- Week 1 : Project Management

- Week 2 : Computer-aided

- Week 3 : Computer Controlled Cutting

- Week 4 : Embedded Programming

- Week 5 :3D Scanning and Printing

- Week 6 : Electronic Design

- Week 7 : Computer Controlled Machining

- Week 8 : Electronics Production

- Week 9 : Input Devices

- Week 10 : Output Devices

- Week 11 : Networking and Communication

- Week 12 : Mechanical Design and Machine Design

- Week 13 : Midterm Review

- Week 14 : Molding and Casting

- Week 15 : Interface and Application Programming

- Week 16 : System Integeration

- Week 17 : Wildcard Week

- Week 18 : Applications and Implications, Project Development

- Week 19 : Invention, Intellectual property and Income

- Week 20 : FInal Project Requirements

Week 5: 3D Printing and Scanning

Objectives of the Week

Group Assignment

Individual Assignment

Group Assignment Contribution

In this Week, I have Contributed in the understanding characteristics of My 3D Printer

Characteristics of my 3D Printer

In our Lab we have two Printers one is from Creality and another one is from Flash Forge

For more about Group AssignmentAbout FlashForge Creator 3 Pro

The FlashForge Creator 3 Pro is a professional IDEX (Independent Dual Extruder) 3D printer, allowing dual-material and multi-color printing. It has a 300°C high-temperature extruder, enabling compatibility with a wide range of filaments like PLA, ABS, PETG, PC, and Nylon. The heated flexible build plate improves adhesion and makes print removal easy. With an enclosed chamber, it maintains stable temperatures for better print quality. The active leveling system ensures precise calibration. It features Wi-Fi, USB, and Ethernet connectivity for remote operation. It cost comes around Rs. 2L

Specifications

| Feature | Specification |

|---|---|

| Printing Technology | Fused Filament Fabrication (FFF) |

| Build Volume | 300 x 250 x 200 mm |

| Layer Resolution | 0.05 - 0.4 mm |

| Nozzle Diameter | 0.4 mm (Standard) |

| Printing Speed | ≤ 150 mm/s |

| Filament Diameter | 1.75 mm |

| Extruder Type | Independent Dual Extruders (IDEX) |

| Compatible Materials | PLA, ABS, PETG, TPU, PVA, Nylon, Carbon Fiber |

| Heated Bed | Yes (Max Temp: 120°C) |

| Nozzle Temperature | Max 320°C |

| Enclosure | Fully enclosed for temperature stability |

| Connectivity | USB, Wi-Fi, Ethernet |

| Power Supply | 24V / 500W |

| Display | 4.3-inch Touchscreen |

| Supported File Formats | STL, OBJ, 3MF, G-code |

| Compatible Software | FlashPrint, Simplify3D, Cura |

| Weight | 40 kg |

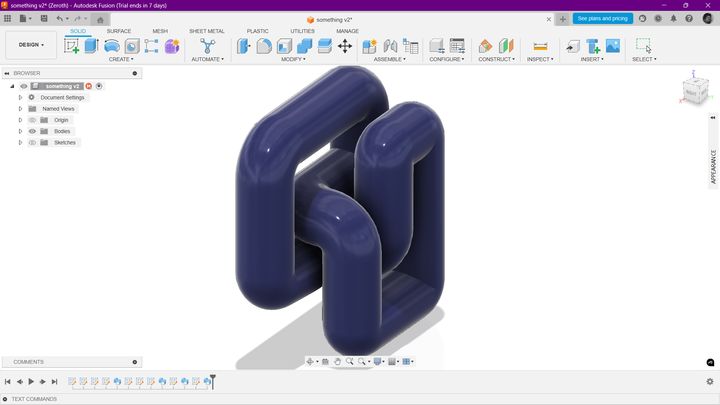

Designing the 3D Printer File

For Designing the File we are going to Fusion 360 which is a software for 3D moels and can able to render and simulate in it

