design a machine that includes mechanism+actuation+automation

build the mechanical parts and operate it manually

The idea is to build a machine that mills a cube from all 6 sides without taking it out and putting it back

in.

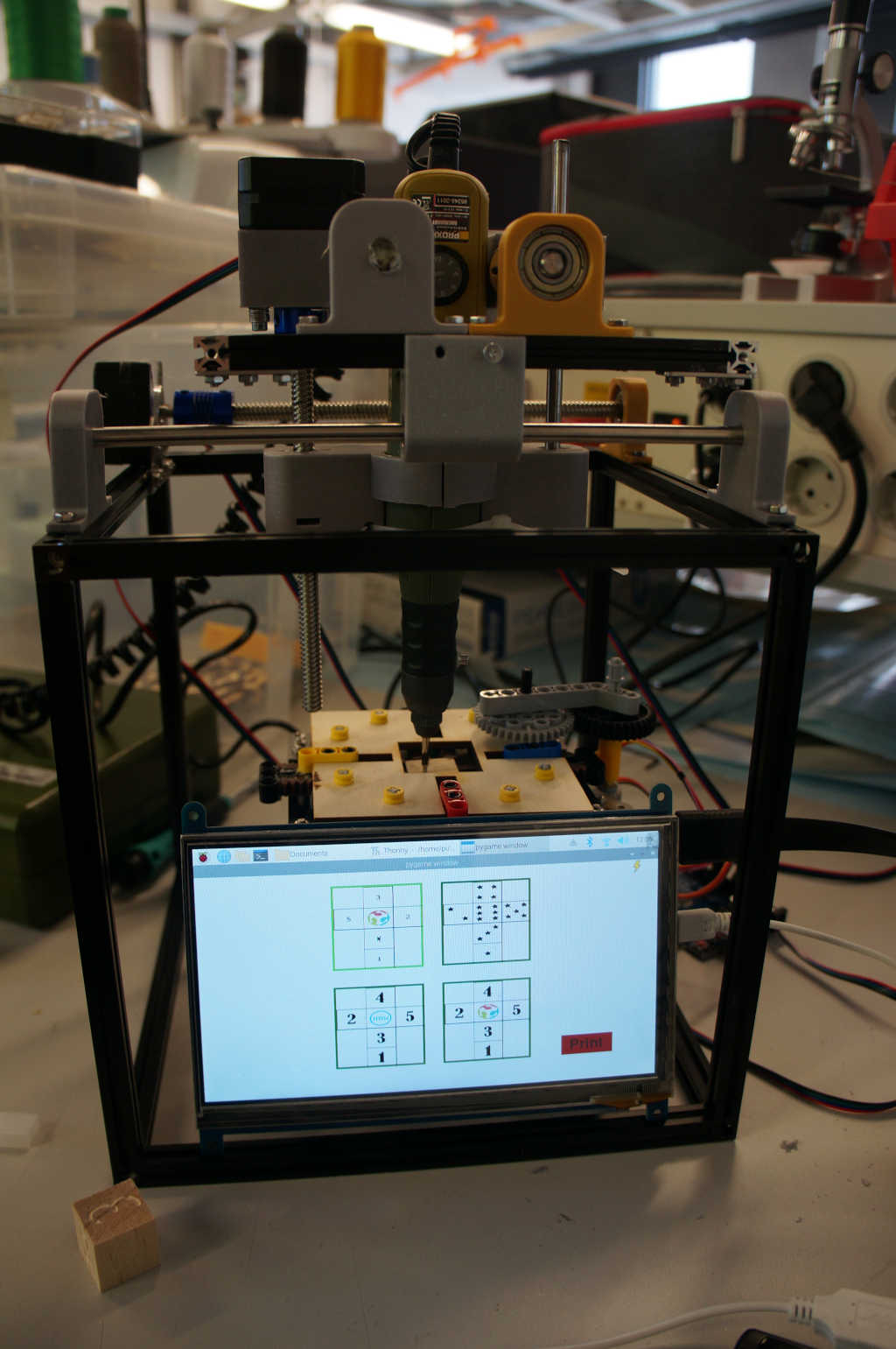

This should be set up so that you have a 3-axis CNC milling machine which can engrave on a surface of 3 x 3 cm.

