Extra: Molding and casting:¶

For full documentation click here

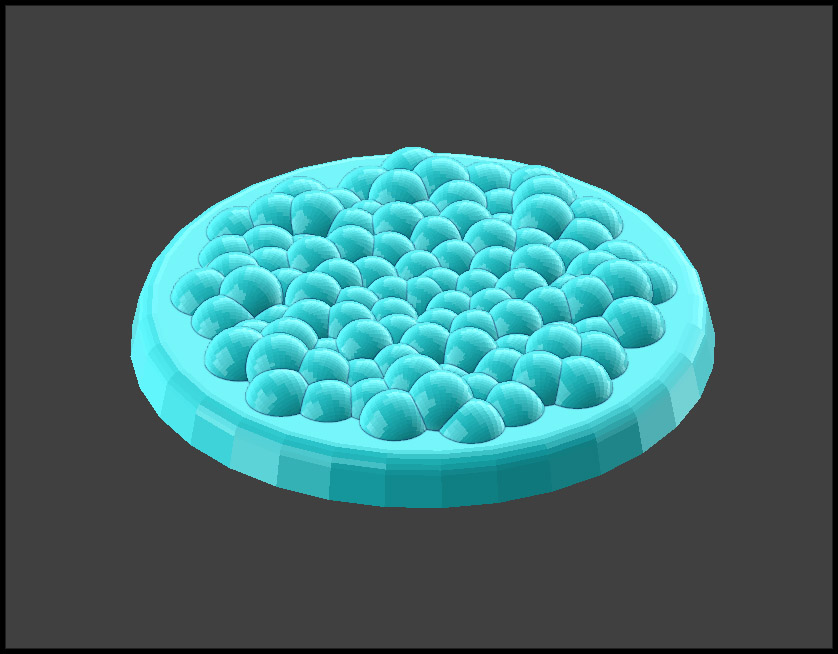

Fibonacci model¶

I made a second a 3D parametric generator that generate a Fibonacci model for my final project, in a wax with 153x153x72 mm.

