Computer controlled machining:¶

Files to download¶

DXF and SVG files:

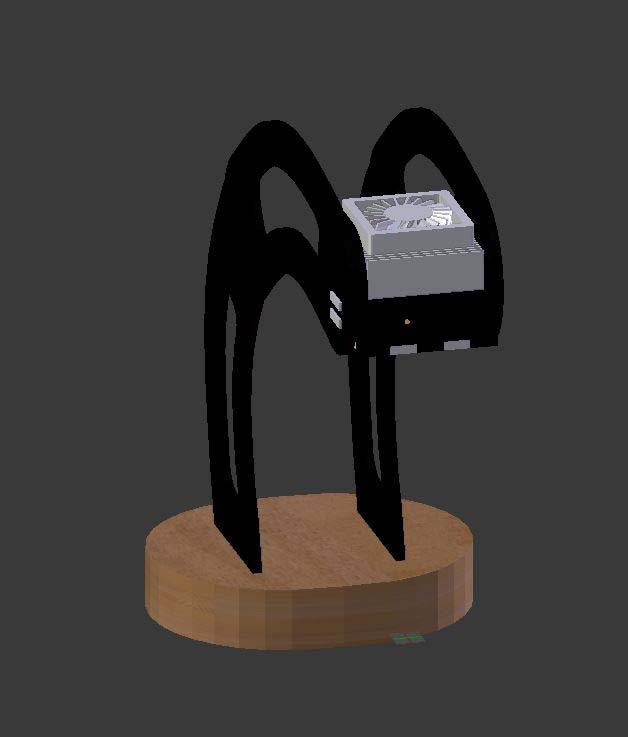

Modeling a bloom sculpture:¶

Programs:¶

Tools that I used to model a new bloom shape:

-

Artcam2017.

-

Inkscape.

Based on the design from 3D modeling:¶

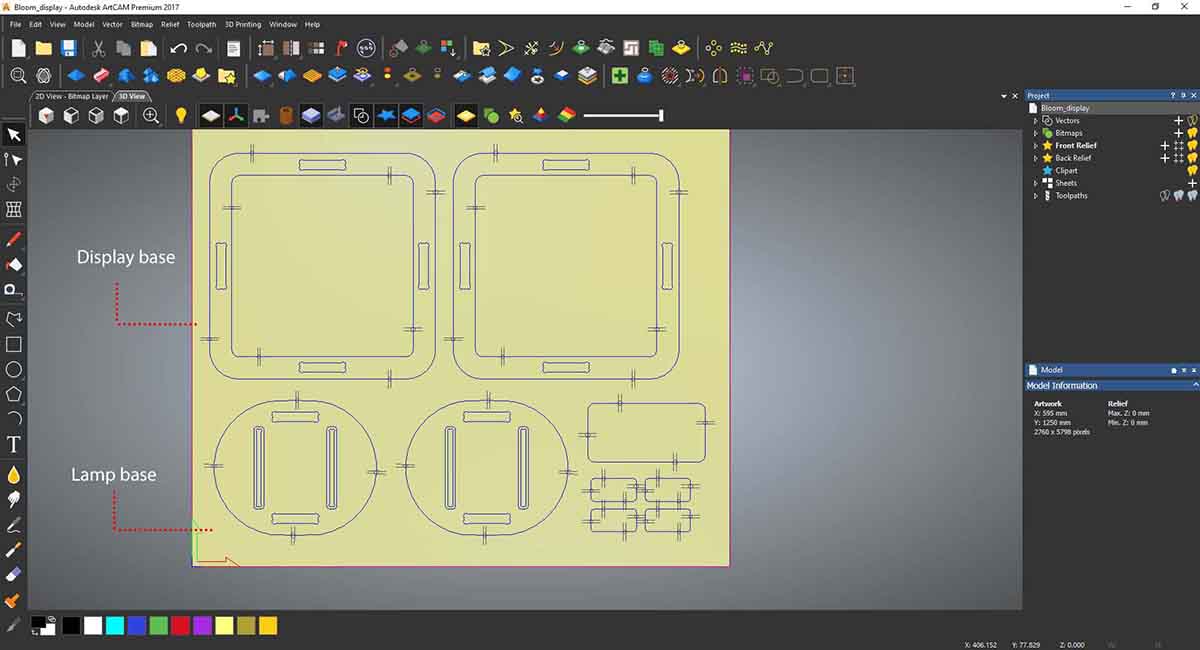

Based on the design from 3D modeling, I have redrawn them on Artcam as vectors.