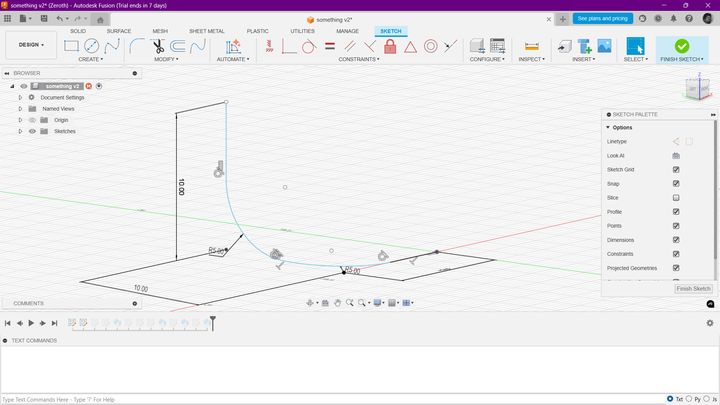

Initially what we are gonna do is to draft a 2D sketch of a hollow pipe by drawing a single line with a 10mm lenght and 10mm height

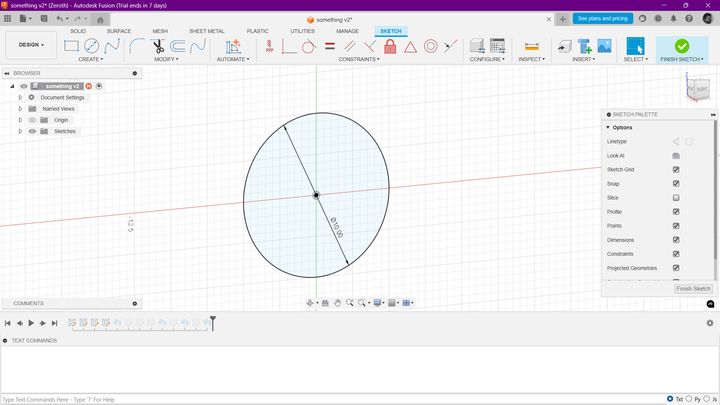

Next we are gonna draw the profile of the hollow pipe by drawing a circle on the opposite plane

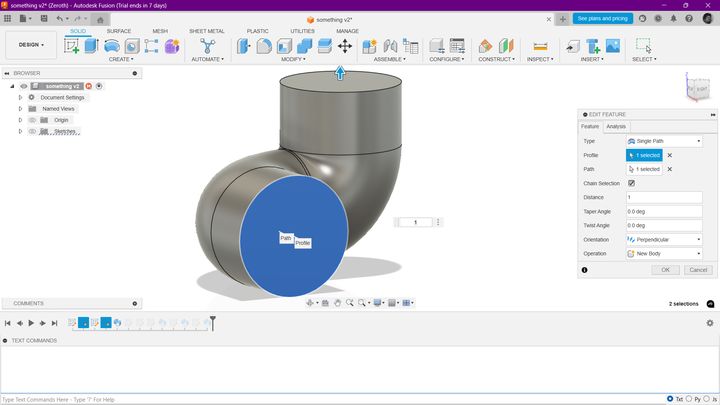

Then we will use the Sweep Protrusion to extrude the pipe to a height of 100mm

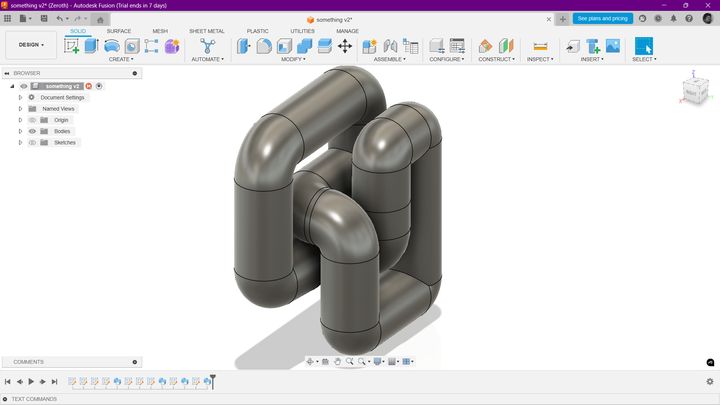

Then repeat this process for the all 4 Directions

Afterwards we can make it more shine by adding colors

Why can't we design the 3D printer file subractively?