Molding¶

Prepare the CNC machine¶

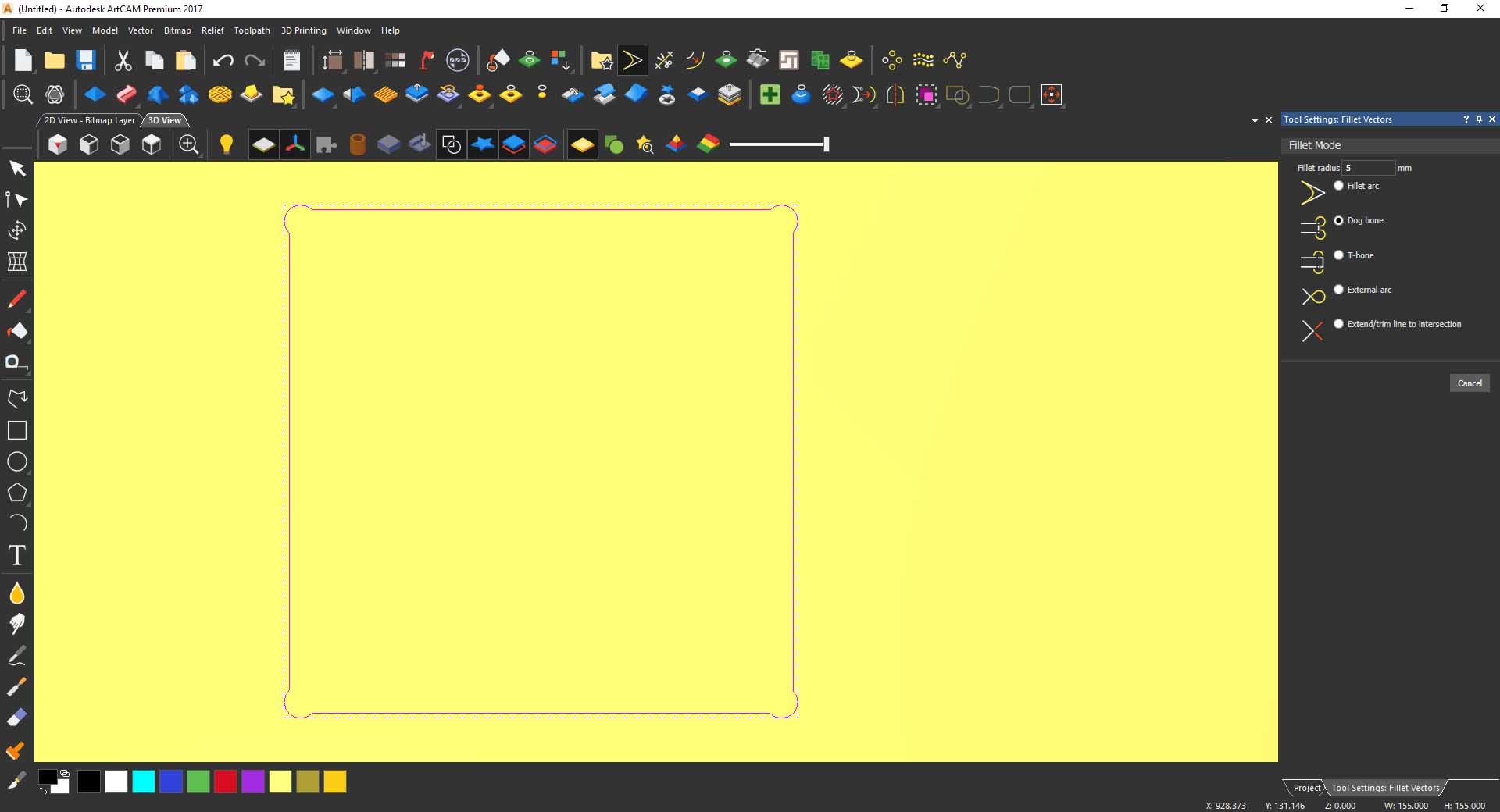

- Give the box dogbone filets around the corners to fit the wax, then cut using endmill

6mmwith6mmcollet.

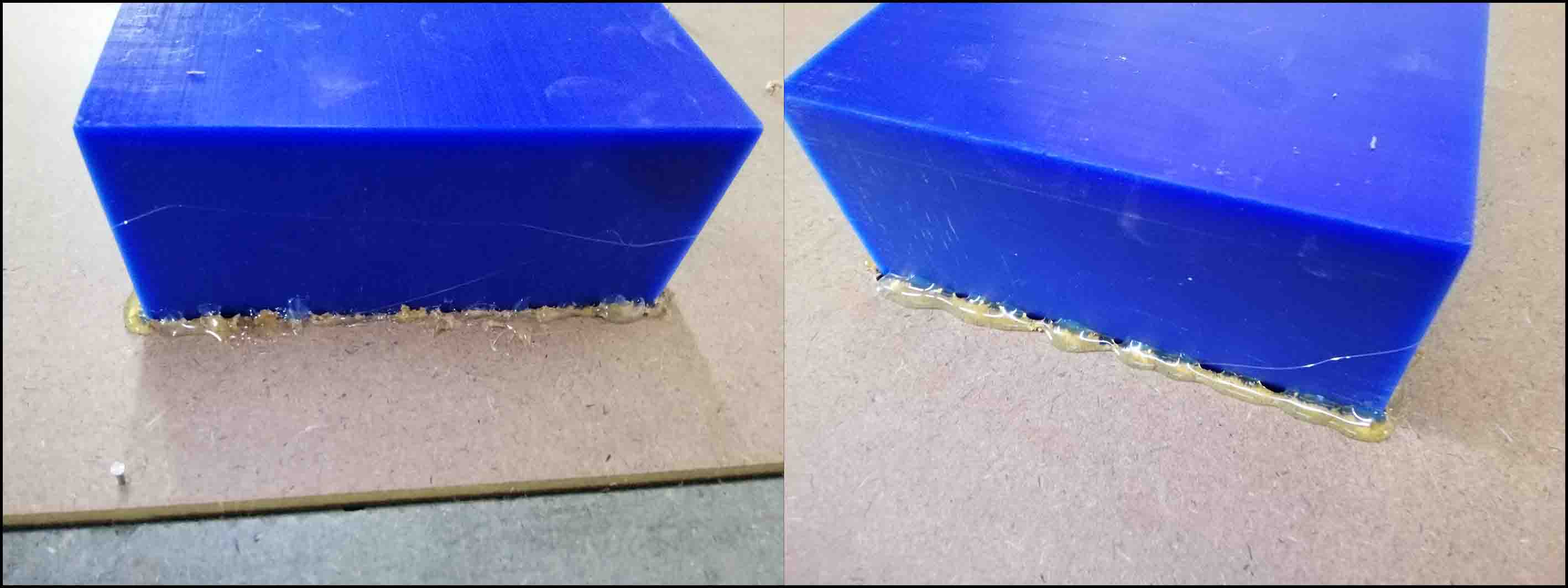

- I used a hot glue gun to fix the wax into the mdf board.