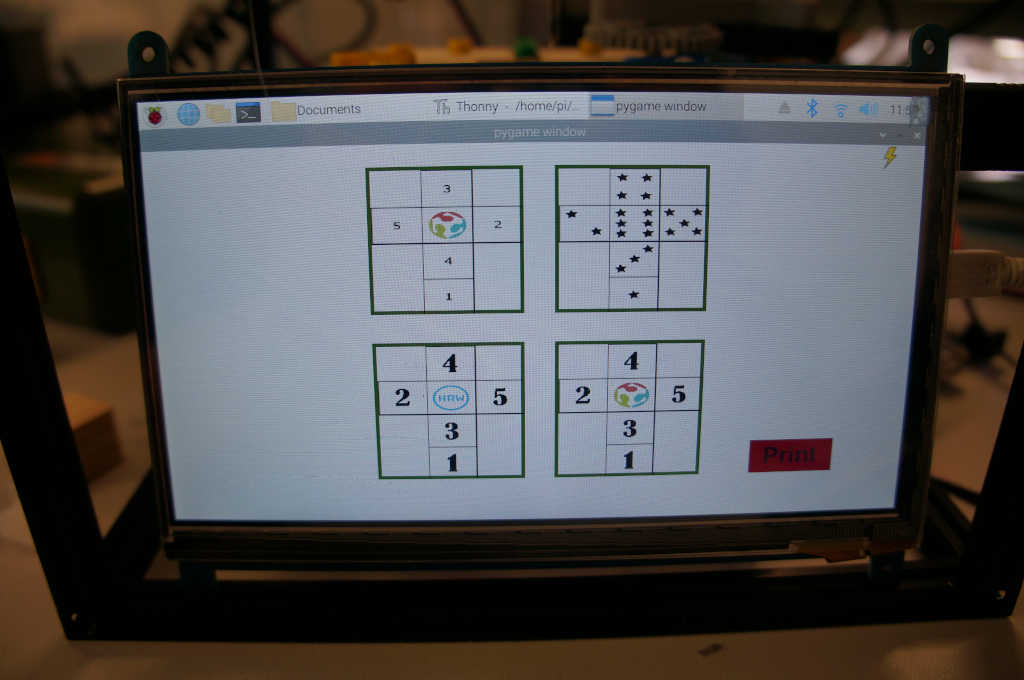

Then the machine has a display on which you can choose your model.

Behind the display there is a Rasbery Pi which controls the CNC and the dice turning

The cube itself is turned and held by a mechanism as soon as it receives a message about i2c from pi. The last

part is my task in the project.