Its because the Moulding can be done for the straight and some certain angles can be moulded but here the pipes are internally connected so that it can't be done by any moulds

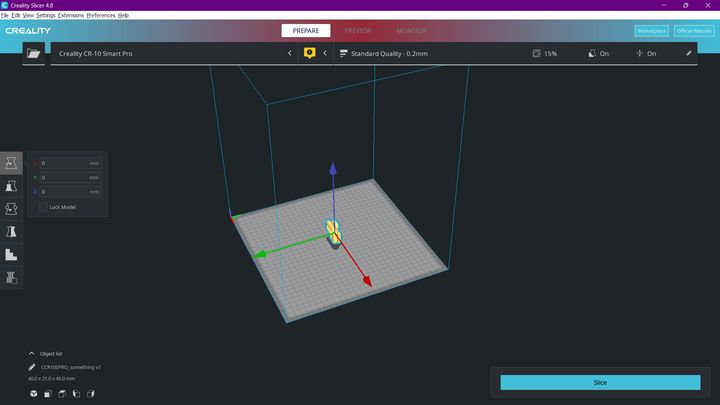

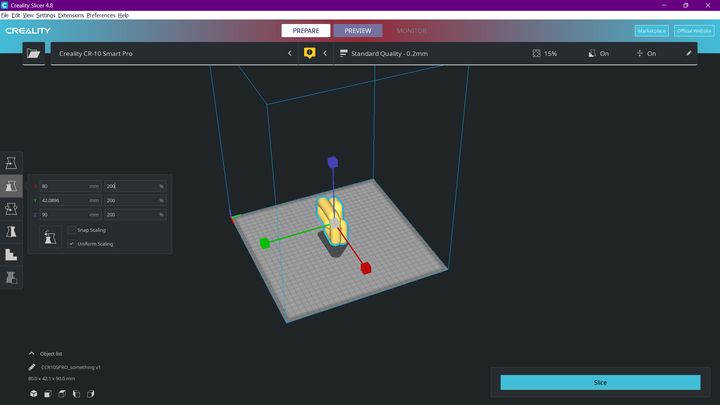

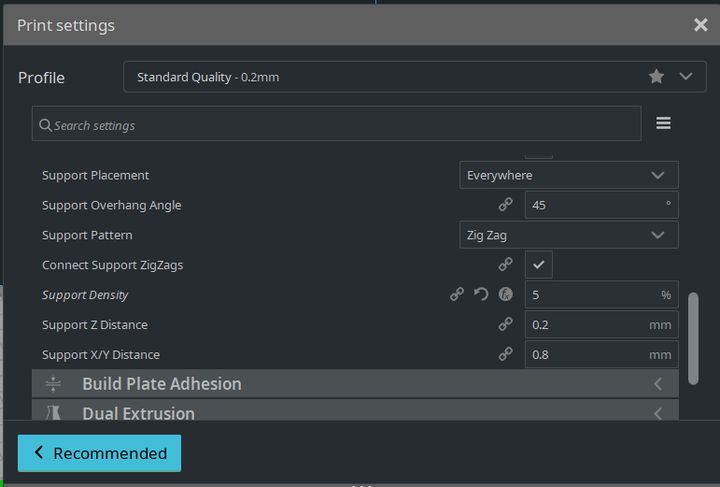

Creality Slicer 4.8.2

Creality Slicer 4.8.2 is a powerful slicing software designed for 3D printing enthusiasts. It offers a user-friendly interface and a variety of features to optimize your 3D printing workflow. With advanced slicing algorithms, you can achieve high-quality prints with ease.

