Final Project

Week 0: Digital Fabrication Principles and

Practices

Week 1:

Collaborative Technical Development, Documentation and Project

Management

Week 2:

Computer Aided Design

Week 3:

Computer Controlled Cutting

Week 4:

Electronics Production

Week 5:

3D Scanning and Printing

Week 6:

Electronics Design

Week 7:

Moulding and Casting

Week 8:

Embedded Programming

Week 9:

Computer Controlled Machining

Week 10:

Input Devices

Week 11:

Composites

Week 12:

Interface and Application Programming

Week 13:

Output Devices

Week 14:

Networking and Communications

Week 15:

Mechanical Design and Machine Design

Week 16:

Applications and Implications

Week 17:

Invention, Intellectual Property and Income

Week 18:

Project Development

Week 19:

Final Project Presentation

|

Invention, Intellectual Property and Income

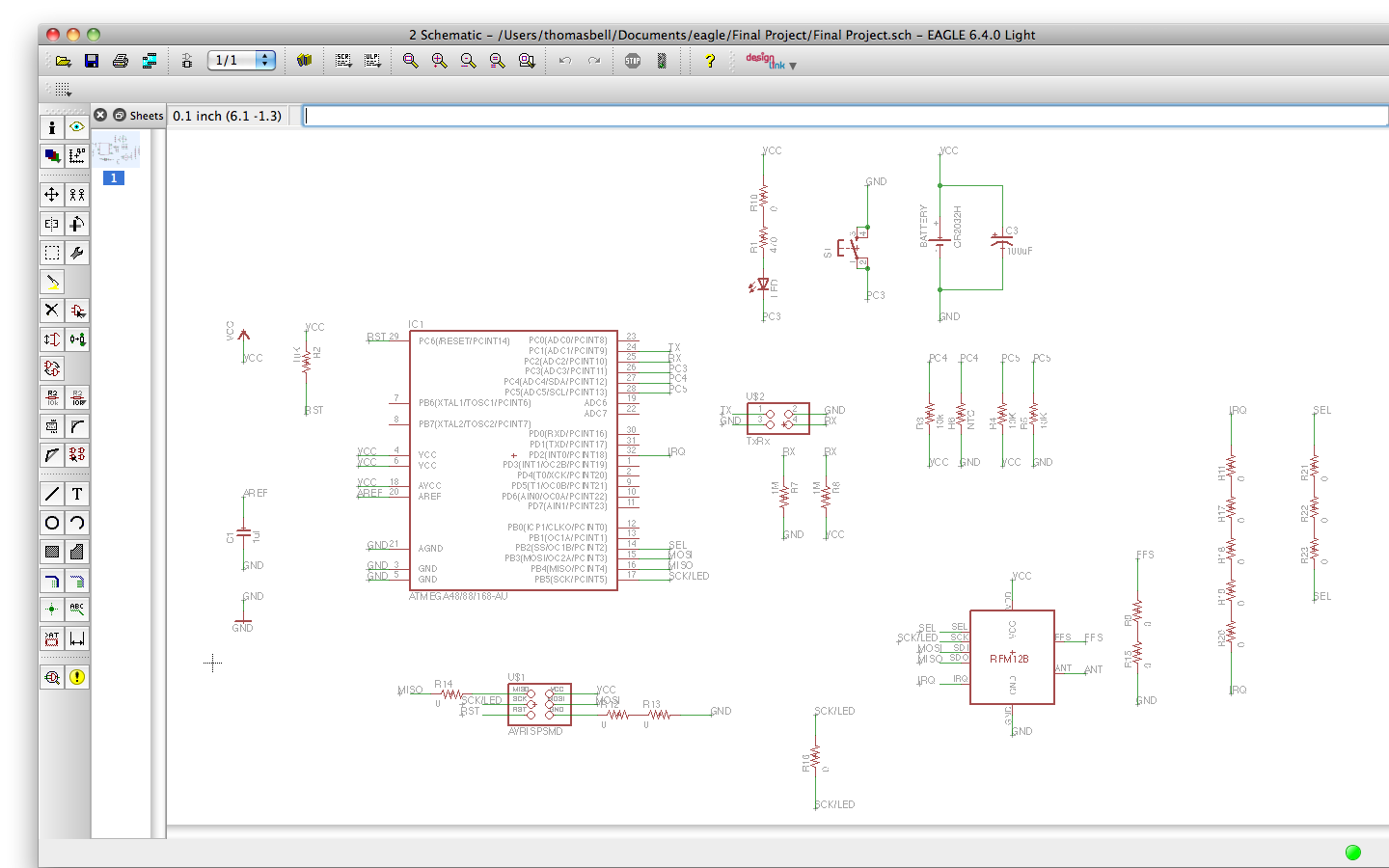

This

week mainly consisted of developing the circuit for my final

project. The idea here was to create an amalgamation of several

different input sensors and the implementation of an output via a

wireless network.