CNC part:¶

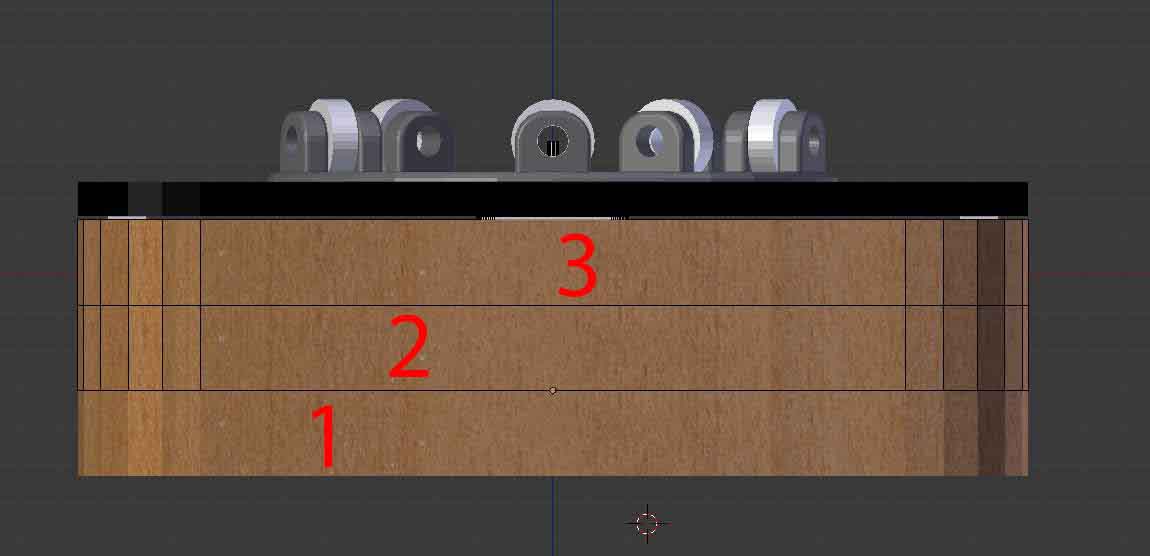

I have made joint parts to be fitted by pieces of scarp 10mm MDF wood that I have with the 65x50mm for the display box, and 50x25mm for lamp holder.

Toolpaths used:¶

Working on a beech wood with 2.25mm thickness.

For the display box:

- Profile cut using a

6mmendmill, for two pieces2 and 3. - Area clear for joints parts and the area inside using a half inch endmill, going down by

1.5mm.

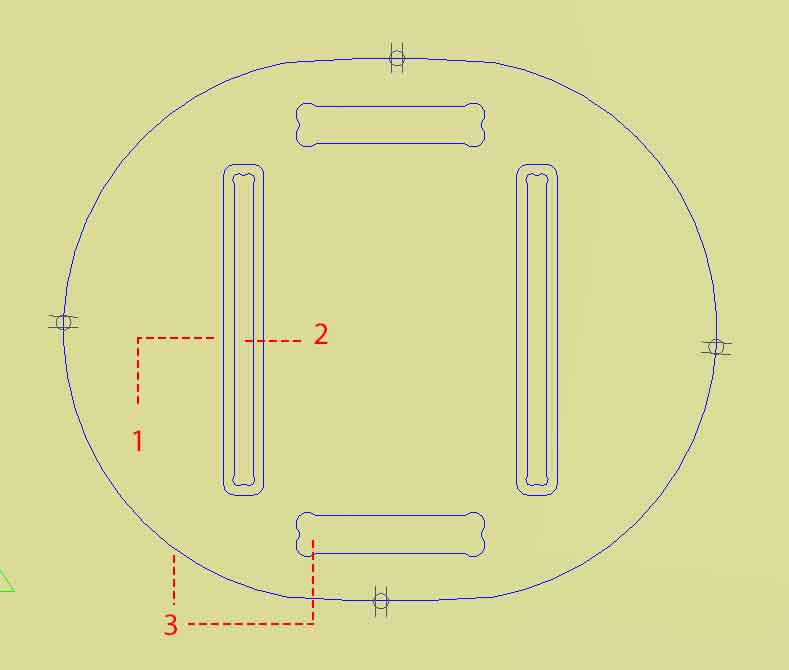

For the Lamp, I was out of the beech wood, so I have used veneer plywood with 17mm thickness:

1- Area Clear using a 3mm endmill, because I want to fit a piece of acrylic inside it with 5mm thickness, and the length of the tool is 15mm, so I used Area clear to go down 3mm so tool wont be affected while cutting the part.