Prepare the CNC gcode¶

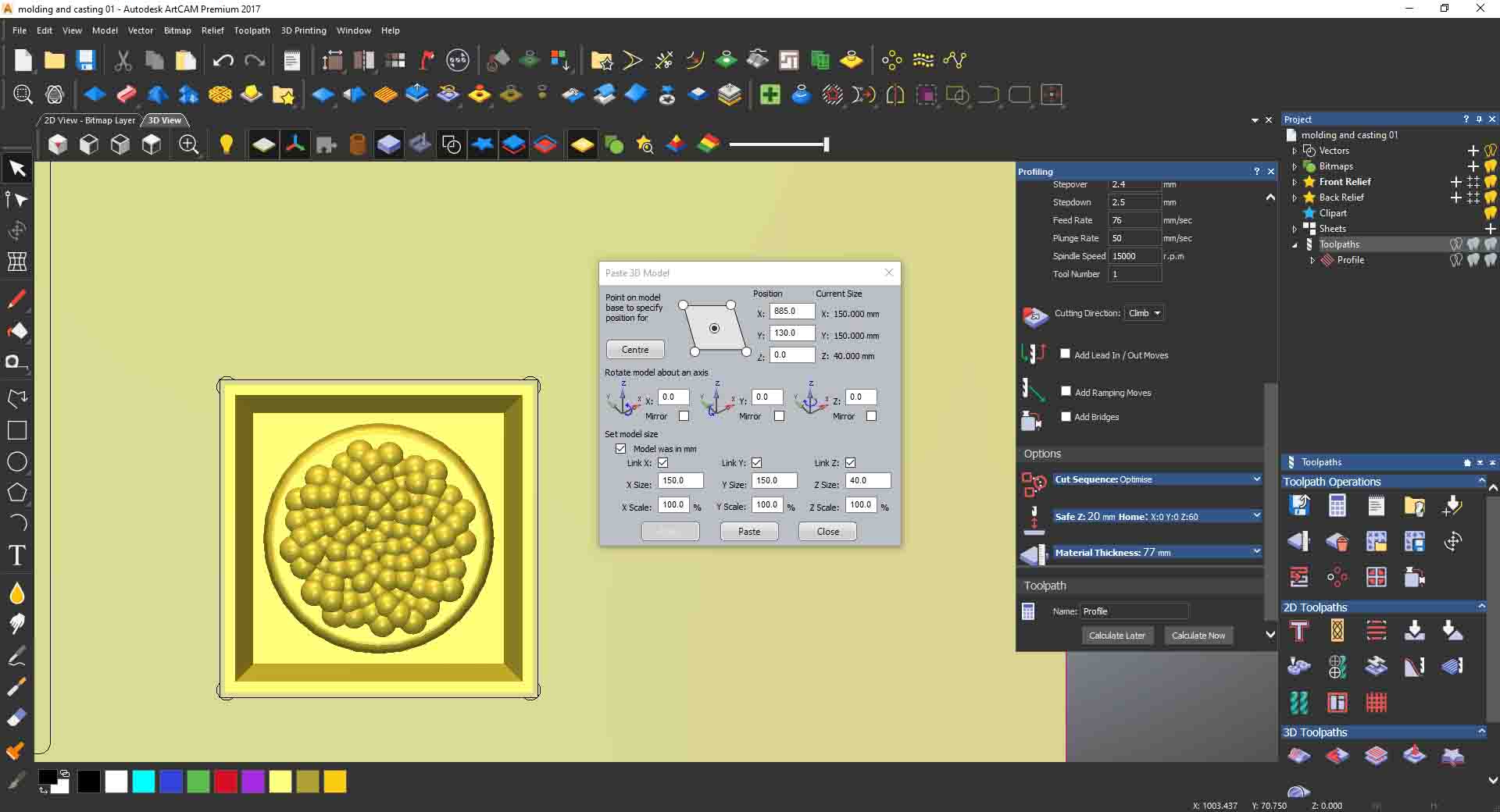

- I imported the STL file into the artcam from

Relief, and put the center of the model in coordinationx=885mm andy=130mm, same as the box because there is no need to zero theX and Y axis.

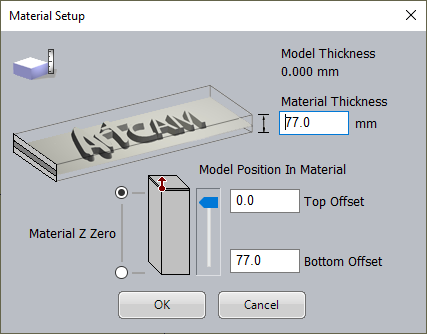

- Then Adjust the material height into

77mm.

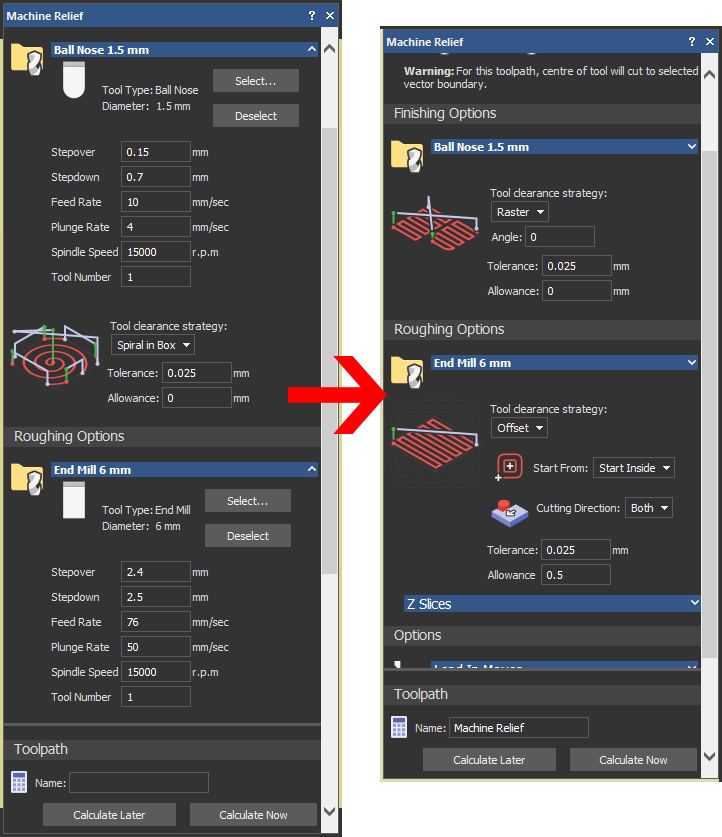

- I started it of to use the Tool clearance strategy

Spiral in Boxfor Finishing Option, but I check it on NC studio simulation to get the time and it was around3 hours, then I changed it back to raster.