Features:

- Customizable settings for precision and speed.

- Supports multiple file formats including STL, OBJ, and AMF.

- Advanced support generation for complex models.

- Real-time print simulation.

Download Guide:

- Visit the official Creality website.

- Navigate to the "Software" section.

- Select "Creality Slicer 4.8.2" from the list.

- Choose the appropriate version for your operating system (Windows, MacOS, Linux).

- Click the "Download" button and wait for the download to complete.

- Locate the downloaded file and run the installer to complete the installation.

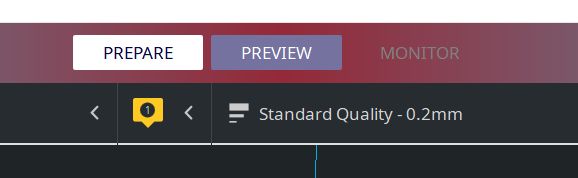

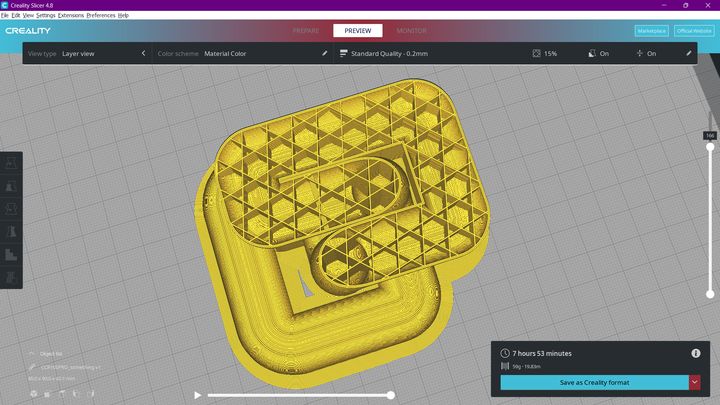

Initially we need to choose the 3D printer to match the bed size, we have chosen Creality Smart CR-10 Pro