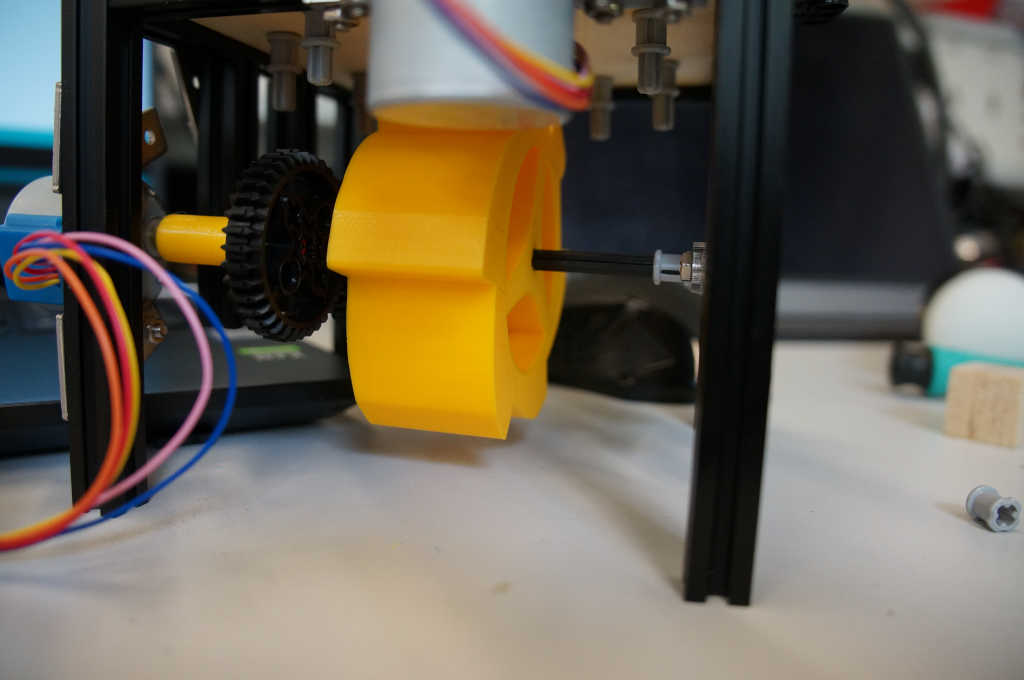

We still had rods for the axles in the laboratory.

It took us a lot of work to shorten them to the right length. Neither with a metal saw nor with a lathe we could

do it. In the end our neighbor lab had a flex and we could shorten the rods.

The rest of the parts we have ordered on Amazone:

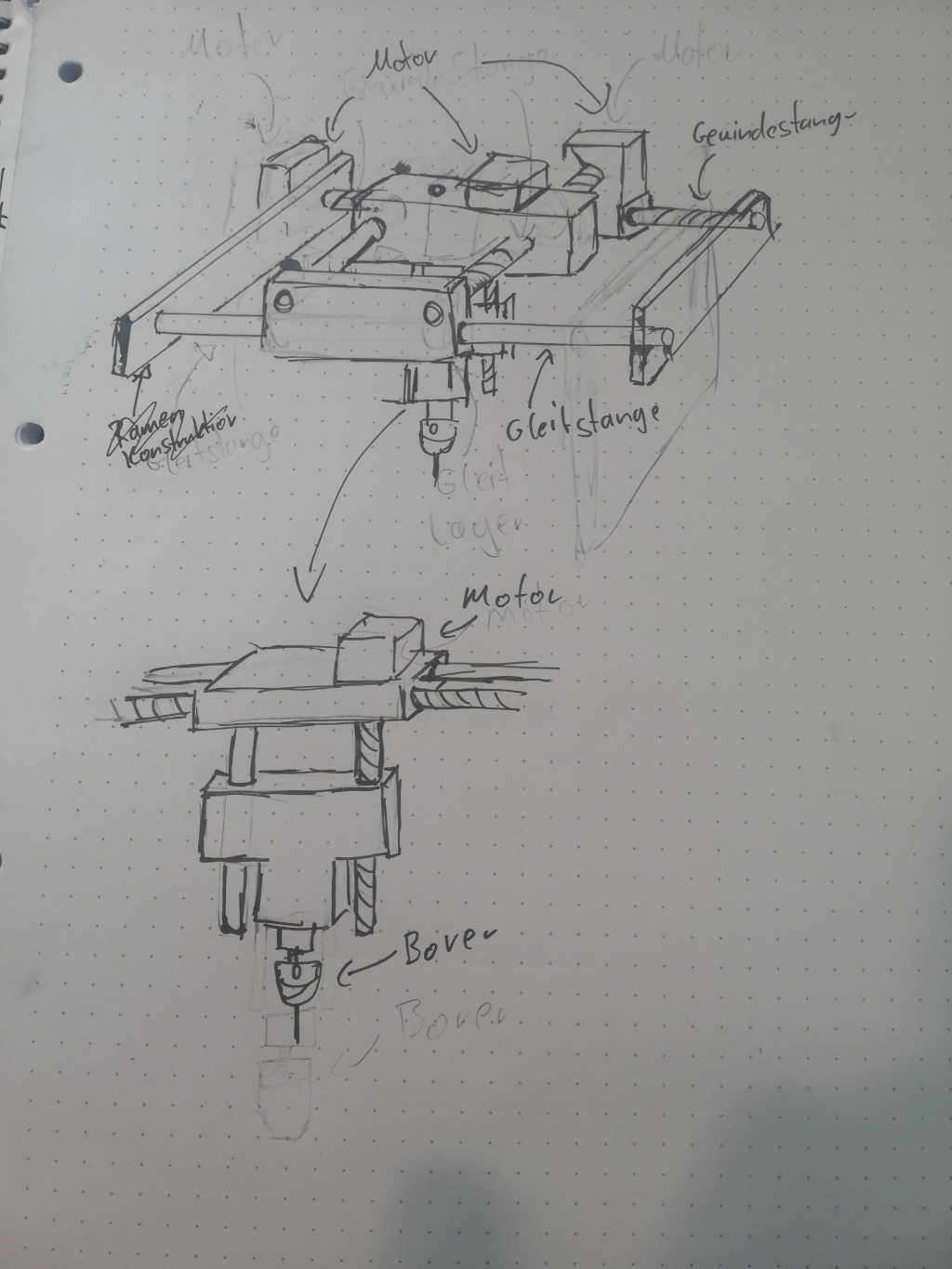

One task is to fix the cube and turn it automatically. This is best done with 2 motors. I have started to fix the cube.