And for the Roughing Options I usedOffset, because my 3D model shape is round, and is the better Tool clearance strategy for it, and machining time reduced to1.5 hour.

Roughing toolpath¶

Using the same endmill 6mm to rough the wax.

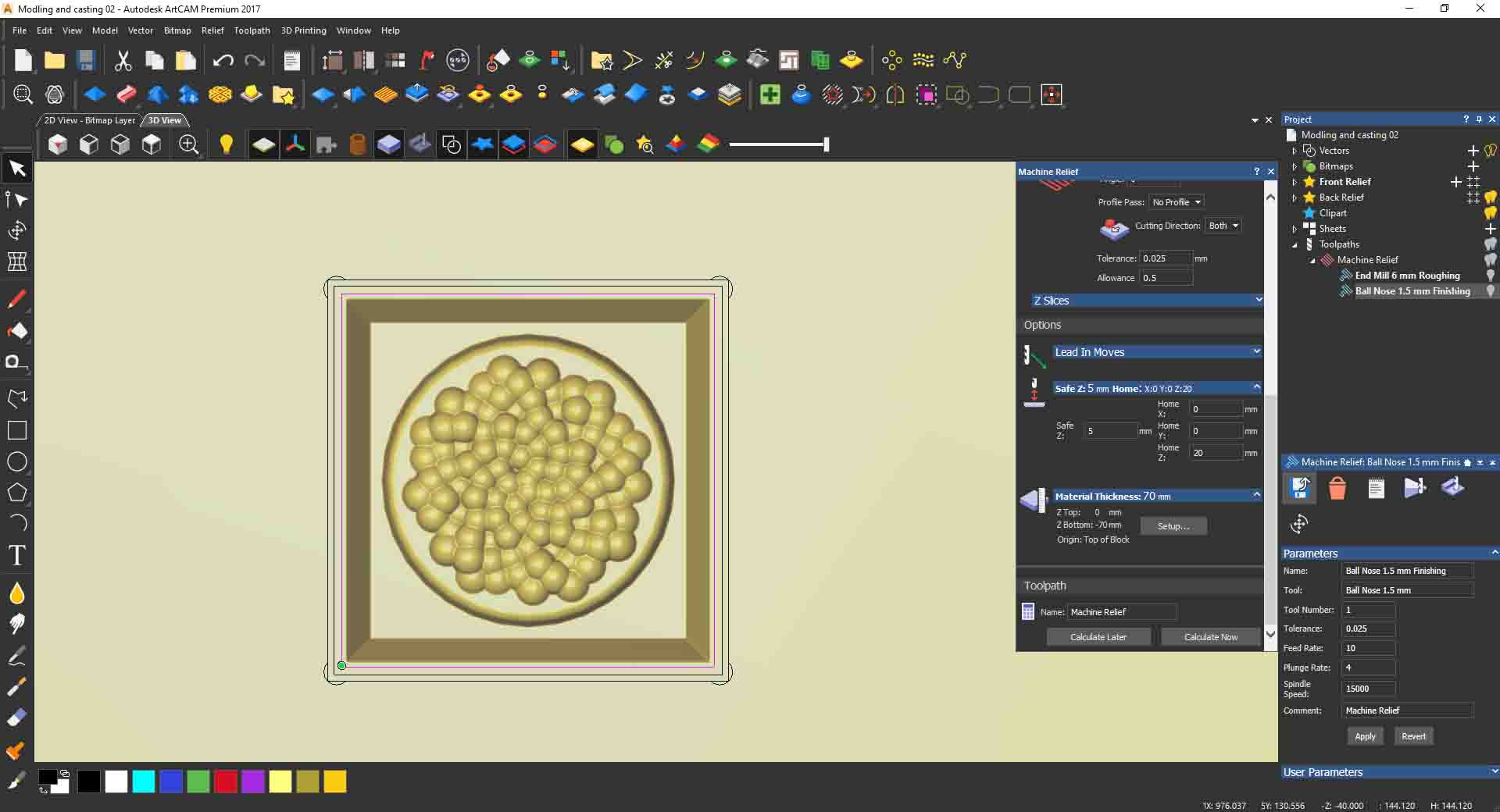

Finishing toolpath¶

I used Tapered End Mill 1/4 inch Shank with 1.5mm Ball Nose for the finishing toolpath.

Then I decided to smooth the first part by going down with the Z-axis by 0.2mm to give smooth finish, but still showing.