Creality Import

Importing the Model to Slice

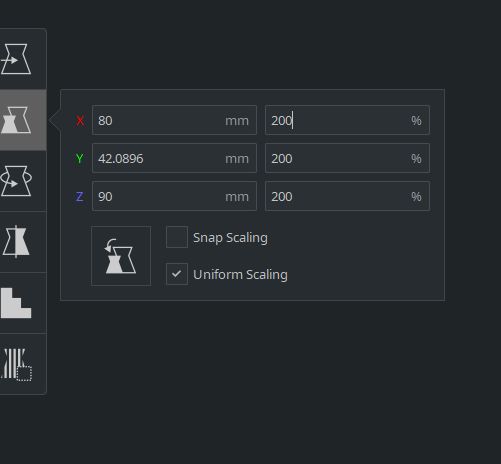

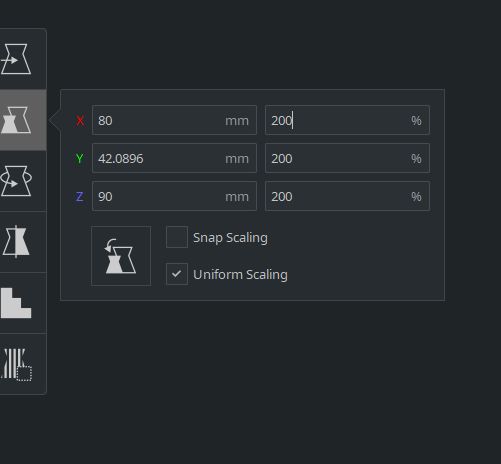

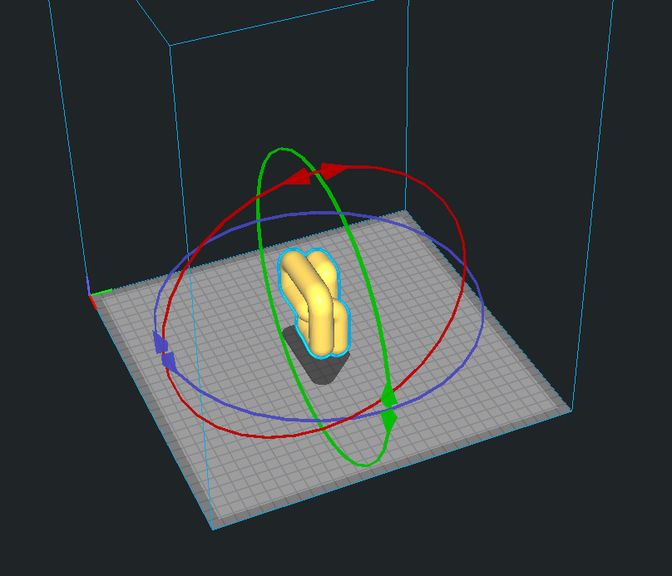

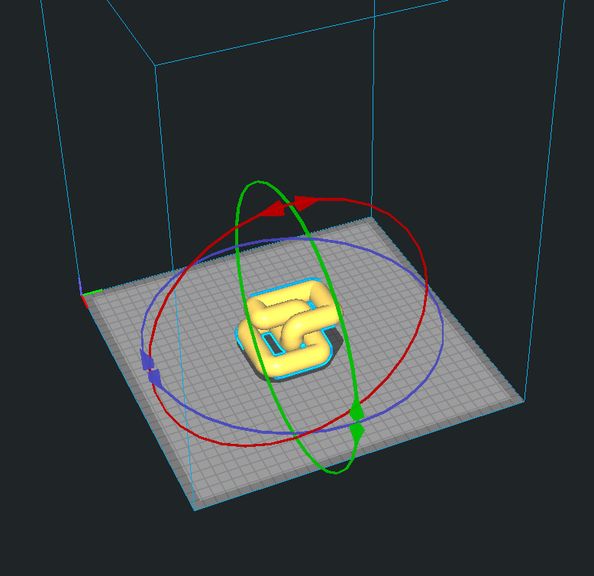

Scaling and then Rotating the Mesh

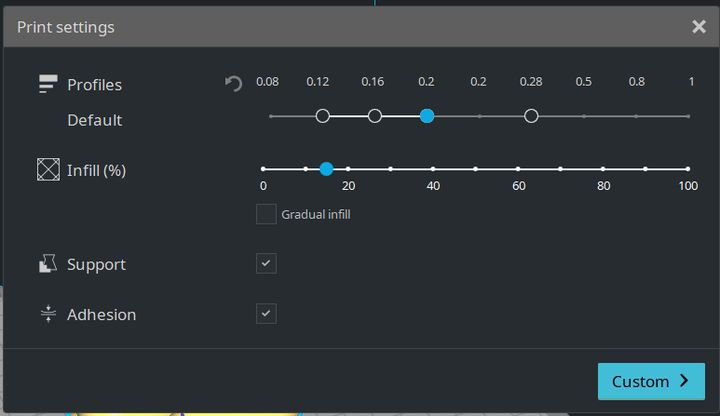

Setting Configuration & Support Selection

Exporting as Gcode

Machine Setup

We have to setup the proper bed Temperature in our Machine

- For the Material what we are using is PLA

- So the Bed temperature we would be set around will be around 210°C to 220°C

- And the Bed temperature will be around 60°C

- So this is the setup we have to get it done in our machine

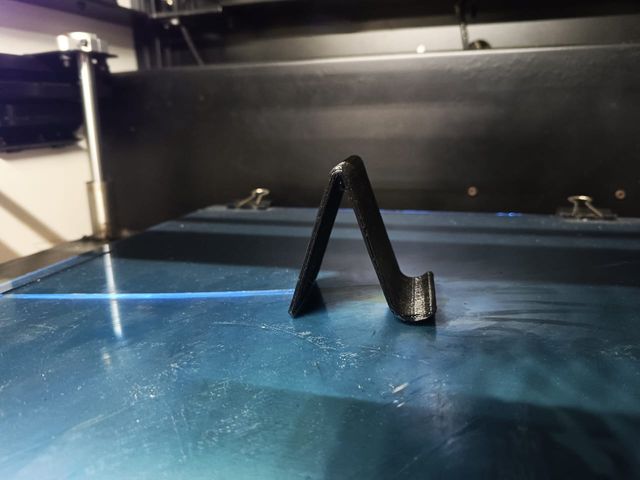

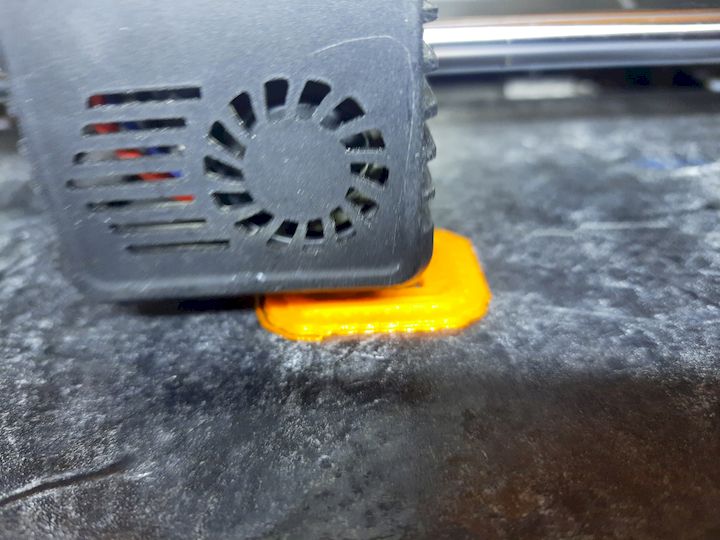