2- Profile cut inside using a 3mm endmill, to fit the acrylic part.

3- Profile cut using a 6mm endmill, to clear the joint fittings and cut out the pieces.

Laser part:¶

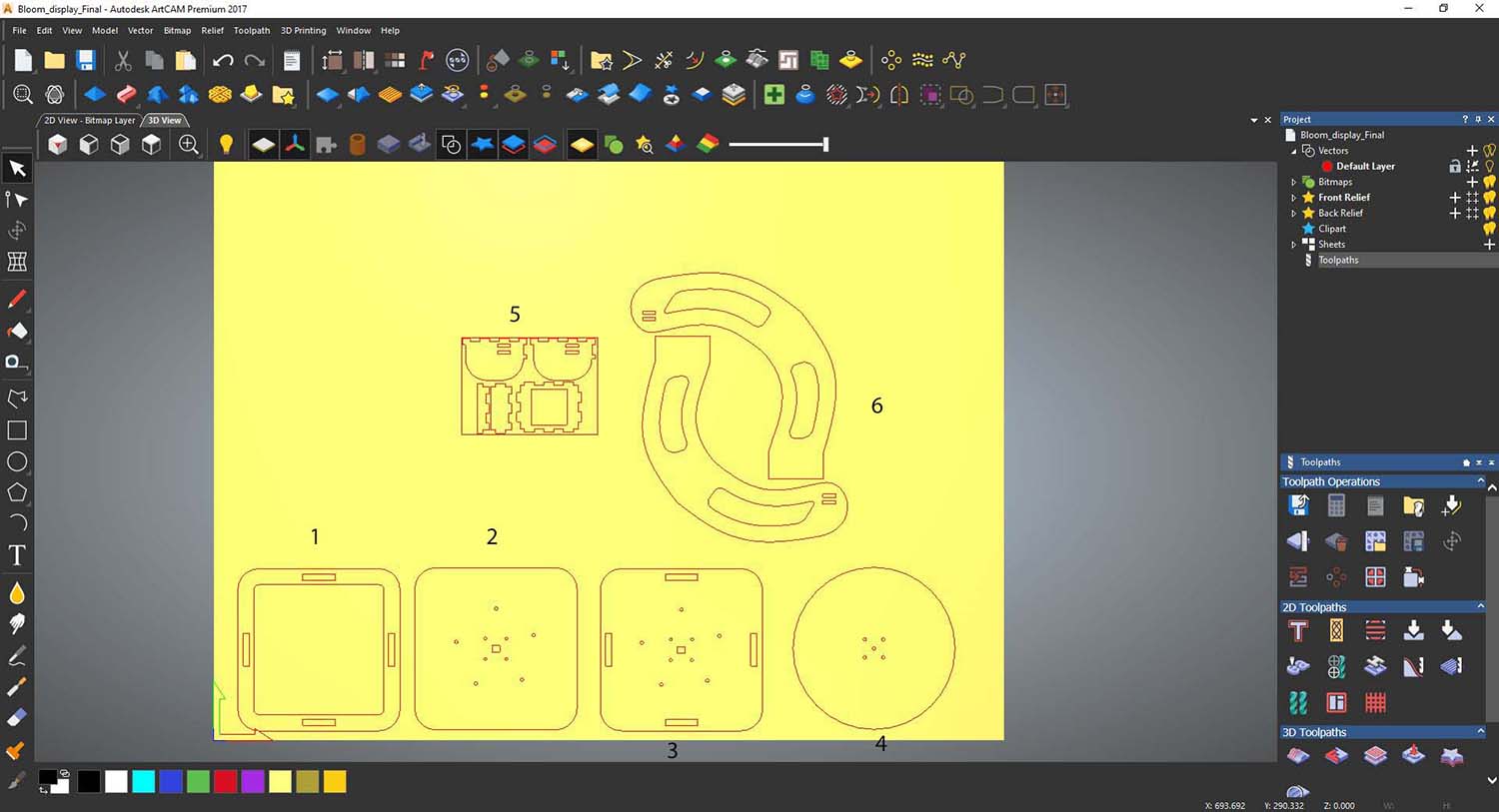

The parts from 1 to 3 are for the display box, 4 is for rotating part; where it turn around on the lazy Susan.

Part 5 is a containing open box for holding the LED and cooling fan

Part 6 is to hold part 5.

Here is small video using Trotec Speedy 400 laser engraver.