Hero shoot mold!¶

Casting Silicone¶

Casting Silicone OOMOO™ 30¶

I mixed the part by weight, from the OOMOO™ 30 page the mix ratio is:

Mix Ratio By Weight 100A:130B

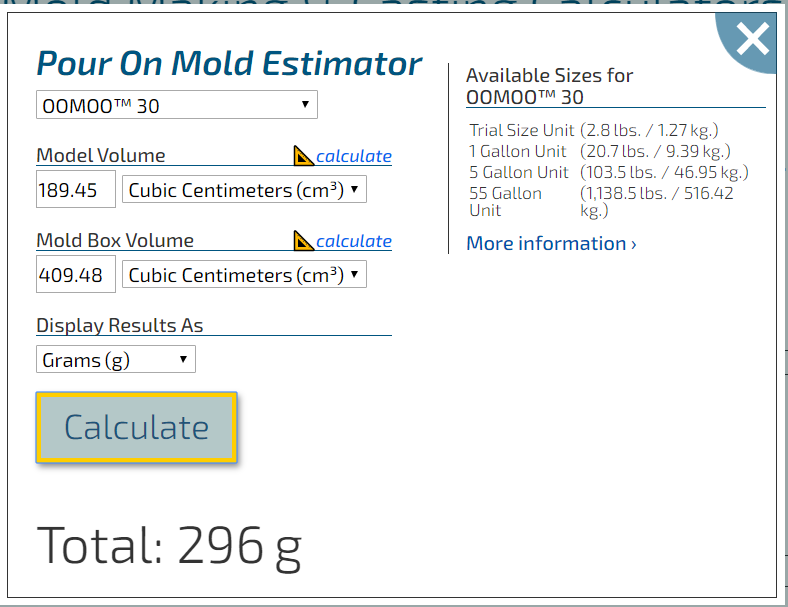

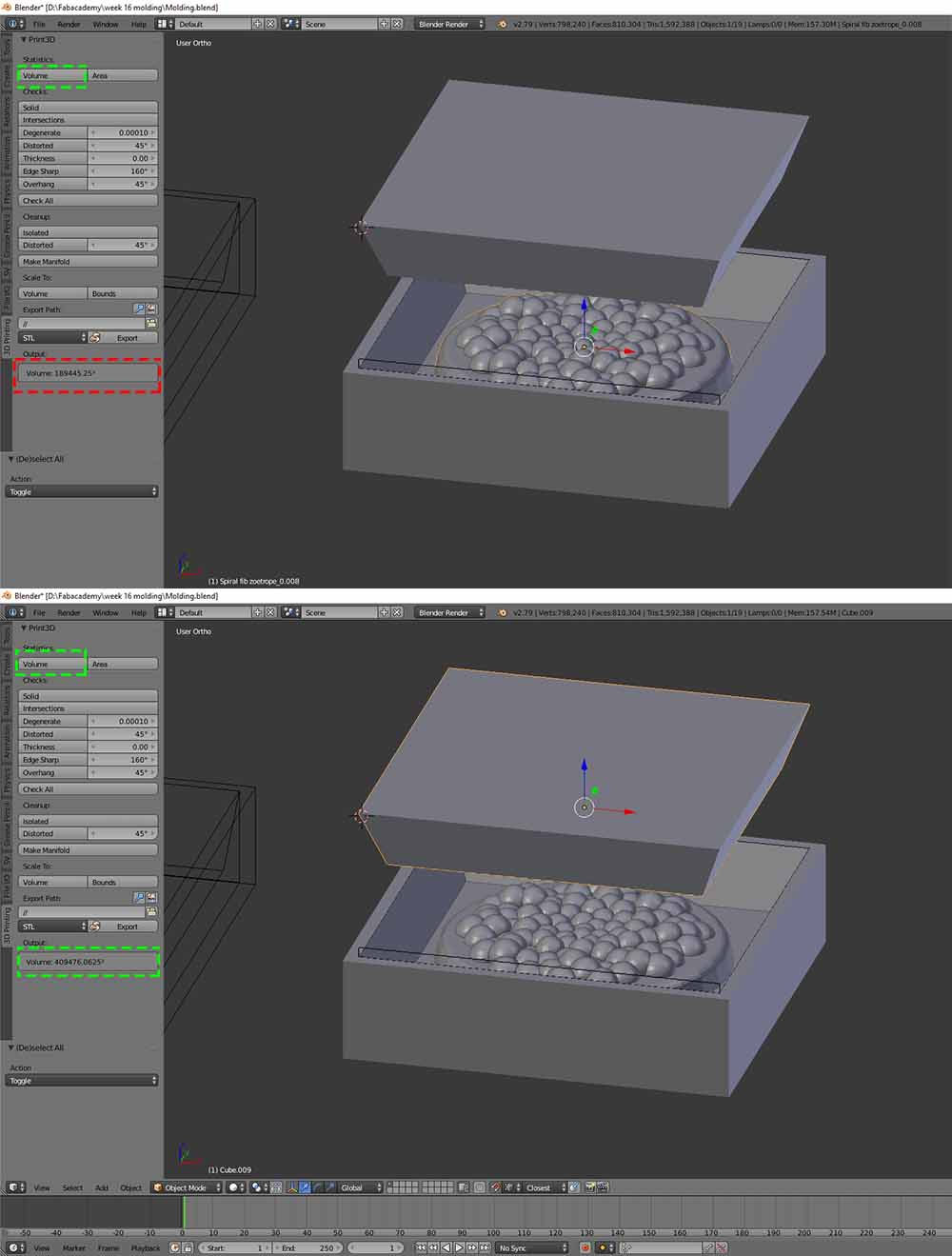

I calculate the volume of the 3d model and the mold box using an addon in Blender called Mesh: 3D Print toolbox.