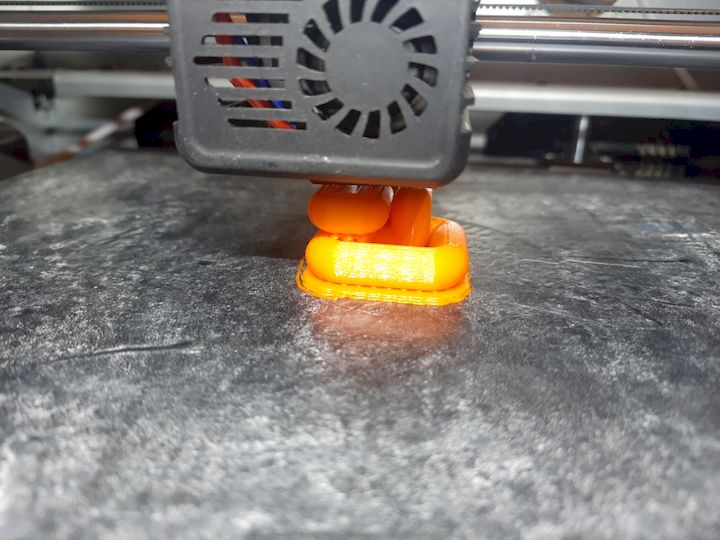

In the below image we can see the initial stage of part printing

3D Printed Model

3D Scanning

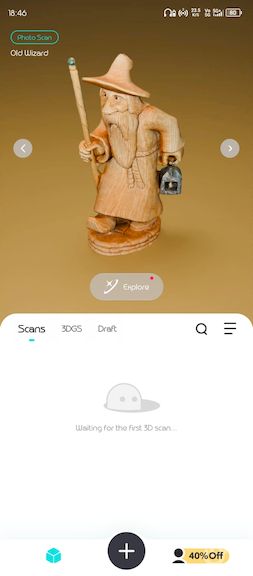

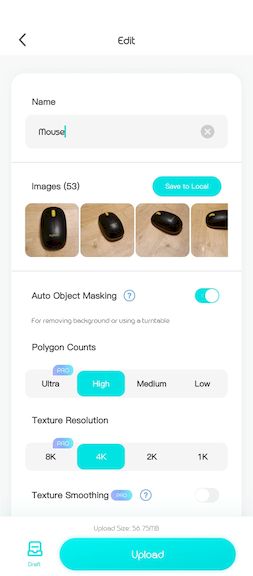

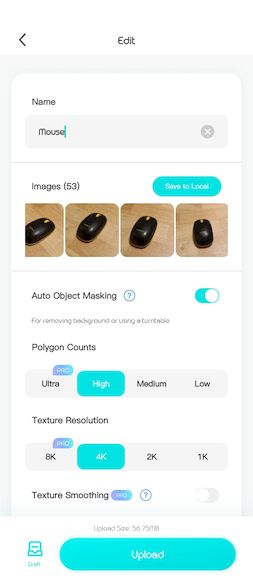

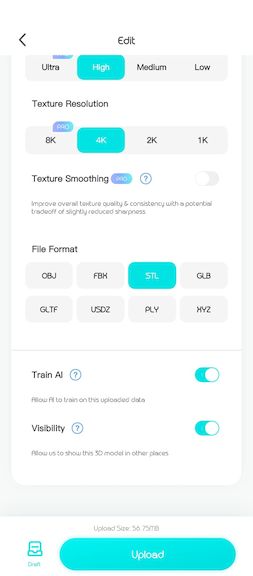

As in our lab we don't have any 3D Scanner, so we have to use the app called KIRI Engine

Model that I planned to scan is my day to day friend

About KIRI Engine

KIRI Engine is a 3D scanner app that can be downloaded from the Google Play Store. This app allows users to scan objects in 3D using their smartphone camera. The app can be used to scan small objects, but it is not suitable for large objects. The app is available for both Android and iOS devices.

