- Week 1 : Project Management

- Week 2 : Computer-aided

- Week 3 : Computer Controlled Cutting

- Week 4 : Embedded Programming

- Week 5 :3D Scanning and Printing

- Week 6 : Electronic Design

- Week 7 : Computer Controlled Machining

- Week 8 : Electronics Production

- Week 9 : Input Devices

- Week 10 : Output Devices

- Week 11 : Networking and Communication

- Week 12 : Mechanical Design and Machine Design

- Week 13 : Midterm Review

- Week 14 : Molding and Casting

- Week 15 : Interface and Application Programming

- Week 16 : System Integeration

- Week 17 : Wildcard Week

- Week 18 : Applications and Implications, Project Development

- Week 19 : Invention, Intellectual property and Income

- Week 20 : FInal Project Requirements

Week 16 : Wildcard Week

Objectives of the Week

Wildcard Week: Exploring Metal Laser Cutting

For Wildcard Week, I explored metal laser cutting using CAM tools, aiming to learn how digital designs are transformed into precise metal parts. This involved creating CAD models, generating CAM toolpaths, and executing the cutting process on a metal laser cutter. I gained valuable hands-on experience with machine setup, material-specific parameters, and safety protocols, all while understanding the potential and limitations of high-precision metal fabrication.

What is CAM?

Computer-Aided Manufacturing (CAM) automates the production process using software and computer-controlled machines like CNCs, laser cutters, and 3D printers. It converts CAD models into toolpaths and machine instructions, allowing for high accuracy, repeatability, and complex geometries. CAM is essential in industries like automotive, aerospace, and electronics for both prototyping and production.

Introduction to Metal Laser Cutting

Metal laser cutting uses a high-powered laser to precisely cut materials such as steel, aluminum, or brass. It is a non-contact, computer-controlled process that delivers clean edges, supports intricate patterns, and minimizes waste. Common in fabrication, automotive, and aerospace, this method is ideal for both custom and mass manufacturing.

Type of Metal Laser Cutter

| Type | How It Works | Best For | Limitations | Power Range |

|---|---|---|---|---|

| CO2 Laser Cutters | Uses a gas mixture (mostly CO2) excited by electrical discharge to generate laser. | Non-metal materials (wood, acrylic); thin metals with coatings. | Less efficient with reflective and thick metals. | Up to 1–3 kW |

| Fiber Laser Cutters | Solid-state laser transmitted through fiber optic cables. | Reflective metals like aluminum, copper, brass, stainless steel. | Higher initial cost; may need protection from back-reflections. | 500 W to 20+ kW |

| Crystal Laser Cutters (Nd:YAG / Nd:YVO4) | Uses neodymium-doped crystals as laser medium. | High-precision tasks in electronics, medical device industries. | Shorter lifespan, higher maintenance. | 100 W to several kW |

| Hybrid Laser Cutters | Combines laser cutting with other processes (e.g., punching, plasma). | Multipurpose manufacturing environments. | Complex systems; higher maintenance and upfront costs. | 1–6 kW (varies by system) |

| High-Power Laser Cutters | Uses high-power fiber or CO2 lasers for thick metal cutting. | Industrial-scale cutting (automotive, aerospace, shipbuilding). | Very high cost, large size, complex infrastructure needs. | 10–30+ kW |

WILA 3015 CNC Metal Laser Cutting Machine – Overview

The WILA 3015 from WILA CNC Machine Tools Inc. is a high-performance CNC fiber laser cutting machine engineered for precision and productivity. Featuring a large cutting bed (typically 3000 mm x 1500 mm), it accommodates a variety of metal materials, making it ideal for industrial, custom fabrication, and educational use. The machine integrates efficiently with CAM software, enabling users to transform digital CAD models into clean, accurate, and repeatable cuts.

Advantages of the WILA 3015 CNC Metal Laser Cutting Machine

- High Precision & Accuracy: Delivers clean, sharp edges suitable for intricate and complex designs.

- Fast Cutting Speeds: Efficiently cuts both thin and thick metal sheets, enhancing overall productivity.

- CAM Integration: Seamlessly connects with CAM tools for an automated and streamlined workflow.

- Versatile Material Support: Effectively cuts materials like steel, stainless steel, and aluminum.

- Minimal Finishing Required: Produces smooth surfaces, reducing the need for post-processing.

- Low Material Waste: Optimized toolpaths help minimize scrap and improve material utilization.

Limitations of the WILA 3015 CNC Metal Laser Cutting Machine

- High Energy Usage: Fiber laser technology can demand substantial electrical power.

- Expensive Setup: The high initial investment may not be suitable for small-scale operations.

- Limited to Metals: Not compatible with non-metal materials like wood or acrylic.

- Maintenance Requirements: Needs regular calibration and servicing to maintain performance.

- Safety Considerations: Requires strict adherence to safety protocols due to high-power laser operation.