And we got the values in mm³, and we convert to cm³:

-

Volume of the model is

189.45 cm³. -

Volume of the mold box is

409.48 cm³

And we get the weight in grams 296g.

Steps¶

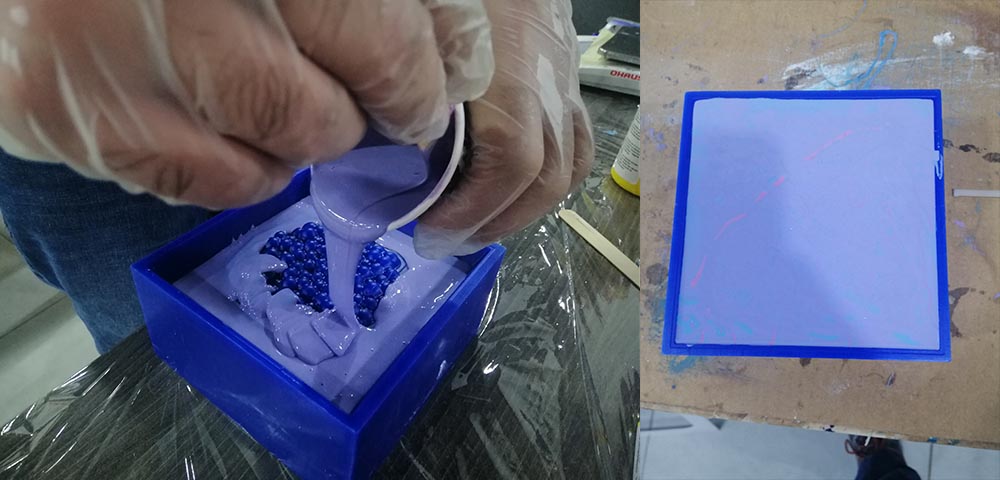

- Using a brush, I covered the model with release agent “grease”

- Measuring the weight of A and B to the ratio mention before, the mixing them until the color changed to Light Blue.

- Pour OOMOO 30 mix into the mold, I used a paper cup to mix, and it was hard to see the parts

A and Bare mixed properly, in the end of the cast I had un mixed parts, but it did not matter.

- Because we had a limited access to the lab, the cure time of the silicon is

6 hours, and I had to wait until the next day to see the finished cast.

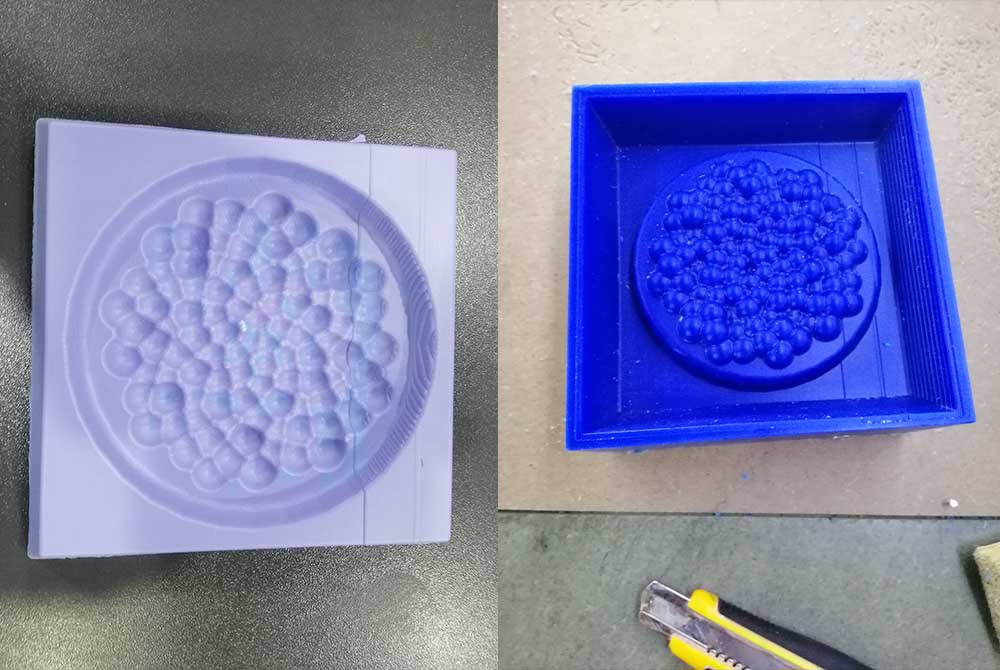

Hero shoot Silicone Cast!¶

Cast compare to the mold.

Casting Liquid Plastic and EPOXY¶

For these materials, we cast them into the silicone and they will give the positive of the mold.

