embedded programming

section of the course notes. I tried to program the board through

he AVR-Dude protocols - unfortunately first time this didn't work

because I was using the ATmega328 chip and not the ATmega 128 as

specified in the .make file. I altered the .make file to the

necessary descriptor, although the correct type of chip was not

specified in the library and I got a chip signature error. As a

work around I located the avr.config file within Terminal and altered

the chip signature manually to mimic the installed chip

signature. Once I had altered the file the board programmed

successfully.

Now, I have to alter the programming for the Hello Ardiuno so it

correlates with the protocols specified within the FabScan Project.

|

FAB ACADEMY 2013

FAB ACADEMY 2013