I thought about designing a 4-jaw chuck which can be controlled by one motor.

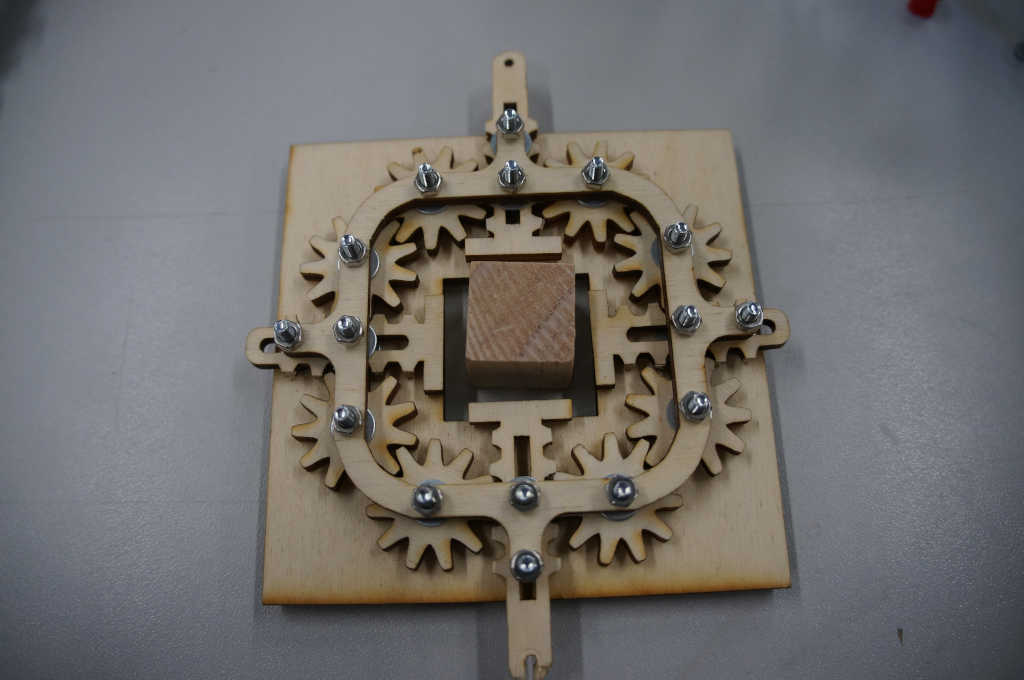

First I designed a wooden prototype with the lasercutter. The bikes are not very

stable or long lasting but they can be removed quickly.

After I improved the gears two and three times it worked out very well.

But as already feared it was not stable enough to function properly.