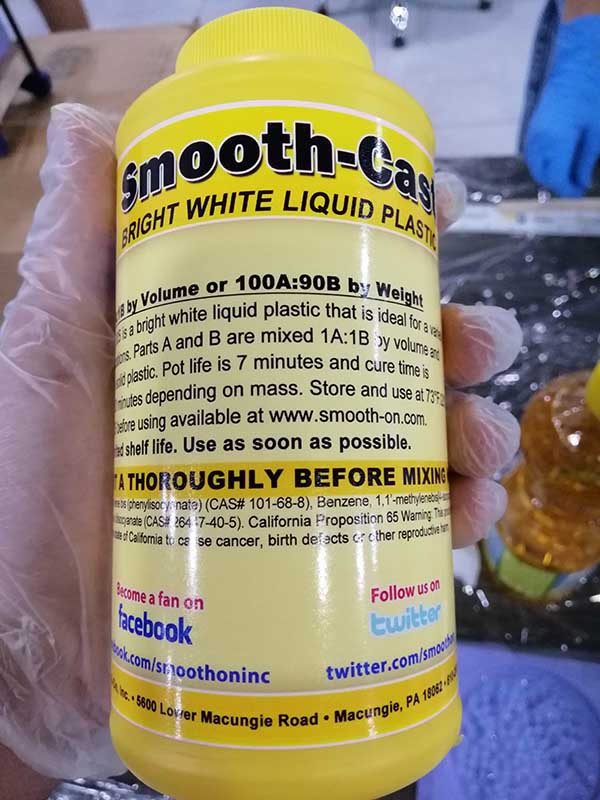

Casting Liquid Plastic Smooth-Cast® 305¶

As you can see the next image that the Smooth-Cast® 305 mixing ratio is 100A:90B.

And we do the same steps of casting silicone, but we cast the Liquid Plastic into the silicone.

You can see in the next pictures the curing of the Liquid Plastic, changing from clear liquid into white hard material.