Electronic Design:

Initially

I looked into using a resistance approach at defining the moisture

content in a material, but was shown in class tutorial that the

transmit receive method was the best and simplest way of obtaining a

moisture content. Whereby the circuit will send a voltage across

the material and will measure the amount of voltage it receives,

thereby through a process of calibration will determine the moisture

content within the timber. An initial problem is that different

species of timber have different levels of natural conductivity, so

through the calibration and input you would have to include for several

different species for the product to be useful in practice To do

a calibration for many different types of trees is beyond the remit of

this project and I will calibrate the sensor for Sitka Spruce,

additional species could be added in at a later date through the

interface program.

I began understanding the layouts for the transmit and receive and the

temperature board. The inclusion of the temperature board was

decided because it would potentially give you a more accurate reading

of the moisture content if the temperature is known. Furthermore,

I wanted to include a mobile power source and a wireless sender so the device could be truly portable and could be placed in hard to reach places.

Due to the fact that I am to include, an additional sensor and a

wireless transmitter I thought it was necessary to develop my circuit

using the ATMega 328 chip. Once I had decided on the components

(particular the RF element outside the Fab Lab inventory) and the

techniques of measurement I began working up the schematic of my board

using Eagle.

You should be careful to import the correct libraries from any products

that aren't within the existing Fab Lab libraries, for the RF component I used this Library. It was important to check the datasheets for the chip and the RF component to make sure they were compatible, moreover I sieved through the sensor C files to ensure that the ports were going to the correct ports on the chip.

|

Afterwards, I began working out the board layout. Obviously the

smaller the better for the board layouts, but I was aware that the time

in creating a board would take a fair amount of time and could inhibit

further development of my time. Therefore I decided on a size of

a circuit that would be suitable for a first prototype and began

designing the circuit into these parameters.

For future

debugging, particularly when using the RF component it was necessary to

obtain a serial output to ensure that the embedded programming was

correct. To keep the circuit size to the original sizes I

specified I decided to create a FTDI header to four pin break out

adaptor to debug the circuit before putting in the RF section of the

circuit. Hopefully I will get the boards milled and stuffed at

the earliest opportunity so I can begin what I perceive as the hardest

most time consuming part of the build, embedded programming and

interfacing with the computer.

Case Design:

Using

the preset dimensions I began developing an idea for the case. I

was keen to provide a useful method of fixing the moisture sensor to

the timber. Typically the sensor needs to be driven into the

timber by approximately 20mm or so, usually achieved by a hammer

arrangement or by brute force. To not destroy the electronic

components, I decided to split the moisture sensor components as a

separate element that could be installed and then the electronic

component fixed/clipped to the moisture sensors. I hope the

mounting of the sensors will allow for easy removal of the sensor

embedded into the timber.

The choice of material was one that had to be robust enough to

withstand being driven and knock around whilst being quick and easy to

develop. My initial choice was to use laser cut 6mm ply as it

enabled rapid prototyping of the product. In the future, his

could be made for injection moulding or vacuum formed rigid plastic

casing. For the original casing design I decided to produce a

snap fit ply wood model of the case for easy construction. The final .dxf vector file can be found here.

What I have still left to do?

For

the following week I need to mill and stuff the circuit boards once all

the components have arrived that are not in the Fab Inventory.

Mount the board in the case, potentially using some 3D printed lugs to

fix the board in place. Develop the moisture sensoring prongs, I

was thinking of using needle value pump adaptors as an immediately

available source of metal prongs that could be mounted in the sensor

box. Additionally I need to construct the embedded programming and

develop the python interface to read and calibrate the moisture sensor.

Project dissemination?

The

project is being posted in an open source atmosphere, so it stands to

reason that access to the complete source package should be easily

achieved through my Fab Academy pages. This should aid people who

are trying develop projects with multiple sensors and an application

interface - Hopefully through a wireless network!

|

FAB ACADEMY 2013

FAB ACADEMY 2013