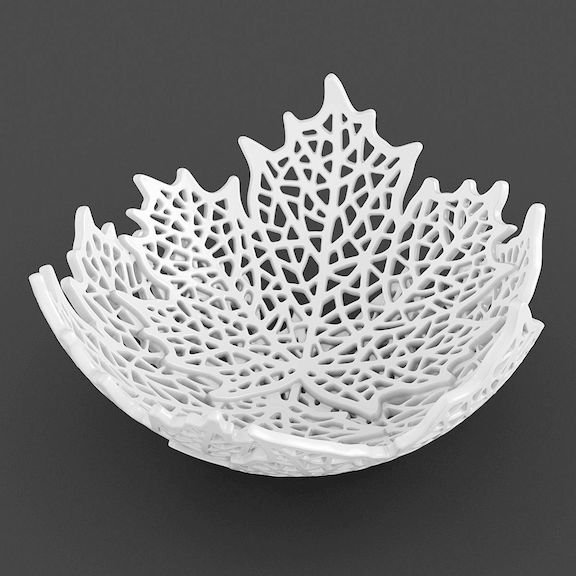

Getting Inspiration for Wild Card Week

As I am having a snacks break I just got inspired by the idea of creating a bowl that holds the things but hoe the things will be look when its like a Leaf edged Bowl, So I try to recreate that idea

Reference Image

I have taken the below image as a reference to convert the image into a DXF file. These images helped me visualize different design styles, shapes, and patterns. I used platforms like Freepik and Pixabay to find high-quality resources that matched my creative vision for the project.

Machining Process

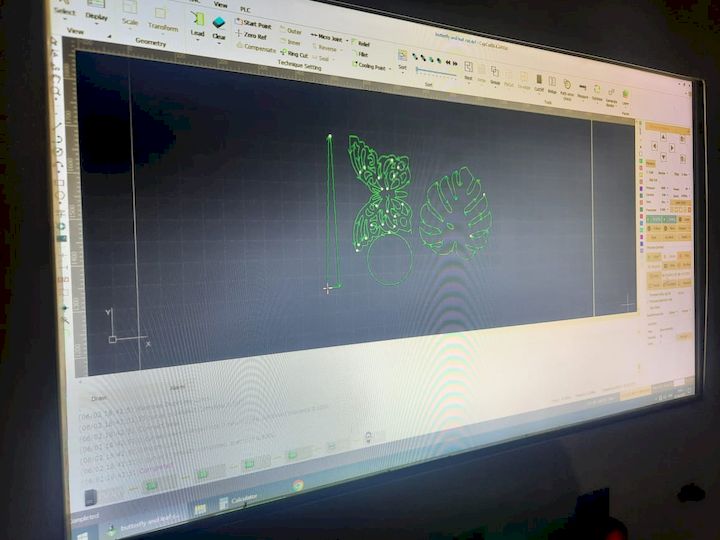

DXF File Preparation and Transfer

I began by converting a downloaded Leaf Image image into a DXF (Drawing Exchange Format) file using vector design software. This format is widely supported by laser cutting machines for precision cutting tasks. Once the conversion was complete, I transferred the DXF file to the laser cutter's system. I ensured that all paths and outlines were correctly aligned and prepared the file for accurate cutting operations.

Machine Setup and Parameter Configuration

After transferring the DXF file to the laser cutter, I refined the cutting paths to ensure smooth and precise outlines. I then configured essential machine settings including laser height, power, and cutting speed, tailoring them to match the material type and its thickness. These adjustments were critical for producing clean, accurate cuts and avoiding material damage during the process.

Executing the Laser Cutting Process

Once all settings and dimensions were finalized, I initiated the cutting process by starting the laser machine. Throughout the operation, I closely monitored the laser's movement to ensure it followed the designated paths with precision. The goal was to achieve clean, accurate cuts without damaging the 0.8 mm CBR aluminum sheet. This stage demanded careful observation to maintain the quality and integrity of the final Leaf design.

Final Output and Results

The completed Leaf design, cut from the 0.8 mm CBR aluminum sheet, demonstrates the precision and effectiveness of the laser cutting process. The final output features clean edges and finely detailed contours, highlighting the importance of accurate preparation and machine settings. This outcome reflects the success of each step—from design and setup to execution—in achieving a high-quality machined product.

Post-Cutting Inspection and Quality Check

After completing the laser cutting process, I carefully removed the machined Leaf parts from the machine. I conducted a thorough inspection by verifying the dimensions against the original design specifications. This quality check was crucial to ensure that the final output met all required measurements and maintained the intended precision and accuracy.

Here, I simply held the finished piece to see how it looks in real life. This hands-on inspection helped me appreciate the design’s details, the smoothness of the cuts, and the overall craftsmanship. It’s an important moment to connect the digital work with the physical outcome before any further finishing or assembly.