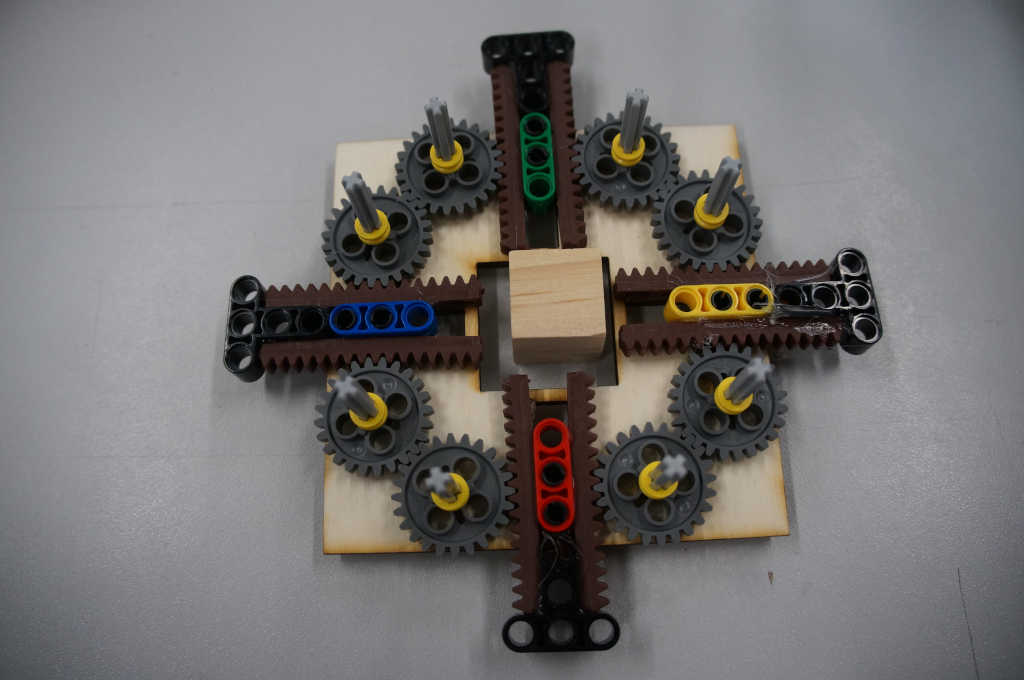

In the next step I built a new version with the same mechanism of wood and lego in combination. It worked much better.

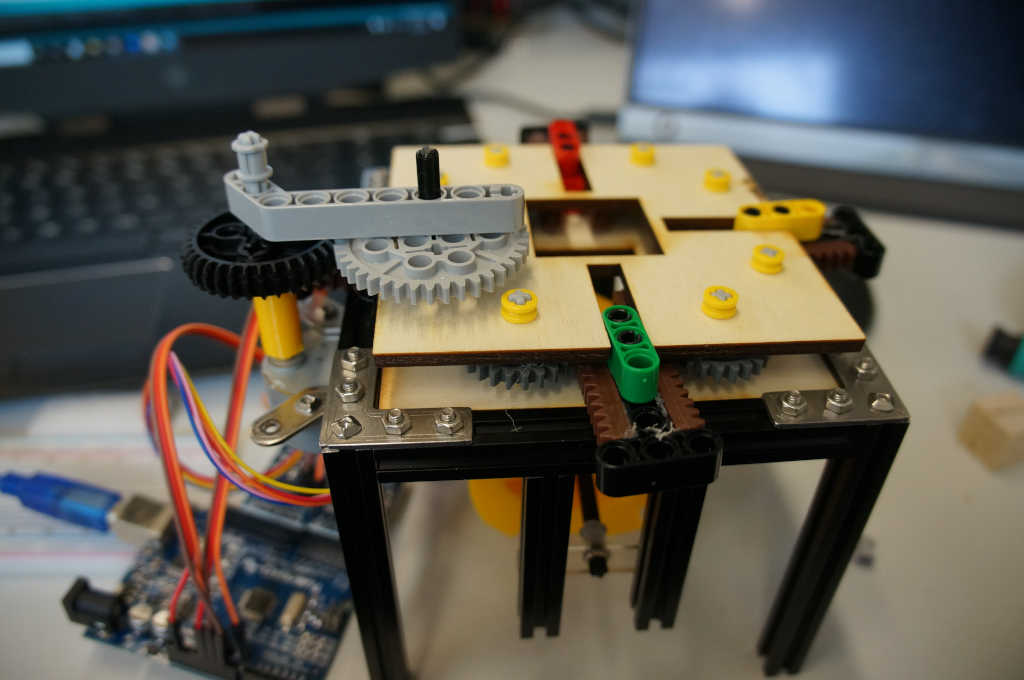

In the next step I built the whole thing firmly into a frame which can later be screwed firmly to the milling machine.

To be able to turn the cube automatically I designed a 3D part that reliably tilts the cube 90 degrees in one direction by turning 60 degrees.

Turning the cube 90 degrees in the other direction works most of the time.