Hero shoot! Liquid Plastic¶

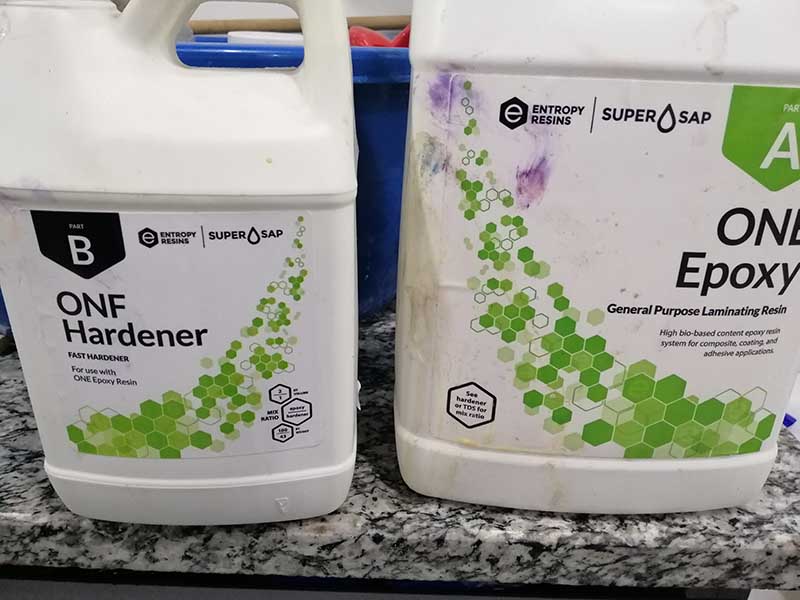

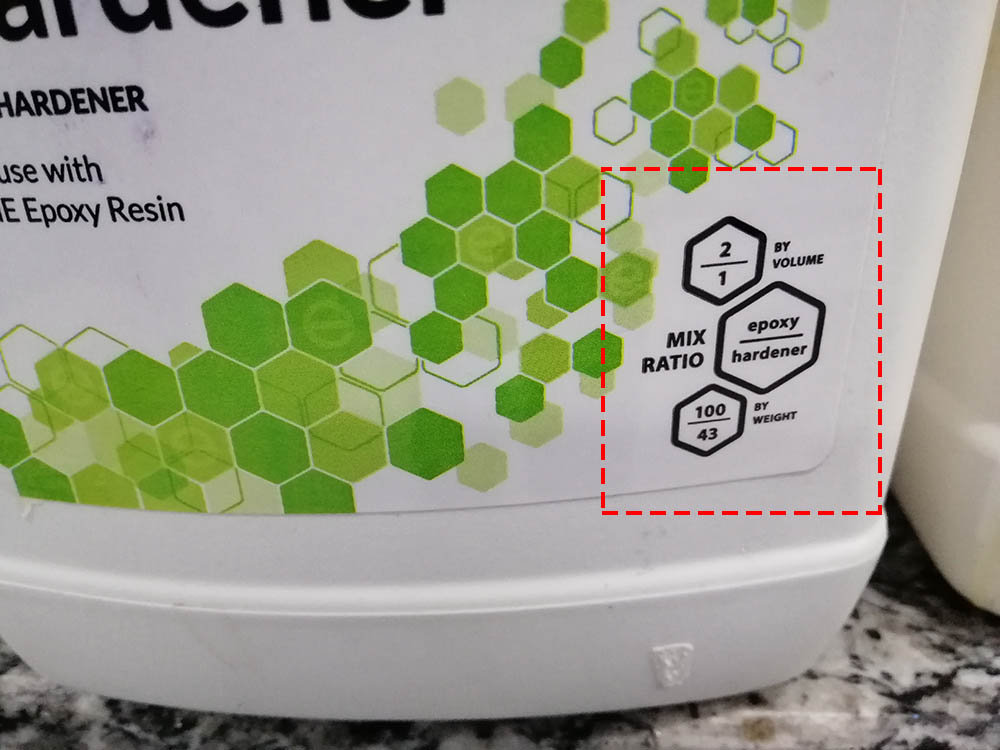

Casting EPOXY¶

I mix the epoxy and the hardener by weight, ratio is 100 to 43

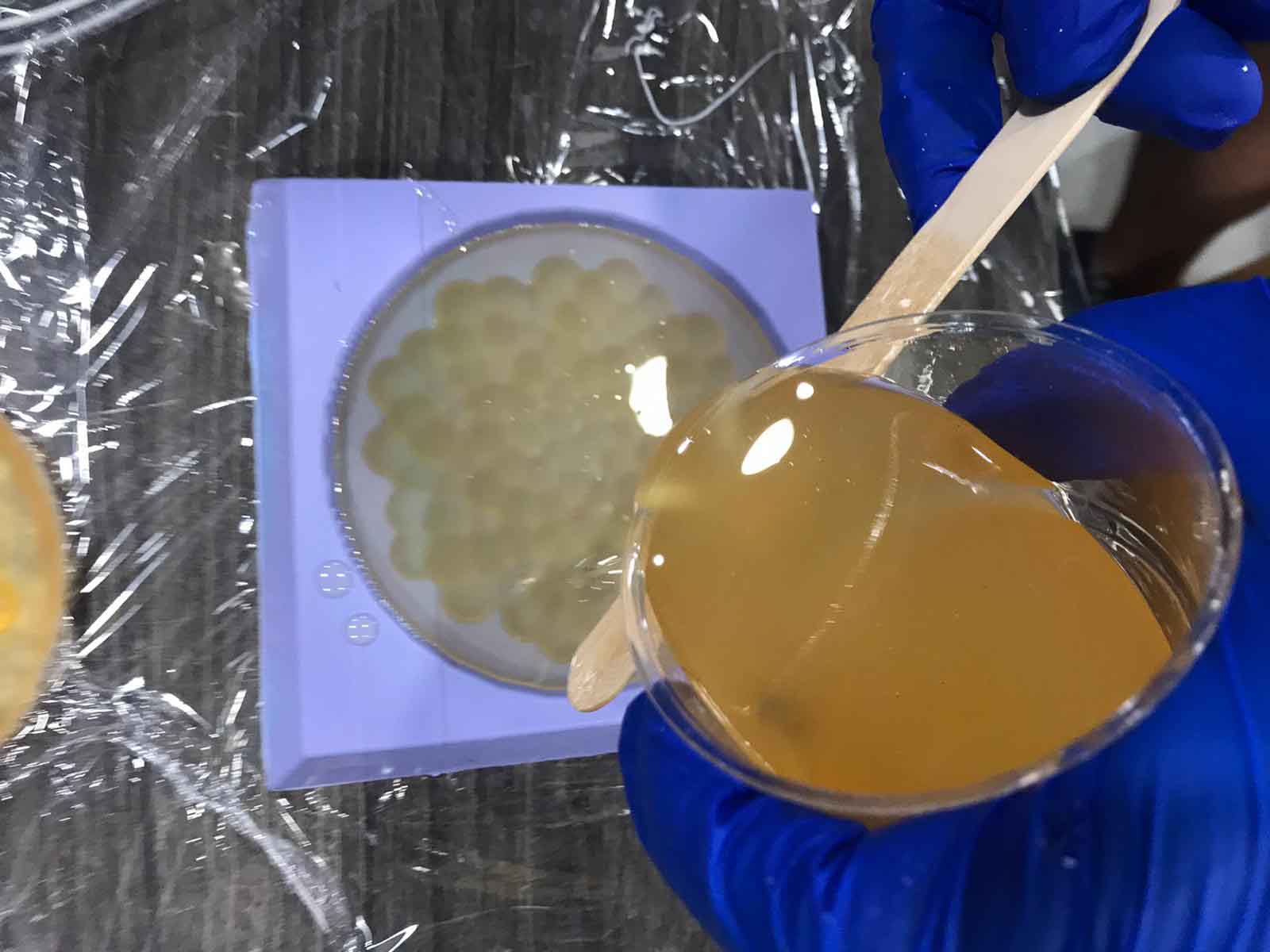

Pouring the epoxy in the silicon.

The chemical reaction between the epoxy and hardener causing a high temperature.

Hero shoot! EPOXY¶

Conclusion¶

After test the models, there was something not quite right about them, and that is you need to make space between each Fibonacci spiral to give you the animation result.