Download KIRI Engine from Google Play Store

For the 3D scanning we are gonna use the app known as KIRI engine

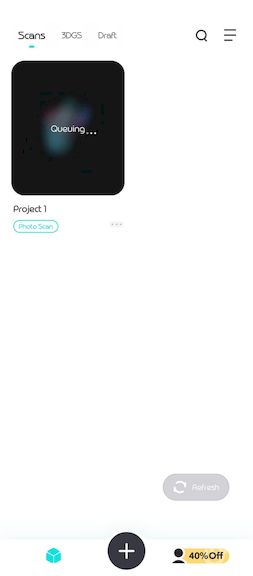

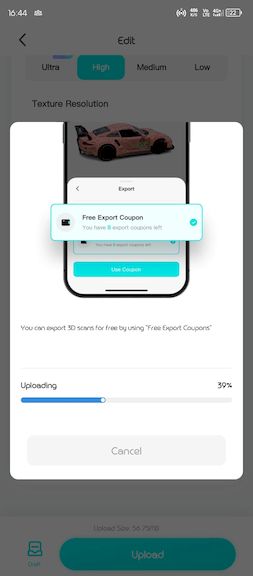

Here we need to give around as a 50 Images as input then It would blend all the images then it will give us a 3D model and it can be downloaded

Initially the model was not the best model so we have to refine it by using the Refine feature of the app. So I need to do the same Process again

After Further Refination I got this model

Learning Summary

- Learned how to design a 3D object using Fusion 360.

- Understood how to export a 3D model as an STL file.

- Learned how to prepare a 3D model for 3D printing using Slicer.

- Successfully printed a 3D model using a 3D printer.

Hero Shot