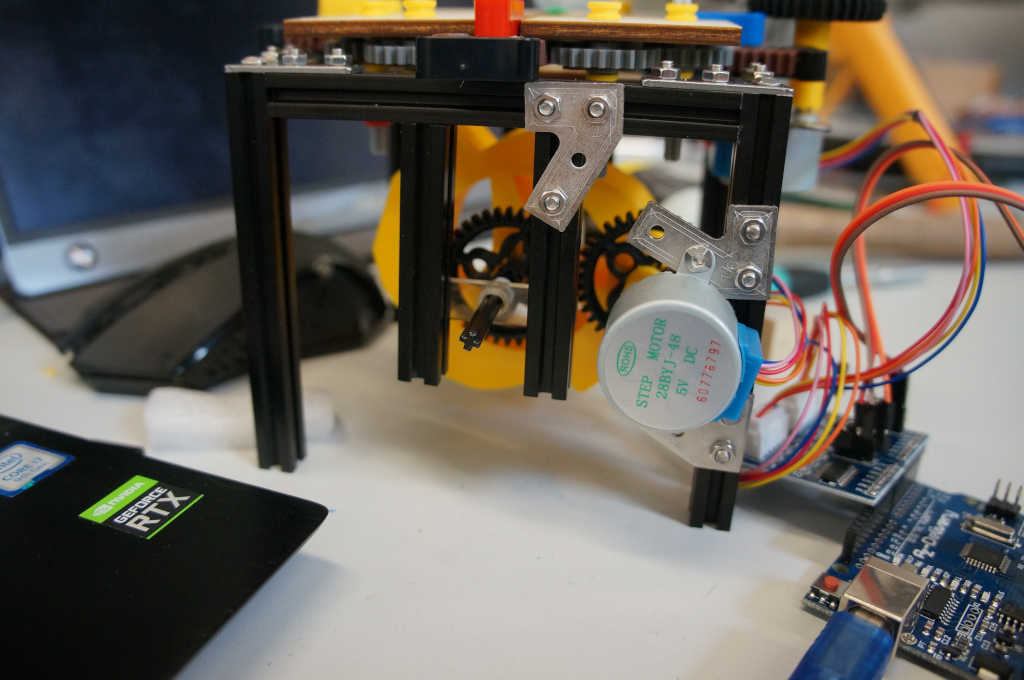

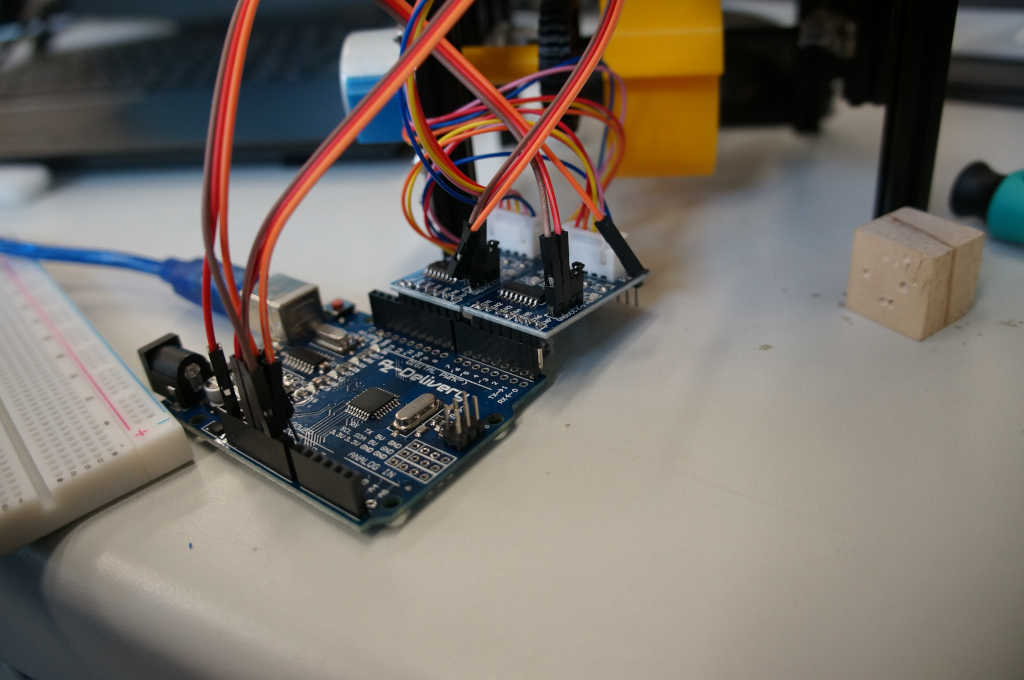

The Cube turner is again driven by a stepper motor. The two motors can be simply plugged onto an ARduino uno and then only need electricity.

To control the turn of the cube I wrote a small program which receives a message via serial communication. Then it lets go of the cube, turns the other motor by 60° and tightens the cube again.

#include

int SPU = 2048;

Stepper dreh(SPU, 2,4,3,5);

Stepper fest(SPU, 10,12,11,13);

void setup()

{

Serial.begin(9600);

dreh.setSpeed(10);

fest.setSpeed(10);

}

int what;

void loop() {

if (Serial.available() > 0) {

what = Serial.read();

}

// open ->turn -> fix

if(what == 1){

//open

fest.step(-380);

delay(1000);

//turn

dreh.step(340);

delay(1000);

//close

fest.step(-380);

delay(1000);

}

}

You can see how this works in video.

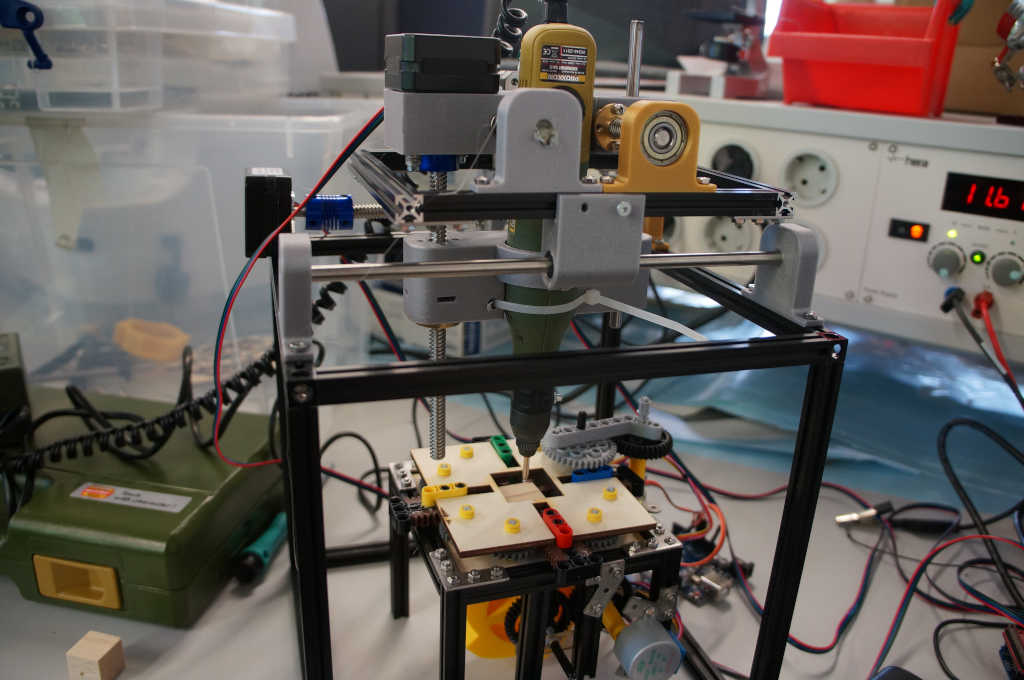

To engrave the cube we need a 3 axis CNC. Two axes to cut the desired pattern and one to lower and raise the cutter on the cube.

The whole is to be accommodated in a stable case, therefore we have built the linkage with Macker Case. At Amazone we made threads and ordered an Arduino Motorbard and engines. Together everything cost about 100 €.

So we have built a classic CNC machine.

As we did not find a single spindle motor that could be delivered in half the time we planned with a lathe.

The parts that hold the rods and axes to the frame are 3D designed and printed.

The electronics consist of an Arduino uno on which a motorboard is plugged which controls the 3 motors.

All axis values for x, y and z are defined by the GCODE.

To control the whole machine we have equipped a raspberry pi with a touch display. In Python we wrote a program on which you can choose one of 4 designs to be engraved.

We built all the parts together. It's not perfect but it's something to see.

On the display you can now choose a desine.

The machine is still optimising and expandable but the week is over.

In the video you can see how one is engraved.